Page 8000744MAN-02 25 MAY 2009

values can be found in APPENDIX A.

Units are shipped with the MED position selected for

nominal air flow. The air flow can be further reduced by 15% by

making a dry contact across AR1and AR2on the terminal strip.

This can be used for applications that have multiple zones, or

retrofits with undersized ductwork, to help reduce air flow noise

in the ductwork. It is recommended that airflow reduction only

be used with the High or Max air flow setting. Care should be

taken to ensure that the unit does not trip a safety control in

heating or cooling mode if the 15% reduction is used in conjunc-

tion with the Med or Low air flow setting.

CONTROL TRANSFORMER

The low voltage controls for all models are powered by a

100VA transformer with primary and secondary fuses for circuit

protection. Should a fuse blow, determine the problem and rec-

tify it before replacing the fuse.

SAFETY CONTROLS

The heat pump has two built in safety controls which are

designed to protect the unit from situations which could damage

it should the operation of the refrigeration circuit fall outside the

allowable operating range.

A. Low Pressure Control

The low pressure control monitors the compressor suction

pressure and will shut the compressor down if the refrigerant

evaporating pressure becomes too low.

There only reason this control would activate in response

to the operating conditions of the unit in the heating mode

would be due to a ruptured loop, causing a low refrigerant

charge. Any other low pressure trips would be due to a fault in

the unit.

B. High Pressure Control

The high pressure safety control monitors the compressor

discharge pressure and will shut the compressor down if the

condensing pressure becomes too high.

There are (3) main reasons why this control would activate

in response to the operating conditions of the unit while operat-

ing in heating mode:

1. Low or no airflow (or water flow).

2. High return air temperature (or water temperature).

3. Dirty air coil due to poor filter maintenance.

Each of the controls are auto-reset controls. There is also

a manual reset high pressure control should the control board

be faulty and fail to disengage the compressor. It can be reset

by pressing the rubber button on the end of it. It is electrically

located between the Y output of the control board and the com-

pressor contactor coil.

The control board (see next section) monitors the pressure

controls and shuts the compressor off immediately for a set pe-

riod of time (adjustable) should there be a fault. The counter for

the safety control in question will be increased by 1. The LED

indicator for the control will flash until the control is reset as the

pressures equalize in the unit. The unit may restart after the

timer period has expired. Should the unit trip on the safety con-

trol again , the compressor will once again shut down and the

counter will be incremented by one again. Each time this occurs

the count is incremented until the counter reaches the max

value (default is 3) at which point a permanent lockout will occur

if this occurred within a set period of time (default 6 hours) and

the compressor cannot be started again until the control board is

reset by shorting the reset pins together or turning the power off

and on again. The lockout count is decreased after a set period

of time (default 6 hours) if there are no more occurrences.

If the control board enters permanent lockout mode there

is a serious problem with the system and it must be rectified if

the unit is to maintain good service.

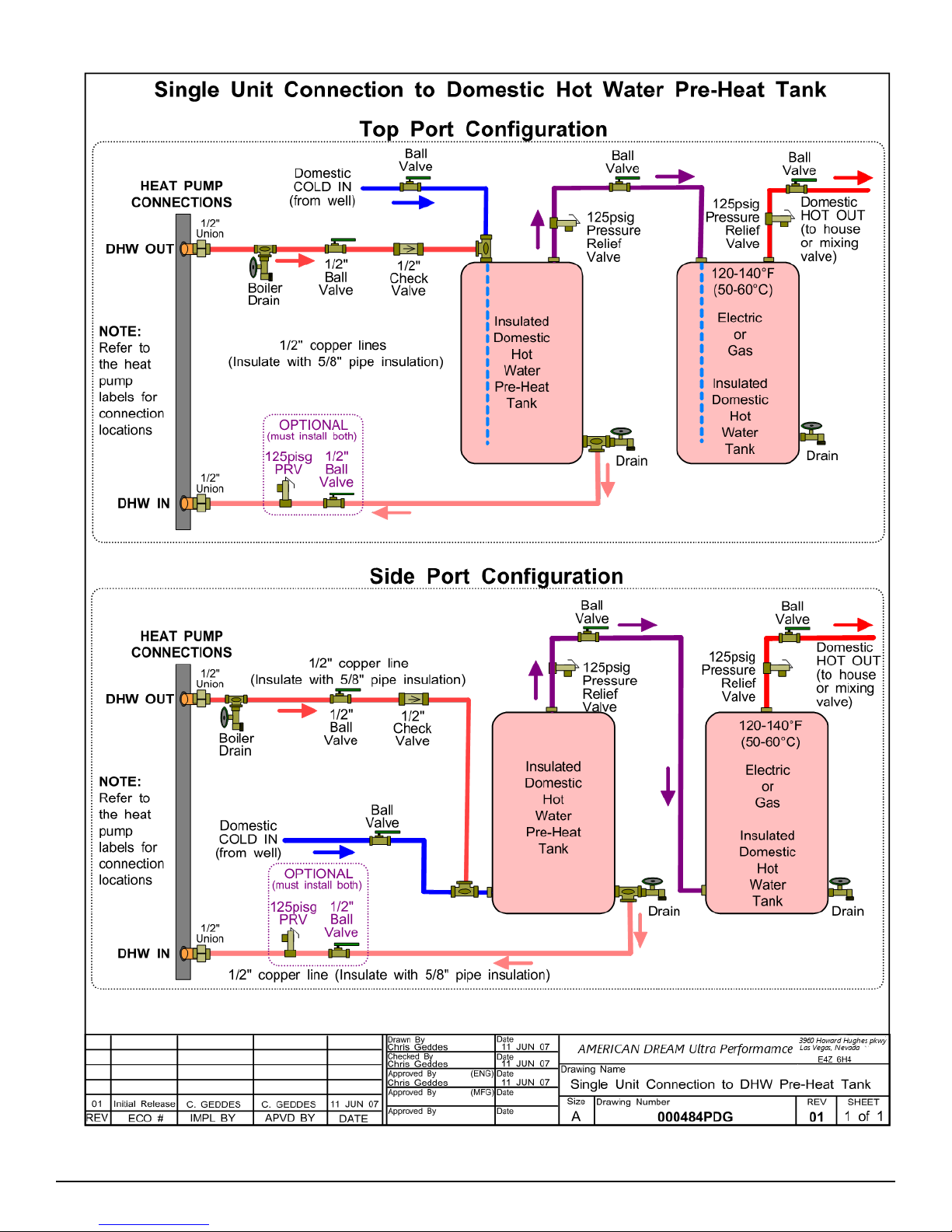

DOMESTIC HOT WATER

CONNECTIONS

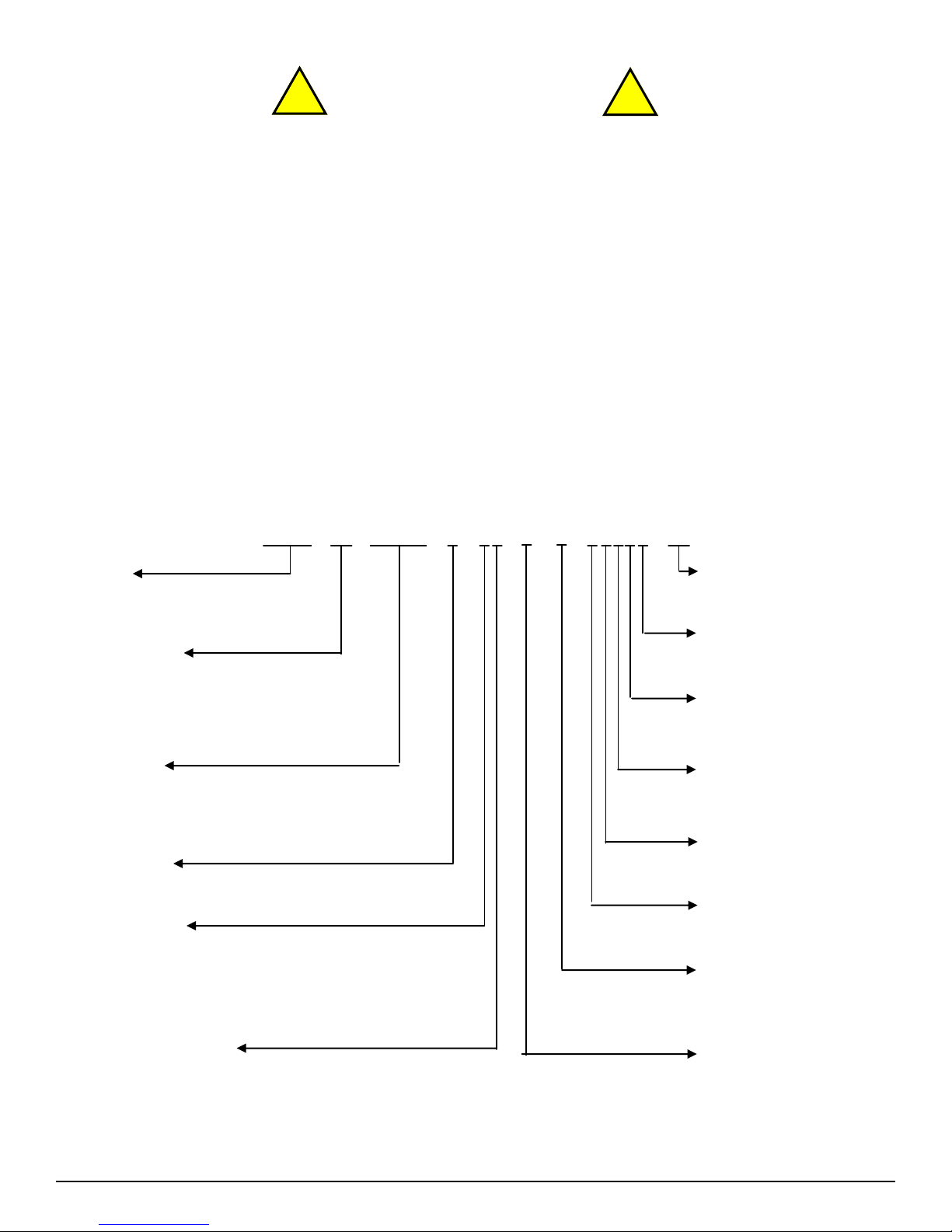

A typical piping diagram for a pre-heat tank configuration

can be found in drawing 000484PDG at the end of this

section. Be sure to note the position of the check valve

and the direction of water flow. Other configurations are possi-

ble, and there may be multiple units tied together in larger build-

ings.

WARNING: USE ONLY COPPER LINES TO

CONNECT THE DESUPERHEATER. TEMPERATURES

COULD REACH 200F SHOULD THE DHW

CUTOUT SWITCH FAIL, POTENTIALLY RUPTURING

PEX PIPING.

Ensure the tank is filled with water and under pressure

before activating the heat pump. Slightly loosen the boiler

drain on the DHW Out pipe to allow air to escape from the

system before the unit is started. This step will make certain that

the domestic hot water circulator in the unit is flooded with water

when it is started.

CAUTION: the domestic hot water pump is water lubricated;

damage will occur to the pump if it is run dry for even a

short period of time.

Connect the brown wire with the blue insulated terminal to

L1 of the compressor contactor. Ensure the power is off

when connecting the wire.

The DHW loop may have to be purged of air several times

before good circulation is obtained. A temperature difference

between the DHW In and DHW Out can be felt by hand when

the circulator pump is operating properly.

For the pre-heat tank setup, the final tank should be set to

140°F(60°C), unless local code requires a higher setting. The

pre-heat tank does not require electric elements. This setup

takes full advantage of the desuperheater as it is the sole heat

provider to the pre-heat tank. The desuperheater remains active

during the compressor runtime until the pre-heat tank has been

completely heated by the desuperheater alone. This setup is

more energy efficient than a single tank setup.

CAUTION: If two (2) shut-off valves are located on the do-

mestic hot water ines as shown in the diagram, a pressure

relief valve must be installed to prevent possible damage to

the domestic hot water circulator pump should both valves

be closed.

!

!