5 August 18, 2003

A. CHANGING SENSOR ACTIVE LENGTH RANGE

NOTE: IF THIS STEP IS REQUIRED, IT SHOULD BE

PERFORMED BY QUALIFIED SERVICE PERSONNEL. SEE

THE QUALIFIED SERVICE PERSONNEL SECTION. There

are two sensor active length ranges — 1”-7.99” and 8”-60”. If

the instrument is currently calibrated for a sensor in a particular

range and the new sensor is in the same range, then this step

does not need to be taken—the range-setting jumpers are

already in the correct position. For example, if the instrument is

currently calibrated to an 18” sensor active length, and is being

re-calibrated to a 12” sensor active length, then the jumpers are

already both in the 8”-60” position; there is no need to open up

the unit. All needed adjustments can be made through the side

access holes in the lid.

B. ACTIVE LENGTH CALIBRATION

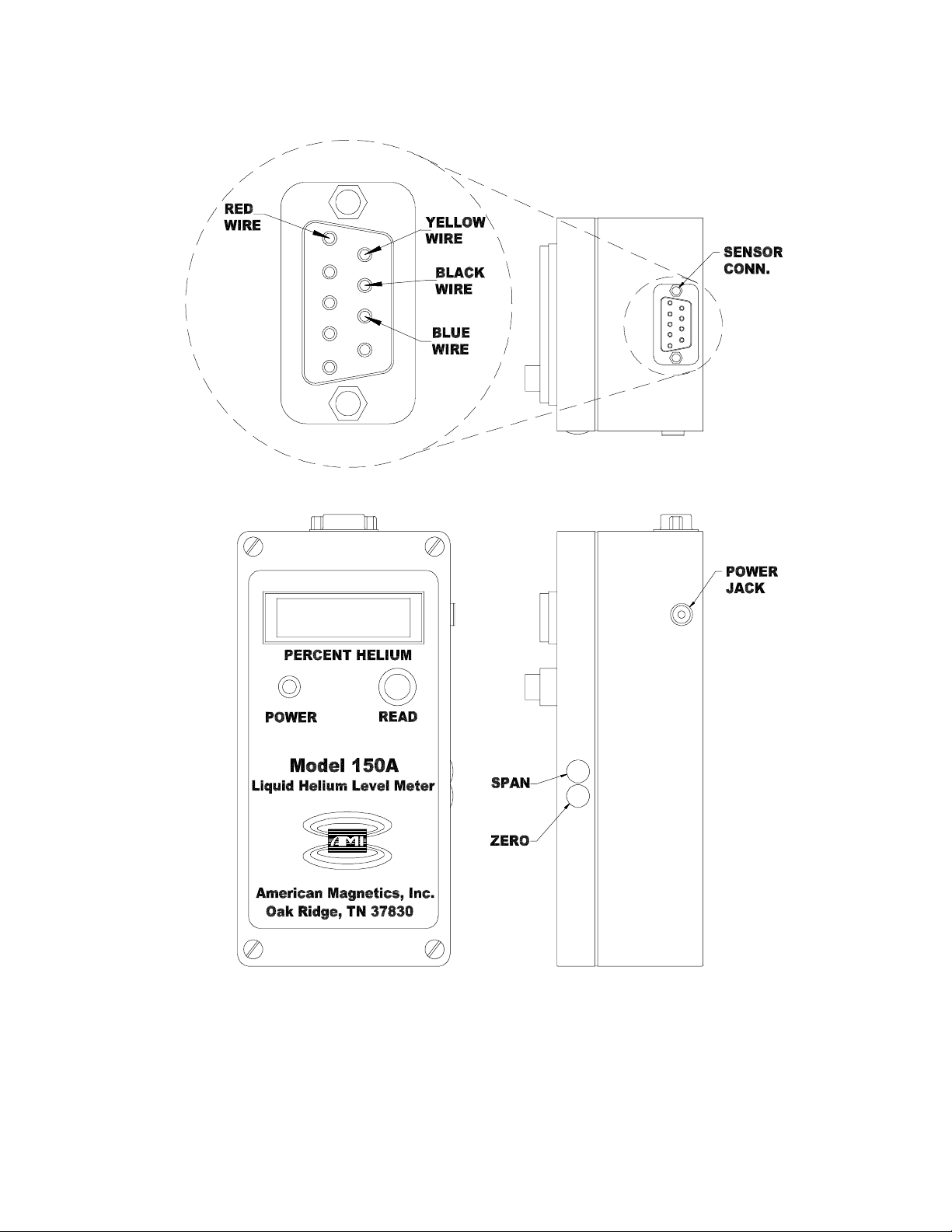

1. Jumper the I+ and V+ contacts (pins 1 and 8) on the SENSOR connector together

and connect to one side of the calibration resistor. Jumper the I- and V- contacts

(pins 6 and 7) on the sensor connector together and connect to the other side of

the calibration resistor. The value of the calibration resistor should be (4.56

ohms) x (the active length of the sensor in cm); remember that the active length

of AMI standard sensors is 1 inch less than the overall length.

2. Temporarily install a short circuit (using a clip lead or other means) across the

calibration resistor.

3. Depress the READ switch.

4. Adjust the SPAN potentiometer located on the circuit board through the side

access hole in the lid until the display LCD reads 100.0. Refer to Figure 1.

5. Release the READ switch.

6. Remove the short from the calibration resistor.

7. Depress the READ switch.

8. Adjust the ZERO potentiometer located on the circuit board through the side

access hole in the lid until the display LCD reads 0.0. Refer to Figure 1.

9. Release the READ switch.

10. Repeat steps 2 through 9 until neither potentiometer needs adjusting.

11. Remove the jumper wires and calibration resistor.

12. The calibration procedure is complete.

13. Reconnect the sensor to the instrument.