Page 2

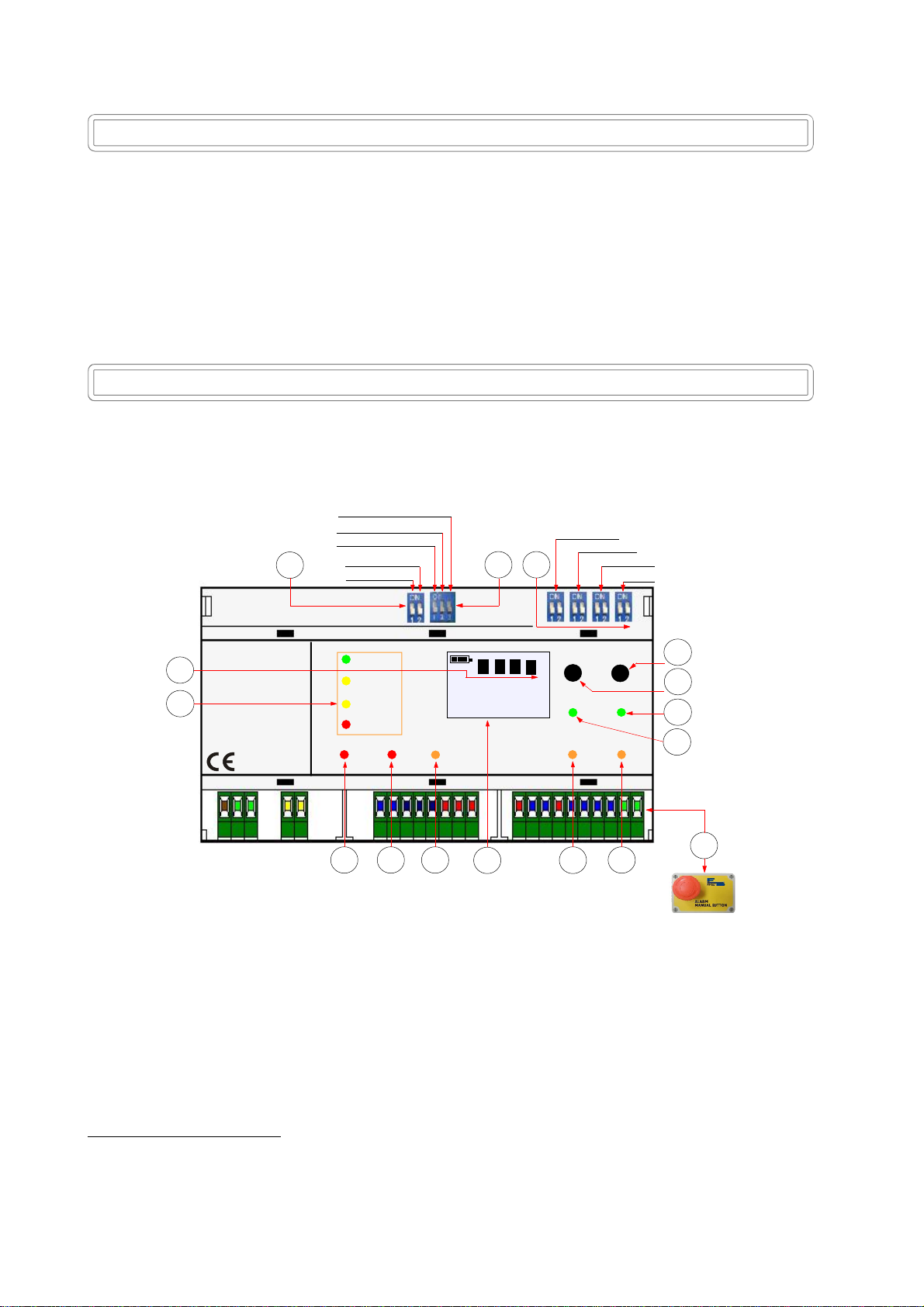

90 mm

45 mm

37 mm

90 mm

45 mm

159 mm

FaultMain AlarmPre Alarm BX449F probes battery

RESET TEST

Explosive Toxic

000LEL

ppm

1 2 3 4

OVER LOAD

1

2

3

4

OpenLine

CloseLine

FIRE

Alarm

Precautions

CHECK the integrity of the unit after having removed it from the box.

Check that the data written on the box correspond to the type of gas used.

When doing the electrical connections, follow the drawing closely.

Any use of the detector for purposes other than the intended one is considered improper,

and as a result of which BEINAT S.r.l. therefore disclaims any responsibility for possible

damages caused to people, animals or objects.

IMPORTANT: the functional test must not be carried out with the gas tap open as this does not guarantee

sufficient concentration to activate the main alarm.

TERMS and EXPECTATIONS: The installation of the BX449F control unit, its ordinary and extraordinary

maintenance, every six months, and its out of service removal at the end of the functional life guaranteed by

the manufacturer, must be carried out by authorized or specialized personnel.

Do not allow it to become wet.

The unit can be seriously damaged as it is not waterproof so when immersed in water or exposed to high

humidity levels.

Do not drop it.

Heavy knocks or falls during transportation or installation can damage the appliance.

Technical Specifications

Main power ........................................................................................... 110/240VAC 50/60Hz ±10%

Insulation ..................................................................................................................... Class II

Secondary Power Through Battery Max 2,2 Ah (Optional) ........................................................ 12 V ±10%

Battery charger max. 2.2 Ah ..................................................................................................... Controlled

Power demand ....................................................................................................... 11W max. 230 VAC

Power demand ........................................................................................................ 6W max. @ 12 VDC

Range of the contacts on the gas pre-alarm, alarm and fault relay ............................... 10A 250 VAC resistive

Range of the contacts on the fire alarm relay ............................................................ 10A 250 VAC resistive

Detection

Pre alarm ......................................................................................... 13% of L.E.L. or 200 ppm for CO

Final alarm .............................................................................. Set to 20% of L.E.L. or 300 ppm for CO

The LEL is calcuaded for Gas Methane .................................................................... 5000 ppm = 5% V/V

Data refresh ............................................................................................................................ 2 ms

OXYGEN alarm ............. <Oxygen deficiency,> Excess Oxygen ......................... see thresholds on page 5

Monitored events .................................................................................... Through backlit color display

Zones ............................................................................................................................................ 4

Number of connectable gas sensors ......................................................................... 4 (1 for each zone)

Types of conventional gas sensors ....................... Semiconductor, Catalytic, Electrochemical cell, Pellistor

Number of connectable fire sensors ....................................................................... 20 (5 for each zone)

Types of fire sensors connectable ......................... Optical smoke - fixed temperature - increment temperature

Micro-switches to include or exclude the gas sensors, Exclusion only for CO ....................... 1 for each zone

Microswitches to select the OXYGEN detection ................................................... ................ incorporated

Microswitches to display ............................................... ......................... Over Range and Under Range

Type of faults detected by fault circuit ..................................................... Interruption, short circuit, or wear

OVER LOAD Check .....................................................................................................1 for each sensor

OVER LOAD Check ............................................................................................................ 1 for battery

Input signal GAS................................................................................................. 4 ÷ 20 mA on 220 Ohm

Input signal FIRE....................... 2.2 VDC at rest, 8.7VDC in alarm, 13.92 VDC with short-circuited cables

Functioning temperature ................................................................................................. -10°C ÷ +60°C

Waiting, blinking time (warm-up) ................................................................................. About 2 minutes

Manual test ............................................................................................................................. Built in

Max. distance between sensors and unit ..................................................................................... 100 m

Max. distance between battery and unit.......................................................................................... 0,5 m

Cable diameter to connect the senors ....................................... .................................................. 1 mm2

Connection: The cable of connection of the sensor must not be installed together with the power cables.

Otherwise, make sure to use a shielded cable

Omega-type size DIN EN 50092 9 modules ................................................................................. 158*90*58

Degree of protection .................................................................................................................... IP20