AMSAFE SEATBELT AIRBAG SYSTEM

INSTALLATION, HANDLING AND SHIPPING INSTRUCTIONS E510629

01-Aug-2013

Page ii

Revision History

Rev. Prepared Approved Revision Summary Date

– F. Armenta W. Gehret Initial Issue 10-Feb-2009

A F. Armenta J. Magish Page 1003 – updated page 1003 SDT Diagnostic

Check procedures table.

Pages 4003-4005 – Removed recommendation

that the EMA is disconnected for shipment of

seats. Added statement to prevent buckle from

being in proximity of the switch.

17-Mar-2009

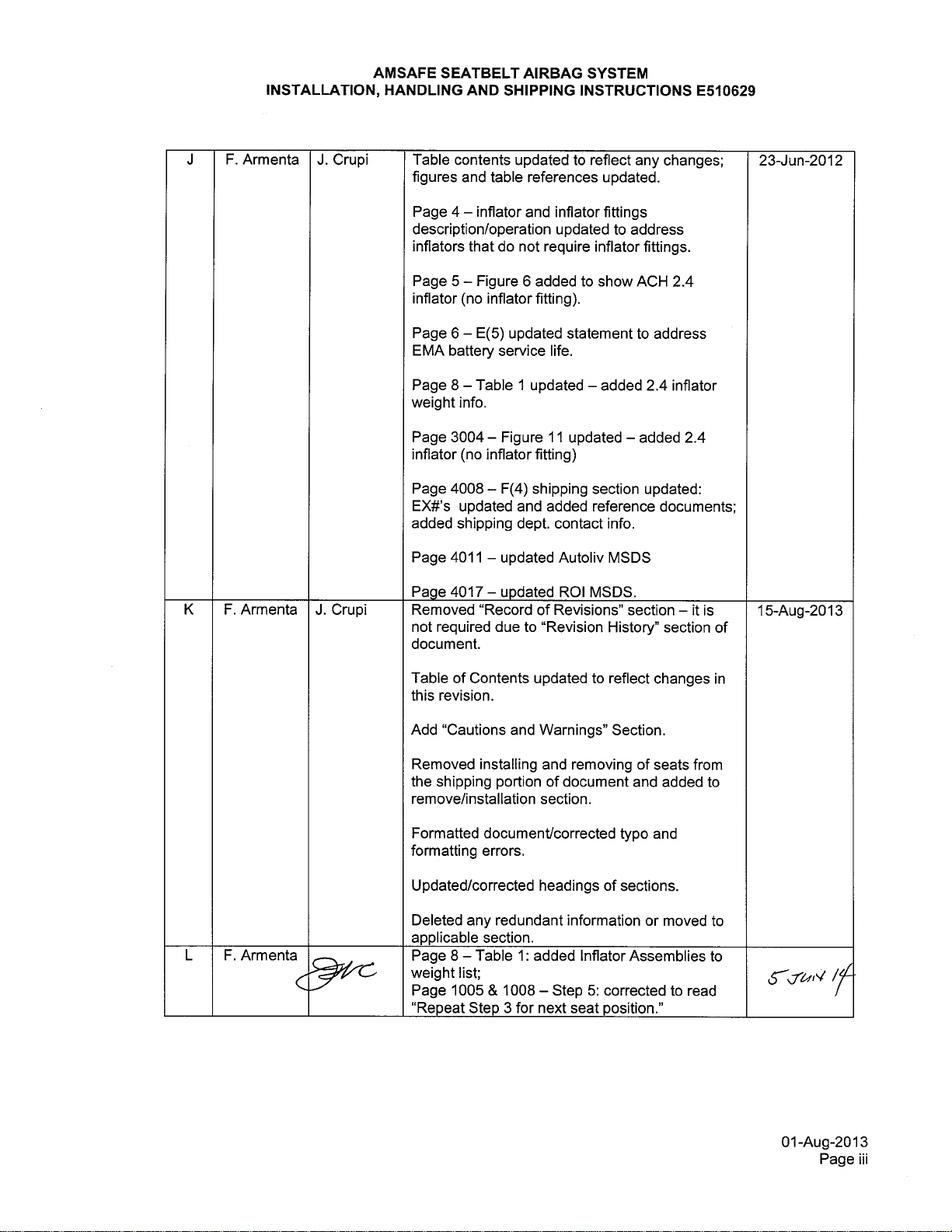

B F. Armenta J. Magish Updated EMA and Inflator pics;

Page 1003 – added warning to disconnect SDT

after diagnostic check in order to prevent EMA

battery from draining.

11-Nov-2009

C F. Armenta J. Magish Updated nomenclature: Inflatable Lap Belt Assy

was Seatbelt Airbag Assembly (SAA);

Page 3002 – added EMA torque values to Table

06-Apr-2010

D. F. Armenta D. Potter Updated nomenclature: AmSafe Airbag System

(AmSafe Airbag) now AmSafe Seatbelt Airbag.

Updated Packing and Shipping Requirements for

Inflators: removed statement to use cargo only

when shipping; added EX numbers for Autoliv

Inflators

07-May-2010

E F. Armenta J. Magish Revision History – removed “Added Section

2000, Inspection/Check.” This section was never

added.

Page 4007 – Updated Packing and Shipping

Requirements for Inflators: removed statement to

use cargo only when shipping

30-Jun-2010

F L. Langston J. Magish Reformatted document; added instruction for

systems with no activation switch throughout

document; removed warnings/cautions with

instruction to avoid magnetic fields in vicinity of

EMA as this is no longer a valid issue; added

MSDS, EX numbers, and weights for ROI

inflators.

31-Aug-2010

G F. Armenta J. Magish Added Figure 3 – dual inflator system;

referenced dual inflator system throughout

document where inflator is referenced. Updated

Figure 11 to show locked and unlocked

connector position. AmSafe logo updated;

nomenclature: AmSafe was AmSafe Aviation.

14-Apr-2011

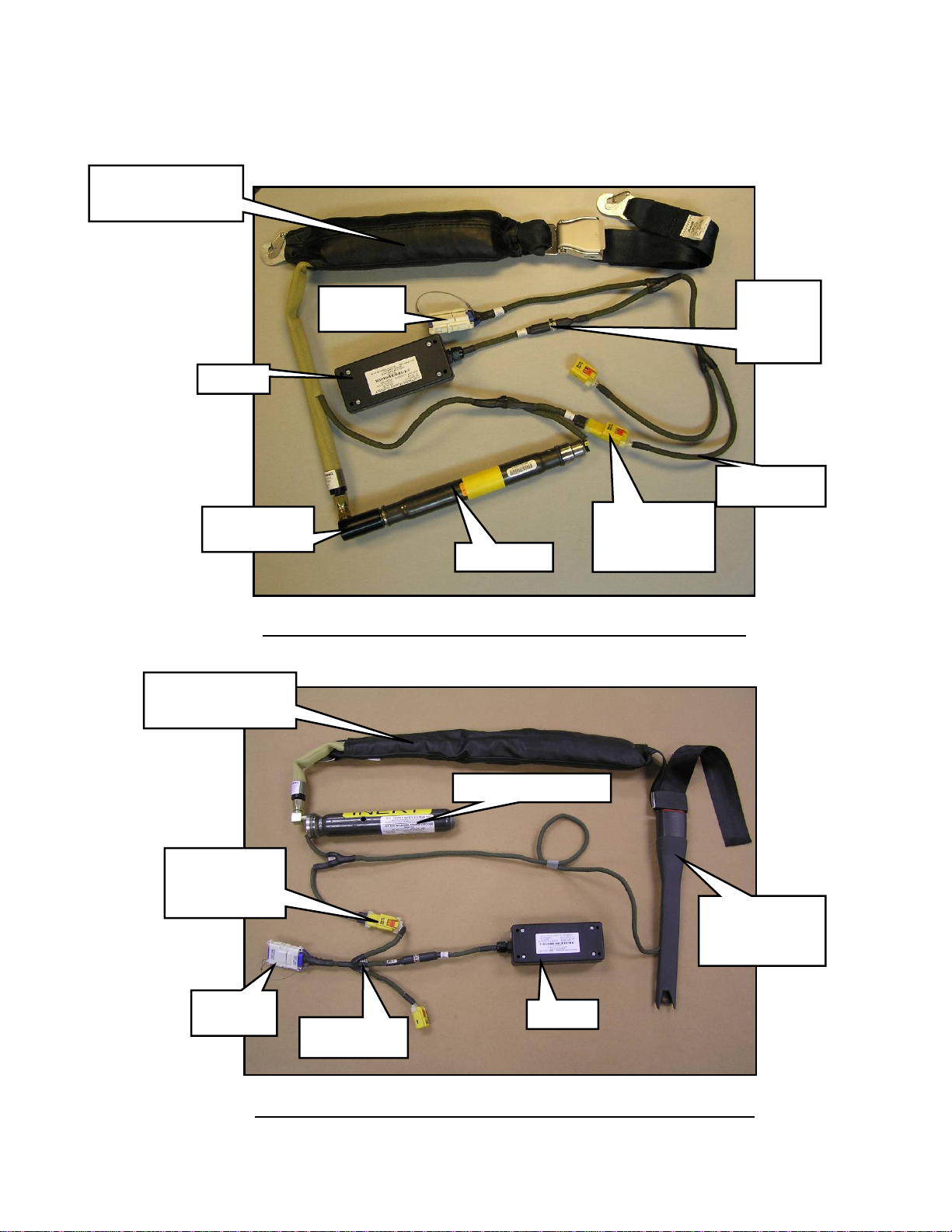

H F. Armenta J. Magish Updated to reference a structure mounted

system; added Figure 4 – Representative

Structure Mounted System; added Figures 14 &

15 for detail on expiration date of Inflator and

EMA; updated caution statement for mishandling

of EMA.

11-Mar-2011