Acromet 3000 Series User manual

3000 SERIES

DIAPHRAGM METERING PUMP

Precise metering begins with precise design

MP3000PR 001 to 010 Plunger Pump Updated June 2012

Series 3000PR Plunger Pump

Precise metering begins with precise design

Choosing the right metering pump may seem like a straight forward

decision.....but in industry today there are often pumps that are either

under-specified, so the job is not being performed efficiently,

inadequate for the duty.....or over-specified. You need to be looking for

the right pump at the right price by making sure you are specifying the

right pump for the job. We supply Australia’s only manufactured range

of metering pumps to suit the right application to a remarkable range

of industries.

For more than 45 years there has been one name synonymous with quality, accuracy and

reliability in metering pumps.....and this is Acromet.

Laboratory Accuracy, Industrial Reliability

Proudly manufactured in

Australia, every piece of Acromet

equipment is the product of

leading edge technology in

design and manufacture. Our

commitment to our own in-house

R & D, our patented designs, plus

our precision manufacturing, has

built the Acromet reputation for

laboratory accuracy and

industrial reliability. From the

very first stages of design and

specification, right through to the

delivery of each finished product,

and our after sales service,

Acromet quality is never

compromised.

Heavy duty credentials

You will find the Acromet name working in some

of the toughest industrial applications. From

water treatment.....to oil refineries......to

mining........to petro-chemical installations

wherever an environment demands outstanding performance and equipment durability.

Australian Owned

www.acromet.com.au

MP3000PR 001 to 010 Plunger Pump Updated June 2012

Series 3000PR Plunger Pump

MP3000PR 001 to 010 Plunger Pump Updated June 2012

Series 3000PR Plunger Pump

Contents

1. SAFETY ...................................................................................................................................................1

1.1 General ................................................................................................................................... 1

1.2 Mechanical Precautions.............................................................................................................. 1

1.3 Electrical Precautions ................................................................................................................ 1

2. INTRODUCTION........................................................................................................................................1

3. INSTALLATION.........................................................................................................................................2

3.1 Location................................................................................................................................... 2

4. PIPING.......................................................................................................................................................2

4.1 General ................................................................................................................................... 2

4.2 Suction.................................................................................................................................... 3

4.3 Discharge ................................................................................................................................ 3

4.4 Piping Arrangement .................................................................................................................. 4

5. OPERATION..............................................................................................................................................5

5.1 Before Starting......................................................................................................................... 5

5.2 After Starting ........................................................................................................................... 5

6. CAPACITY ADJUSTMENT .......................................................................................................................5

7. MAINTENANCE.........................................................................................................................................6

7.1 Pre Maintenance Cleaning .......................................................................................................... 6

7.2 Lubrication............................................................................................................................... 6

7.3 Suction & Discharge Valves........................................................................................................ 6

7.4 ‘V’ Packings (Packing Seal Item 5) .............................................................................................. 7

7.5 Capacity Control –Zero Adjustment............................................................................................ 8

8. TROUBLESHOOTING...............................................................................................................................9

9. 3000 SERIES METERING PUMPS.........................................................................................................12

9.1 Drive End –Model 3000PR Series - Section A-A ......................................................................... 12

9.2 Drive End –Model 3000PR 001-000 Series –Section A-A –Parts List .......................................... 13

9.3 Drive End –Model 3000PR 001-000 Series –Section A-A - Parts List cont..................................... 14

9.4 Drive End –Model 3000PR 001-000 Series –Section B-B ............................................................ 15

9.5 Drive End –Model 3000PR 001-000 Series –Section B-B - Parts List............................................ 15

9.6 Solution End Model 3000PR –001-000 Series ............................................................................ 16

9.7 Solution End Model 3000PR –001-000 Series –Parts List......................................................... 17

9.8 Valve Assembly Model 3000 PR 001 - 000 ................................................................................. 18

10. CALIBRATION OF A METERING PUMP................................................................................................19

CALIBRATION CYLINDER –INSTALLATION GUIDE ...................................................................... 20

11. SERIES 500 VALVE INSTRUCTIONS....................................................................................................21

APPENDIX................................................................................................................................................................25

1EQUIPMENT DECONTAMINATION PROCEDURE DOC. No. QAPM-SD-19.0-1 .................................... 26

2EQUIPMENT DECONTAMINATION ADVICE DOC. No. SD-19.0-1 .................................................... 27

Rev:12/2015

MP3000PR 001 to 010 Plunger Pump Updated June 2012

Series 3000PR Plunger Pump

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 1

Series 3000PR

METERING PUMPS

3000PR PLUNGER PUMP SERIES

1. SAFETY

1.1 General

Please read and familiarise yourself with all sections of this and other equipment

manuals before proceeding with installation.

Observe all standard precautions which apply to moving machinery.

Observe all standard precautions which apply to electrical equipment, drives

and controls.

Pay particular attention to special safety 'cautions' and 'notes' in this

manual.

1.2 Mechanical Precautions

Prior to undertaking any mechanical maintenance repair, installation, etc.

SWITCH OFF, and disconnect the power before proceeding.

Personnel must wear the appropriate protective safety attire and remove

loose clothing, jewellery etc.

1.3 Electrical Precautions

Before undertaking work on the electrical controls or drives, disconnect

power and place a notice to advise others of the type of work in process.

Ensure all necessary grounds are in place and solid.

Do not disconnect or disable ground connections

CAUTION Follow all electrical regulations where required by electrical

engineering trades.

2. INTRODUCTION

2.1 Acromet metering pumps are designed and manufactured for long, low

maintenance service life and when properly applied, will give many years of

consistent accurate metering and trouble free operation.

2.2 The following instructions should be read and followed to correctly install and

operate the pump and ensure optimum pump life and performance.

2.3 The Pump specification sheet is enclosed at the end of this manual.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 2

Series 3000PR

3. INSTALLATION

3.1 Location

3.1.1 It is desirable to locate the pump as close as possible to the supply source

(eg tank) in order to minimise suction losses.

3.1.2 The location should be dry and protected from rain and the possibility of

hosing down, with sufficient free space provided around the pump to

allow access for adjustment and maintenance.

3.1.3 The mounting surface should be even and level. The pump base is

provided with two (2) holes for mounting bolts.

4. PIPING

4.1 General

4.1.1 The pump suction valve is located at the bottom of the pump head and

the discharge valve on top. The pump cannot operate without these

valves and for correct operation, valves must be vertical.

4.1.2 Discharge pressure should be more than 20 kPa greater than suction

pressure to prevent over feeding or syphoning and to maintain metering

accuracy.

NOTE When the difference is less than 20 kPa, a back pressure valve and

pulsation dampener should be installed in the discharge line. The

pulsation dampener should be located between pump and valve,

as close to the pump as possible.

4.1.3 A characteristic of reciprocating pump performance is pulsating flow.

Piping should be sized for flow rates at least 3.5 times greater than

maximum capacity of pumps.

NOTE Small diameter piping will produce unpredictable flow rates and

system pressures.

4.1.4 Piping should be as short and straight as possible and arranged to avoid

loops or pockets where gas may accumulate.

4.1.5 All piping should be separately supported close to the pump to avoid

imposing pipe loads on the pump. When handling high or low

temperature liquids, measures should be taken to prevent distortion of

piping imposing loads on the pump.

4.1.6 All pipe work should be flushed clean of any solids which may be present

in the pipe work (i.e. weldslag, dirt following construction or repair)

before final connection to the pump and start-up.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 3

Series 3000PR

4.2 Suction

4.2.1 Piping must be air tight.

4.2.2 For ease of maintenance an isolating valve should be located near the

pump inlet.

4.2.3 Solids should be prevented from entering low volume pumps or pumps

used for high accuracy metering. A strainer of 150-200 mesh is

recommended and should be adequately sized to prevent restriction of

flow.

4.2.4 Suction pipe entrance should be at least 75 mm above the bottom of

solution tank to allow settlement of larger solids in the tank.

4.3 Discharge

4.3.1 Should it be necessary to install an isolating valve in the discharge line, a

relief valve must be installed between the pump and isolating valve.

4.3.2 The 3000 Metering Pump, being a positive displacement pump, will be

damaged if operated against a closed or partially open isolating valve.

NOTE The relief valve should be set to operate at the maximum rated pump

discharge pressure or maximum rated system operating pressure,

whichever is lower.

CAUTION When pumping hazardous liquids the relief valve discharge should

be piped back to the supply source. This will avoid spillage should

relief valve operate.

NOTE To ensure correct operation and maximise valve life, a pulsation

dampener should be installed between valve and pump

4.3.3 A pressure gauge with gauge protector should be installed to check if the

pump is not operating at too great a discharge pressure. The gauge

should be provided with a petcock valve for isolation from the system

when not required.

4.3.3 When pumping into a high pressure system, a non return valve should be

installed as a safety precaution at the injection point.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 4

Series 3000PR

4.4 Piping Arrangement Please note Plunger Pumps must have a flooded

suction to avoid damage by running the unit dry

Should it be necessary to

install an isolating valve in

the discharge line, a relief

valve must be installed in

the line between the pump

and isolating valve.

WRONG

CORRECT

Metering pumps are positive displacement pumps and produce pulsating flow. Consequently there

is considerable line pressure loss and suction piping should be sized to ensure adequate NPSHA. If

piping extends for a considerable distance a suitable break tank or pulsation dampener should be installed near

pump.

the pump.

Avoid pockets or loops in piping where gas may accumulate.

WRONG

CORRECT

Where the pump discharge line connects

with a high pressure line, install a

non return valve as a safety precaution.

The presence of solids in the pumped liquid can cause incorrect

pump valve operation and affect metering accuracy.

If solids are present install a strainer with 150 to 200 mesh

and large mesh surface in order to keep pressure drop as small

as possible and ensure that strainer does not become

quickly clogged.

CORRECT

NOTE The diagrams above are representational and are intended as a guide

only. For specific system design or advice please consult a pump systems

engineer or contact Acromet.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 5

Series 3000PR

5. OPERATION

5.1 Before Starting

5.1.1 Ensure the pump will be operated within its specification.

5.1.2 Check gearbox oil level. Prior to leaving factory, each pump is filled to

the correct level with the recommended grade of oil (see maintenance

section). Any suggestion of oil loss should be investigated.

5.1.3 Check direction of rotation. Correct direction is clockwise when viewing

pump from top of motor.

5.1.4 Ensure system control or isolating valves in discharge line are open.

5.2 After Starting

5.2.1 Pump will normally prime automatically. However, it may be necessary to

run the pump at maximum capacity to clear air. If this is unsuccessful,

disconnect the discharge pipe work or install a petcock in the discharge

line next to the pump to allow air to escape.

CAUTION If pumped liquid is hazardous do not disconnect discharge pipe

work. Install a petcock in the discharge line next to the pump and

pipe petcock discharge to suction vessel or drain to avoid spillage.

5.2.2 Check that pump is operating correctly against discharge pressure.

5.2.3 Ensure that any problems are noted and appropriate corrective or

preventative action is taken.

6. CAPACITY ADJUSTMENT

6.1 Standard manual capacity adjustment is by means of a micrometer. For multiplex

pumps, each pump head is individually controlled by a micrometer located behind

the respective pump head.

6.2 Adjustment should be made whilst the pump is running, though under certain

conditions adjustment is possible when the pump is stopped. To adjust whilst

stopped, rotate the flexible coupling by hand to unload the micrometer. This can

be sensed by the ease with which adjustment can be made. When unloaded,

adjust to desired setting.

NOTE Ensure power supply is disconnected before removing drive-shaft

guard.

[Type a quote from the

document or the summary of an

interesting point. You can

position the text box anywhere in

the document. Use the Text Box

Tools tab to change the

formatting of the pull quote text

box.]

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 6

Series 3000PR

7. MAINTENANCE

7.1 Pre Maintenance Cleaning

Flush the pump to remove all chemical residue.

Clean the pumps exterior to ensure chemical free surface.

Check that appropriate chemical handling and cleaning standards have been

met.

CAUTION ACROMET (AUST)PTY LTD IS UNABLE TO ACCEPT ANY METERING PUMP RETURNED

FOR MAINTENANCE THAT HAS NOT BEEN SUITABLY CLEANED.

It is an Acromet Quality Assurance policy that all equipment returned for repair or service

be supplied with a completed copy of the 'Equipment Decontamination Advice' form, as

shown on page 42 of this manual.

7.2 Lubrication

7.2.1 Change oil after the first month of operation and at 6 months intervals

thereafter.

The following are recommended grades:

SHELL : OMALA 320

BP : GR-XP-320 ISO

MOBIL : MOBIL GEAR 632

CASTROL : ALPHA SP 320

7.2.2 Correct oil level is the horizontal centre line of the solution head.

7.3 Suction & Discharge Valves

7.3.1 During routine maintenance, valves should be dismantled and checked.

Replace worn balls and valve seats. When pumping clean liquids of

moderate viscosity, valves will give many years of trouble free service.

However, valve life can be reduced in applications where discharge

pressure is high, liquid viscosity low or solids are present.

NOTE Should it be necessary to service the valves, cleanliness is

essential and care should be taken to avoid damaging

components.

Refer to valve drawing at end of manual prior to dismantling.

7.3.2 When reassembling, ensure that all O-Rings, ball checks and ball stops

are in the correct position. Failure to fit ball stops can result in closed

head situation and severe pump damage.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 7

Series 3000PR

7.4 ‘V’ Packings (Packing Seal Item 5)

Pump maintenance should only be carried out by authorised qualified

personnel with appropriate metering pump and system maintenance

experience.

The suction and discharge lines must be isolated and pipework de-

pressurised and drained of chemicals.

Procedure for replacing packing seals is as follows:

7.4.1 First isolate suction and discharge lines.

7.4.2 Disconnect suction and discharge pipe work from Pumping Head.

CAUTION If liquid is hazardous then all necessary precautions must be taken.

7.4.3 Slacken off Adjustment Cap (Item 9).

7.4.4 Remove Pumping Head securing bolts (Item 20) and gently slide off

pumping head.

7.4.5 Remove Adjustment Cap (Item 9) Follower (Item 8) Glad Spacer (Item 7)

Lantern Ring (Item 6) V-Packings (Item 5) and Necking bush (Item 4).

7.4.6 Discard damaged or worn V-Packing seals and thoroughly was and clean

all parts. Check plunger, gland spacer and necking bush for signs of

excessive wear or scoring. If excessive wear or scoring is evident, then

parts must be replaced.

7.4.7 Re-assemble in reverse order using new V-Packing Set.

NOTE V-Packings must face towards pressure (Product).

7.4.8 Adjust seal pressure via Adjustment Cap (Item 9). Correct adjustment is

critical and care must be taken not to over tighten.

Adjust as Follows:

(i) Rotate Adjustment Cap (Item (9) just sufficient to stop end float of

Packing Seal arrangement. (No pressure on seal).

(ii) Start up pump. Slowly adjust Cap (Item 9) until leakage stops.

NOTE Adjustment should be just sufficient to stop leakage.

(iii) Run pump and check for leakage re-adjust as necessary as seals bed

in.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 8

Series 3000PR

7.5 Capacity Control –Zero Adjustment

Individual capacity control is provided for each pump head by means of a

micrometer located directly behind the respective pump head.

Should it become necessary to reset the mechanism, the procedure is as follows:

7.5.1 With pump running, screw micrometer mechanism in until piston

movement is just stopped. This can be sensed when resistance to turning

becomes constant. Stop pump. Unfasten both mounting screws and

remove micrometer mechanism

NOTE On some units, oil level will be above micrometer and spillage

will occur on removal. Hence measures should be taken to catch

spillage or tilt pump forward to avoid spillage.

7.5.2 Clamp micrometer anvil in vice and holding the barrel to prevent rotation,

loosen the socket set screw located in rear of barrel. This set screw locks

the barrel to the anvil.

7.5.3 Now, holding the mounting flange to prevent it turning, rotate the barrel

until it reads zero.

7.5.4 Again hold barrel to prevent it rotating and retighten set screw.

7.5.5 Set micrometer at 100% and refit to pump.

CAUTION Should oil spillage have occurred, add oil to correct level

before starting pump.

All major mechanical repairs should be undertaken by Acromet’s specialist

servicing workshop in Melbourne. In most cases a pump can be repaired and

despatched in one day

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 9

Series 3000PR

8. TROUBLESHOOTING

Trouble

Cause

Corrections

(A) Pump does not start.

Blown electrical. Fuse.

Check cause and change to

suitable capacity fuse

Electrical overload relay

trips.

Change relay capacity to

correct value.

Electrical wiring breakdown

or defective contact.

Change or reconnect.

Low voltage.

Difference in supply

voltage and rated voltage

of motor.

Find cause and correct.

Defective motor.

Check and replace.

Excessive pressure in

discharge line.

Reduce pressure.

Valve in discharge line

closed.

Open valve

Pump discharge valve

incorrectly reassembled

during maintenance.

Ballstop cushion missing.

Reassemble correctly.

Air in liquid end.

Relieve pressure in

discharge line.

(B) No Flow.

Valve in discharge line

closed.

Open valve.

Pump discharge valve

incorrectly reassembled

during maintenance.

Ballstop cushion missing.

Reassemble correctly.

Overload relay

Reset the switch after

checking the cause and

correcting.

(c) Pump does not work

after operating

normally.

Overload relay

Reset the switch after

checking the cause and

correcting.

Discharge pipe clogged.

Clear the pipe.

Valve in discharge line

closed.

Open valve.

Pump discharge valve

incorrectly reassembled

during maintenance.

Ballstop cushion missing.

Reassemble correctly

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 10

Series 3000PR

Trouble

Cause

Corrections

(D) Reduced pump flow

rate or unstable rate.

Micrometer out of

adjustment

Re Zero.

Valve clogged.

Clean.

Worn valve seat.

Replace seat or valve.

Flow meter incorrect.

Inspect meter, repair or

change.

Leakage from relief valve.

Inspect, repair or change.

Air leaking into suction

piping

Check for leak source and

repair.

Change in pump RPM.

Correct electric power

sources, speed control etc.

(E) Reduced pump flow

rate.

Unstable flow rate.

Flow rate does not

increase as stroke

length is increased.

Cavitation noise may

be apparent.

Insufficient NPSH

available:

(a) Suction pipe

diameter too small.

(b) Suction lift too great.

Enlarge suction pipe, or

install accumulator in the

line close to pump or raise

level of tank.

Raise liquid level.

Viscosity of liquid too

high.

1. Heat or lower viscosity

by other means.

2. Increase suction pipe

diameter.

3. Increase suction

pressure.

Vapour pressure high.

1. Lower liquid

temperature at inlet

port.

2. Raise liquid level.

Suction piping and/or

valve clogged

Clean

Suction strainer clogged

or too small

Clean or replace with larger

unit.

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 11

Series 3000PR

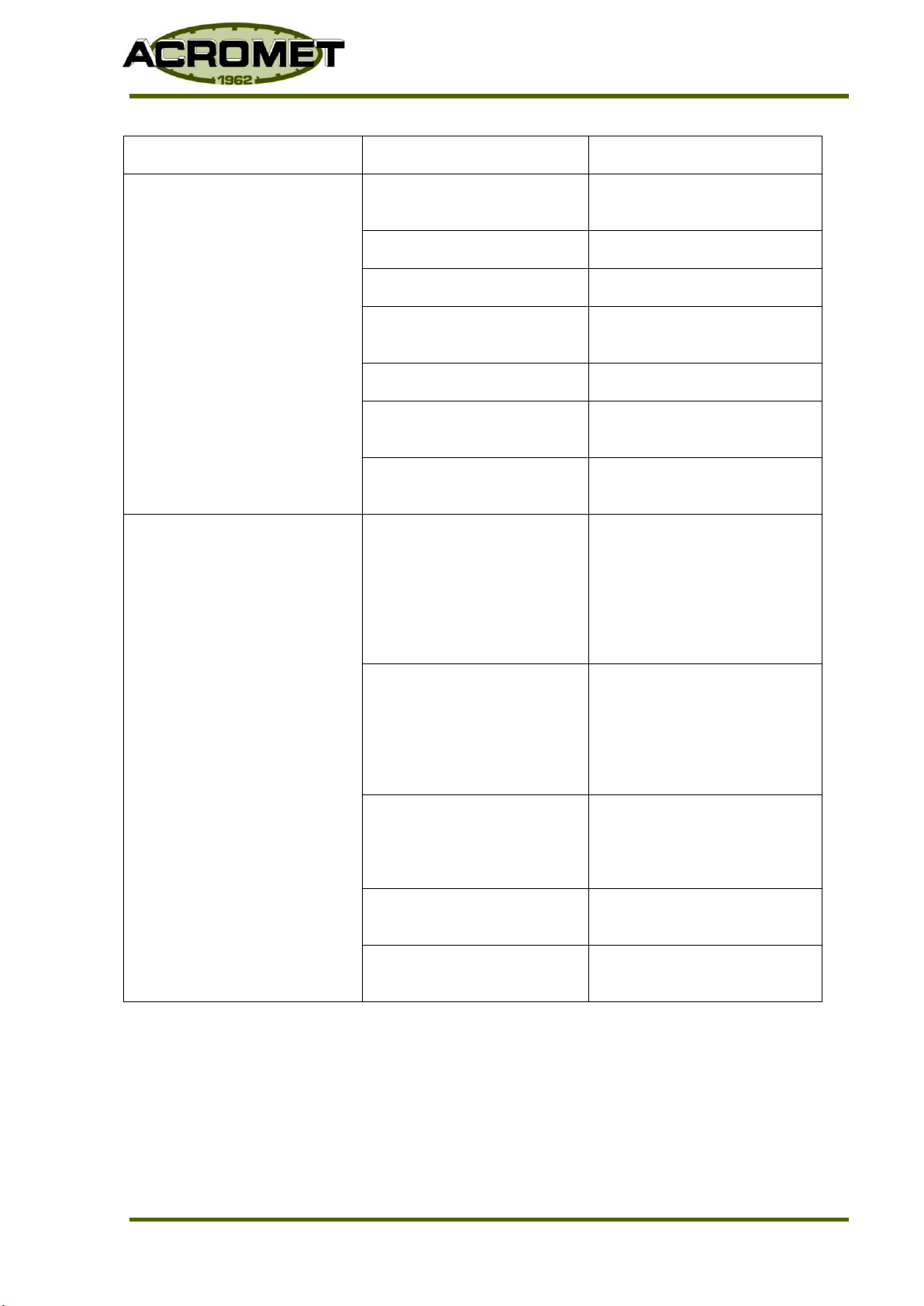

Trouble

Cause

Correction

(F) Excessive pump flow

rate.

Flow continues after

pump has stopped.

Pressure difference across

pump less than 20 KPa

Increase pressure

difference (ie install back

pressure valve).

Discharge line too long or

diameter too small

Reduce length and/or

increase diameter.

Install accumulator in

discharge line.

(G) Liquid leakage from

pump adaptor drain.

Loose or worn V-Packings

Adjust or replace. See

Sec. V-Packings.

(H) Knocking sound in

gearbox.

Excessive discharge

pressure

Check discharge pressure.

(I) Liquid end noise.

Rhythmic noise of pump

valves

Normal

Clogged discharge or

suction valve

Clean valve

(J) Overheating of motor.

Improper voltage

Adjust voltage to motor

specification.

Overload

(Refer to Section K).

Inadequate ventilation

Change motor or relocate

(K) Overload.

Improper Oil

Change

Discharge pressure too

high

Lower to permissible

pressure

Erratic noise of pump

valves

1. Clean valves.

2. Increase pressure

difference (ie install

back pressure valve).

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 12

Series 3000PR

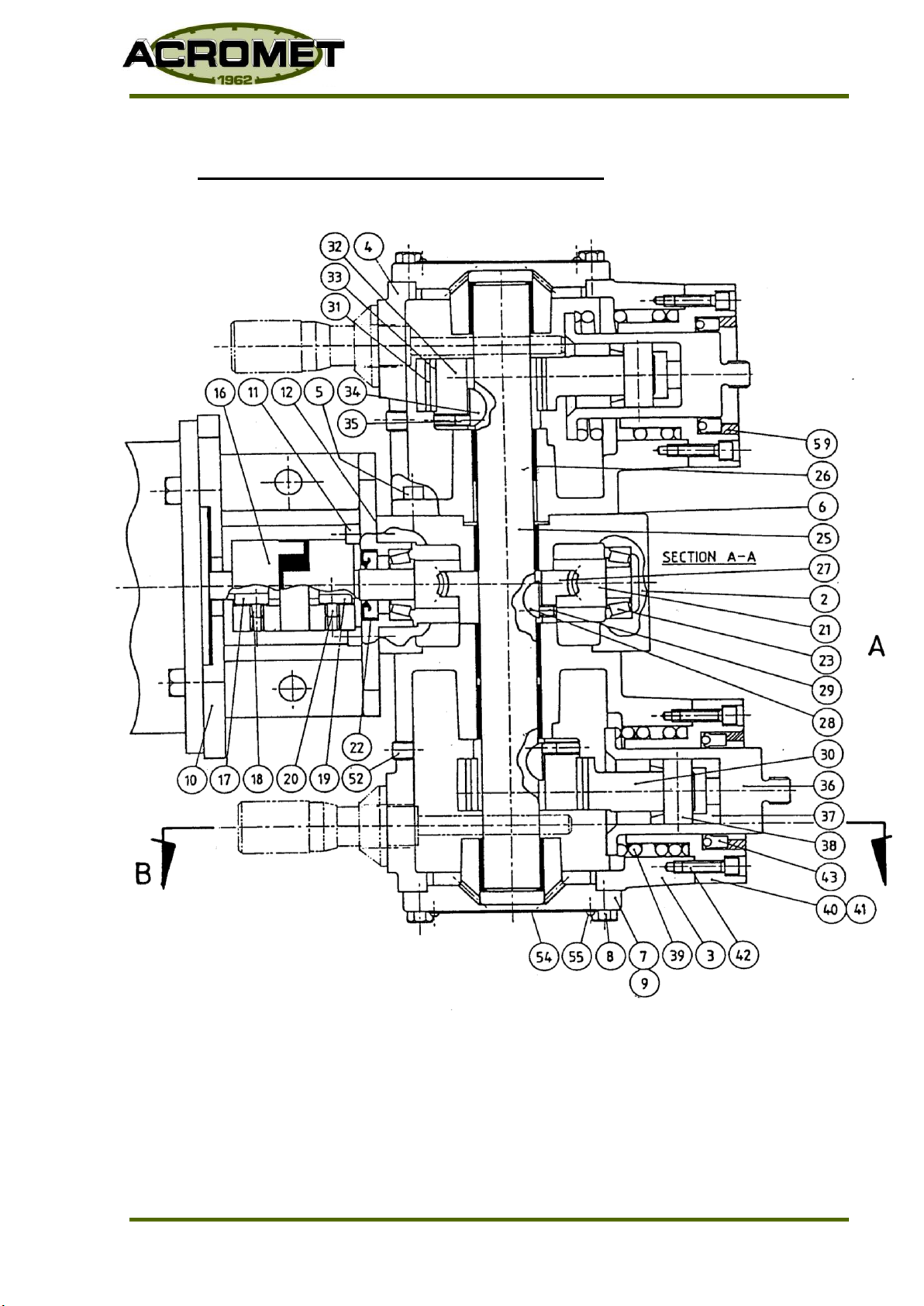

9. 3000 SERIES METERING PUMPS

9.1 Drive End –Model 3000PR Series - Section A-A

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 13

Series 3000PR

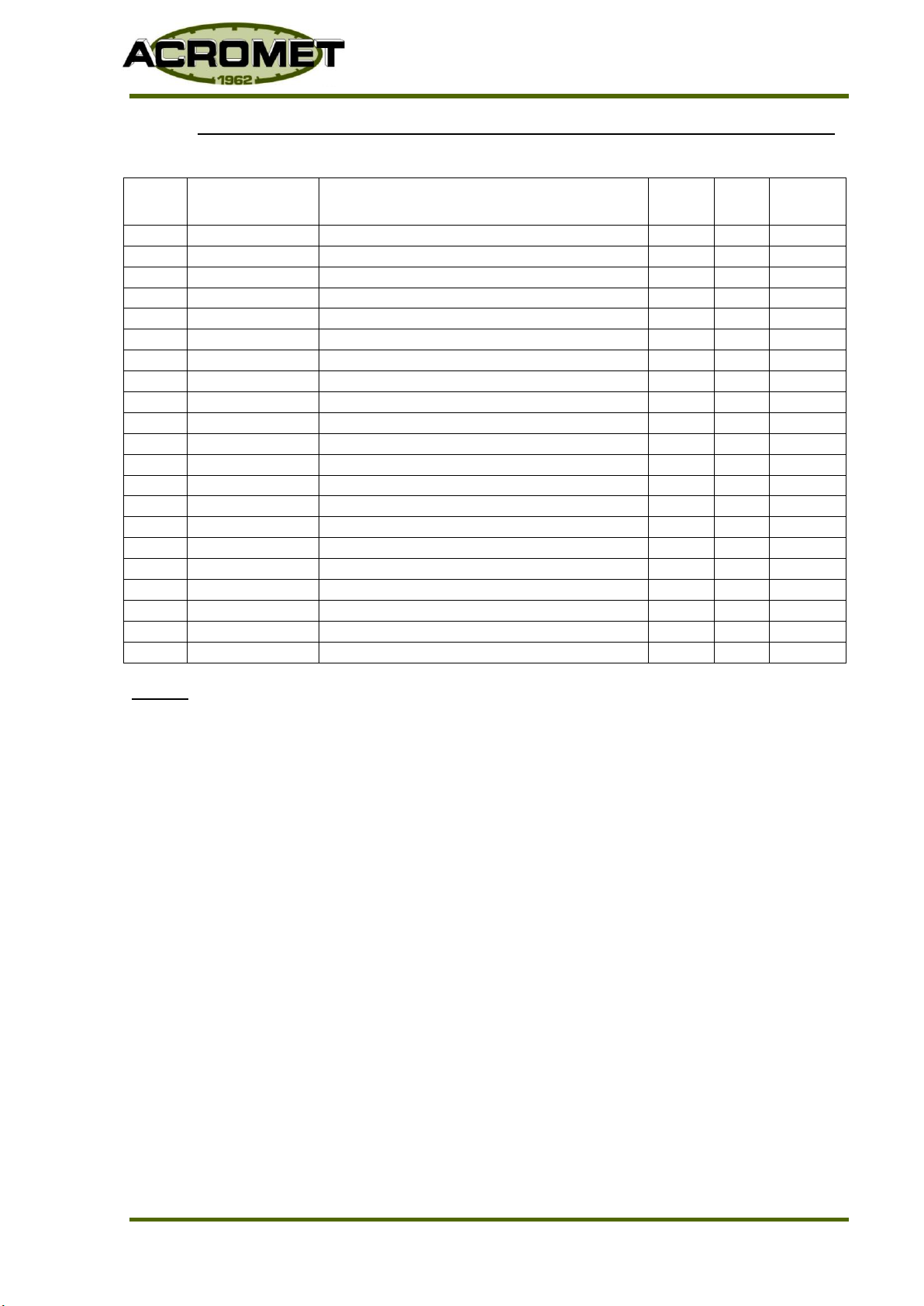

9.2 Drive End –Model 3000PR 001-000 Series - Section A-A –Parts List

ITEM

PART NO

DESCRIPTION

SIMP

QTY

DUP

QTY

NOTES

1

8800

Gearbox

1

A

2

8801

Gearbox

1

3

8002

Multiplex Chamber - Simplex

1

1

4

8001

Multiplex Chamber –Duplex

1

5

08-01-14

Screws Multiplex Chamber

4

8

6

8019 *

Gaskets

1

2

7

8003

End Cover

1

2

8

08-02-08

Screws End Cover

4

8

9

8019 *

End Cover Gasket

1

2

10

8802

Motor Spool

1

1

11

08-01-15

Screws Spool

4

4

12

8803 *

Motor Spool Gasket

1

1

16

9130

Coupling

1

1

17

9120

Key, Motor Shaft (supplied with motor)

1

1

18

08-13-01

Screws Motor Shaft Key

1

1

19

9121

Key Coupling (on assembly)

1

1

20

08-01-09

Screw Coupling

1

1

21

2802-

Worm Shaft

1

1

B

22

07-01-01 *

Oil Seal Worm Shaft

1

1

23

06-01-12 *

Bearing Worm Shaft

2

2

24

8804

Main Shaft - Simplex

1

A

25

8006

Main Shaft - Duplex

1

26

06-04-01

bush main Shaft

4

6

27

2021-

Worm Wheel

1

1

B

28

12-01-09

Key Worm Wheel

1

1

29

08-01-09

Screw Worm Wheel Key

1

1

30

8209

Con Rod

1

2

Notes:

A Not Shown

B State Stroking Rate (SPM)

C State Size

* Recommended Spare Parts

MP3000PR 001 to 010 Plunger PumpUpdated January 2017

Page 14

Series 3000PR

9.3 Drive End –Model 3000PR 001-000 Series –Section A-A - Parts List cont.

ITEM

PART NO

DESCRIPTION

SIMP

QTY

DUP

QTY

NOTES

31

8216

Bush Con Rod

1

2

32

8215

Eccentric 0.625”

1

2

C

33

06-05-02

Liner Eccentric

1

2

34

12-01-09

Key Eccentric

1

2

35

08-13-01

Screws Eccentric key

1

2

36

10000

Piston Primary

1

2

37

8026

Cross Head

1

2

38

8024

Pin Wrist

1

2

39

8829

Spring Return

1

2

C

40

8028

Sleeve, Piston

1

2

41

8831

Gasket, Piston Sleeve

1

2

42

08-01-17

Screw Piston Sleeve

2

4

43

07-01-02

Seal Primary Piston

1

2

51

08-12-01

Plug, Drain

2

1

A

52

08-12-02

Plug

1

2

54

9111

Plate, Name

1

2

55

08-10-01

Screw Name Plate

4

8

56

06-04-02

Wrist Pin Bush

1

2

57

09-02-03

Spring Washer, Motor

4

4

A

58

08-08-10

Thumb Screw, Barrel Lock

1

2

A

59

08-01-3

Screw, Adaptor

4

8

A

Notes:

A Not Shown

B State Stroking Rate (SPM)

C State Size

* Recommended Spare Parts

Table of contents

Other Acromet Water Pump manuals

Popular Water Pump manuals by other brands

Speck pumpen

Speck pumpen BADU Spyder I operating instructions

Stenner Pumps

Stenner Pumps SVP4L1 Installation and maintenance manual

CPA

CPA EL 7 IM Programming instructions

SAER Elettropompe

SAER Elettropompe NCB Use and maintenance manual

moyno

moyno 2000 Service manual

KISANKRAFT

KISANKRAFT KK-WPK-20 Operation manual

Varian

Varian Turbo-V 81-M Series instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 0 Series Installation, operation, and maintenance manual with parts list

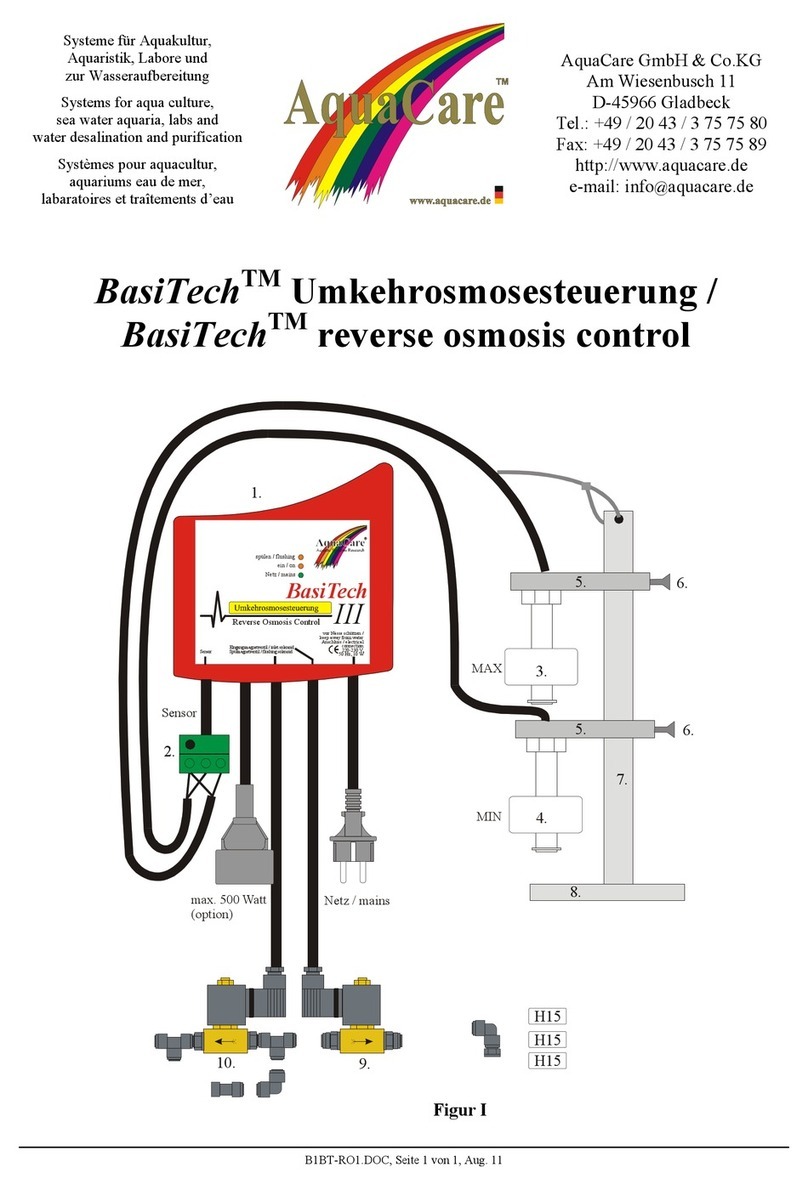

AquaCare

AquaCare BasiTech instruction manual

Senci

Senci SCWP-25 operation instruction

EINHELL

EINHELL GC-DP 3730 Original operating instructions

Levitronix

Levitronix PuraLev 600MU user manual