RRAS-MC/A1

3/18 rras-mca1_g_en_101

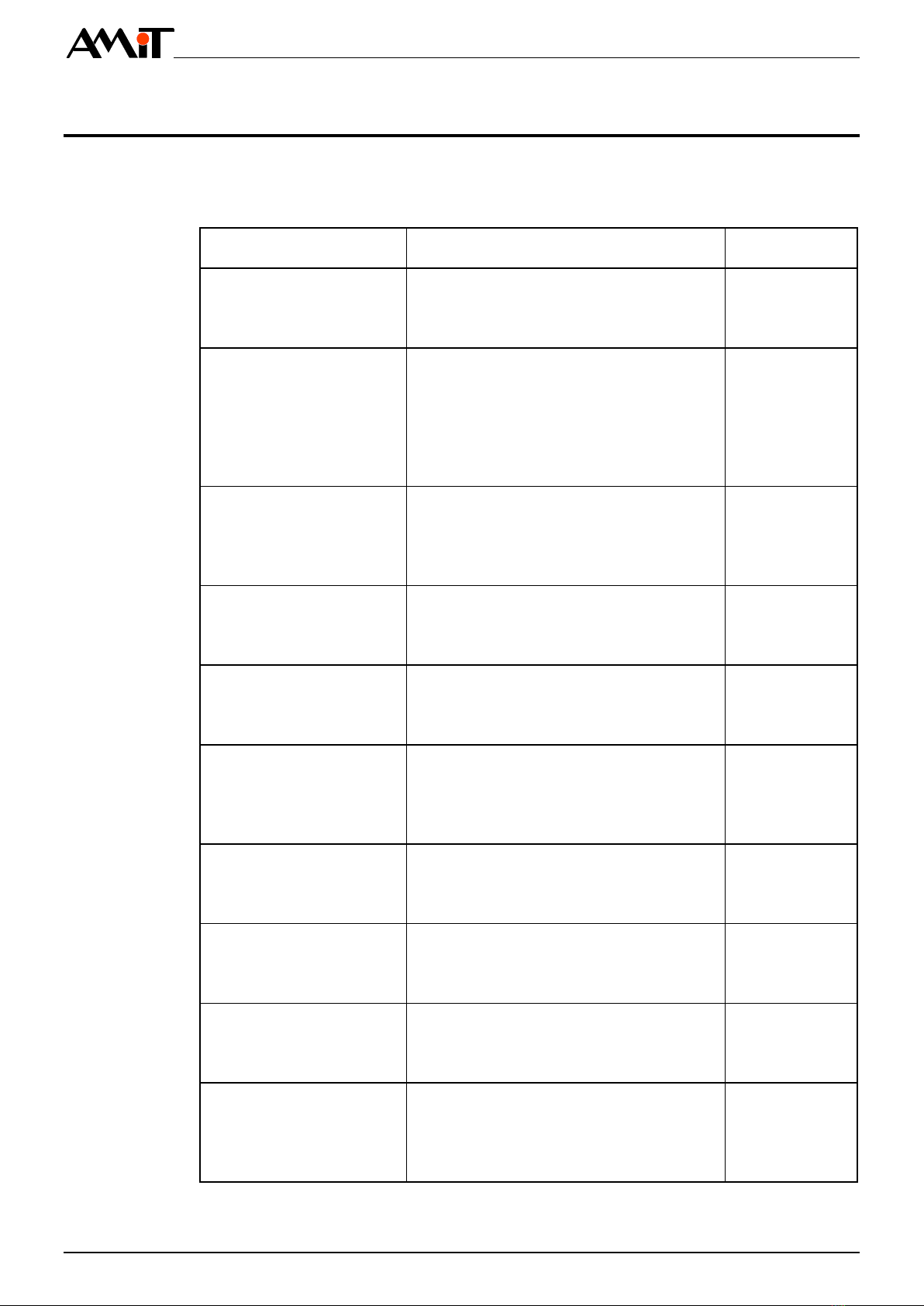

Contents History of revisions.........................................................................................4

Related documentation...................................................................................4

1. Introduction..........................................................................................5

2. Technical parameters..........................................................................6

2.1. Dimensions.....................................................................................................8

2.2. Design of front panel ......................................................................................9

2.3. Recommended drawing symbol .....................................................................9

3. Conformity assessment ....................................................................10

3.1. Other tests....................................................................................................11

4. Front panel .........................................................................................12

4.1. Microphone...................................................................................................12

4.2. ALS indication LED.......................................................................................12

5. Ethernet...............................................................................................13

6. Configuration .....................................................................................14

6.1. Factory setting..............................................................................................14

Ethernet factory setting.................................................................................14

7. Mounting.............................................................................................15

7.1. Installation rules............................................................................................15

8. Ordering information and completion .............................................16

9. Maintenance .......................................................................................17

10. Waste disposal...................................................................................18