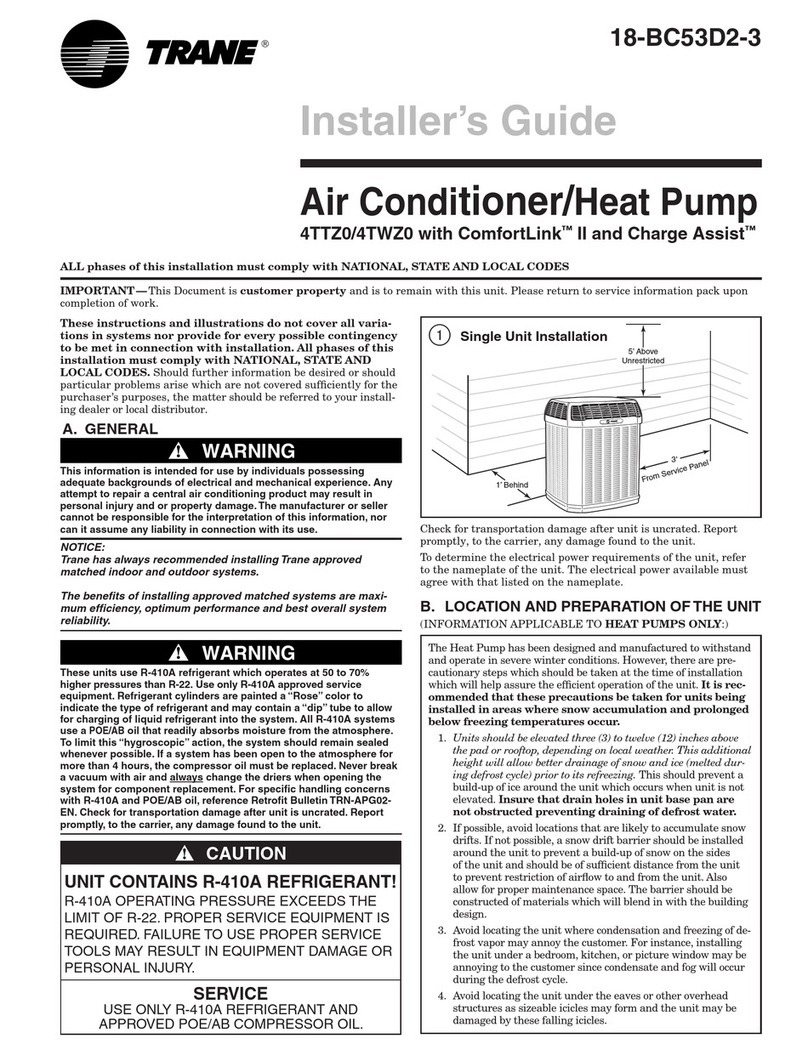

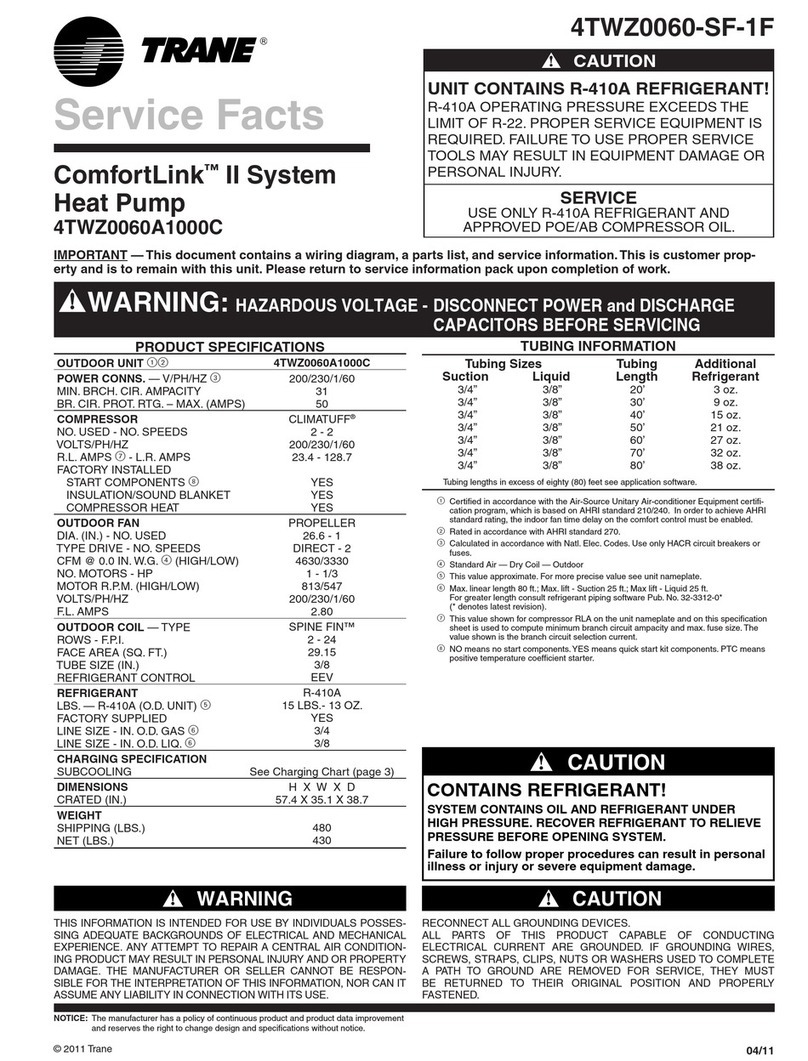

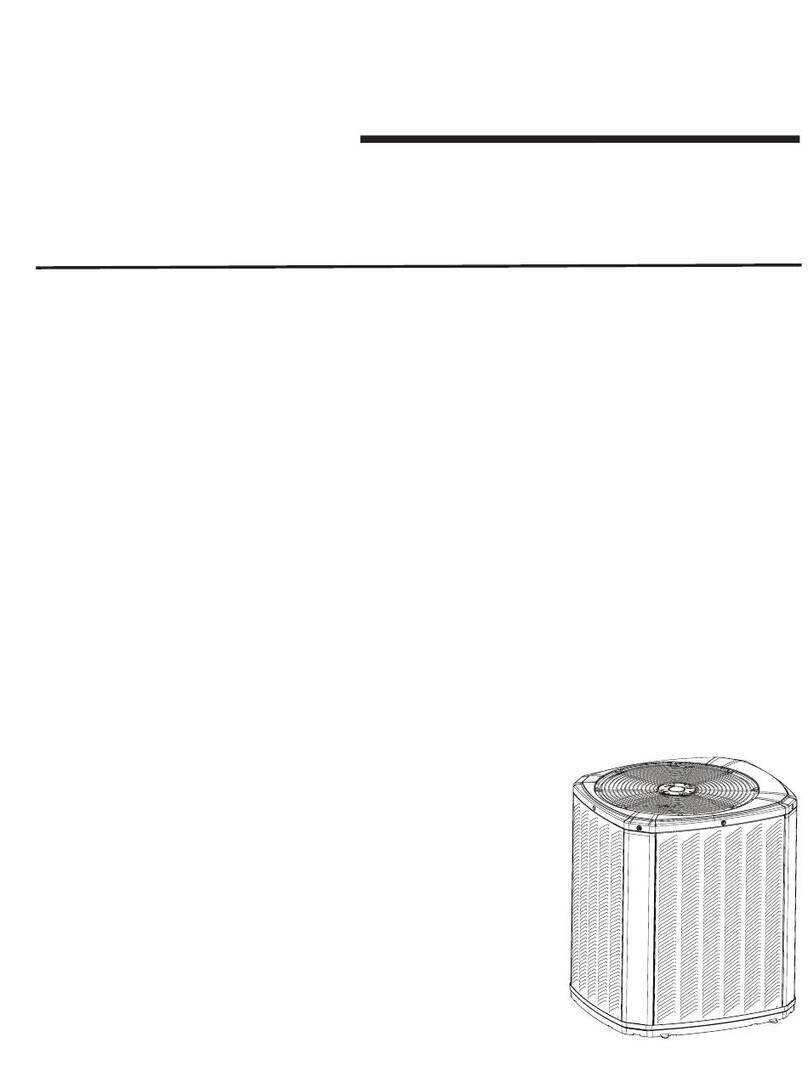

PRESSURE CURVES FOR 4TWR2036A1000AA

TXC037C4 4TEP3F36A1 4TEP3F36A1

Cooling with FCCV Cooling with Thermal Expansion Valve Heating

DISCHARGE PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

SUCTION PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

COOLING PERFORMANCE CAN BE CHECKED WHEN THE OUTDOOR TEMP IS ABOVE 65 DEG F.

TO CHECK COOLING PERFORMANCE, SELECT THE PROPER INDOOR CFM, ALLOW PRESSURES TO STABILIZE. MEASURE INDOOR WET BULB

TEMPERATURE, OUTDOOR TEMPERATURE, DISCHARGE AND SUCTION PRESSURES. ON THE PLOTS LOCATE OUTDOOR TEMPERATURE (1);

LOCATE INDOOR WET BULB (2); FIND INTERSECTION OF OD TEMP. & ID W.B. (3); READ DISCHARGE OR SUCTION PRESSURE IN LEFT

COLUMN (4).

EXAMPLE: (1) OUTDOOR TEMP. 82 F.

(2) INDOOR WET BULB 67 F.

(3) AT INTERSECTION ACTUAL:

(4) DISCHARGE PRESSURE @ 1200 CFM IS 330 PSIG DISCHARGE PRESSURE SHOULD BE +/- 10 PSI OF CHART

(5) SUCTION PRESSURE @ 1200 CFM IS 134 PSIG. SUCTION PRESSURE SHOULD BE +/- 3 PSIG OF CHART

INTERCONNECTING LINES

GAS - 3/4" O.D.

LIQUID - 3/8" O.D.

DWG.NO. 4TWR2036A1

100

105

110

115

120

125

130

135

140

145

150

155

160

165

170

40 60 80 100 120

100

105

110

115

120

125

130

135

140

145

150

155

160

165

170

40 60 80 100 120

250

300

350

400

450

500

40 60 80 100 120

250

300

350

400

450

500

40 60 80 100 120

(1)

(1)

(3)

(3)

(5)

(4)

(2)

(2)

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

30

40

50

60

70

80

90

100

110

120

130

140

-5 5 152535455565

200

250

300

350

400

450

500

-5 5 152535455565

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM 80,

70, AND 60 DEG F.

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM 80,

70, AND 60 DEG F.

TU/DD060R9V3+TXH033A4 1200 0 0 0 12

TU/DD060R9V3+TXH041A4 1200 3 5 0 -11

TU/DD080R9V3+TXH033A4 1125 -1 -2 1 21

TU/DD080R9V3+TXH041A4 1140 2 3 0 -5

TU/DD100R9V5+TXH033A4 1130 -1 -2 1 20

TU/DD100R9V5+TXH041A4 1200 3 5 0 -11

TDY060R9V3+TXH033A4 1080 -2 -4 1 26

TDY060R9V3+TXH041A4 1070 0 1 0 2

TDY080R9V3+TXH033A4 1100 -2 -3 1 24

TDY080R9V3+TXH041A4 1100 1 2 0 -1

TDY100R9V4+TXH033A4 1050 -3 -5 1 30

TDY100R9V4+TXH041A4 1050 0 0 0 5

TUY060R9V3+TXH033A4 1070 -2 -4 1 28

TUY060R9V3+TXH041A4 1025 -1 -1 0 8

TUY080R9V3+TXH033A4 1000 -4 -7 1 38

TUY080R9V3+TXH041A4 1025 -1 -1 0 8

TUY100R9V4+TXH033A4 1050 -3 -5 1 30

TUY100R9V4+TXH041A4 1050 0 0 0 5

TVF030A14 1125 0 0 0 3

TVF036A14 1200 3 5 -1 -17

TWE030C14 949 -9 -14 2 65

TWE036C14 1200 -2 -3 0 15

TWE042C14 1350 3 6 0 -14

TWE048C14 1350 5 9 -1 -29

TXA,TXC030C4,D4 1100 -4 -7 1 45

TXA,TXC031C4,D4 1100 -3 -5 0 14

TXA,TXC035C4,D4 1100 -4 -7 1 45

TXA,TXC036C4,D4 1200 0 0 0 -10

* TXA,TXC037C4 1200 0 0 0 -10

TXA,TXC042C4 1200 1 2 -1 -16

TXA,TXC043C4 1350 3 6 -1 -29

TXA,TXC048C4 1350 5 10 -1 -39

TXA,TXC049C4 1350 5 10 -1 -39

TXA,TXC050C4 1350 5 10 -1 -39

TXH033A4 1125 -1 -2 0 14

TXH041A4 1350 5 9 -1 -29

ALTERNATE INDOOR UNITS

PRESSURE CURVE CORRECTION PSIG

WITH FCCV OR TXV —COOLING——HEATING—

SUCT. HEAD SUCT. HEAD

INDOOR UNIT CFM PRESS PRESS PRESS PRESS

ALTERNATE INDOOR UNITS

PRESSURE CURVE CORRECTION PSIG

WITH THERMAL EXPANSION VALVE —COOLING——HEATING—

SUCT. HEAD SUCT. HEAD

INDOOR UNIT CFM PRESS PRESS PRESS PRESS

4TEE3F31A 1220 0 0 0 13

4TEE3F37A 1160 0 0 0 4

4TEE3F40A 1200 8 4 -1 -39

4TEP3F30A 940 -5 -3 1 51

* 4TEP3F36A 1200 0 0 0 0

4TEP3F42A 1350 6 3 -1 -29

4TEP3F48A 1350 11 6 -2 -59

RXC031S3 1110 0 0 0 0

RXC036S3 1200 5 3 -1 -28

RXC037S3 1200 5 3 -1 -28

RXC054S3 1350 7 4 -1 -45

TDD060R9V3+RXC031S3 1200 2 1 0 -4

TDD060R9V3+RXC036S3 1200 5 3 -1 -23

TDD080R9V3+RXC031S3 1120 0 0 0 4

TDD080R9V3+RXC036S3 1130 3 2 -1 -16

TDD100R9V5+RXC037S3 1180 4 2 -1 -21

TDY060R9V3+RXC031S3 1090 0 0 0 8

TDY060R9V3+RXC036S3 1085 3 1 0 -12

TDY080R9V3+RXC031S3 1050 -1 -1 0 13

TDY080R9V3+RXC036S3 1050 2 1 0 -8

TDY100R9V4+RXC037S3 1050 2 1 0 -8

TUD060R9V3+RXC031S3 1200 2 1 0 -4

TUD060R9V3+RXC036S3 1200 5 3 -1 -23

TUD080R9V3+RXC031S3 1200 2 1 0 -4

TUD080R9V3+RXC036S3 1200 5 3 -1 -23

TUD100R9V5+RXC037S3 1200 5 3 -1 -23

TUY060R9V3+RXC031S3 1050 -1 -1 0 13

TUY060R9V3+RXC036S3 1050 2 1 0 -8

TUY080R9V3+RXC031S3 1040 -1 -1 0 14

TUY080R9V3+RXC036S3 1040 2 1 0 -7

TUY100R9V4+RXC037S3 1060 2 1 0 -9

* BASE INDOOR UNIT(S) CURVES ON 4TWR2036A1

NOTES:

1

For a field installed TXV kit, apply the factor listed with the FCCV model to the TXV curve.