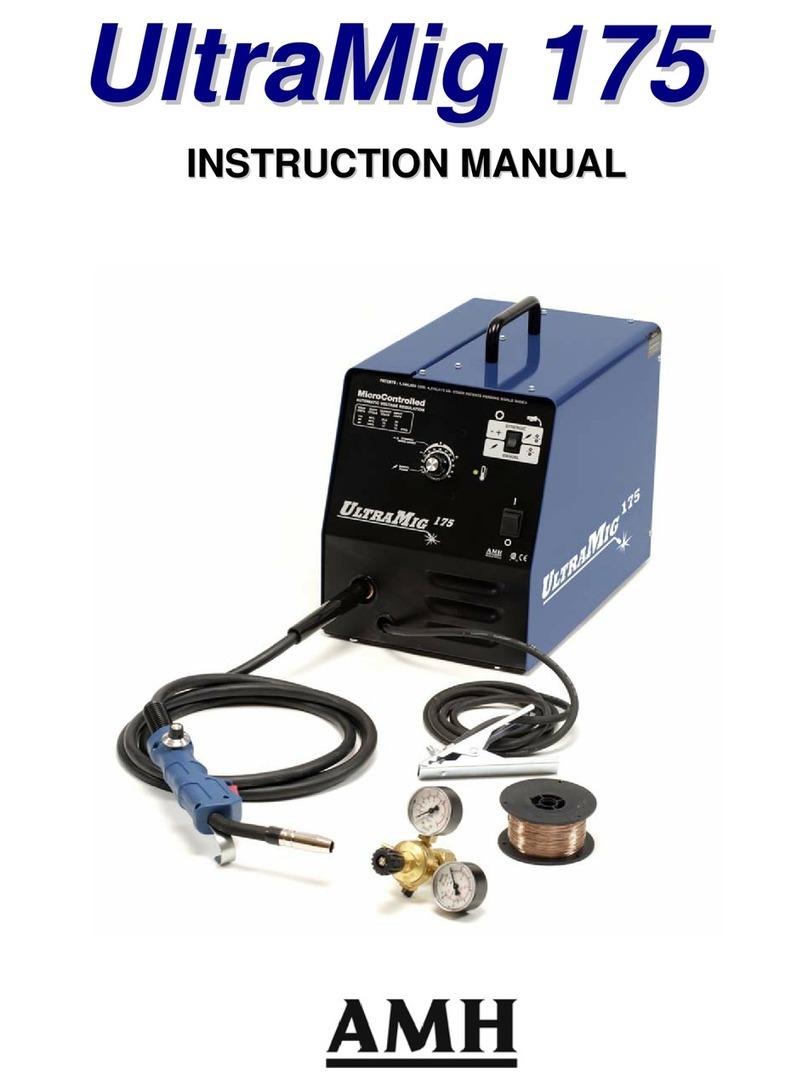

Thank you for choosing AMH Canada’s ULTRAMIG 200 INVERTER. Our welders are of high safety,

reliability, durability and convenient maintenance, as well as excellent welding efficiency. This user’s manual

contains important information about safe installation, operation and maintenance of this product. For welder’s

technical parameters, please refer to technical parameter in this manual. Please read this manual carefully

before operate. In order to ensure the operator’s safety and a reliable working environment, please pay

attention the safety tips and operate according to the instructions. For more AMH Canada products, please

contact AMH Canada headquarters,authorized dealers, or visit our website: http://www.amh.ca.

Declaration

AMH Canada Ltd: We hereby solemnly declare that all products are manufactured according to relative GB

or ISO standard, and conform to IEC60974-1 international safety standard.

All products purchased from our company are covered for one-year defect liability period, starting from the

purchasing day on the contract.

Please read this manual carefully before operation:

1. AMH Canada make every effort to achieve the full accuracy and data integrity of this manual’s

content; AMH Canada assume no liability and responsibility for any nonconforming operation to

this manual.

2. Copyright by AMH Canada Ltd. All rights are reserved. AMH Canada reserves the right to modify

this manual without prior notice.

3. Though contents in this manual have been carefully checked, inaccuracies might still exist. Thank you

for contacting us in case of any inaccuracy you may discover in this manual.

4. Any unauthorized copy, record, reprint or spread of the contents in this manual is prohibited.

5. This manual was released in April, 2021.

AMH Canada LTD.

Address: 391, St-Jean-Baptiste Est, Rimouski (Québec) CANADA

Postcode: G5L 1Z2

Tel: 418-724-4105

Website: http://www.amh.ca

Notes:

To avoid any loss and personal injury, please pay special attention to all “NOTE!”.

Please read this manual carefully before operation.