3“FPER2” and “FPERSR” - Installation and Maintenance manual

GENERAL INFORMATIONS

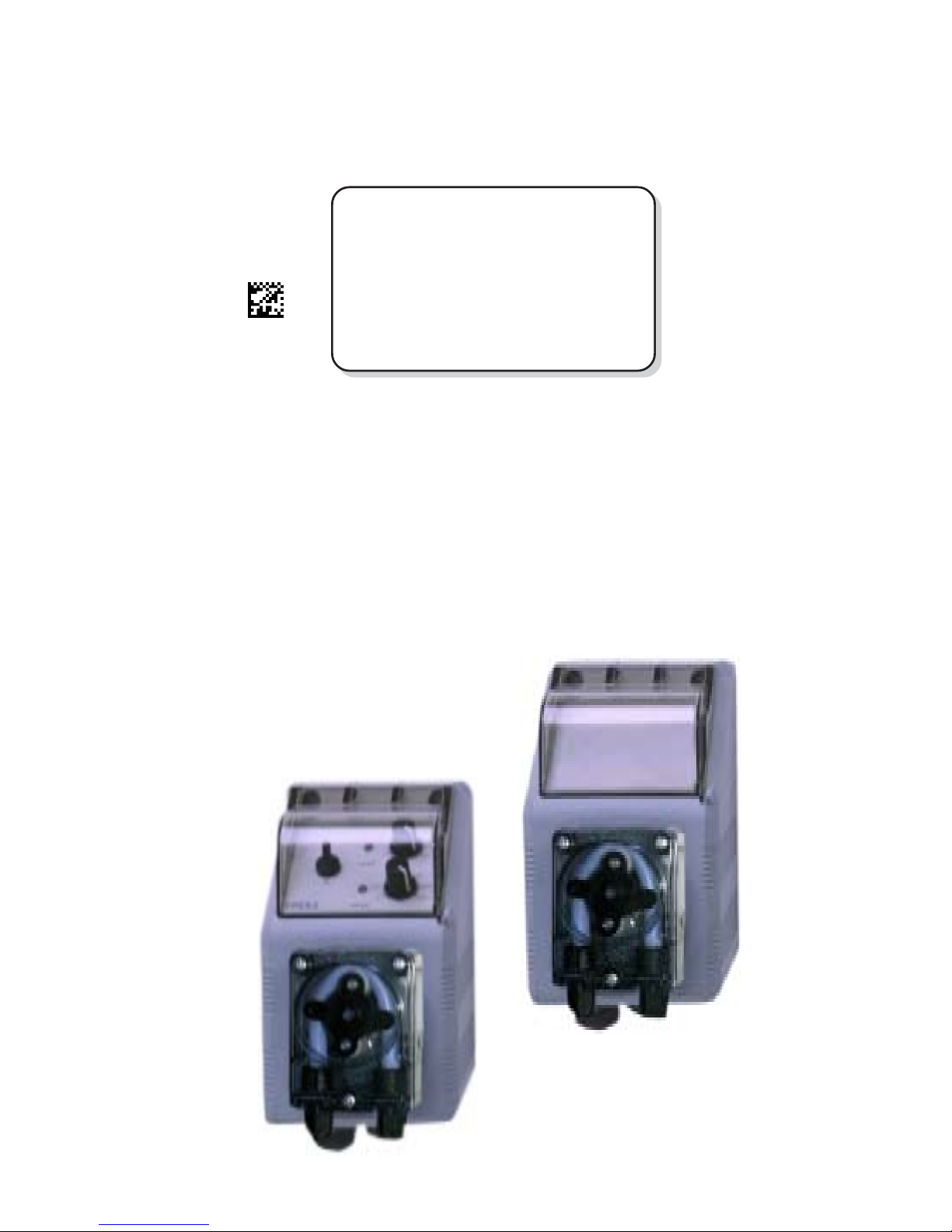

Series “FPER”, “FPER2” AND “FPERSR” peristaltic dosing pumps fits small dosing amounts of liquid

products. They are constituted of the following main assemblies:

Box

Electronic Circuitry

Peristaltic Pump

“FPER” is a peristaltic pump with adjustable electronic time.

“FPER2” is a peristaltic pump with on/off flow adjustment.

“FPERSR” is a peristaltic pump without flow regulation.

Box

Series “FPER2” AND “FPERSR” dosing pumps are assemblied in IP54(PP) plastic material boxes.

Installation is vertical with two screws at a distance of 63mm.

Electronic Circuit

The electronic circuit is made of proven quality.

Peristaltic Pump

2,4 l/h peristaltic pump with 40rpm engine with thermoplastic hose.

INSTALLATION

The pump has all the materials needed for the installation. To start up the series “FPER2” AND

“FPERSR” pump, first mount it on a wall or any other vertical surface. The distance between the

peristaltic engine and the suction filter should not be more then 1.5m. Connect the suction pipe

(transparent one). Be sure the o-ring in the suction valve is in place. Use hands to tight the fitting nut.

Place the suction filter on the bottom of product’s tank. Suction pipe should be as short as possible

in vertical position without any bendes to avoid air bubbles. Install the injection valve and connect it

to the pump head.

To avoid breaking of delivery pipe be sure that it doesn’t touch any other object.

The injection valve should never be installed lower then the product tank to avoid that injection valve

breaking lets the product flow freely into the system. It is reccommended to use an anti-syphon valve

(code 108.136.1) on the delivery side if the only way to install the injection valve is lower then the tank.

This valve prevents vacuum on the pump. Check on a regular basis the delivery valve and immediately

change it when inoperable. Do not install tanks with chemical beneath the pump to avoid the vapors

damaging the pump.

METERING

The series “FPER”, “FPER2” AND “FPERSR” pump features are located in a label on the pump

box. They include: power supply, working counterpressure (Kpa/bar) and pump capacity in

liter per hour (l/h). All the dosing information is withwith water at a 20 °C temperature, at the

maximum counterpressure reported in the label, using the injection valve and the % knob set to

the maximum. Dosing accuracy is ± 2% l/h at constant maximum counterpressure and 1 cps

flow (max viscosity : 60 cps).Warning: Counterpressure changes or viscosity changes at the

same stroke number may change the single stroke injection quantity. Check capacity charts for

further informations.