USER MANUAL

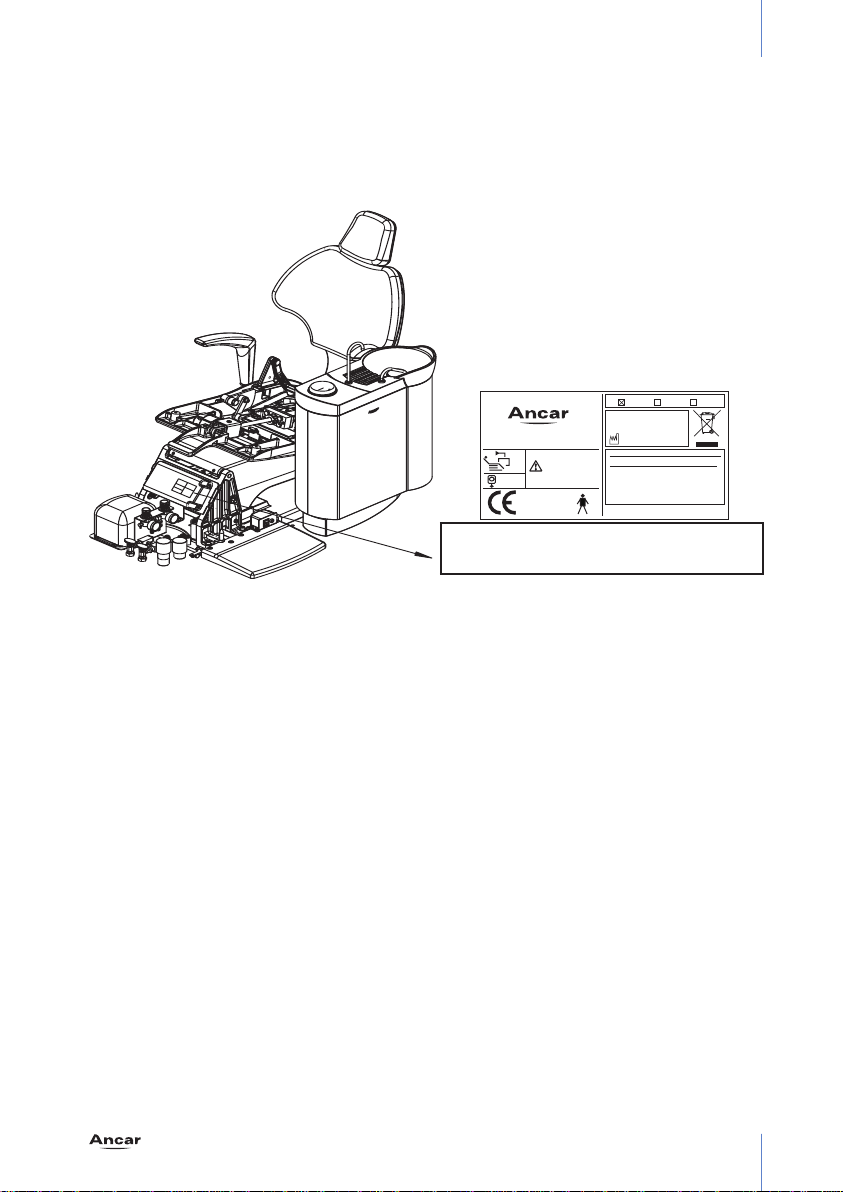

DENTAL UNIT - QS4-366-02 / SD 150

2

Thank you for purchasing the SD-150 dental unit.

This instruction manual contains information on the dental unit, including its configuration and

maintenance.

0434

This symbol means the unit is certified under Directive 93/42/EEC by

the DNV

Notes

This symbol means CAUTION, PRECAUTION

Before starting-up the unit you must have read and fully understood the user

manual.

Keep this manual in a safe place for future reference, for as long as you use

the equipment.

Follow all safety standards.

It is the user’s responsibility to keep the unit clean, disinfected and in perfect

working order.

1.- PRECAUTIONS

This equipment may only be moved by authorised technicians.

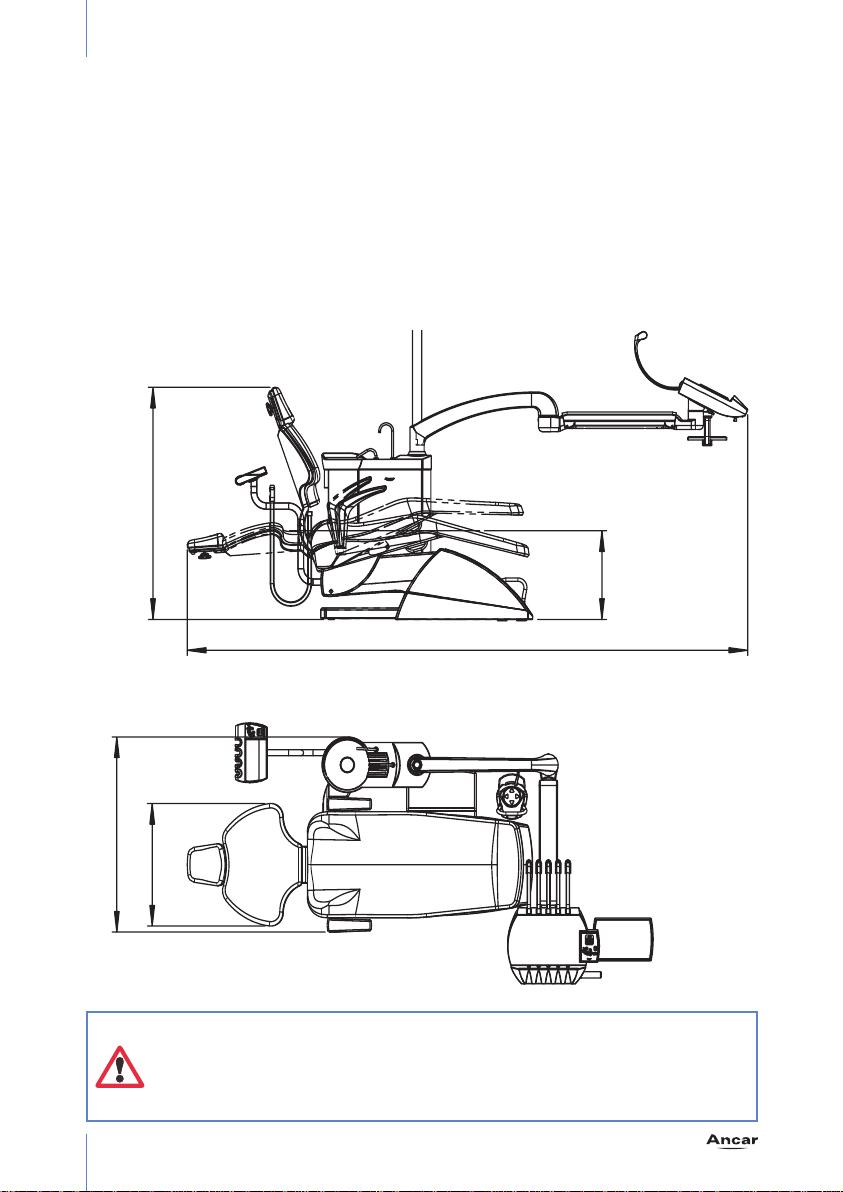

The unit must be installed in an environment with controlled conditions, including temperature

(+10˚C to +40˚C), humidity (30-75 %) and atmospheric pressure (700 a 1060 hPa), free from

dust and condensation and protected from direct sunlight.

The electrical circuit at the premises where the unit is to be installed must satisfy the provisions

in standard IEC 601.1 regarding protection against electric shock for class I equipment.

Antoni Carles, S.A.reserves the right to make any improvements or modifications to the dental

unit without prior warning.

The unit must be used in accordance with the use instructions.

Under Directive 93/42/EEC, the dental unit and dental chair manufactured by Antoni Carles,

S.A.are class IIa equipment. It is absolutely prohibited to install any class IIb or III dental

instrument, e.g. surgical lasers, electronic scalpels, X-rays or electric cauterizers. Only class

I or IIa equipment may be installed, in compliance with the provisions in the aforementioned

Directive and standardised regulations EN60601-1, EN60601-1-2.

2.- GUARANTEE

The device comes with a Certificate of Guarantee. If you do not receive this, ask your dealer

directly. The Certificate of Guarantee must be completed and returned to the manufacturer

(Antoni Carles, S.A.) within 8 days of delivery of the device.

The guarantee is only valid if the device has been used correctly and installed by an authorised

technician.

Moreover, to comply with Health Equipment traceability in accordance with Directive 93/42/

EEC, you must also return the installation form.