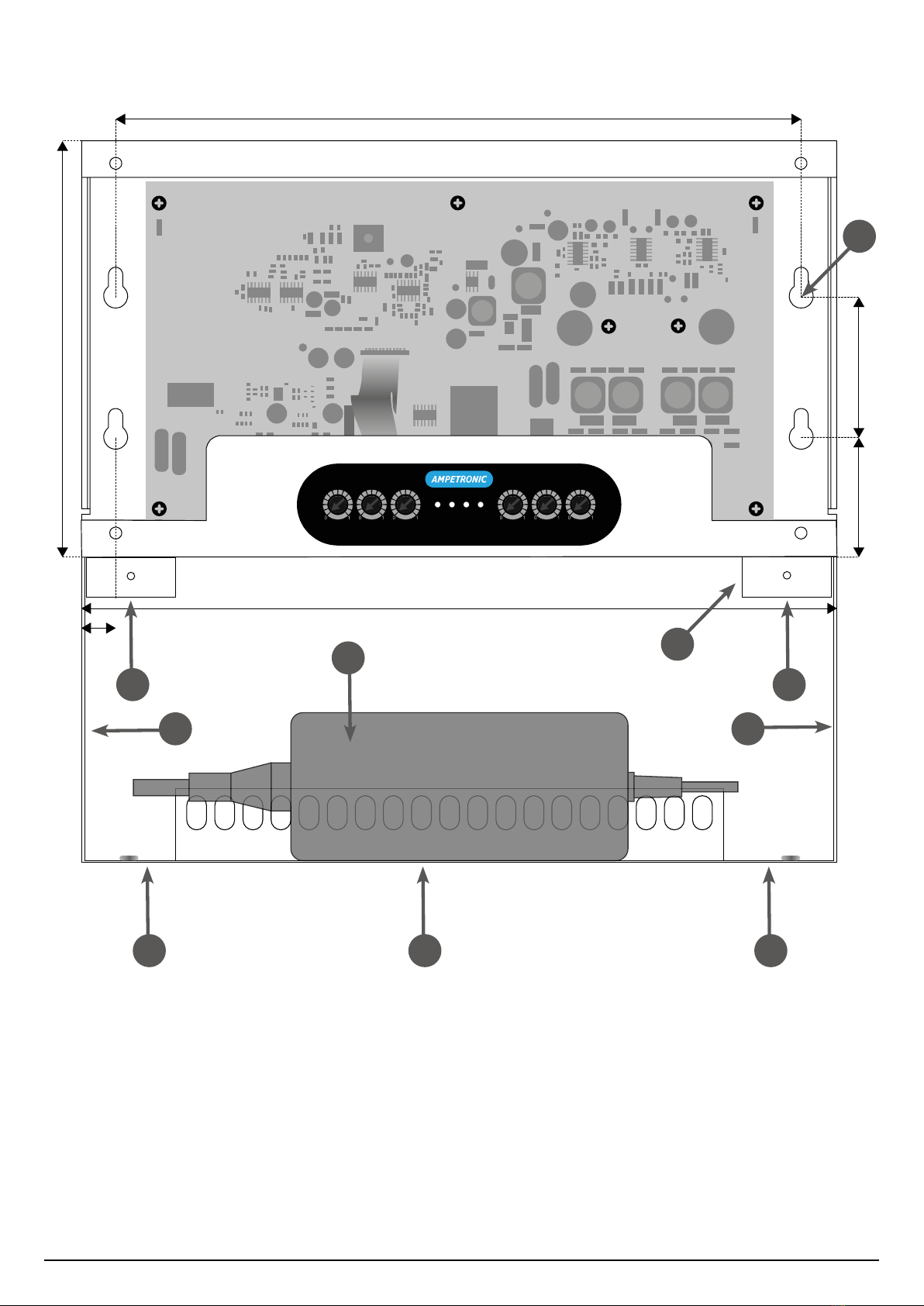

8. Connect the signal inputs appropriately:

Microphones (balanced only): Suitable dynamic or condenser microphones. Select

phantom power as required. Connect to the provided 3 pin 3.5mm terminal blocks and

insert into INPUTS 1 & 2 (with mic/line selector switch in the mic. position) see Connections

drawing.

Line Input Sources: For feeds from PA or AV systems and other line level signal sources.

Ensure a mono summed, balanced connection is available. This may require the use of a 3rd

party adapter such as a direct box. Make sure phantom power is turned o. Connect to the

provided 3 pin 3.5mm terminal blocks and insert into INPUTS 1 & 2 (with mic/line selector

switch in the line position) see Connections drawing.

100V line: Connect to the provided 2 pin 5mm terminal block and connect to 100V

Input (see Connections drawing). This input may have a hazardous voltage on its

terminals and must only be connected by a suitably qualied person.

9. Connect the provided DC PSU to the DC input (see Connections drawing) and the

mains plug into a suitable outlet.

Ensure all relevant tests of AC supply have been carried out before turning supply on.

10. Turn on AC power feed. The STATUS LED will illuminate green. If the LED fails to illuminate

consult the Troubleshooting section.

11. Set the Loop Ind switch to the right position for the amount of cable used in your loop

installation. Refer to details in Technical Specications or on design documentation.

12.Set the Test Signal switch to the middle “Field” position. Turn the CHA and CHB output

current controls clockwise until the CHA and CHB output current indicators light up green.

13.The loop system should now be providing a magnetic eld inside the area of the loop. Use

a Field Strength Meter or Loopworks R1 to measure signal levels. Field strength should

achieve 0dB +/-3dB re. 400mA/m in all intended listening positions.

Adjust the CHA and CHB controls until this performance is achieved. In most cases the two

output channels should be set to the same level.

Once the correct eld strength level is achieved the CHA and CHB controls should NOT need

re-adjusting.

14.Set the Test Signal switch to the right “Freq” position. The driver will now be outputting 3

sinewaves simultaneously at 100Hz, 1kHz and 5kHz in order to measure the frequency

response of the system.

With a Field Strength Meter adjust the receiver height until 0dB is measured in the 1kHz

setting, then check the signal level at 100Hz and 5kHz, these should both be within +/-3dB

of the 1kHz level. If 5kHz is too low turn the MLC control clockwise until a at frequency

response is achieved, making sure that the 100Hz level does not drop below -3dB.

15.If not already done so, steps can now be taken to integrate the W5-2 into a PA / mixer

arrangement following standard audio techniques. If any unusual eects are experienced

refer to the Troubleshooting section.

NOTE: Ideally, each input signal level should be set to just illuminate the AGC LED with the

quietest level of input likely to be used. This will maximise the dynamic range of the system

and ensure satisfactory performance.

16.Repeat the above procedure for each input used. When adjusting each input, make sure the

signals are removed from the other inputs. This ensures that all signals are set to equivalent

loudness and drive the AGC properly.

Ampetronic W5-2 Hearing Loop Driver Installation Handbook & Maintenance ManualPage 6