SteelMax ARC Runner User manual

The tools of innovation.

15335 E. Freemont Drive, CO 80112

1–87STEELMAX, FAX 303 –690 –9172

www.steelmax.com [email protected]

OPERATOR’S MANUAL

A

AR

RC

C

R

Ru

un

nn

ne

er

r

WELDING CARRIAGE

Contents

1.GENERAL INFORMATION................................................................................................ 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 6

2.SAFETY PRECAUTIONS.................................................................................................. 7

3.STARTUP AND OPERATION............................................................................................ 9

3.1. Preparing................................................................................................................... 9

3.2. Connecting to the welding circuits.............................................................................10

3.3. Positioning at the worksite ........................................................................................11

3.4. Starting.....................................................................................................................13

3.5. Programming............................................................................................................13

3.6. Welding procedure....................................................................................................15

3.7. Operating..................................................................................................................16

3.8. Using oscillator (option).............................................................................................17

3.9. Troubleshooting........................................................................................................20

4.MAINTENANCE ...............................................................................................................21

5.ACCESSORIES................................................................................................................22

5.1. Oscillator...................................................................................................................22

5.2. Torch clamps............................................................................................................24

5.3. Rods.........................................................................................................................25

5.4. Torch holders............................................................................................................26

5.5. Torch extension arm .................................................................................................28

5.6. Guide arms...............................................................................................................29

5.7. Dual torch mount.......................................................................................................34

5.8. Flexible guide set......................................................................................................35

5.9. Guide adjustment tool...............................................................................................37

5.10. 76 mm cross slide...................................................................................................38

5.11. Display protection shield .........................................................................................39

5.12. Fall arrester.............................................................................................................39

5.13. Stainless steel wheels.............................................................................................40

6.115–230 V EXPLODED VIEWS AND PARTS LIST..........................................................41

7.42 V EXPLODED VIEWS AND PARTS LIST....................................................................46

8.115–230 V WIRING DIAGRAM.........................................................................................51

9.42 V WIRING DIAGRAM ..................................................................................................52

10. DECLARATION OF CONFORMITY...............................................................................53

11. WARRANTY CARD........................................................................................................54

ARC Runner

ARC Runner Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The ARC Runner is a welding carriage designed to make butt and fillet welds that are

continuous or stitch. The carriage allows MIG/MAG torches and is clamped with

permanent magnets.

Accessories allow welding with oscillation, using torches with a larger diameter

and using two torches at the same time. They also allow the carriage to move along

outside edges, lap joints and templates, walls that are low or have holes, and on

ceilings, pipes, and tanks.

1.2. Technical data

Voltage

1~ 115–230 V, 50–60 Hz

1~ 42 V, 50–60 Hz (60 V DC)

Power

25 W

Welding position (according to

EN ISO 6947 and AWS/ASME)

Horizontal

PA/1F/1G

PB/2F

PC/2G

PD/4F

PE/4G

Vertical

PF/3F/3G (with an optional oscillator)

PG/3F/3G (with an optional oscillator)

Minimum path curve radius

1500 mm (5 ft)

Torch type

MIG/MAG

Torch diameter

16–22 mm (0.63–0.87″)

Maximum torch reach

80 mm (3.15″)

Maximum allowed cable weight

Horizontal work

12 kg (27 lbs)

Vertical work

8 kg (18 lbs)

Minimum workpiece thickness

5 mm (0.2″)

Ground clearance

5 mm (0.2″)

Horizontal pulling force

220 N (48 lbs)

Vertical pulling force

150 N (33 lbs)

Cross slide adjustment range

0–35 mm (0–1.38″)

up-down, left-right

Guide arm adjustment range

0–75 mm (2.95″)

Horizontal speed

0–120 cm/min (0–47.2 in/min)

Vertical speed

0–110 cm/min (0–43.3 in/min)

Noise level

Less than 70 dB

Weight

14 kg (31 lbs)

ARC Runner

ARC Runner Operator’s Manual

4

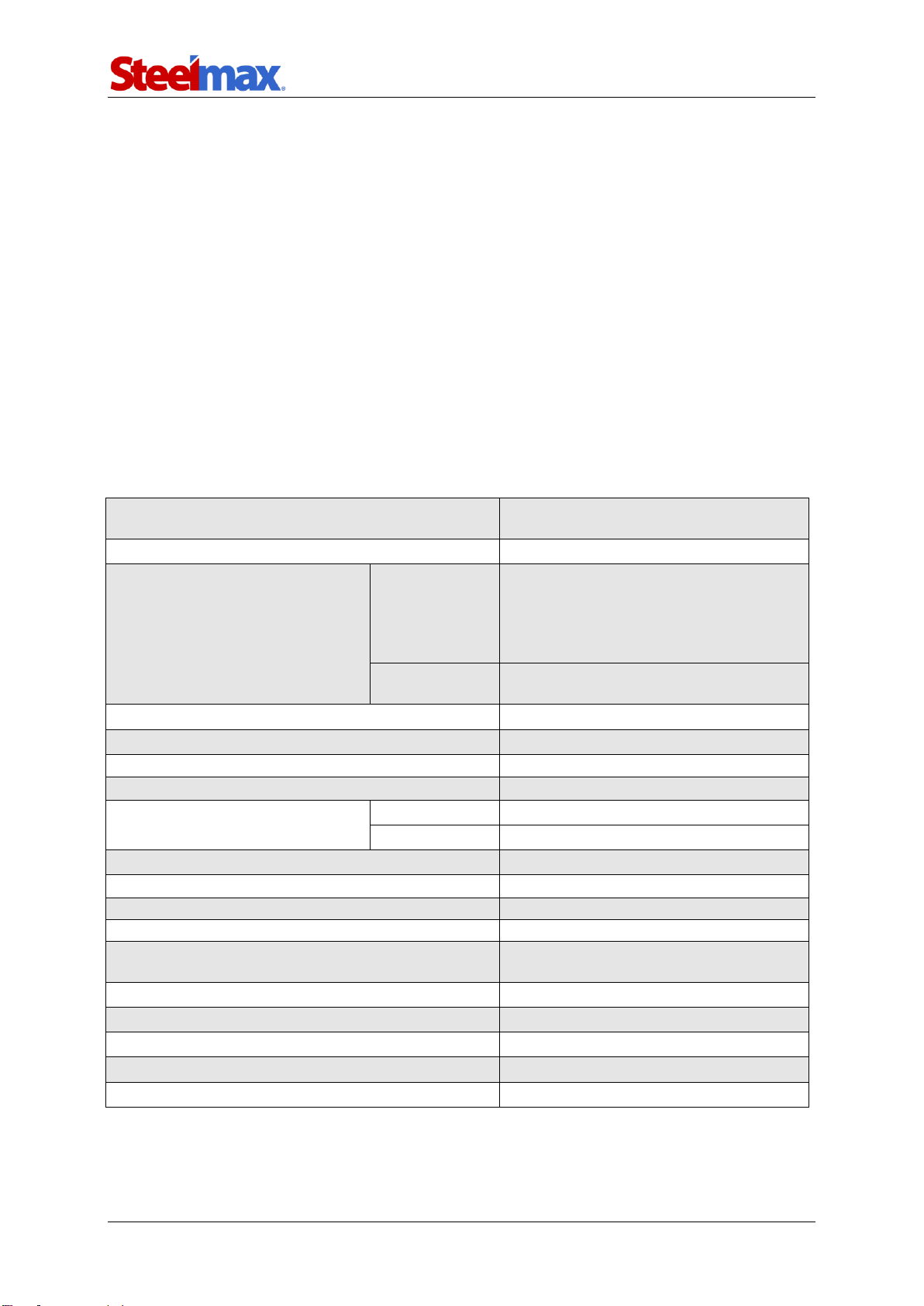

1.3. Equipment included

1

Carriage

1 unit

2

Cardboard box

1 unit

3

Cable anchor

1 unit

4

Short rod torch holder with clip

1 unit

5

3 m (10 ft) power cord

1 unit

6

6.5 m (21 ft) arc ignition cable

1 unit

7

4 mm hex wrench

1 unit

–

Operator’s Manual

1 unit

1

2

3

4

5

6

7

ARC Runner

ARC Runner Operator’s Manual

5

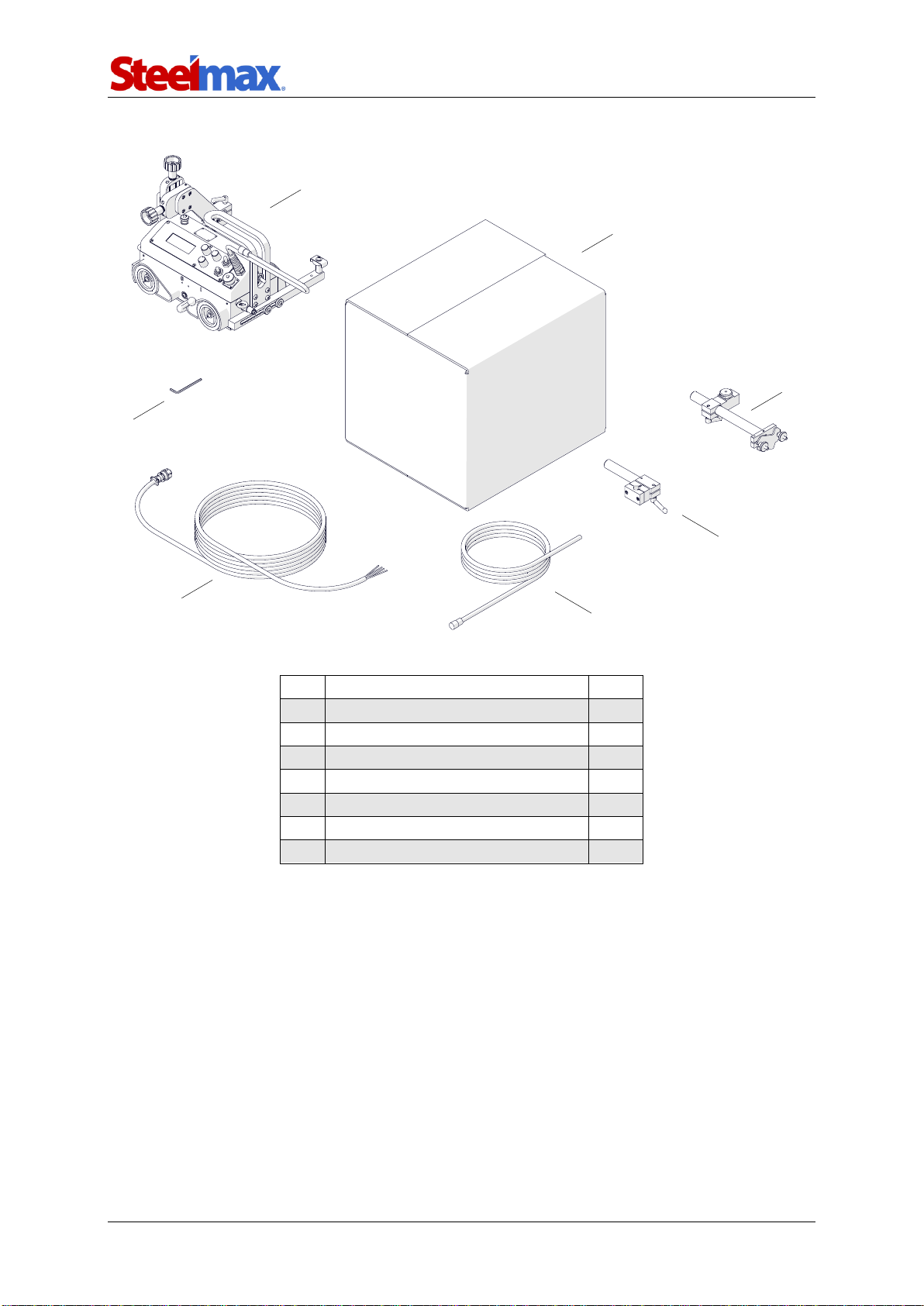

1.4. Dimensions

411 mm (16.2″)

368 mm (14.5″)

447 mm (17.6″)

ARC Runner

ARC Runner Operator’s Manual

6

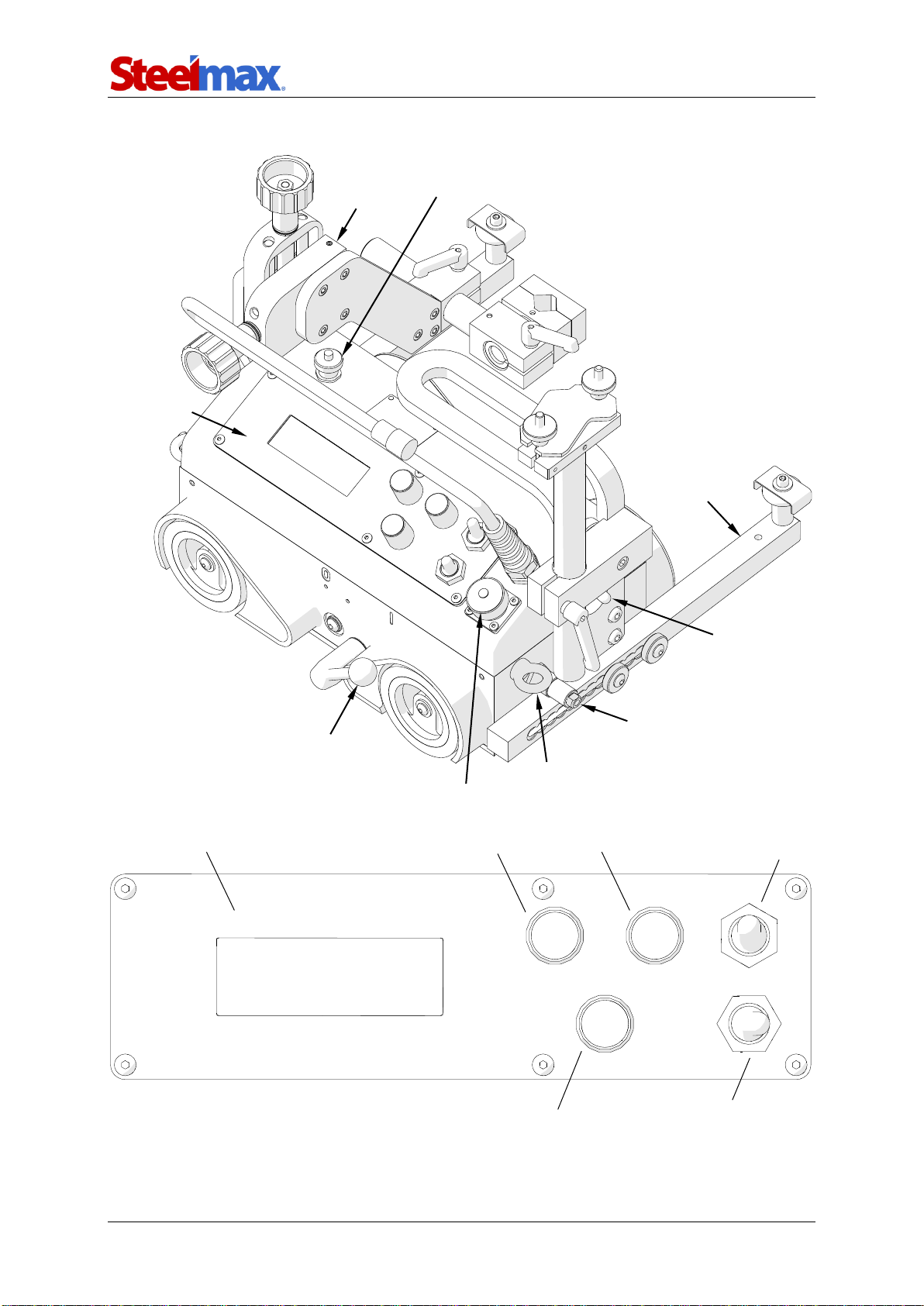

1.5. Design

Lug for fall arrester

Arc ignition socket

Control panel

Cross slide

Oscillation socket

Guide arm

Power switch

Limit switch

Magnet lever

LCD display

Knob F1

Knob F2

Arc ignition switch

(TEST / O / I)

Travel direction switch

(Left / O / Right)

Speed adjustment knob

ARC Runner

ARC Runner Operator’s Manual

7

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the carriage has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. Connect the carriage to a correctly grounded power source.

6. Do not carry the carriage by the cords or arc ignition cable, and do not pull them.

This can cause damage and electric shock.

7. Keep untrained bystanders away from the carriage.

8. Before each use, ensure the correct condition of the carriage, power source,

cords, arc ignition cable, plugs, sockets, control panel, and wheels.

9. Before each use, make sure that no part is cracked or loose. Make sure to main-

tain correct conditions that can have an effect on the operation of the carriage.

10. Keep the carriage dry. Do not expose the carriage to rain, snow, or frost.

11. Keep the worksite well lit, clean, and free of obstacles.

12. Do not use near flammable materials, or in explosive environments.

13. Make sure that the rubber of the wheels is clean and not damaged.

14. Do not remove the cover of the wheels.

15. Remove objects attracted to the chassis by the magnet.

16. Transport and position the carriage by using the carrying handle and only after

you set the magnet lever to ‘O’.

17. Put the carriage so that four wheels are on the surface. Make sure that no con-

tact is between the surface and chassis.

18. Do not stay below the carriage that is put at heights.

19. Connect the cords and arc ignition cable only after you set the power switch to

‘O’.

20. Keep the sockets clean. Do not use high pressure during cleaning.

21. Install only MIG/MAG torches whose diameter matches the diameter of the torch

holder.

22. Do not put the torch more than 80 mm (3.15″) outward from the left or right side

of the carriage.

ARC Runner

ARC Runner Operator’s Manual

8

23. Keep the torch cables away from the surface. Hang the cables to decrease the

load applied on the carriage. Use only cables whose weight is not more than 12

kg (27 lbs) for horizontal work and 8 kg (18 lbs) for vertical work.

24. Do not work on curves with convex or concave radius less than 1500 mm (5 ft).

25. At heights, use a fall arrester not to let the carriage fall.

26. Use eye protection (helmet, shield, and screen), ear protection, gloves, and

protective clothing. Do not use loose clothing.

27. Do not stop the carriage by hand. To stop, set the travel direction switch to ‘O’.

28. Do the maintenance only after you unplug the carriage from the power source.

29. Repair only in a service center appointed by the seller.

30. If the carriage falls, is wet, or has any damage, stop the work and promptly send

the carriage to the service center for check and repair.

31. Do not leave the carriage unattended during work.

32. If you are not going to use the carriage, remove it from the worksite and keep in a

safe and dry place.

ARC Runner

ARC Runner Operator’s Manual

9

3. STARTUP AND OPERATION

3.1. Preparing

Use the carrying handle to transport the carriage to the worksite. Then, set to ‘O’ all

switches (power, travel direction, and arc ignition switch) and the magnet lever.

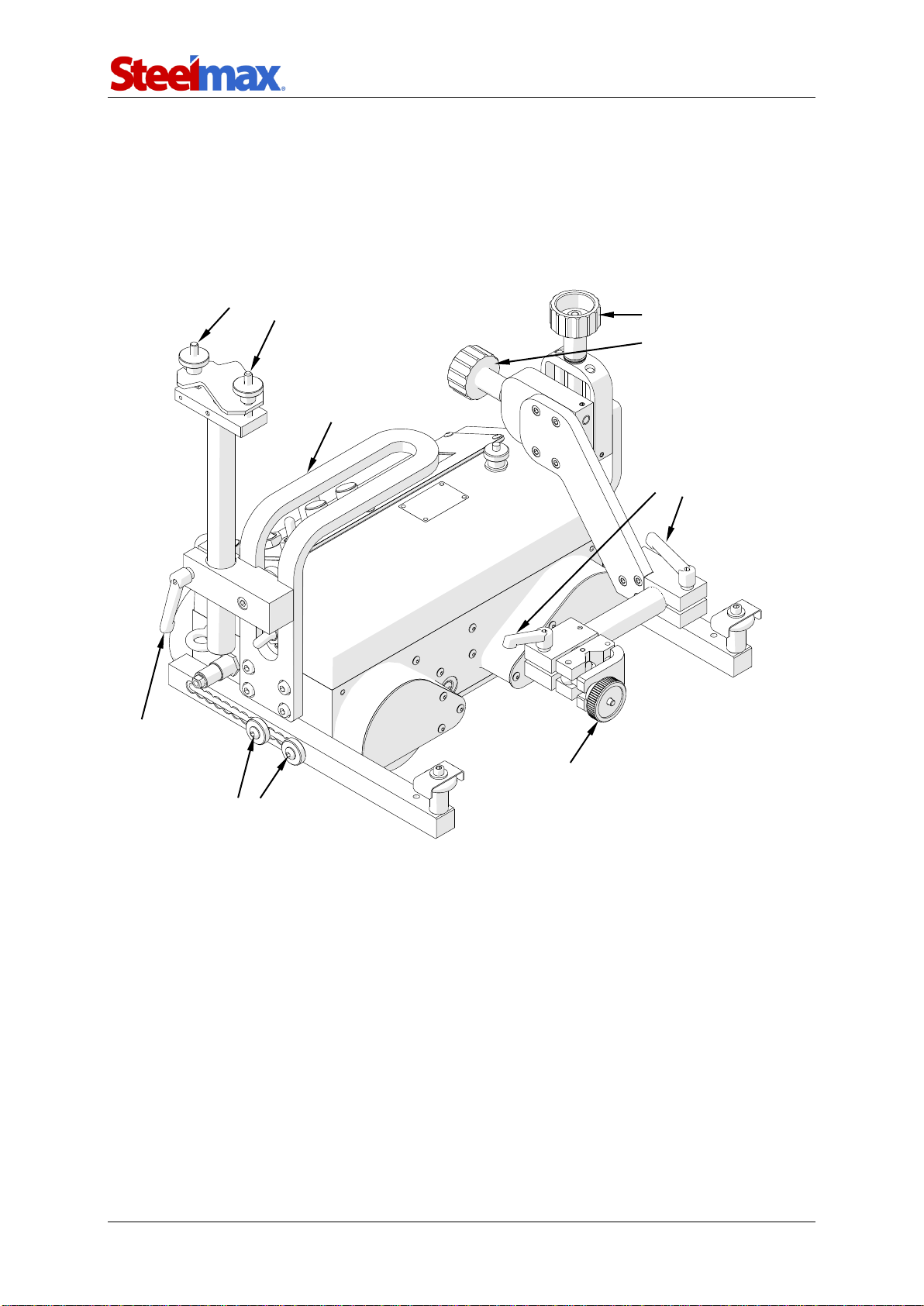

Fig. 1. View from the back side

Use the power cord to connect the carriage to the power source. Then, put the

torch into the torch holder and tighten with the knob. Put the torch cables into the

cable anchor and tighten with the knobs.

Knobs for

precise torch

adjustment

Knobs to secure the

cable in the anchor

Lever to secure the

cable anchor

Knob to secure the torch

in the holder

Levers to secure

the torch position and

angle

Screws to secure the guide arm

Carrying handle

ARC Runner

ARC Runner Operator’s Manual

10

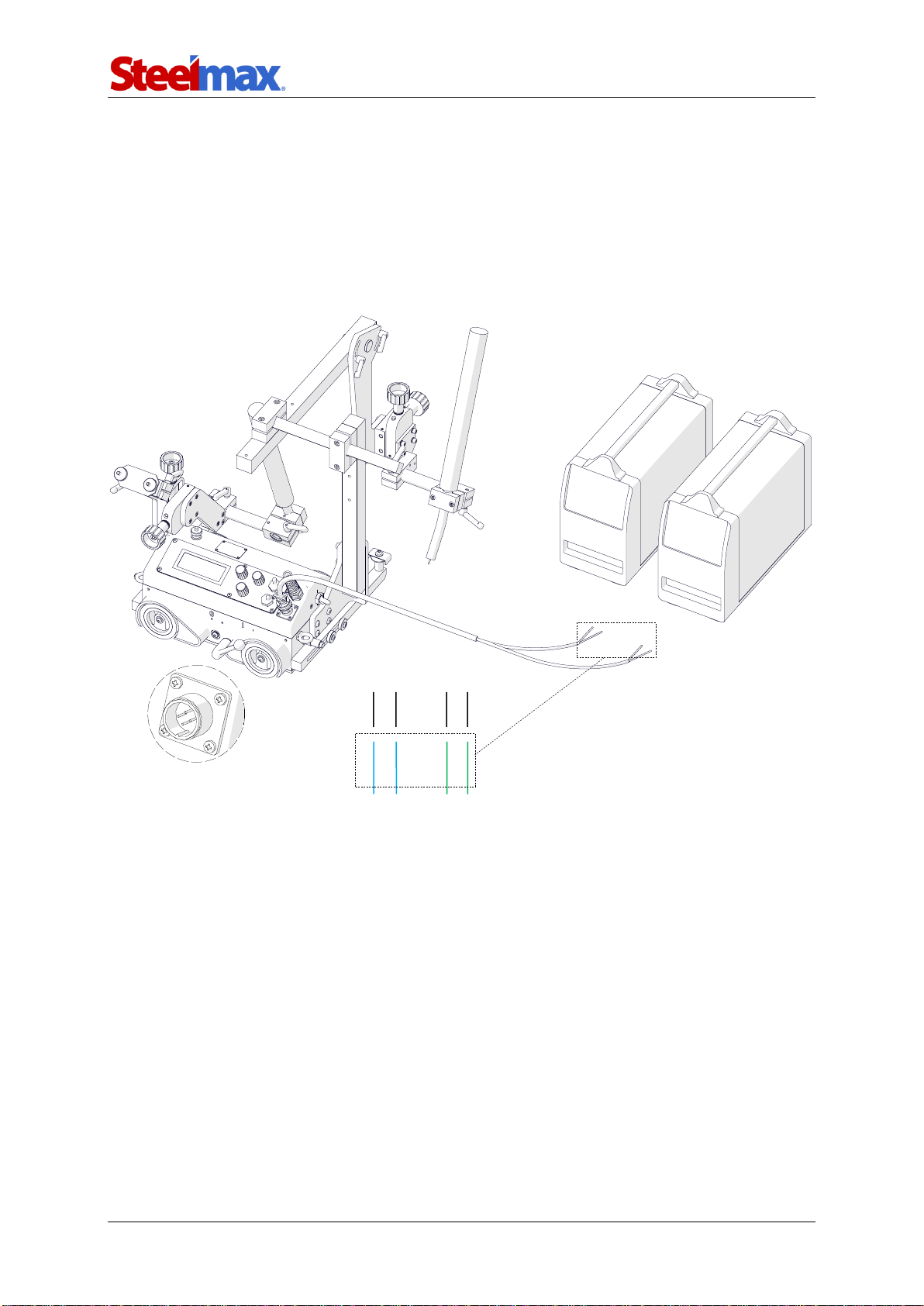

3.2. Connecting to the welding circuits

The carriage can control two torches by using the arc ignition cable plugged into the

arc ignition socket. To do this, refer to the diagram from Fig. 2 and connect one blue-

jacketed wire to one terminal of the welding circuit. Then, connect the other blue-

jacketed wire to the other terminal of the same circuit. To control the second torch,

connect the green-jacketed wires to the terminals of the second welding circuit.

Fig. 1. Connecting the arc ignition cable to welding circuits

Make sure that the arc ignition cable is connected correctly. To do this, turn on the

power of the carriage, and then set the arc ignition switch to TEST. This should

enable the arc for a while.

blue

blue

Welding circuit 1

green

green

Welding circuit 2

ARC Runner

ARC Runner Operator’s Manual

11

3.3. Positioning at the worksite

Put the guide arms so that the carriage is in constant contact with the workpiece. You

can set them by a constant step (interval adjustment), or continuously after you swap

them (continuous adjustment). To set them correctly when the carriage moves to the

left, use the 4 mm hex wrench to loosen the screws that secure the right guide arm.

Next, move out the right arm about 10 mm (0.4″) or one groove more than the

left arm (Fig. 3), and then tighten the screws again.

Fig. 2. Correct positioning of the guide arms

The roller assemblies may be installed at

the other end of the guide arms

Interval adjustment

Travel direction

Continuous adjustment

Swap the guide arms

to change between

methods of adjustment

Grooves

Moving out the right arm

by one groove

Lug for fall arrester

ARC Runner

ARC Runner Operator’s Manual

12

To put the carriage closer to the workpiece, use the 4 mm hex wrench to remove

the roller assemblies. Next, install them at the other end of the guide arms, and then

swap the guide arms (Fig. 3).

Switch the magnet lever from left (‘O’) to right (‘I’). This will change the clamping

force from minimum to maximum. Loosen the levers to adjust the position and angle

of the torch. Use two knobs at the cross slide to precisely set the torch position.

At heights, attach a fall arrester (not included) to a lug (Fig. 3) to prevent fall of

the carriage. This will avoid possible injury to the operator in case the carriage loses

the clamping. Do not stay below the carriage that is put at heights.

ARC Runner

ARC Runner Operator’s Manual

13

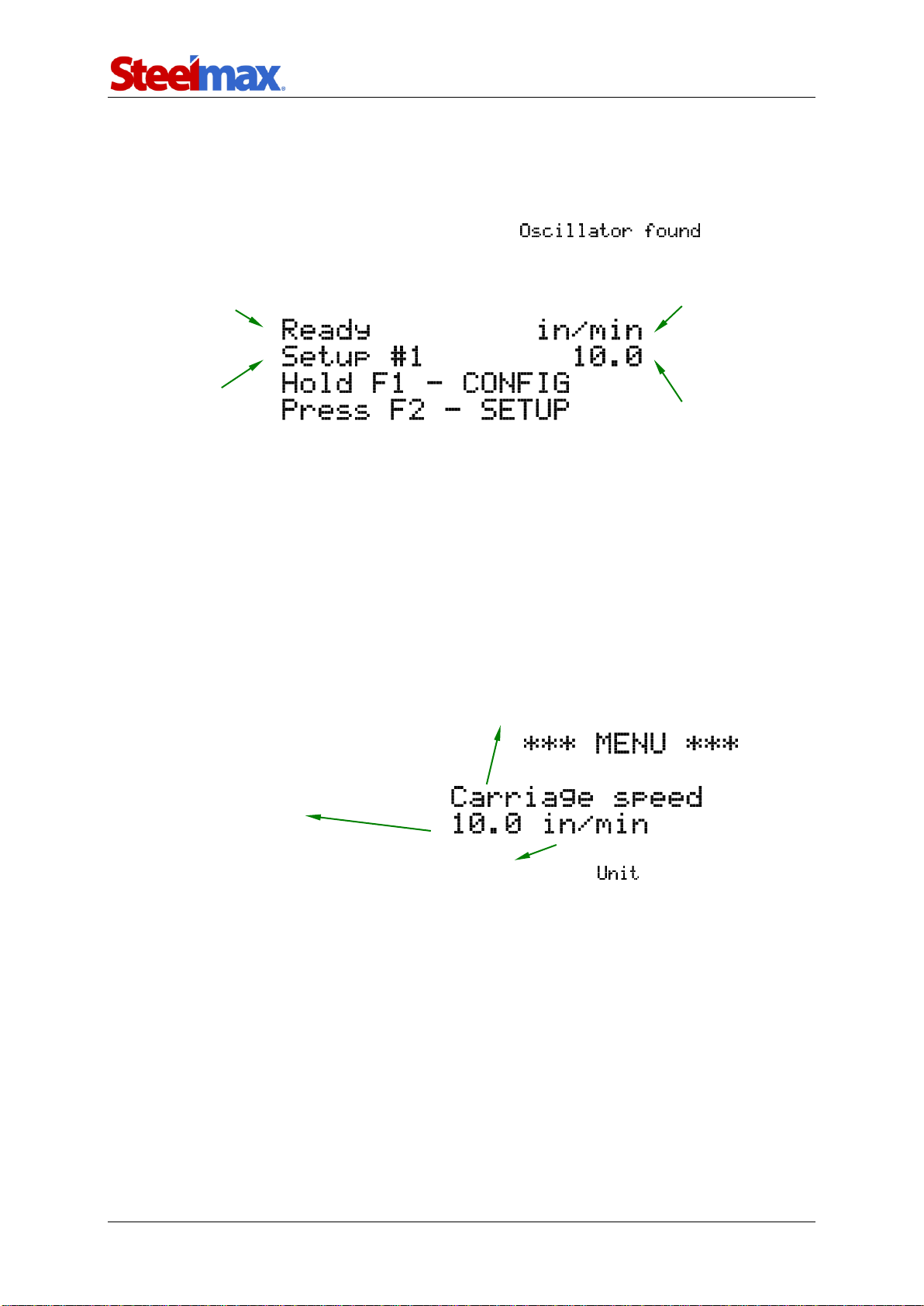

3.4. Starting

Plug the power cord into the power source and set the power switch to ‘I’ to turn on

the carriage. Then, an initial screen with the current firmware number shows. If an

oscillator is connected to the oscillation socket, shows. After

the control system is loaded, the main menu from Fig. 4 shows.

Fig. 1.View of the main menu

Press and hold the knob F1 for about 3 seconds to go into the configuration

menu and set the welding parameters.

3.5. Programming

The carriage allows you to define up to 40 welding programs. After you go to the

configuration menu, continue as described in Fig. 5.

Fig. 2.Configuration menu

Current operating mode

Program

number

Unit of speed

Value of

speed

Name of parameter. Rotate the knob F1 to

change among parameters shown in Tab. 1.

Value of parameter. Rotate the

knob F2 to change the value by the

higher step shown in Tab. 1. Press

and rotate the knob F2 to change

the value by the lower step.

Unit of parameter. Can be changed from the setting.

ARC Runner

ARC Runner Operator’s Manual

14

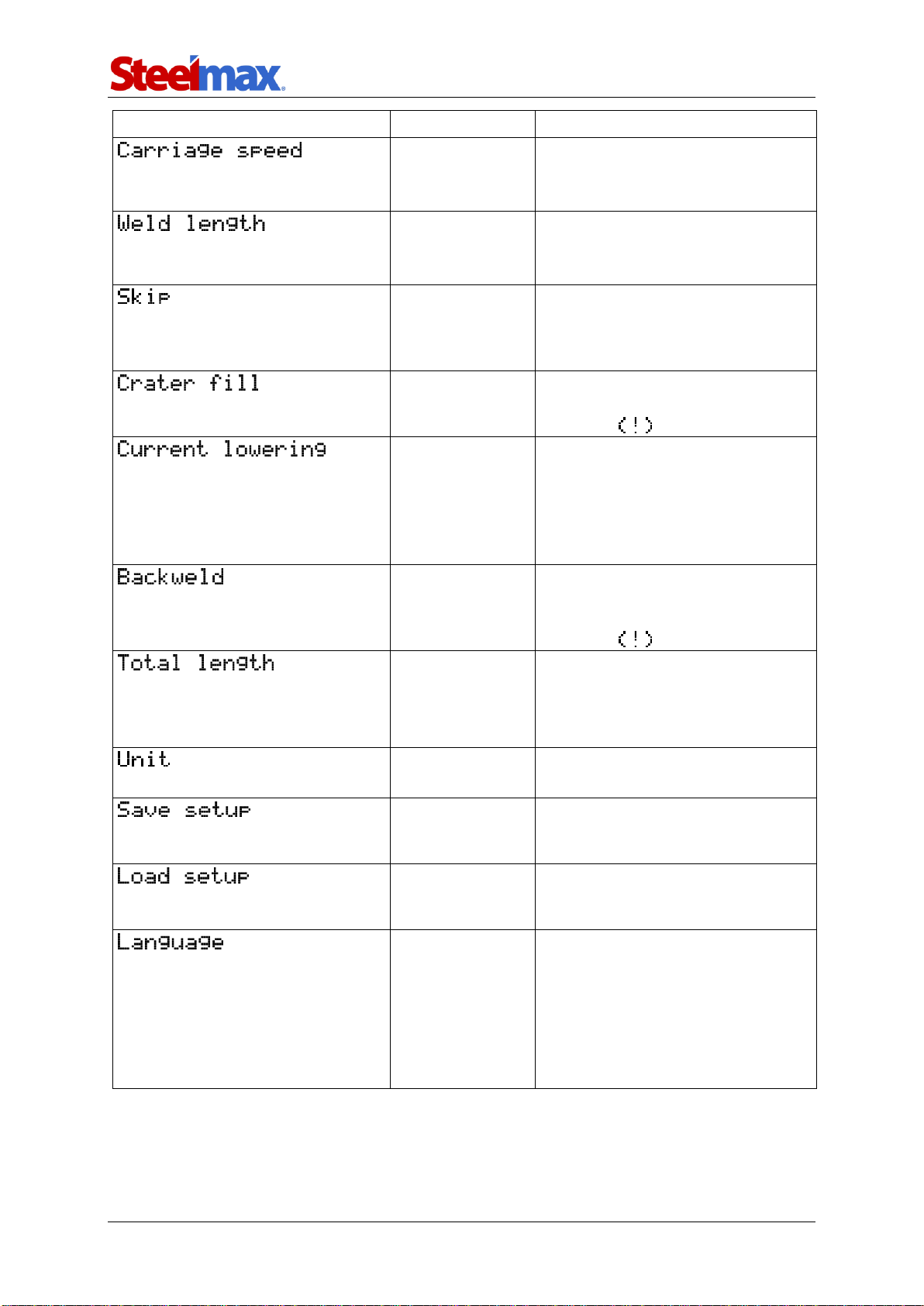

Parameter

Value

Description

0–130 cm/min

0–52 in/min

[step: 1 or 0.1]

Speed of the carriage.

1–250 cm

1–100 in

[step: 1 or 0.1]

Length of a single weld.

0–100 cm

0–40 in

[step: 1 or 0.1]

Space between welds. If set to

zero, ‘crater fill’ and ‘backweld’ are

reset and the carriage works in

the continuous welding mode.

0–3 s

[step: 0.1]

Time of filling the crater. Inactive if

‘skip’ set to zero, which is indicat-

ed by the sign.

YES

NO

Function of the welding source to

lower the current of the arc while

filling the crater. Time of filling the

crater must be set higher or equal

to the time of the current lowering

that is set at the welding source.

0–2 cm

0–2 in

[step: 0.1]

Length of the backweld. Shorter or

equal to ‘weld length’. Inactive if

‘skip’ set to zero, which is indicat-

ed by the sign.

0–1000 cm

0–400 in

infinity

[step: 10 or 1]

Longer or equal to the sum of

‘weld length’ and ‘skip’. If set to

infinity, the program executes until

you stop the carriage.

cm

in

Unit used in the menu.

1–40

Pressing knob F2 saves the

current configuration to the indi-

cated program number.

1–40

Pressing knob F2 loads the

configuration from the indicated

program number.

ENGLISH

POLISH SPAN-

ISH FRENCH

PORTUGUESE

TURKISH

GERMAN

RUSSIAN

Language of the menu.

Tab. 1. Settings available in basic version of the carriage

ARC Runner

ARC Runner Operator’s Manual

15

To change the language of the menu, go to setting by rotating the

knob F1 to the right, and then rotate the knob F2 to choose among the available

languages. After the rest of the parameters from Tab. 1 is set, go to ,

choose a program number by rotating the knob F2, and press the knob to save the

current values to this number. The message shows for a short time. To load

a previously saved program, continue as described, but from setting.

To go back to the main menu (Fig. 4), press the knob F1 and hold it for 3 seconds. If

you do not save the chosen parameters, they will be active only until you change the

current program number in the main menu.

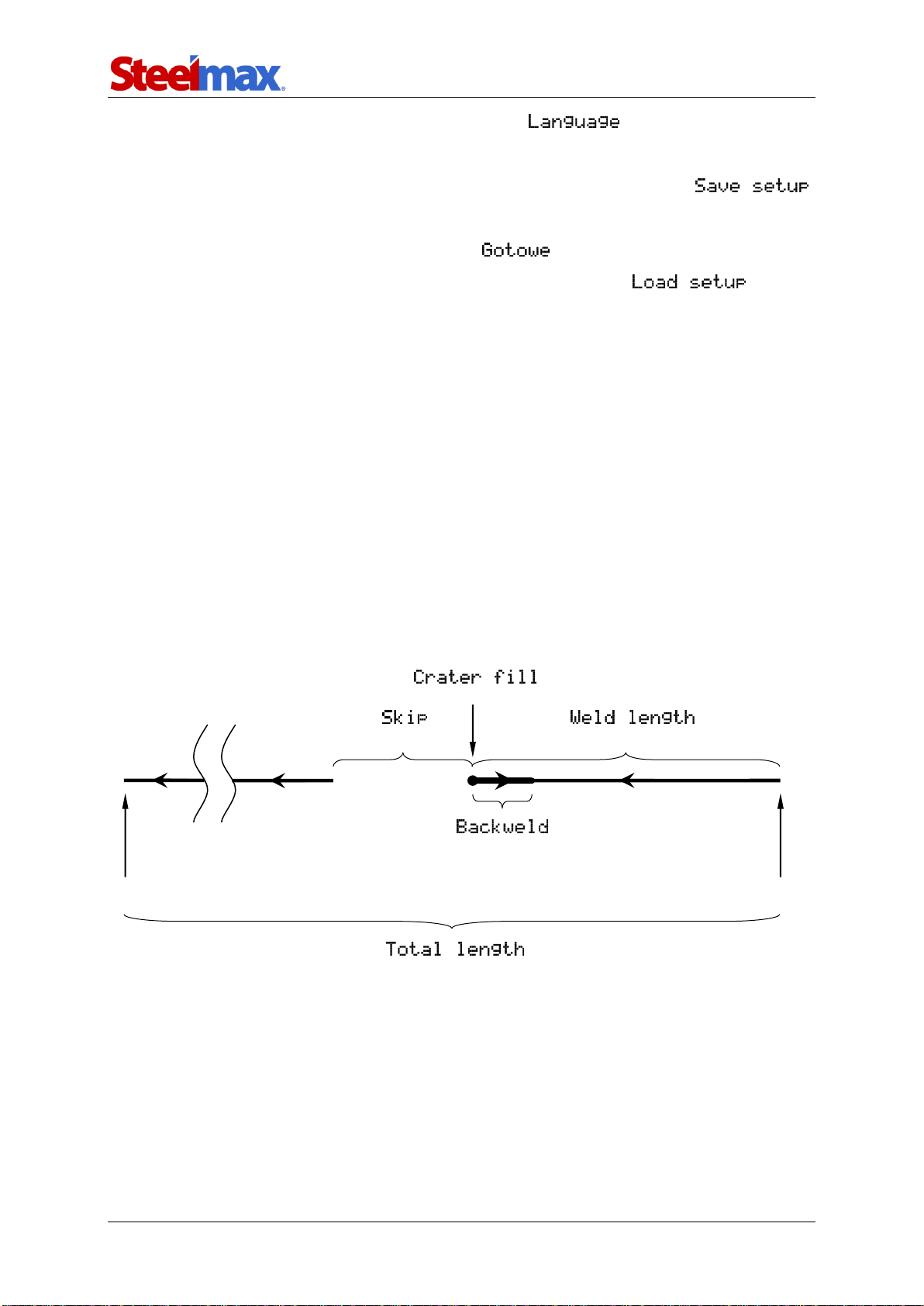

3.6. Welding procedure

Fig. 6 shows a graphic description of the welding procedure that starts with the speed

value shown in the main menu when you select a travel direction. The first stage is

making the weld, and then the carriage fills the crater (stage 2) for the chosen time.

Next, the carriage does the backweld (stage 3) and then moves to the start of the

next weld (stage 4). This process is repeated until the carriage reaches the value of

the total length.

Fig. 3. Visualization of the welding procedure according to parameters from Tab. 1

(stage 1)

(stage 3)

Starting point of the first weld

(stage 2)

(stage 4)

Final point of the welding procedure

ARC Runner

ARC Runner Operator’s Manual

16

3.7. Operating

To control the torch through the carriage, set the arc ignition switch to ‘I’.

If the arc ignition switch is set to ‘I’, the torch starts welding promptly

after you select a travel direction.

With mode shown on the main menu (Fig. 4), you can press and rotate the

knob F2 to change the current program . You can also use the speed knob

to change the current welding speed. Rotate the knob to the right to increase the

speed by the step of 0.1. Rotate to the left to decrease the speed by the step of 0.1.

Use the travel direction switch to select a direction of travel. Then, the carriage

starts moving according to the chosen program parameters. The current operating

mode shows on the display while the program continues. You can change the car-

riage speed during work with the speed knob. The new speed will be saved only if

you do not change the current program in the meantime.

The carriage stops after it reaches the total length and message

shows on the display. Then, set the travel direction switch to ‘O’ to go into the main

menu. After the work is finished, use the power switch to turn off the carriage. Then,

unplug the carriage from the power source.

ARC Runner

ARC Runner Operator’s Manual

17

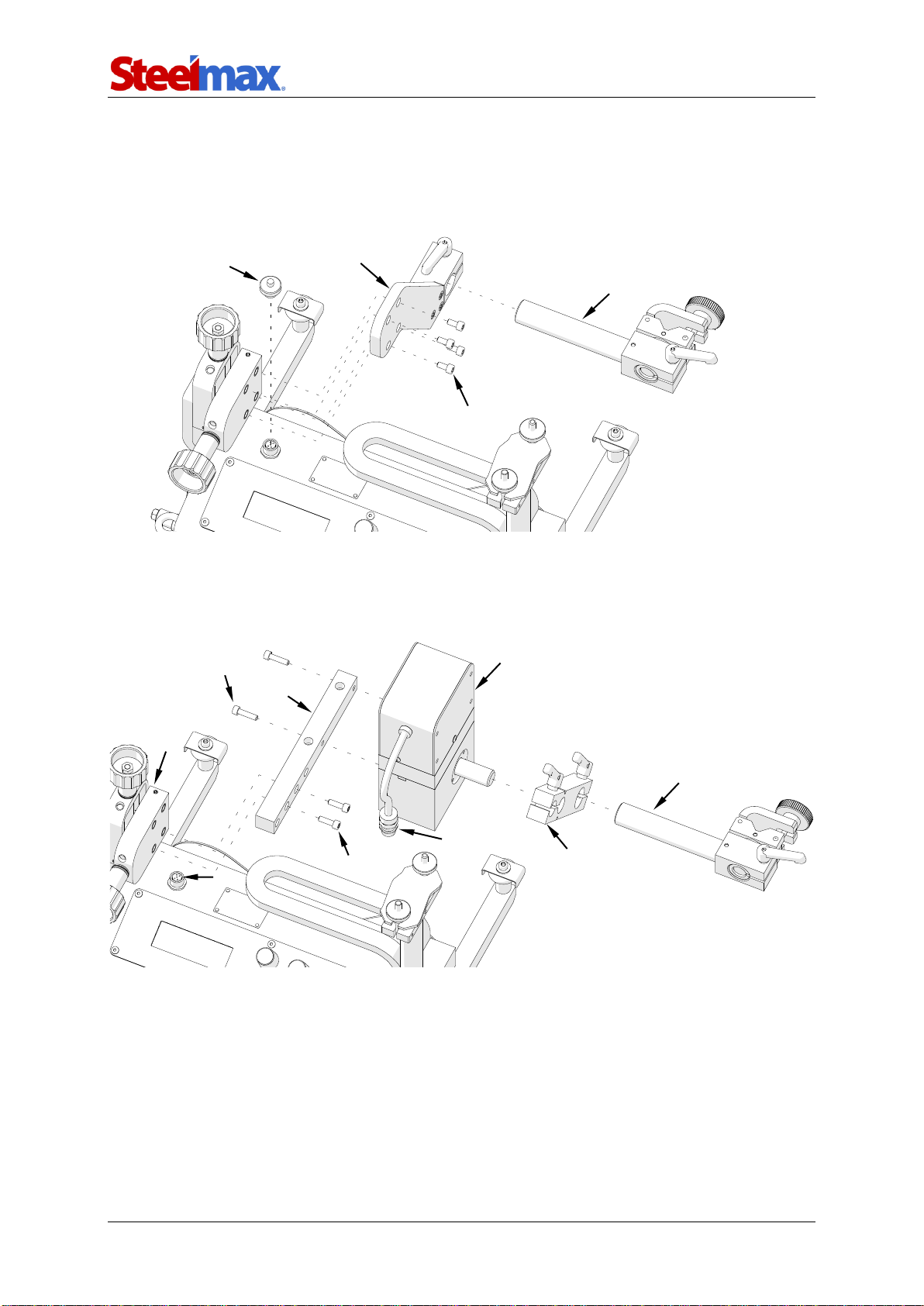

3.8. Using oscillator (option)

3.8.1. Installing

Install the oscillator in the shown sequence.

•Remove the torch holder (1).

•Use the 4 mm hex wrench to remove the screws (2) and the torch holder plate (3).

•Remove the cap (4).

•Attach the arm (5)to the oscillator (6).

•Use two screws M5x20 (7) to attach the oscillator (6) to the bracket (8).

•Use two screws M5x16 (9) to connect the bracket (8) to the cross slide (10).

•Put the oscillator plug (11) into the oscillation socket (12).

•Attach the torch holder (13) to the oscillator arm (5).

8

6

7

8

9

12

10

6

11

5

13

4

3

2

1

ARC Runner

ARC Runner Operator’s Manual

18

3.8.2. Welding with oscillation

After you connect the oscillator to the welding carriage, several new settings will

show in the menu (Tab. 2). Welding with oscillation is done in the standard manner,

but the weld form a shape similar to the shape shown in Fig. 7 instead of the straight

line from Fig. 6.

Parameter

Value

Description

0–100%

[step: 10% or 1%]

Relative amplitude of the oscilla-

tion.

0–100%

[step: 10% or 1%]

Relative speed of the oscillation.

The higher the speed, the shorter

the oscillation period.

0–5 s

[step: 1 or 0.1]

Dwell time in the top position of

the oscillation.

0–5 s

[step: 1 or 0.1]

Dwell time in the bottom position

of the oscillation.

YES

NO

With YES, you cannot change

dwell times during welding.

Tab. 2. Additional settings available with connected oscillator

Fig. 3.Graphic description of the oscillation parameters from Tab. 2

Weld start

Weld end

1 /

ARC Runner

ARC Runner Operator’s Manual

19

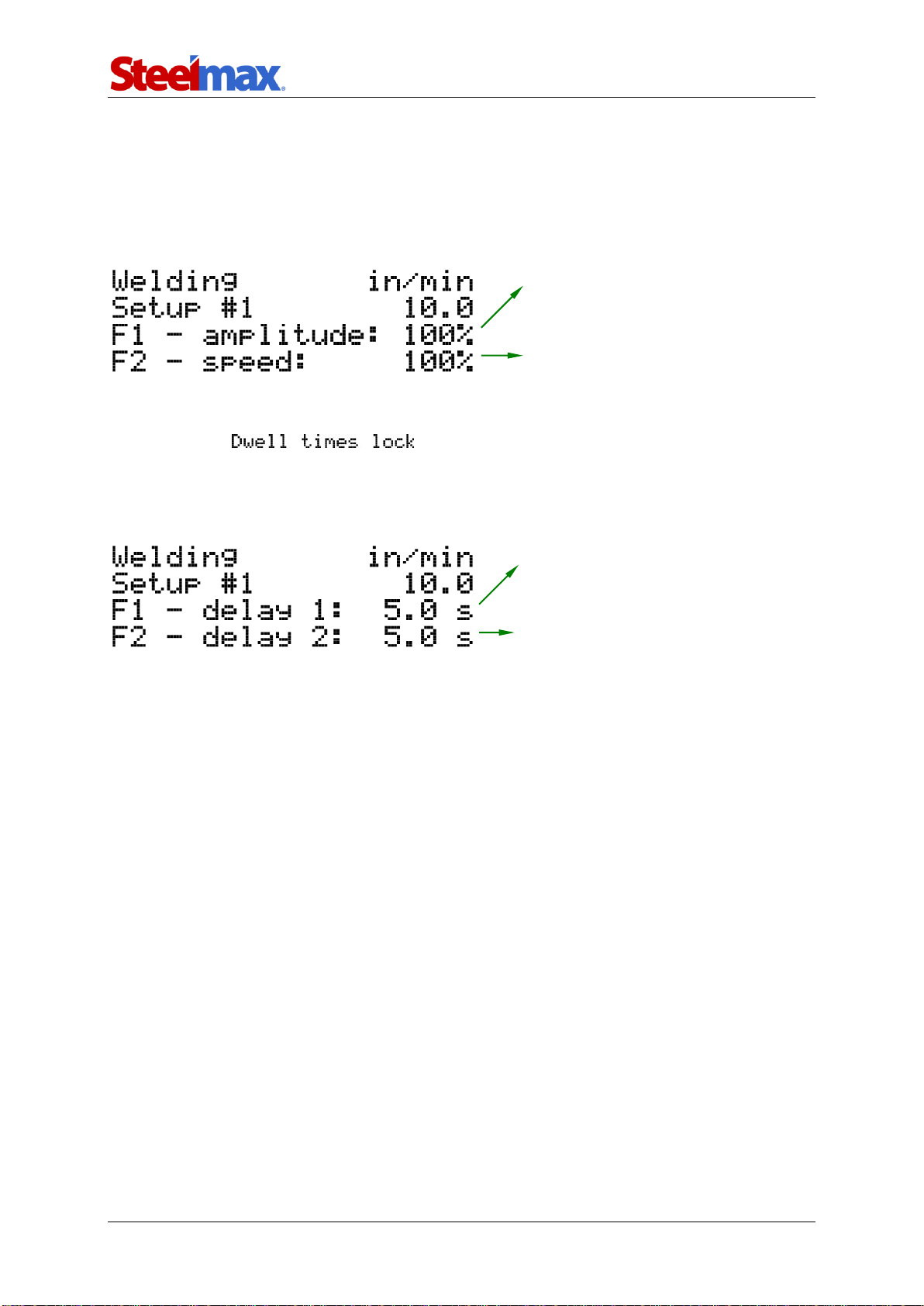

3.8.3. Operating

The carriage with connected oscillator is operated similarly to operating without the

oscillator. During welding with the oscillator, the menu from Fig. 8 shows on the

display.

Fig. 4.Menu shown during welding with the oscillator

If you set to YES, nothing happens when you press the

knob F1 or F2 during work. If you set the parameter to NO, the delay parameters

show on the display and you can adjust them online (Fig. 9).

Fig. 5.Menu for changing the oscillator dwell times

Rotate the knob F1 to change the

oscillation amplitude by 1%.

Rotate the knob F2 to change the

oscillation speed by 1%.

Rotate the knob F2 to change the delay 2

by 0.1 s. Press the F2 to switch from

showing delay 2 to oscillation speed.

Rotate the knob F1 to change the delay 1

by 0.1 s. Press the F1 to switch from

showing delay 1 to oscillation amplitude.

ARC Runner

ARC Runner Operator’s Manual

20

3.9. Troubleshooting

Problem

Cause

Solution

Dark LCD display after power-

ing.

Malfunction of the power

cord, power switch, power

supply, or controller.

Contact service center for

check and repair.

Errors on the LCD display.

Values cannot be read.

Malfunction of the display

or power supply unit.

Contact service center for

check and repair.

Carriage reached an

obstacle at the front.

Remove the obstacle that

blocks the carriage or choose

the opposite travel direction.

Carriage reached an

obstacle at the rear.

Remove the obstacle that

blocks the carriage or choose

the opposite travel direction.

Too fast switching between

left and right travel direc-

tion.

Set the travel direction switch

to ‘O’.

Travel direction switch not

set to ‘O’ when powering.

Set the travel direction switch

to ‘O’.

Shown during travel indi-

cates a malfunction.

Contact service center for

check and repair.

Other manuals for ARC Runner

1

Table of contents

Other SteelMax Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric POWERPLUS 1000HD Operator's manual

Lincoln Electric

Lincoln Electric BULLDOG IM10074 Operator's manual

Miller

Miller ADI 253 instruction manual

PlasmaPart

PlasmaPart Cut 45CI Eclipse Operation & safety manual

Jasic

Jasic EVO 2.0 EM-200CT Operator's manual

Century

Century INVERTER ARC 230 Operator's manual