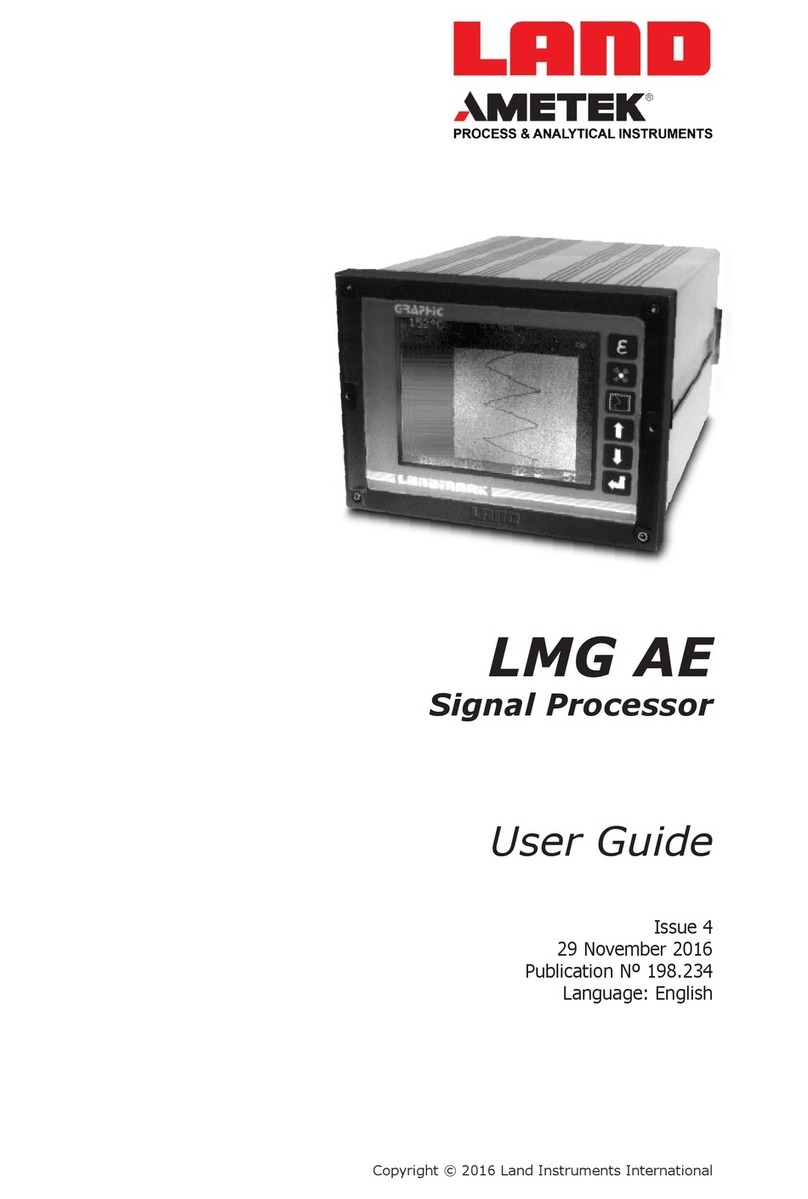

Signal Processor

LMG MkII

1.3 Specification

Model Landmark Graphic

Accuracy ±0.12%ofreading

Stability(Temp) 0.01%ofspan/°

Discrimination 0.015%offullscale

Display LEDlit,800x480pixels

Displayupdate 0.5sText,0.1sGraphics

Screens Numeric,linechart,deviationchart,4channelbargraph,4channeldeviationbar

graph

Line/Deviationchartranges 1°steps,100°minspan,setable

Bargraphranges 1°steps,100°minspan,setable

Timespan 1,3,6,12,30,60,90,270mins

Userlabel Upto10characters

Signal Outputs Tosuittemperaturerangeofthermometer

Current 0to20mAor4to20mA

Selectablerange 50°steps,100°minimumspan

Voltageoutput 1mV/°

Outputupdate 1.25ms

Thermometer

Thermometerinputupdate 1.25ms

Emissivity 0.050to1.000in0.001steps

(Note: below 0.200, system operation is unspecied and not guaranteed)

Nongreyness 0.800to1.250in0.001steps

Peak Picker Reset,holdorpeaksample,selectable

Threshold 1°steps,setable

Ondelay 0to10sin0.1ssteps

Odelay 0to10sin0.1ssteps

Decayrate 0,0.25,0.5,1,2,4,8,16,32,64,128,256,512°/s

Acquisitiontime 1.25ms

Valley Picker Reset,holdorvalleysample,selectable

Threshold 1°steps,setable

Ondelay 0to10sin0.1ssteps

Odelay 0to10sin0.1ssteps

Recoveryrate 0,0.25,0.5,1,2,4,8,16,32,64,128,256,512°/s

Acquisitiontime 1.25ms

Interval 10to250sin1ssteps

Averager

Timeconstant 0,0.05,0.1.0.15,0.25,0.5,1,2,4,8,16,32,64,128,256,512s

Track and Hold

Controlsignal 5to24Vdc.orswitch/relay

Responsetime 1.25ms

Alarms Highorlow,setable

Triplevel 1°steps,setable

Relaycontactrating 50Va.c.ord.c.at0.5A

Update 10ms

Hysteresis 3°

Power Supply

Powerrequirement

(LMGMkII)

24Vdc±10%,3AMax.

ExternalDINRailPSU

(supplied) 100-240Vac,50/60Hz,2.4Amax

Environment

Ambientoperatingtemp 5to50°C/40to120°F(specied)

5to60°C/40to140°F(max.operating)

Sealing ToIP65/NEMA4(withprotectioncovertted)

Humidity 0to99%noncondensing

Vibration 1gAnyaxis10to300Hz

EMC EN61326-1

RoHS 011/65/EUcompliant