18-BC53D1-4 3

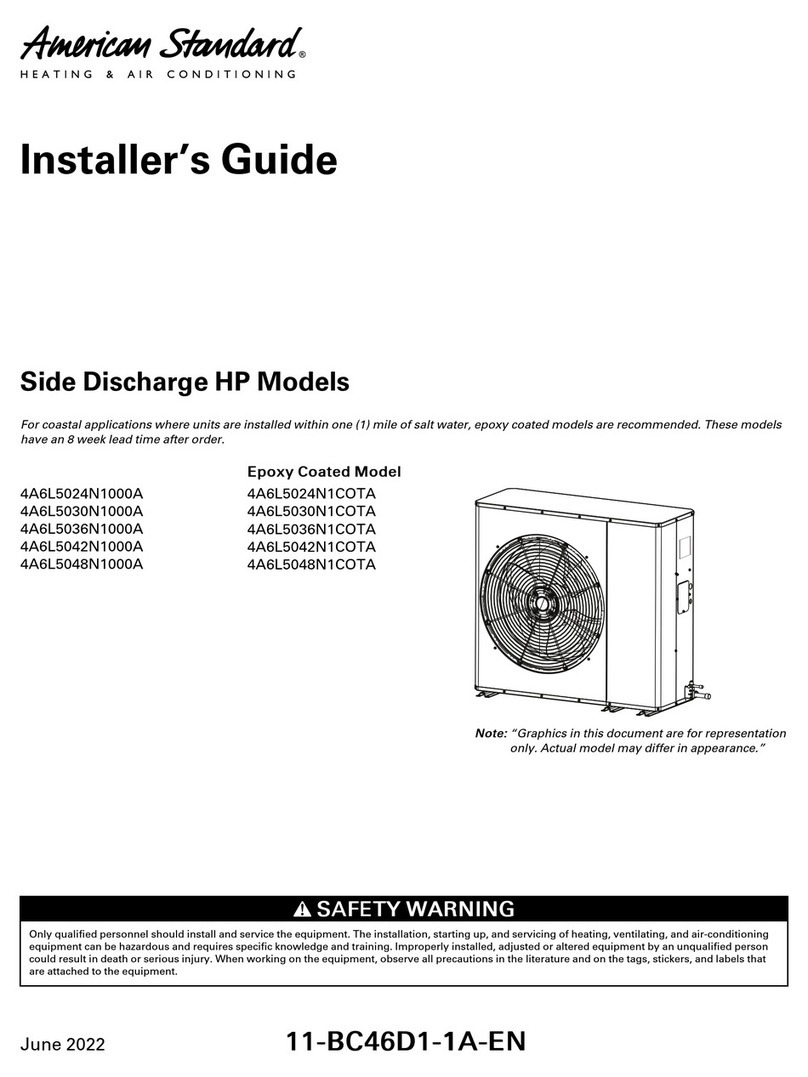

Installer’s Guide

After the brazing operation of refrigerant lines to both the outdoor

and indoor unit is completed, the field brazed connections must be

checked for leaks. Pressurize through the service valve ports, the

indoor unit and field refrigerant lines with dry nitrogen to 350-400 psi.

Use soap bubbles or other leak-checking methods to see that all field

joints are leak-free! If not, release pressure; then repair!

SYSTEM EVACUATION

NOTE:

Since the outdoor unit has a refrigerant charge, the gas and liquid

line valves must remain closed.

1. Upon completion of leak check, evacuate the refrigerant lines

and indoor coil before opening the gas and liquid line valves.

2. Attach appropriate hoses from manifold gauge to gas and liquid

line pressure taps.

NOTE:

Unnecessary switching of hoses can be avoided and complete

evacuation of all lines leading to sealed system can be accom-

plished with manifold center hose and connecting branch hose to

a cylinder of HCFC-22 and vacuum pump.

3. Attach center hose of manifold gauges to vacuum pump.

4. Evacuate until the micron gauge reads no higher than 350 microns.

5. Close off valve to vacuum pump and observe the micron gauge.

If gauge pressure rises above 500 microns in one (1) minute,

then evacuation is incomplete or system has a leak.

6. If vacuum gauge does not rise above 500 microns in one (1)

minute, the evacuation should be complete.

7. Blank off vacuum pump and micron gauge, close valves on

manifold gauge set.

NOTE:

DO NOT VENT REFRIGERANT INTO THE ATMOSPHERE.

NOTE:

A 3/16" Allen wrench is required to open liquid line service valve.

A 1/4" Open End or Adjustable wrench is required to open gas line

valve. A 3/4" Open End wrench is required to take off the valve

stem cap.

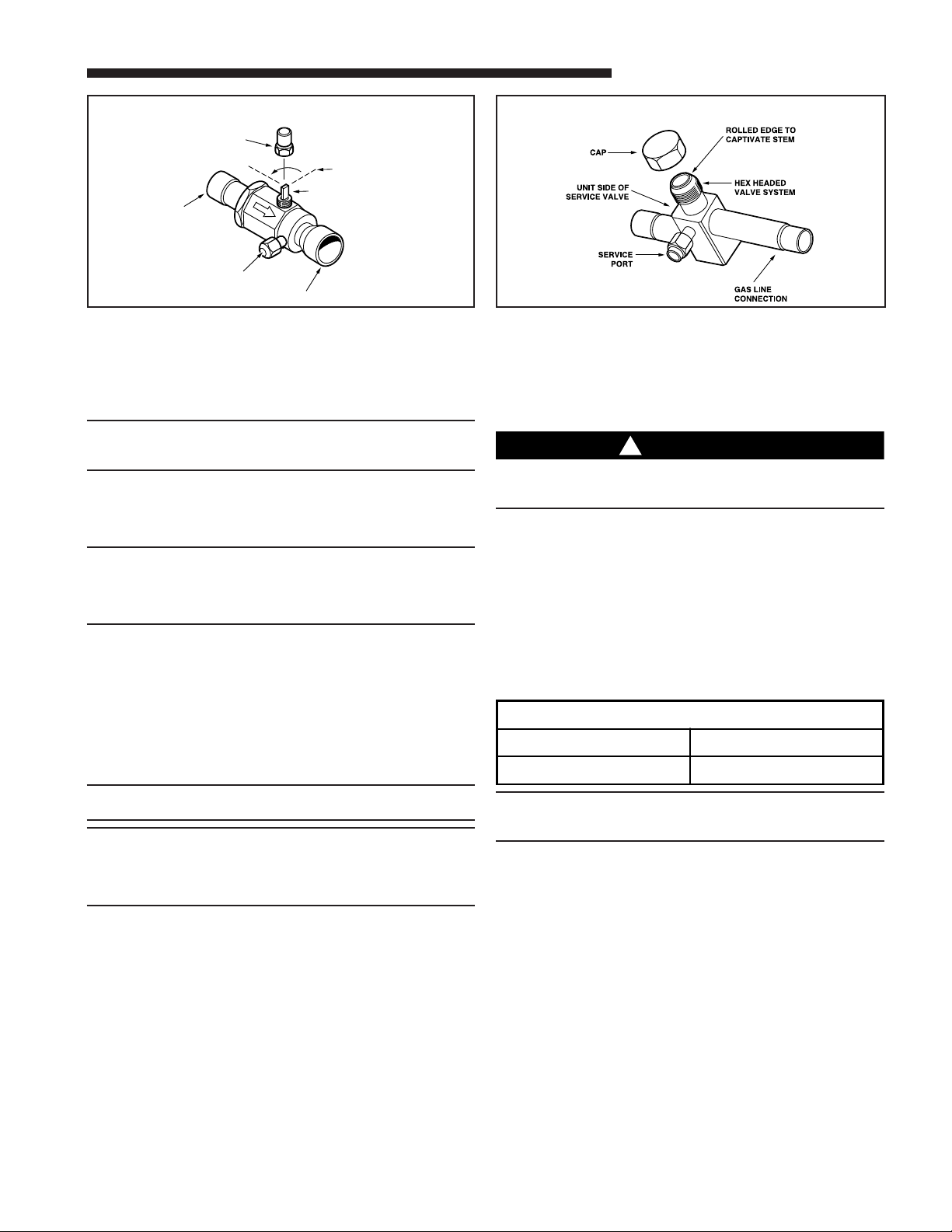

8. The liquid line shut-off valve can now be opened. Remove shut-

off valve cap. Fully insert hex wrench into the stem and

backout counterclockwise until valve stem just touches rolled

edge (approximately five [5] turns) observing WARNING

statement on page 2. See Figure 3.

9. Replace liquid service pressure tap port cap and valve stem cap.

These caps MUST BE REPLACED to prevent leaks. Replace

valve stem and pressure tap cap finger tight, then tighten an

additional 1/6 turn.

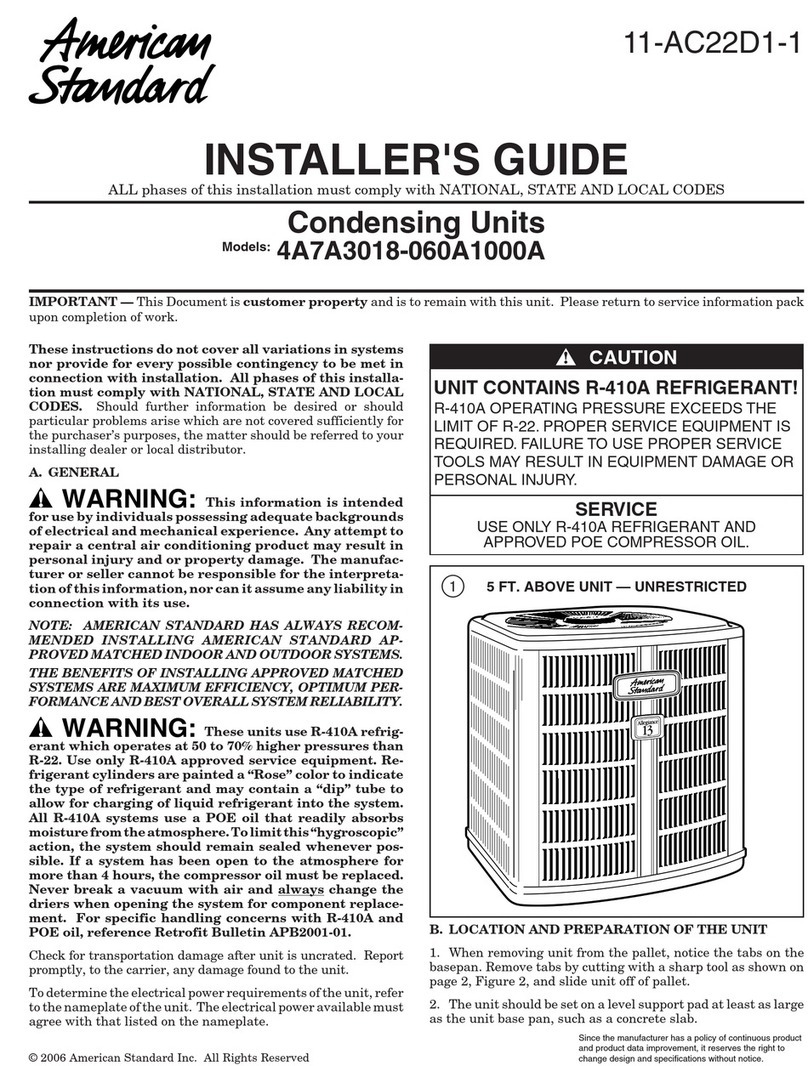

10. The gas valve can now be opened. For a ball type gas valve, open

the gas valve by removing the shut-off valve cap and turning the

valve stem 1/4 turn counterclockwise, using 1/4" Open End or

Adjustable wrench. See Figure 4. For brass gas line service valve

opening, follow 8 and 9 above. See Figure 5.

11. The gas valve is now open for refrigerant flow. Replace valve

stem cap to prevent leaks. Again, these caps MUST BE

REPLACED to prevent leaks. Replace valve stem and

pressure tap cap finger tight, then tighten an additional

1/6 turn. See Figure 4.

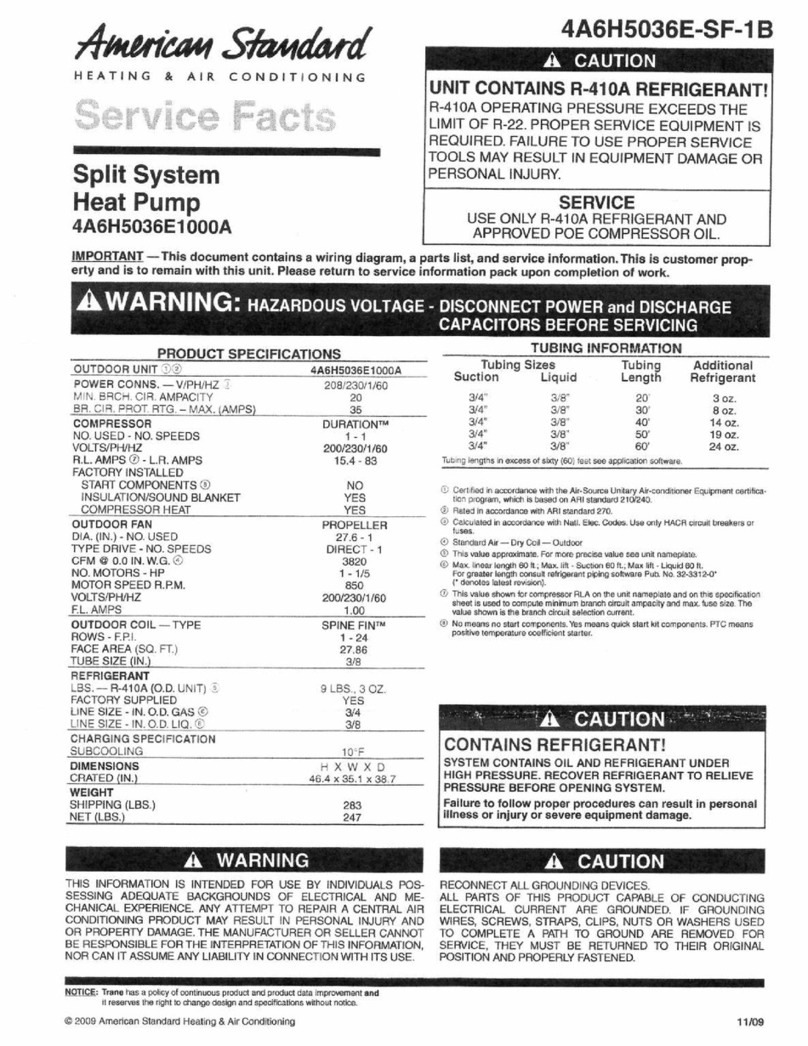

If refrigerant lines are longer than fifteen (15) feet and/or a different

size than recommended, it will be necessary to adjust system

refrigerant charge upon completion of installation. See unit Service

Facts.

E. ELECTRICAL CONNECTIONS

WARNING

!

When installing or servicing this equipment, ALWAYS exercise

basic safety precautions to avoid the possibility

of electric shock.

1. Power wiring and grounding of equipment must comply with

local codes.

2. Power supply must agree with equipment nameplate.

3. Install a separate disconnect switch at the outdoor unit.

4. Ground the outdoor unit per local code requirements.

5. Provide flexible electrical conduit whenever vibration transmis-

sion may create a noise problem within the structure.

6. The use of color coded low voltage wire is recommended to

simplify connections between the outdoor unit, the

ComfortLink™ II control and the indoor unit.

Table 1 – NEC Class II Control Wiring

CAP 1/4 TURN ONLY

COUNTERCLOCKWISE

FOR FULL OPEN

POSITION

VALVE STEM

GAS LINE CONNECTION

UNIT SIDE

OF VALVE

PRESSURE TAP PORT

GAS LINE BALL SERVICE VALVE

4GAS LINE SERVICE VALVE

5

NOTE:

The maximum total cable length for the entire Comfort Control

communicating system is 500 ft. 18 AWG.

7. Mount the ComfortLink™ II control in accordance with

instruction included with the ComfortLink™ II control.

Wire per appropriate hook-up diagram (included in these

instructions).

F. DEFROST CONTROL

The demand defrost control measures heat pump outdoor ambient

temperature with a sensor located outside the outdoor coil. A second

sensor located on the outdoor coil is used to measure the coil

temperature. The difference between the ambient and the colder coil

temperature is the difference or delta-T measurement. This delta-T

measurement is representative of the operating state and relative

capacity of the heat pump system. By measuring the change in

delta-T, we can determine the need for defrost. The coil sensor also

serves to sense outdoor coil temperature for termination of the

defrost cycle.

FAULT IDENTIFICATION

A fault condition is indicated by the fault LED on the control board

inside the heat pump control box.

In normal operation, the status LED will flash once each second. If

the light is flashing more than once per second or not at all, refer to

the service manual for that unit.

ComfortLink™ II Control Wiring

WIRE SIZE MAX. WIRE LENGTH

18 AWG 250 FT