UltraMig 175

- 4 -

Safety Instructions

1. Safety in the use of a power source

for electric arc welding

The equipment which you have just acquired will give

you complete satisfaction if you follow the operating

and maintenance instructions.

Its design, specification of components, and its

manufacture are in accordance with CE and ULC

standards.

When using this equipment, safety rules must be

observed, especially those concerning power sources.

For your safety, you will find listed below a complete

set of recommendations or requirements as found in

government labor safety codes.

2. Work station

The use of arc welding equipment requires the

establishment of strict safety conditions with regard to

electrical currents.

It is necessary to check that no metal on which an

operator will be working can come into direct or indirect

contact with a phase conductor and the ground of the

electrical supply network.

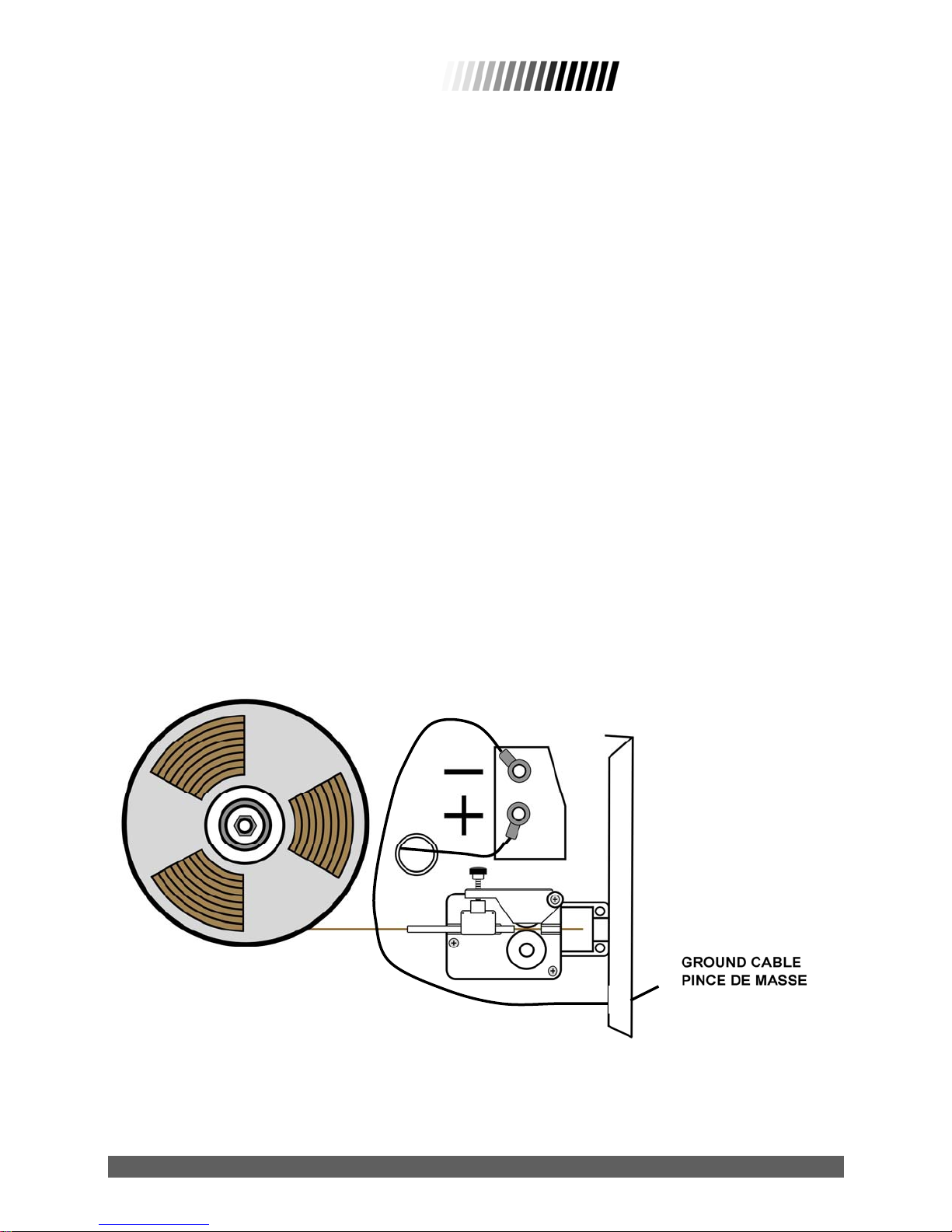

All ground cables for the welding operation that are

within reach of the user should be connected to a

single point.

All extension cords must be made with cables whose

wire size is at least equal to that of the largest power

cable.

If welding work has to be carried out in a confined

space, the following extra precautions should be taken:

• Increased individual protection.

• Complete insulation of the electrode holder, torches

or guns.

• The welding machine itself should be kept outside the

confined space and if this is not possible, the low

voltage parts of the equipment should be insulated and

the workpiece ground cable should be held in place by

solder.

3. Servicing

Before beginning any inspection or repair of the inside

of the machine it is necessary to make certain that the

equipment has been disconnected from the electrical

circuit by lockout and protective devices:

• The plug must be removed from the socket and

provisions are taken to prevent the accidental

connection of the plug in a socket.

• All cutout switches for fixed connection systems

should be omnipolar (phases and neutral). Such

switches must be in the "OFF" position, and secured or

“locked out” so that they cannot be accidentally put into

opération.

• Maintenance work on electrical equipment must be

undertaken only by persons qualified to do such work.

4. Wire feed devices

Make sure the wire or torch cannot touch any metal

parts, including the inside of the cabinet.

Do not allow the wire outlet or torch to point toward

your face or body.

Gloves should be worn when handling wire.

5. Maintenance

The insulation of equipment and the electrical

accessories must be checked regularly and kept in

good condition. This includes plugs, flexible cables,

sheaths, connectors, extension cords, workpiece

clamps or torches.

Maintenance and repair work on insulating sheaths and

covers should never be done in a makeshift manner.

AS REQUIRED:

• Replace defective accessories where possible.

Repairs should only be made by a trained specialist.

• Electrical connections must be checked regularly for

proper tightening and to insure they are not

overheating.