3-1

Uncrating/Installation Instructions 122994-142

InstallationInstructions

1. Install the Amsco®Reliance®444 Single Chamber Washer/

Disinfector according to the Uncrating/Installation Instructions,

P-122992-165, provided with the washer.

IMPORTANT: Make sure to review washer Installation Checklist

before installing Load/Unload modules.

IMPORTANT:Ifthecharacterinposition7oftheunitserialnumber

is a 4 or less (S/N 36xxxx4xxx), modifications must be made to the

washer using upgrade kit #444-022, before installing conveyor

modules.

2. Review installation requirements for conveyor modules:

a) Clearance - Clearance space shown on Equipment Drawing

is necessary for easy installation and proper operation and

maintenance of conveyor modules.

b) Utility Service Lines - Utility service requirements are shown

onEquipmentDrawing.Theconveyormodulesrequire120 V,

60 Hz, 1-phase, 2 wires. Check Equipment Drawing or Iden-

tificationplate (located insidesprayhead compartment door)

for proper voltage.

c) Check floor level and note floor slope to determine how high

conveyor sections should be raised above floor when level-

ing.

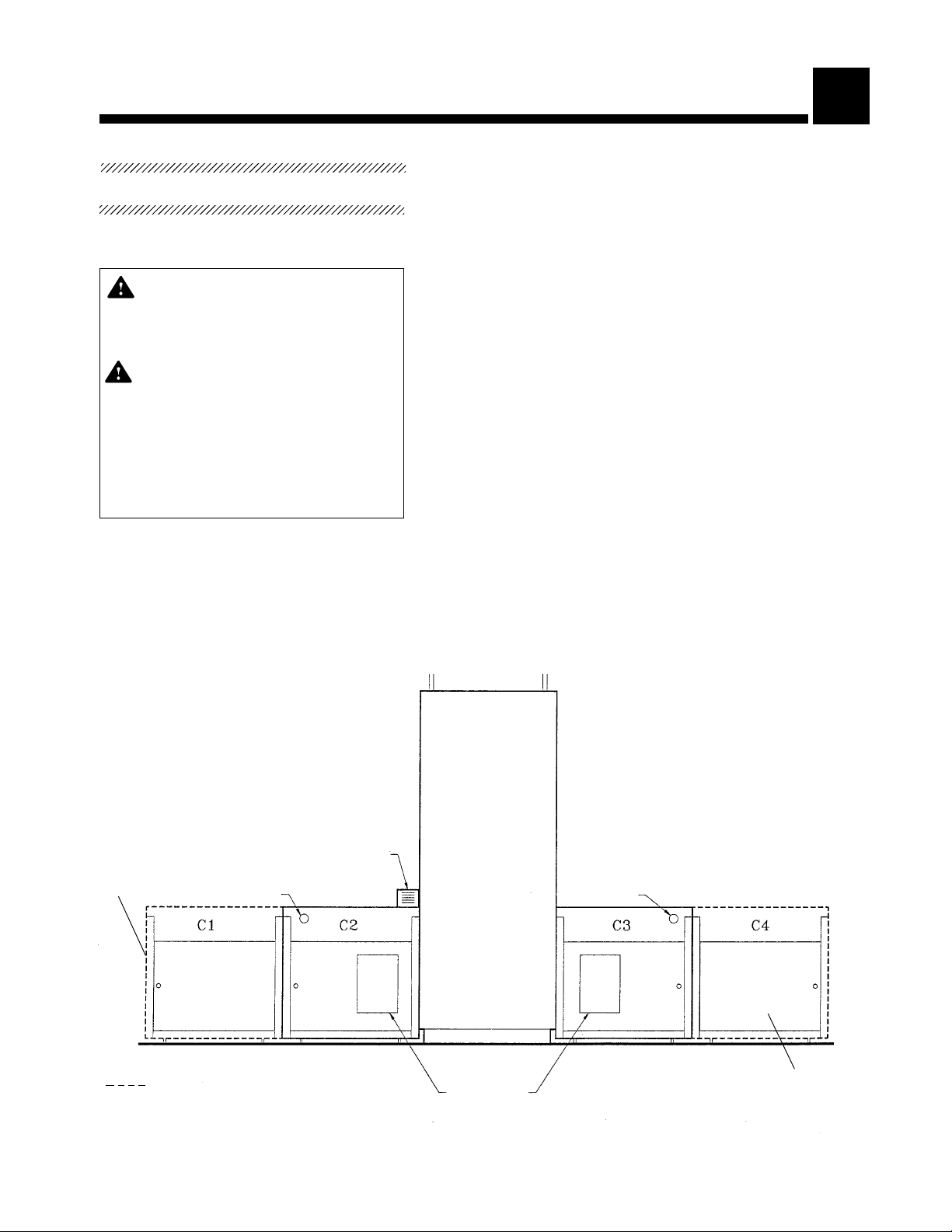

3. Place conveyor modules in order shown on the Equipment

Drawing, in correct relation to washer and building supply lines.

If modules are not at installation site, refer to Uncrating Instruc-

tions (Section 2) for proper moving instructions.

NOTE: Leave sufficient space between and around modules to

performinstallation.

4. Lock out and tag out electrical supply disconnect switch on the

washer to OFF position and close washer supply valves.

5. Remove lower service access doors from both ends of the

washer.

NOTE: Thefollowingconnectionsarerequiredtotiethemodulecold

water piping to the existing washer cold water piping.

1. Locate washer cold water piping connecting cold water inlet to

condenser (see Figure 3-1). Piping is made of two parts.

2. Remove union (located underneath sump) connecting both

pipes (see Figure 3-1, item 1).

3. Remove piping attached to cold water inlet side (see Figure 3-

1, item 2).

4. Replace piping with cold water supply piping provided (see

Figure 3-2).

3

INSTALLATION INSTRUCTIONS

Before Installing

Equipment

WARNING - PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Only fully qualified ser-

vice personnel should assemble

and/or make adjustments to this

equipment. Assembly or adjust-

ments done by inexperienced, un-

qualified personnel could cause

personal injury or result in costly

damage.

Cold Water Connections