2 ULS Owner’s Manual Rev 0.0

Released: 12/2021

1General Description

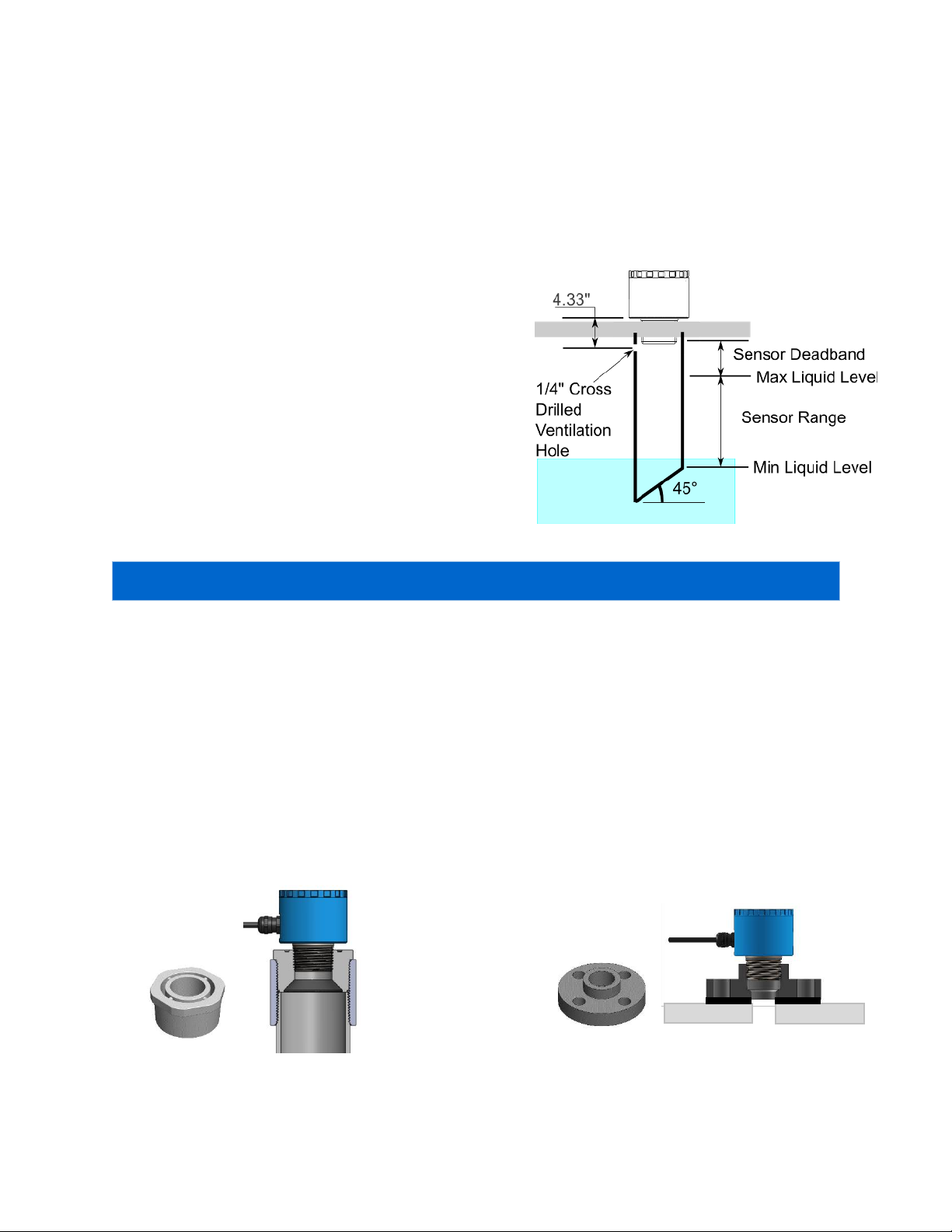

The ultrasonic level sensor measures level or distance and has a 4-20 mA analog output and 4 digital outputs. It

is a robust option for level sensing that offers flexibility and precision. The device is configurable either by

push-button programming with a LED display or through a USB software interface.

2Features and Benefits

Non-contact continuous level measurement with analog output, four switches and control functions

for distance of up to 82.68” (2.1 m),

Fast programming through USB software interface or field-adjustable programming through push

button interface and display,

LED display indicates current measurement in inches or centimeters with 0.01” (1 mm) resolution,

Precise 12-bit 4-20 mA output with invert 20-4 mA option,

Four programmable relays each able to handle up to 200 mA peak load current,

Selectable signal processing, fluid compensation, failsafe features that enable optimization for

installation,

Robust all-metal enclosure with 316SS port for corrosive environments,

Automatic temperature compensation for accurate measurements.

3Table of Contents

1General Description .............................................................................................................................................2

2Features and Benefits..........................................................................................................................................2

3Table of Contents.................................................................................................................................................2

4Specifications .......................................................................................................................................................3

5Installation............................................................................................................................................................4

6Electrical Connection ...........................................................................................................................................7

7Display Elements..................................................................................................................................................7

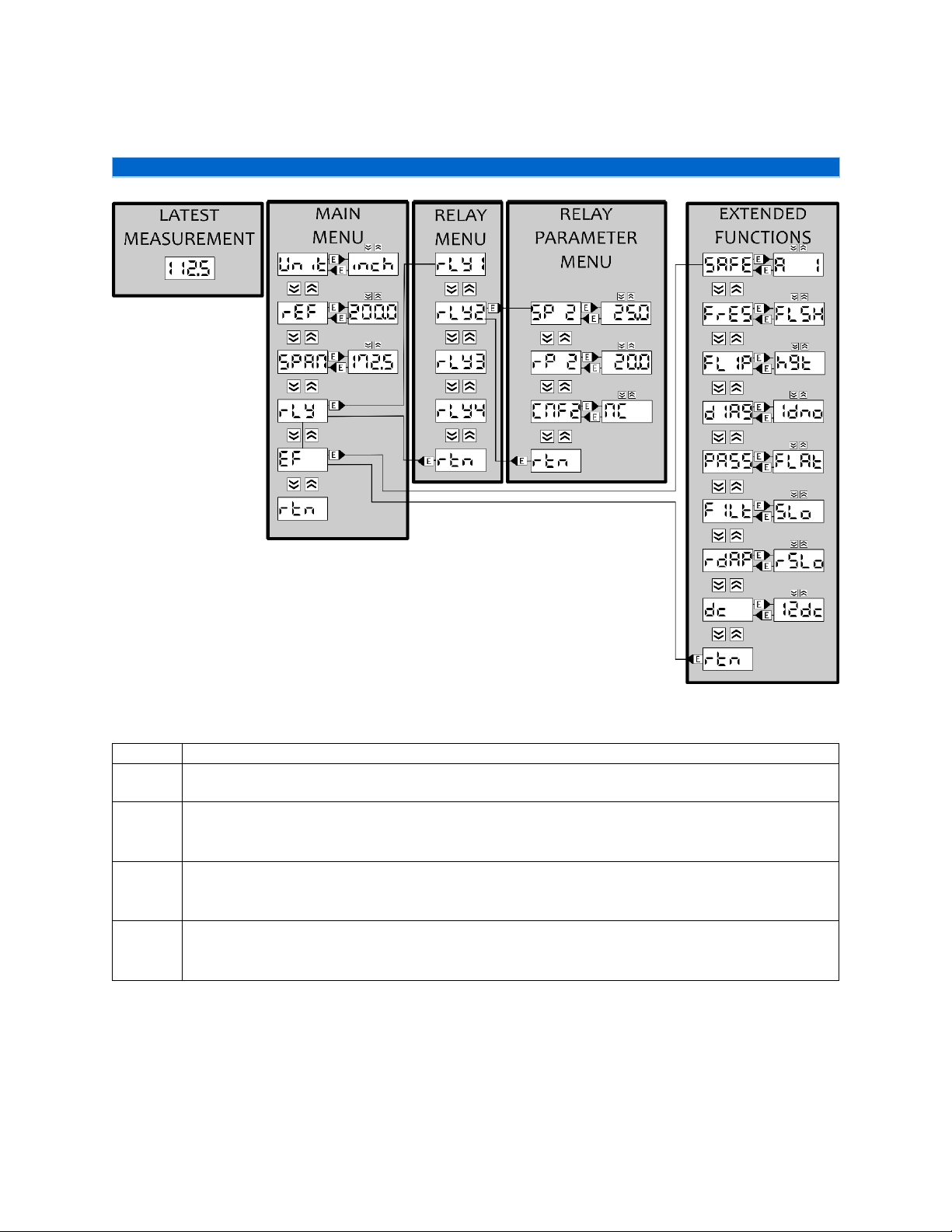

8Menu Hierarchy................................................................................................................................................... 8

9Parameter Selection .......................................................................................................................................... 10

10 Setting up the ULS ............................................................................................................................................. 12

11 Troubleshooting/FAQ ........................................................................................................................................ 19