INTRODUCTION

3

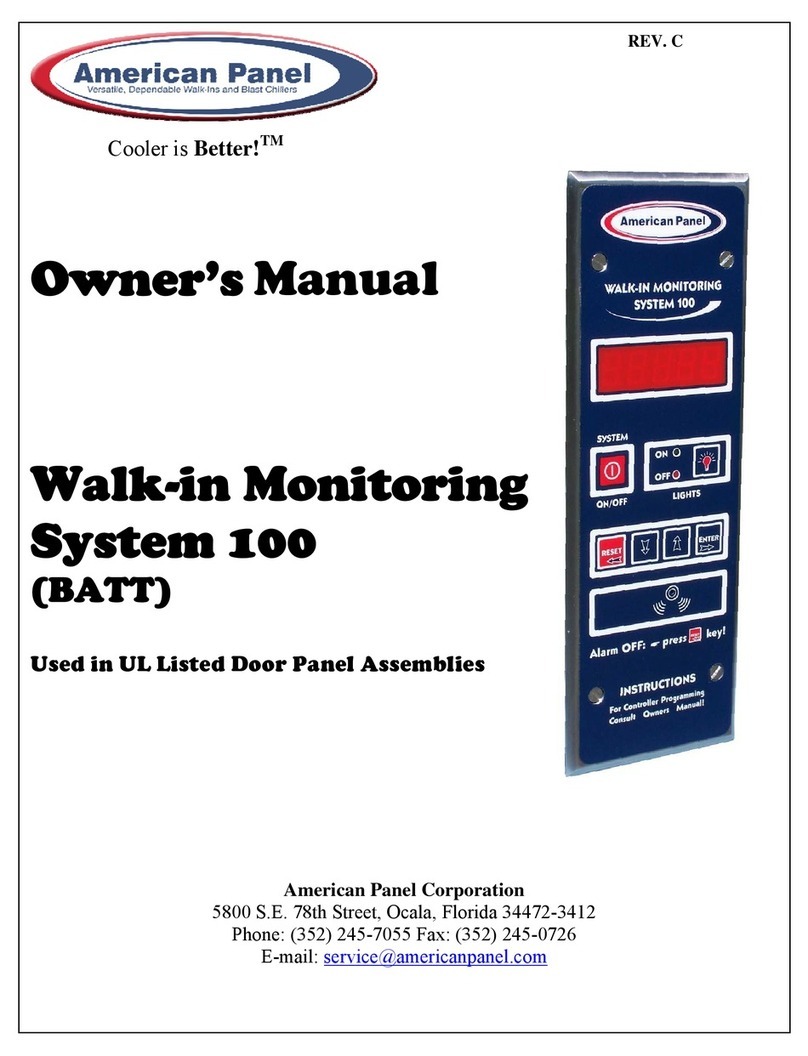

Index

1.INTRODUCTIONANDFEATURES.................................................................................................................................................4

1.1.TEMPERATUREMONITORINGANDALARMS...............................................................................................................................................4

1.2.DOORFRAMEHEATERTEMPERATURECONTROLANDMONITORING..............................................................................................................4

1.3.HACCPCOMPLIANTDATALOGGERANDTHEPCCOMMUNICATIONPROTOCOLANDSOFTWARE........................................................................5

1.4.ELECTRONICALLYCONTROLLEDLIGHTSWITCHANDAUTOMATICLIGHTOFF....................................................................................................5

2.CONTROLLER.............................................................................................................................................................................6

3.PARAMETERPROGRAMMING....................................................................................................................................................7

4.CHANGETHEACCESSCODE......................................................................................................................................................12

5.TECHNICIANMENU(CELSIUS/FAHRENHEITUNITSELECTION,TEMPERATUREPROBEOFFSET,PCCONNECTIONSETTINGS,

HACCPDATARECORDINGSETTINGS)...........................................................................................................................................14

6.RESTORETHEDEFAULTSETTINGS............................................................................................................................................17

7.OPERATINGWIMS200.............................................................................................................................................................18

7.1.TURNONTHECONTROLLER.................................................................................................................................................................18

7.2.READTHEWALK‐INAIRTEMPERATUREANDTHECURRENTTIME...............................................................................................................18

7.3.DISPLAYTHECURRENTDATEANDTIME.................................................................................................................................................18

7.4.DISPLAYTHEDOORFRAMEHEATERTEMPERATURE..................................................................................................................................18

7.5.OPERATETHELIGHTSWITCH................................................................................................................................................................19

7.6.HIGHALARM....................................................................................................................................................................................19

7.7.LOWALARM.....................................................................................................................................................................................19

7.8.PANICBUTTON(OPTIONAL).................................................................................................................................................................19

7.9.DOORSWITCH...................................................................................................................................................................................19

8.HACCPDATADOWNLOADVIASD/MMC..................................................................................................................................20

8.1.CLEARTHEEVENTSMEMORY...............................................................................................................................................................22

9.ERRORMESSAGES...................................................................................................................................................................23

9.1.TEMPERATUREPROBEFAILUREMESSAGES.............................................................................................................................................23

9.2.POWERFAILUREMESSAGE..................................................................................................................................................................24

9.3.SDCARDOPERATIONERRORMESSAGE.................................................................................................................................................24

10.BATTERIES.............................................................................................................................................................................25

10.1.CONNECTTHEBATTERYPACK............................................................................................................................................................25

10.2.REPLACETHEBATTERIES...................................................................................................................................................................25

11.PCCONNECTIONKITANDSOFTWARE(OPTIONAL).................................................................................................................26

11.1.PACKAGECONTENT..........................................................................................................................................................................26

11.2.CONNECTWIMS200TOYOURPC....................................................................................................................................................26

11.3.PCCONNECTIONFORTWOORMORECONTROLLERS.............................................................................................................................27

11.4.COMMUNICATIONSOFTWARECPX‐200..............................................................................................................................................28

11.4.1.SpecialOperationMenu......................................................................................................................................................28

11.4.2.PanelOperationMenu........................................................................................................................................................29

11.5.PCCONNECTIONTROUBLESHOOTING..................................................................................................................................................30

11.5.1.BlankDisplay.......................................................................................................................................................................30

12.FIELDWIRING........................................................................................................................................................................31

13.ELECTRICALDIAGRAM...........................................................................................................................................................32

13.1.WIRINGDIAGRAM...........................................................................................................................................................................32

13.2.PCCONNECTIONWIRINGDIAGRAM....................................................................................................................................................36

14.APPENDIX1AIRTEMPERATUREPROBEOFFSET.....................................................................................................................37