The Production Cycle Timer

Owners Manual

1.0 Getting Started

Thank you for your urchase of an AMERICAN LED-gible® roduct. We take ride in the equi ment we build, and

we a reciate your su ort. We will do everything we can to kee you ha y with your urchase for many years

to come. Please review this manual carefully, and if you have any questions, call, e-mail, or fax us and we will be

glad to hel you. American LED-gible su ort can be reached at:

1.1 Product Description

The roduction cycle timer (PCT) is a s ecial ur ose numeric marquee designed to ace the roduction rate of a

manual rocess with long cycle times. The PCT GOAL line dis lays the o erator entered goal cycle time. This

field does not change unless adjusted by the o erator via the key ad. The PCT ACTUAL line starts at the

rogramed goal cycle time, and times down to zero. Once zero has been reached, the ACTUAL line begins to

flash and time u to dis lay the amount of cycle time overage. The PCT can be configured to time in tenths of

seconds, seconds, tenths of minutes, minutes, tenths of hours, or hours. See section 1.4.7 for directions on how

to select the timing mode.

If the PCT has the o tional RED / YLW stack light installed, then PCT o erator may s ecify a yellow time length,

and a red time length in addition to the goal cycle time. Initially when the PCT is reset, the stack light starts out off.

After some time has ela sed the stack light will switch from off to yellow. Then after the rogrammed yellow time

has ela sed the stack light will switch from yellow to red. Then after the rogrammed red time has ela sed the

stack light will switch from red to flashing red.

By default, the stack light switches from off to yellow when the actual time remaining reaches zero (Time Minus

Mode). However the PCT can be configured so that the stack light transitions from red to flashing red when the

actual time remaining reaches zero (Time Plus Mode). See section 1.4.8 for directions on how to select time

minus mode or time lus mode.

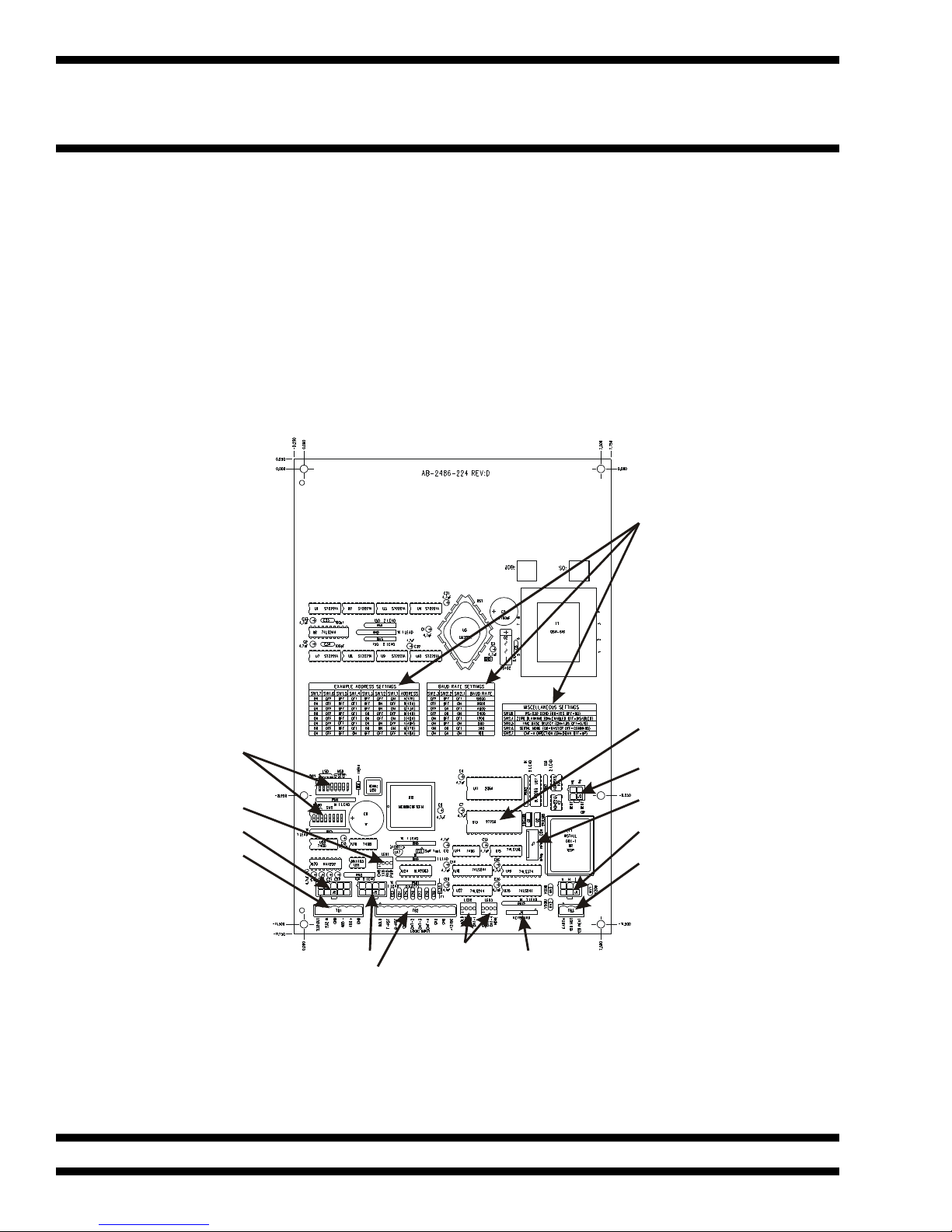

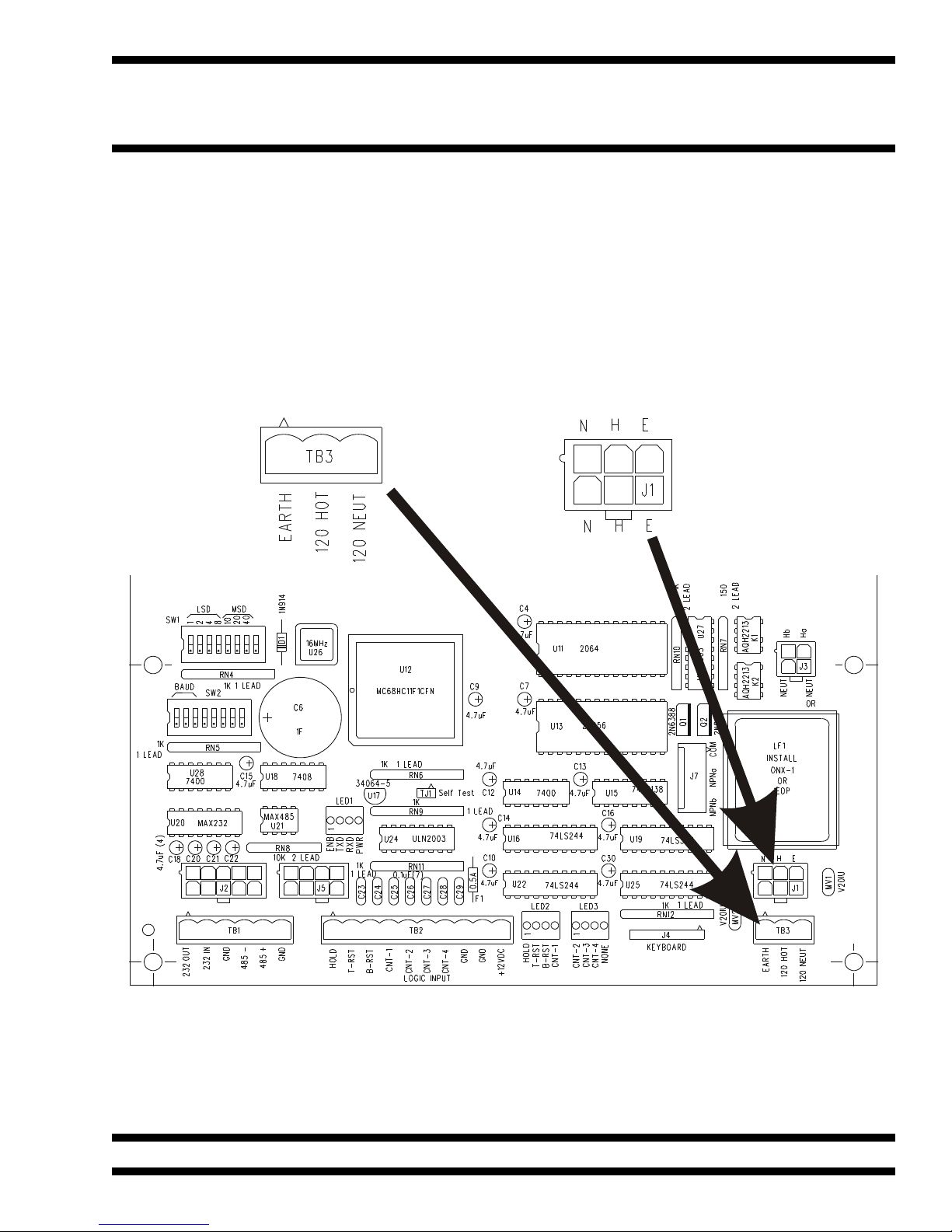

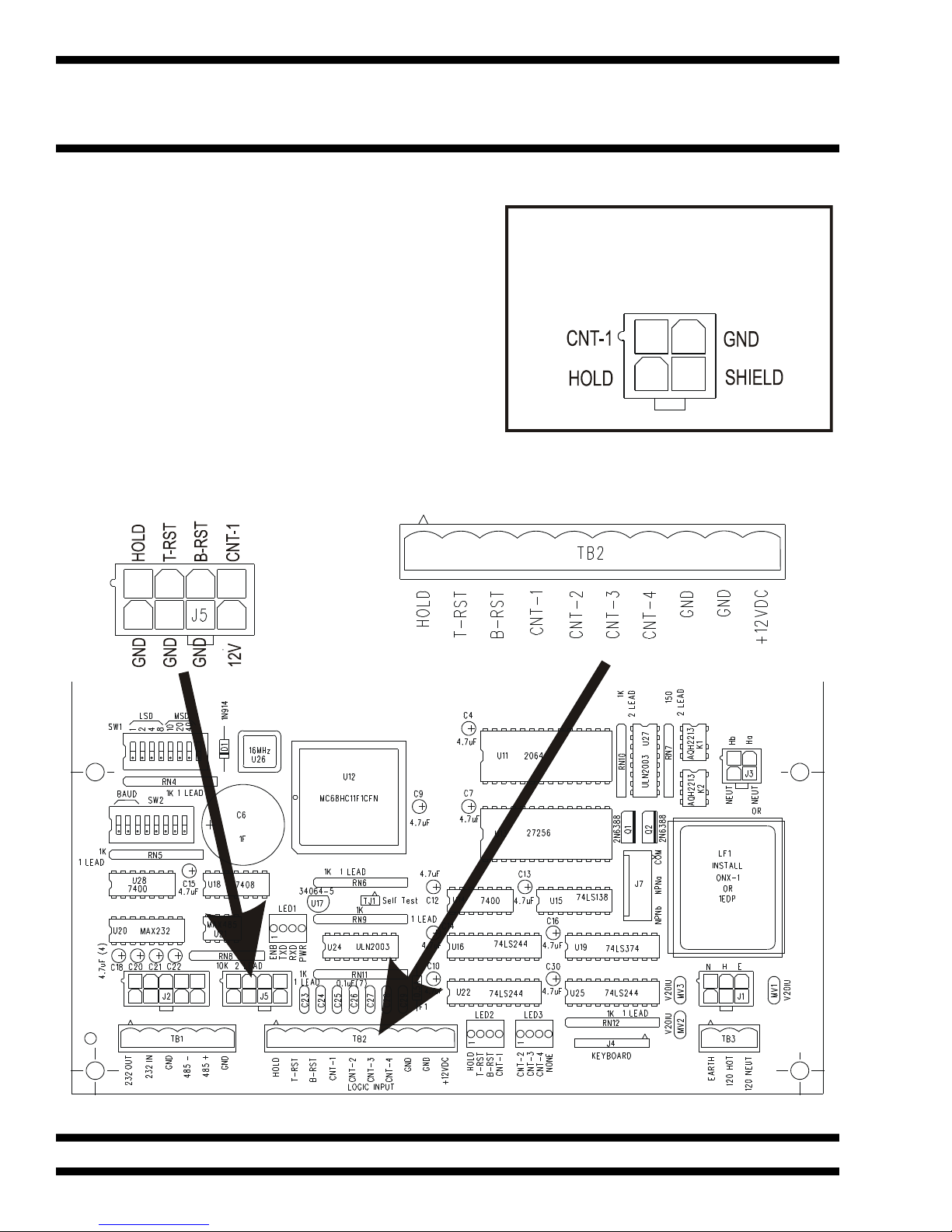

The PCT has seven logic in uts (HOLD, T-RST, B-RST, CNT-1, CNT-2, CNT-3, CNT-4). The HOLD in ut auses

the PCT timer for as long as the in ut is activated. Both the T-RST and the B-RST reset in uts reset the actual

timer to the rogrammed goal cycle time. All four CNT-x count in uts also reset the actual timer to the

rogrammed goal cycle time. During breaks activate the HOLD in ut to ause the actual timer. At the start of

each cycle, ulse one of the reset or count in uts to reset the actual timer back to the rogrammed goal cycle

time.

A 1 Farad Su er-Ca backs u the CCTs memory. The Su er-Ca allows the PCT to retain o erational values for

five days without ower. Unlike batteries, Su er-Ca s do not require s ecial recharge circuitry and have an

ex ected life s an in excess of 10 years.

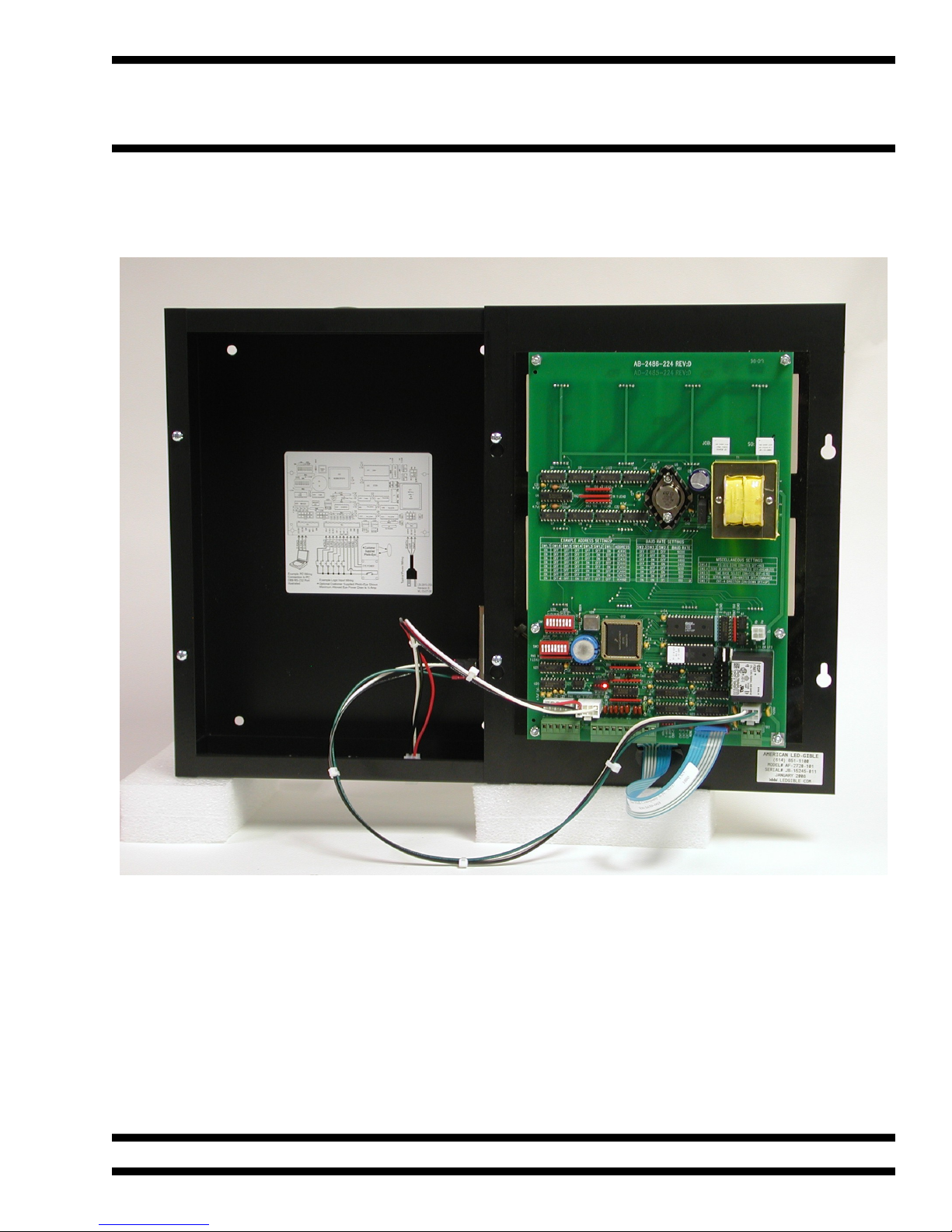

The PCT is enclosed in a NEMA-1 black satin ainted 16-gauge steel enclosure with a 1/8” thick, acrylic dis lay

lens. The enclosure is designed to be mounted to a wall by four holes in the back of the enclosure.

Page 1

American LED-gi le® Inc.

1776 Lone Eagle St.

Columbus, OH 43228

(614) 851-1100 Phone

(614) 851-1121 Fax

www.ledgible.com www

su ort@ledgible.com e-mail