anatol.com

9

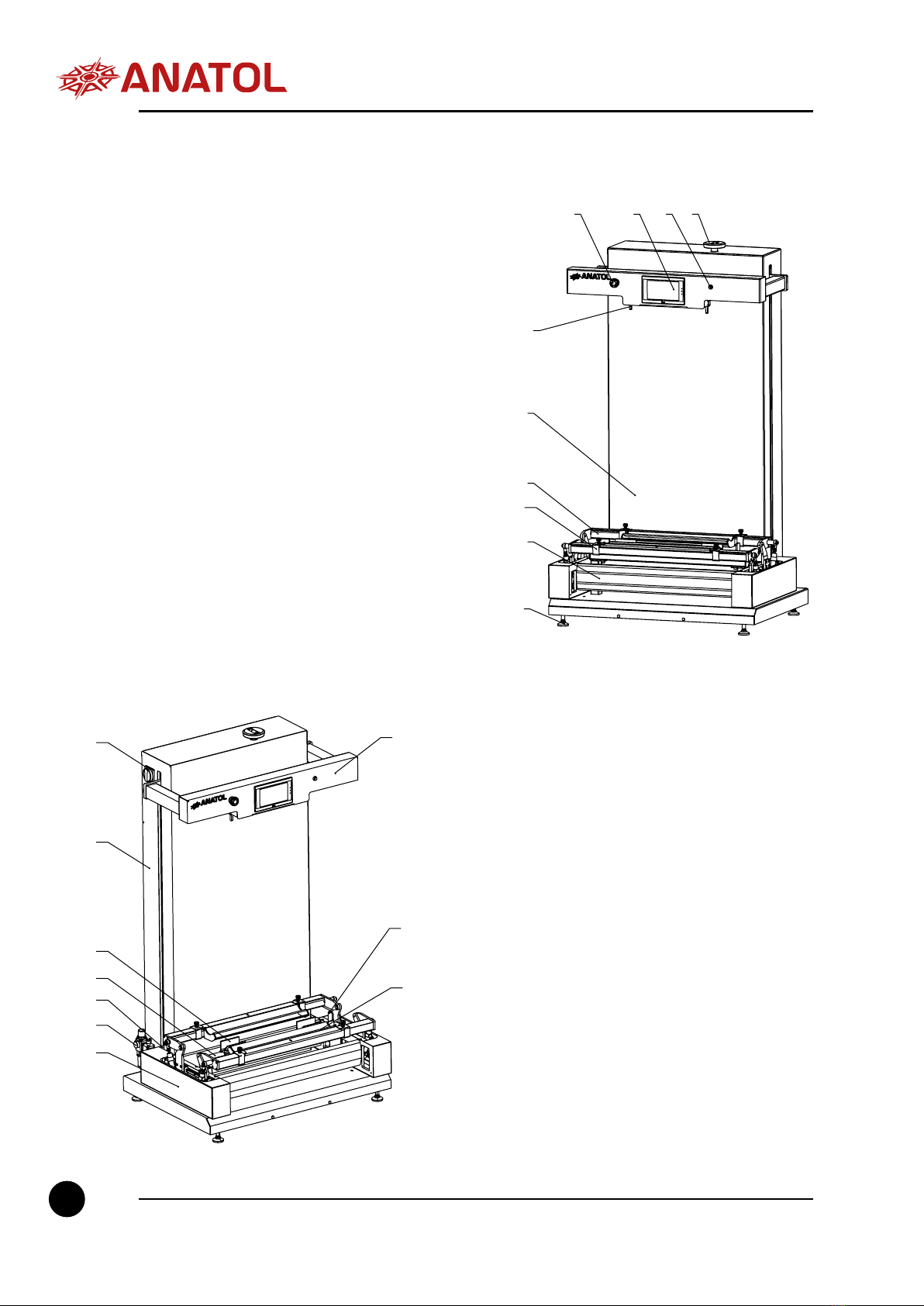

5.2 INTENDED USE

lThe Quik-Kote emulsion coating machine is intended for the automatic

application of various types of emulsion on one or two screens of the same size

simultaneously. The emulsion machine has the ability to apply emulsion on one

side of the screen, or both sides of the screen simultaneously.

Any other use of the device besides those described in this manual is strictly

forbidden. Incorrect use of the device will void the warranty.

Air supply

Power supply

6. OPERATION

6.1 WORK SEQUENCE

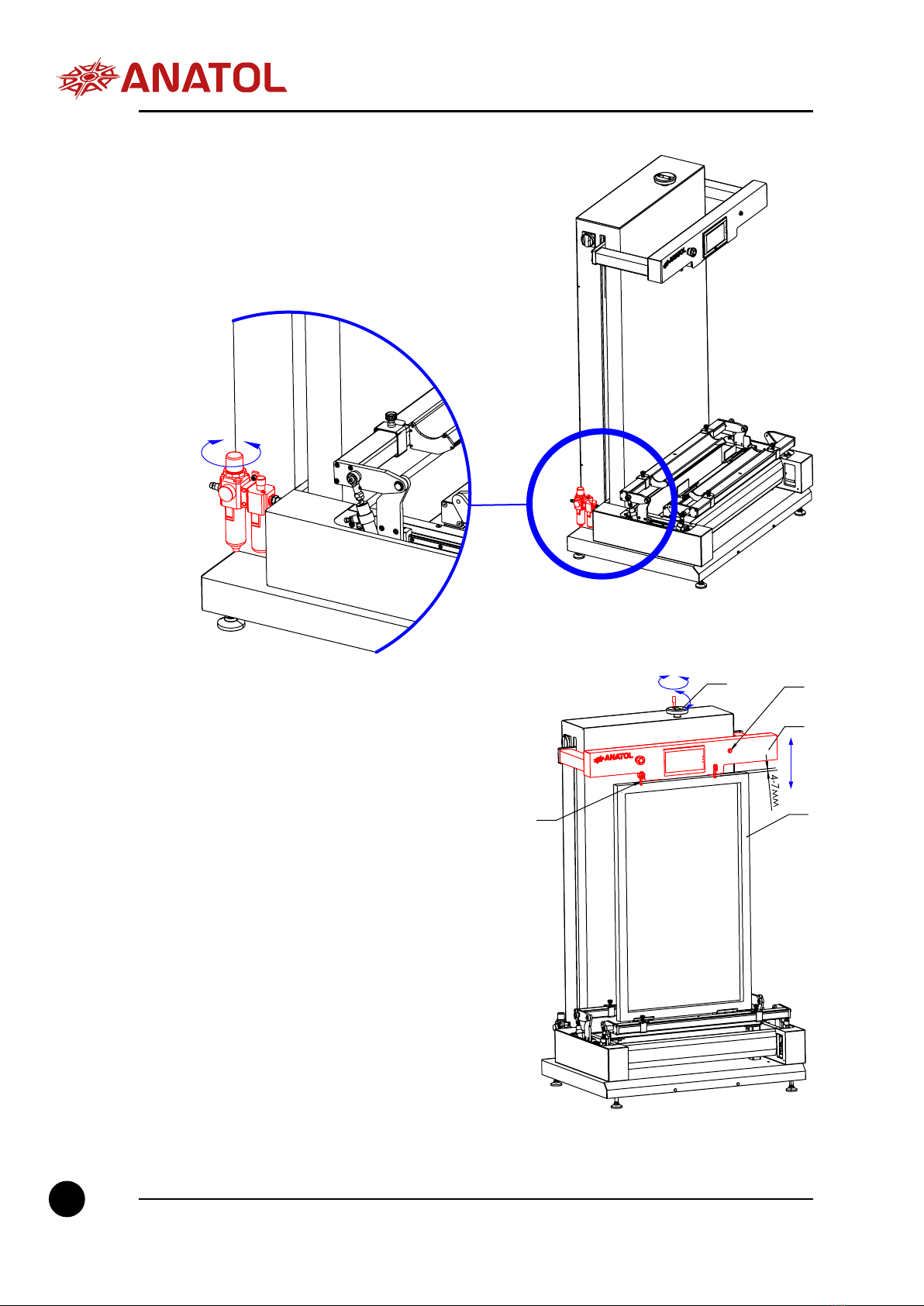

Before using the emulsion coating

machine, make sure that the machine

is connected to the power source

and that the electrical cable is not

damaged or interfering with the

operation of the machine. Ensure that

the air pressure supplied meets the air

requirements specied in the technical

documentation. It is also important

to ensure that all emulsion residues

have been cleaned from the working

surfaces of the machine before use,

and that the tip of the scoop is free of

damage (burrs) as this may prevent

the machine from working properly. In

case of contamination, clean all work

surfaces before starting the machine.

If the nozzle of the ladle is damaged,

such a ladle cannot be used To turn on

the emulsion machine, turn the main

switch (20) to the ON position