DM-MB2ET/A

3/23 dm-mb2eta_g_en_102

Contents History of revisions.........................................................................................4

Related documentation...................................................................................4

1Introduction..........................................................................................5

2Technical parameters..........................................................................6

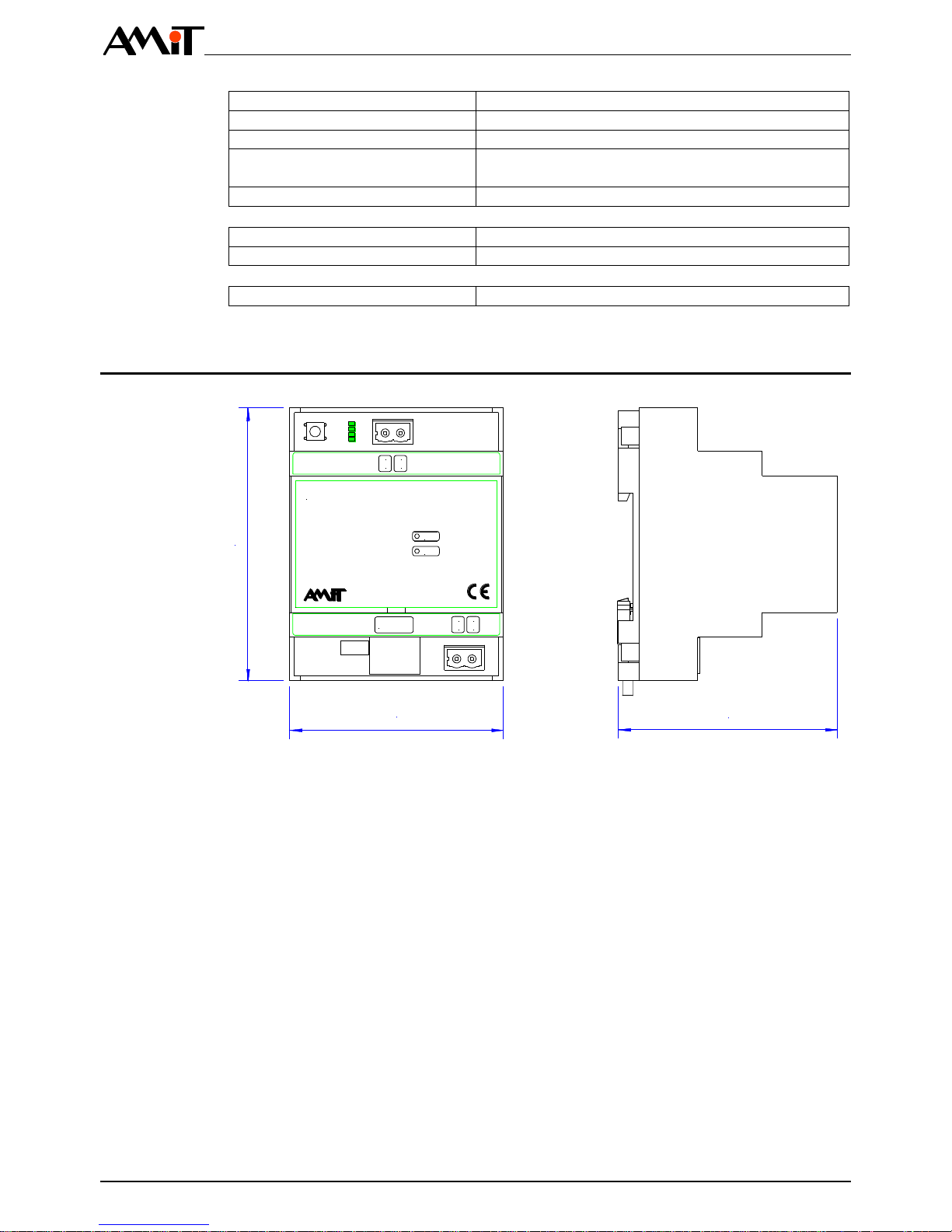

2.1 Dimensions.....................................................................................................7

2.2 Recommended drawing symbol .....................................................................8

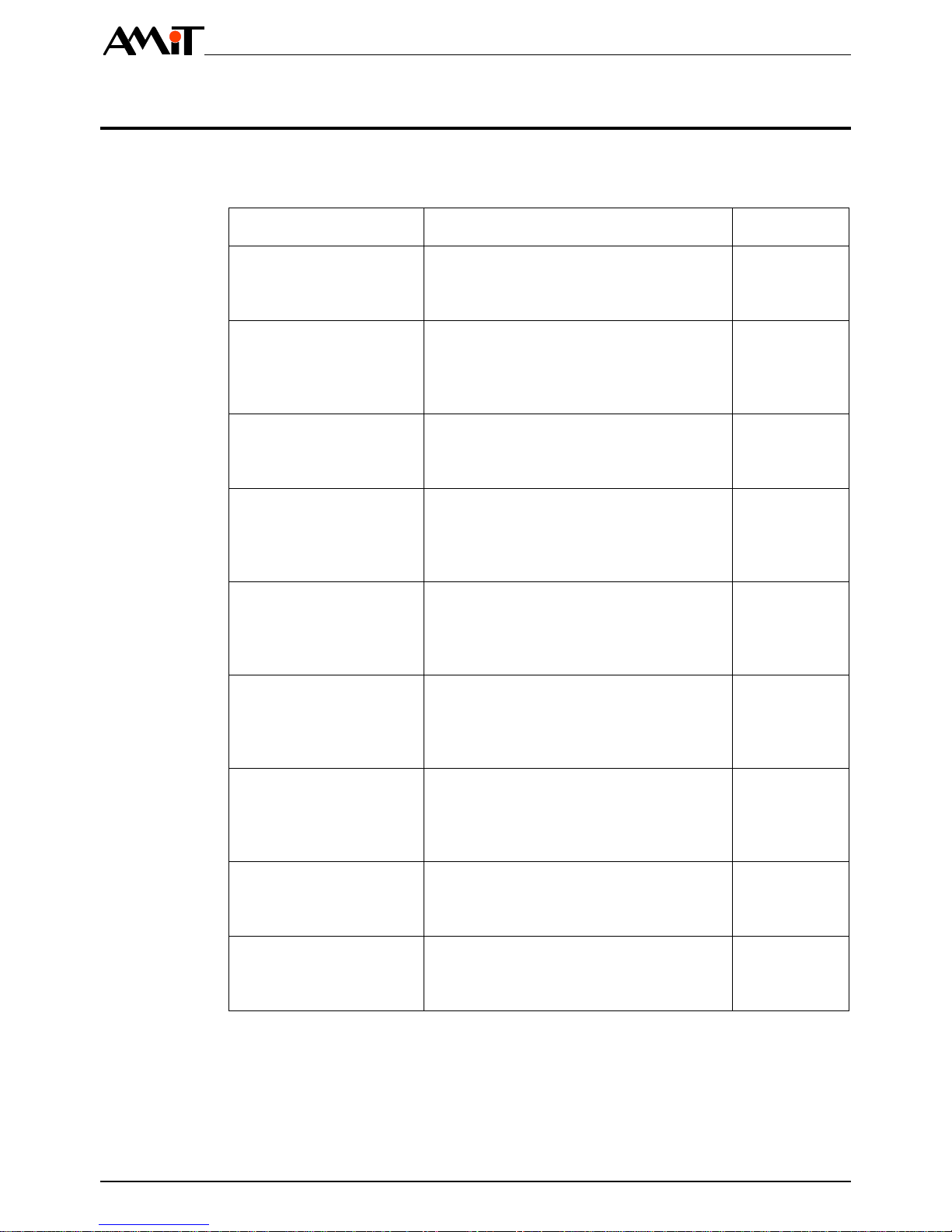

3Conformity assessment ......................................................................9

3.1 Other tests....................................................................................................10

4Power supply......................................................................................11

5Communication interfaces................................................................13

5.1 M-Bus interface ............................................................................................13

5.2 Ethernet interface.........................................................................................14

6Mounting.............................................................................................17

6.1 Installation rules............................................................................................17

7Converter configuration....................................................................18

7.1 Service button...............................................................................................18

7.2 LED RUN......................................................................................................18

7.3 Service mode................................................................................................19

8Factory settings .................................................................................20

Ethernet factory settings...............................................................................20

M-Bus factory settings..................................................................................20

8.1 Factory settings restoring .............................................................................20

9Ordering information and Package contents..................................21

9.1 Package contents.........................................................................................21

10 Maintenance .......................................................................................22

11 Waste disposal...................................................................................23