Boge FOCUS User manual

Operating instructions

FOCUS compressor control

for piston compressors

BOGE FOCUS compressor control for piston compressors Page I

Operating instructions

FOCUS compressor control

for piston compressors

BOGE KOMPRESSOREN

Postfach 10 07 13

33507 Bielefeld

Otto-Boge-Straße 1-7

33739 Bielefeld

Fon: +49 5206 601-0

Fax: +49 5206 601-200

Mail: [email protected]

Net: www.boge.com

Issue: 01 / 2012

No. 596.1021.18

Nominal price: € 5,00

BOGE FOCUS compressor control for piston compressors Page III

Index

Index

Part 1:

FOCUS

1.1 The BOGE control concept............................................................ 1

Installation......................................................................................... 1

Control unit ....................................................................................... 2

1.2 Operation......................................................................................... 3

Switch on the control ........................................................................ 4

Switch on the compressor ................................................................ 4

Ready ............................................................................................... 4

Run-up phase ................................................................................... 5

Load operation.................................................................................. 5

Idling ................................................................................................. 5

Switch off the compressor ................................................................ 5

Maintenance ..................................................................................... 5

1.3 Display information ........................................................................ 6

Main display...................................................................................... 6

Maintenance ..................................................................................... 7

Operating times ................................................................................ 7

Leakage monitor............................................................................... 7

Start leakage measurement.............................................................. 9

Info # 1............................................................................................ 10

Info # 2............................................................................................ 11

Date / Time ..................................................................................... 11

Set date / time................................................................................. 12

Display of version ........................................................................... 12

1.4 Settings.......................................................................................... 13

Entering of codes in general ........................................................... 13

Parameter list.................................................................................. 13

Set parameters ............................................................................... 14

Parameters ..................................................................................... 14

1.5 Grouped parameters / parameter management......................... 21

Servicing interval ............................................................................ 21

Parameter factory setting................................................................ 21

Base load switch control................................................................. 21

Switch clock.................................................................................... 22

Unplanned compressed air requirement......................................... 22

View input status............................................................................. 23

Index

Page IV BOGE FOCUS compressor control for piston compressors

1.6 Functions....................................................................................... 23

Motor switching limitation................................................................ 23

Power failure cycle protection......................................................... 23

Motor spinning time ........................................................................ 24

Pressure range selection ................................................................ 24

TAN test.......................................................................................... 24

Safety valve test ............................................................................. 24

Base load switch control with additional compressors.................... 25

1.7 Warning message / Fault message ............................................. 27

Warning message / Fault message ................................................ 27

Warning message........................................................................... 27

Pre-acknowledgement .................................................................... 28

Acknowledgement of message 45 (Watchdog timer Reset)........... 28

Fault messages .............................................................................. 28

1.8 Data of external connections....................................................... 29

Basic module .................................................................................. 29

RS 485 module ............................................................................... 30

Analogue input module ................................................................... 30

Wire cross sections of external connections................................... 31

1.9 Fault messages............................................................................. 32

List of fault messages ..................................................................... 32

1.10 Parameter overview...................................................................... 34

BOGE FOCUS compressor control for piston compressors Page 1

FOCUS 1.1 The BOGE control concept

Part 1: FOCUS 1.1 The BOGE control concept

Installation FOCUS is a compressor control unit.

It is installed into the switch cabinet as part of the compressor and serves as

a compressor control device.

Prior to commissioning and before accomplishing any kind of maintenance or

servicing work please read the functional descriptions of both control and com-

pressor carefully. First and foremost observe the Safety notes in chapter 1 of

the functional description of the compressor.

Power input

Terminals A1 and A2 for 24V AC / DC

An interruption of the power supply is effected by means of the mains discon-

nector of the compressor.

Modules

The basic equipment of the FOCUS consists of a basic module and a keypad/

display unit (TAN).

Amongst others the following modules are optionally available:

– with a – second – RS485 interface for the connection of additional com-

pressors if the serial interface is used for other purposes

– with changeover contact relay; function can be selected by rotary switch

– system pressure module for a system pressure transmitter on the master

compressor

Interconnection of the modules may only be completed in a currentless state

using the provided leads supplied with the equipment.

FOCUS 1.1 The BOGE control concept

Page 2 BOGE FOCUS compressor control for piston compressors

Control unit The display unit comprises a graphic display and 3 indicator lamps (LEDs) for

an additional illustration of the operating modes.

Fig. 1.1: FOCUS operating panel

1LCdisplay

2 Indicator lamp – Fault (red)

3 Indicator lamp – Warning (yellow)

4 Indicator lamp – Ready (green)

5 Navigation keys

6INFO key

7ENTER key

8ON key

9OFF key

Operating / control element Designation Function

Navigation keys Navigation in the menu, scrolling the displays, scrolling of pages

in the parameter display.

Navigation keys Navigation in the menu, displays, dryer status, navigation in the

parameter display, setting of values.

INFO key Display of faults, warnings or maintenance messages, log book,

quitting of settings.

BOGE FOCUS compressor control for piston compressors Page 3

FOCUS 1.2 Operation

1.2 Operation

Prerequisite

The compressor must be electrically and pneumatically connected, the pow-

er supply voltage must be turned on and the ball valves and / or balanced

disc stop valves between compressor and compressed air receiver must be

opened.

ENTER key Confirmation of inputs, selection of parameters, forced idling, setting

of FC (frequency converter) parameters.

OFF key Acknowledging when switching on the control, switching off the

compressor, switching off forced idling.

ON key Switching on the compressor, forced idling.

Warning / Maintenance

(LED-yellow)

Flashing:

Lit:

Maintenance due – does not lead to automatic

switch-off.

Message was preliminarily acknowledged; the

cause is still recognised, however.

Fault

(LED-red)

Flashing:

Lit:

Upcoming fault, compressor automatically shut

down.

Message was preliminarily acknowledged; the

cause is still recognised, however.

Operation

(LED-green)

Flashing:

Lit:

Compressor in idling operation.

Compressor is switched on.

Emergency-Stop

pushbutton

The Emergency-Stop pushbutton interrupts the power supply for the

contactor coil. The control is still energized and generates a corre-

sponding display.

Operating / control element Designation Function

Caution: Risk of injury!

If the compressor is not closed there is a risk of injury due to rotating or pro-

jecting parts resp. a crushing hazard because of flaps or doors standing

open!

The compressor may only be operated with all flaps and doors closed!

FOCUS 1.2 Operation

Page 4 BOGE FOCUS compressor control for piston compressors

Switch on the control After switching on the compressor supply voltage, the display shows the name

of the control, the manufacturer's name and version number – as described

under version display.

First a parameter adjustment between basic module and TAN is performed

resp. and if applicable the registration of connected and not yet registered ad-

ditional modules.

When the process is finished, either the symbol of the OFF key flashes in

the display, which is acknowledged by pressing the OFF key to leave the

display, or auto re-start and / or remote on / off is active and the display counts

down after voltage returns (mains outage), usually starting with the set auto

re-starting time [s]*. When this time is expired the compressor switches to

Ready status and starts automatically, as soon as the prerequisites are fulfilled.

If an interference is pending when voltage is switched on, it is displayed right

after parameter reconciliation (see also section „1.7 Warning message / Fault

message“, page 27).

* The time is automatically extended temporarily if there are too many motor starts in short suc-

cession.

Switch on the

compressor

At first OFF should be displayed in the bottom frame – the status display of the

compressor.

If this is the case, the compressor can be put in the READY state by pressing

the -key.

A green LED signals that the compressor is ready for operation and the pres-

sure control is active – as long as no "Timer-Off" is due or an external pressure

control was parameterized.

If EMERGENCY STOP is displayed for the compressor status the Emergency-

Stop button has to be unlocked first.

If the status display shows Fault, the control is faulty and the malfunction has

to be corrected first (see also section „1.7 Warning message / Fault message“,

page 27).

Ready If the compressor status Ready is displayed, the compressor is in the "ready-

for-operation" status. That means that the compressor automatically (re)starts

pressure and / or time controlled – as long as the conditions to do so are ful-

filled.

Caution: Risk of injury!

If the compressor is not closed there is a risk of injury due to rotating or pro-

jecting parts resp. a crushing hazard because of flaps or doors standing

open!

The compressor may only be operated with all flaps and doors closed!

BOGE FOCUS compressor control for piston compressors Page 5

FOCUS 1.2 Operation

Run-up phase The compressor motor is started and run up as already described under

„ Ready“, page 4 The status display changes from Ready to Run-up.

To be able to do so, the system pressure* at the compressor must be de-

creased and the motor spinning time finished.

For the star / delta contactor combination applies: First the star contactor and

20 ms later the mains contactor is switched on. The display Run-up signals the

corresponding status of the control.

* If a system pressure sensor is present – the sensor input is optionally used for suction pressure

monitoring.

Load operation The Run-up resp. Star phase is finished after termination of the run-up time.

The control activates the transport valve.

Compressors which are controlled accordingly now change into the delta

switching and the display shows load.

Idling By setting a follow-up time – preset to 0 seconds – and / or exceeding of the

maximum permissible motor switching operations, suitable compressor types

may go through an idling phase after completion of a load run phase.

Otherwise, the control switches off the motor at once – and the compressor

switches back to Ready state.

If the net pressure drops below the set minimum pressure (pmin), the compres-

sor control may automatically change from idling to load operation – the com-

pressor continues with the output.

* Multi-stage compressors (determined by P=41) are not capable of running idle due to delayed

valve control, so that a sufficiently large receiver/net volume and sufficiently large interval between

the upper and the lower pressure target value are required for motor switching operation limitation!

Switch off the

compressor

With the OFF key or via Remote-Off the compressor is switched off. The

pressure control is deactivated. Immediately, Off is displayed in the compres-

sor status display and the green LED goes out.

Maintenance When operating the control the battery voltage has to be checked from time to

time. If the voltage drops too far a warning message is created. In this case

the battery has to be replaced.

The display of the TAN has to be cleaned with a damped yet not wet cloth from

time to time. As detergents customary household detergents for greasy sur-

faces can be used. No further maintenance is required for the control.

FOCUS 1.3 Display information

Page 6 BOGE FOCUS compressor control for piston compressors

1.3 Display information

Main display This is the main display in the control menu, net pressure, system pressure

and suction pressure together with the compressor status are displayed here

(display ).

By pressing the -key, a temperature* is displayed (display ) instead of the

system pressure.

* not for each compressor type, otherwise optional.

* If the functions auto re-start and / or remote start / stop are parameterised, the key must be

pressed after unlocking the emergency stop button to leave the emergency stop function.

Net pressure pNShows the current net pressure.

System pressure pSShows the current system pressure.

Possibly inner hood

or compressed air

outlet temperature °F

Shows the current temperature (within the compressor hood or

of the compressed air at the compressor output). This window

appears if a sensor is present.

Compressor status Meaning

Off Compressor is switched off.

Ready Compressor is ready and starts automatically as soon as the

conditions are fulfilled.

Run-up Compressor is in star phase.

Load operation Compressor runs in delta phase.

The solenoid valve is closed.

Idling – possible

for single-stage

compressor

Single-stage compressor runs in delta phase, solenoid valve

is open.

Fault A fault has occurred on the compressor / compressed air

purification, the compressor is switched off.

The fault has to be rectified prior to a restart.

Emergency-Stop The Emergency-Stop button has been pressed*.

BOGE FOCUS compressor control for piston compressors Page 7

FOCUS 1.3 Display information

Maintenance With the next actuation of the -key you get to the servicing display. Here the

information concerning the servicing times are displayed.

Operating times By pressing the -key you get to the operating times display. On this menu

page the operating times of the compressor are displayed.

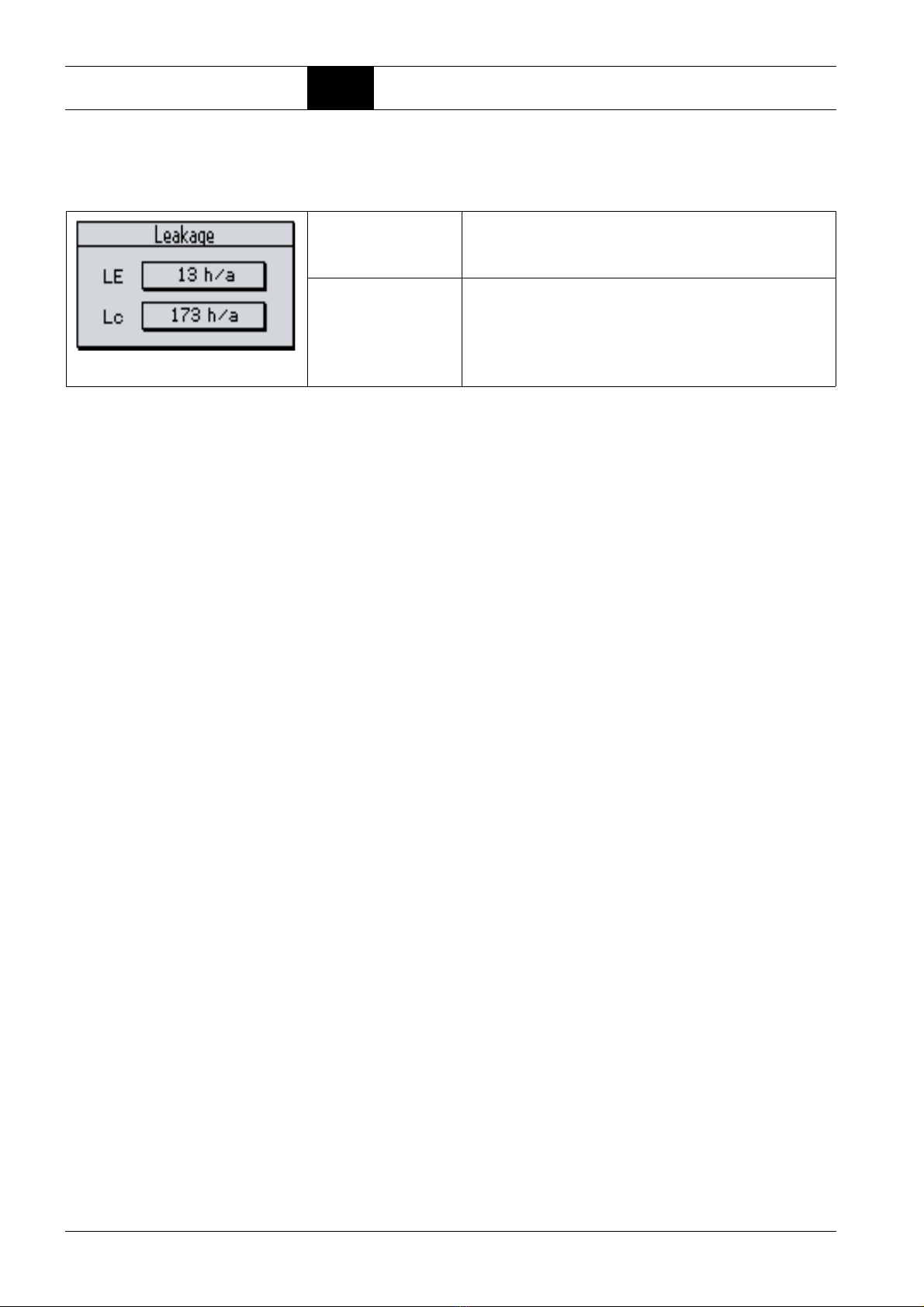

Leakage monitor Pressing the key in the operating hours display causes the control display

to show "leakage". The display serves to enable you to determine the energy

loss resulting from any potential leaks in your compressed air network.

To this purpose, the control unit measures the time period duration of the

operating loads during which, under normal circumstances, no production of

compressed air takes place, as for example over night or operation down-

times.

This, however, is conditioned on the fact that operational compressed air pro-

duction be discontinued for a protracted period of time and that the compres-

sor be set into the "ready" mode by means of the control system. In case of a

potential pressure reduction below the preset minimum pressure value result-

ing from leaks in the compressed air network, this compressor automatically

switches into the operating mode in order to recover the set -pressure range.

The leakage measurement serves to record the duration of the operating load

times and to extrapolate them for the whole year. This allows you to quantify

any leakages and to easily determine their portion of additional costs due to

any energy losses.

Next motor

servicing (h)

Shows the operating hours until the next motor servicing.

Next compressor

servicing (h)

Shows the operating hours until the next compressor servicing.

Next receiver

servicing

Shows the number of load changes until the next receiver serv-

icing.

Normally not used for piston compressors.

Current battery

voltage

Shows the current voltage of the battery for the real-time clock

in the main module.

Motor running

time

Shows the total operating time of the compressor motor in hours,

minutes and seconds.

Idling Shows the share of time in which the compressor was idling in

hours, minutes and seconds.

Efficiency display Shows the ratio of load energy compared to total operating time

energy since the preceding Reset.

Load cycles of internal

receiver

Counts the effected load cycles of the internal combination re-

ceiver.(One cycle consists of 1 x output and 1 x no output each).

Normally not used for piston compressors.

FOCUS 1.3 Display information

Page 8 BOGE FOCUS compressor control for piston compressors

A potential leakage is either measured by a single (LE) or continuous (Lc)

value measurement:

In case of single leakage measurement a single measurement operation

over six hours serves to determine the hourly operating load times per year

due to leakage.

In order to obtain a precise value it is imperative that no operational com-

pressed air consumption take place during measurement, viz. production is to

be shut off for at least six hours. If measurement is actuated by means of the

control system, measurement will be deferred by six hours. This allows you to

activate the leakage function already in the afternoon causing the measuring

operation to start in the evening (six hours later) to continue over night.

Unlike continuous value measurement, single value measurement is also pos-

sible if several compressors are being operated in the basic load mode at the

same time. Starting separate single value measurement of each compressor

enables you, after a six-hour measurement period, to read and to add up all

of the single values of the compressor control units. Their total value corre-

sponds to the annual number of hours of operating load times as a result of

leakage in your compressed air networks.

Continuous leakage measurement is designed to continuously calculate

operating load values at six-hour intervals.

Unlike single leakage measurement, continuous leakage measurement can

also be started during current daily production with measurement starting at

once. The first value obtained after a six-hour period will probably be distorted

since any operational compressed air production will be added to any potential

leakage related operating load. Most probably, however, no operational pro-

duction will be in effect during any subsequent value measurement. The then

obtained value, which is exclusively due to leakage, will be smaller than the

first obtained value. The control system is designed to always display the

smallest value of all measurements, in this case, however, the last obtained

value. This means that any distorted calculation of production operating loads

will be excluded.

In order to determine exact leakage measurement values make sure that, dur-

ing a time frame of 12 hours, there will in all probability be no operational com-

pressed air production.

Single leakage

measurement

(LE)

The abbreviation LE stands for "single leakage measurement".

The displayed value shows the annual operating load times due

to leakage.

Continuous leakage

measurement

(Lc / LC)

The abbreviation Lc stands for "continuous leakage measure-

ment“. The displayed value shows the annual operating load

times due to leakage.

When the abbreviation LC is displayed, continuous measure-

ment has been carried out for more than a week.

BOGE FOCUS compressor control for piston compressors Page 9

FOCUS 1.3 Display information

Start leakage measure-

ment

After editing "leakage" in the control display, please proceed as follows in or-

der to start either of the available measurement methods.

Start single measurement

Single leakage measurement will not start but six hours after actuation of this

process. Your are herefore requested to make sure

– that, after the deferred start of the measurement process no operational

compressed air production will take place over a period of six hours.

– that the compressor be set into the "ready" mode by means of the control

unit and that the green LED of the control be lit.

– that, when using the "external flow release" the external flow release may

not be shut off neither manually nor by the switch clock.

In order to start single measurement:

1. Keep ENTER key pressed for three seconds.

The value next to LE starts blinking.

2. Press ENTER key again for three seconds.

The number 9999 appears and single value measurement will start in six

hours. hours. After a period of twelve hours, the single measurement value

will be displayed. This value will be saved until a new measurement proc-

ess is carried out.

If, during measurement, a power failure takes place the number 9980 will be

displayed. In such case it is recommended to repeat the measurement proc-

ess at a later stage.

If, during measurement, the compressor is put out of operation the number

9990 will be displayed, i.e. the compressor is switched off and the energy loss

due to leakage could not be properly determined during said measurement.

In this case, too, the measurement process should be repeated at a later stage

while making sure that the compressor be switched off during measurement.

If the value next to LE starts blinking and no measurement is to carried out:

–PressINFO key .

The value will stop blinking. The measurement process is not started. By press-

ing the key, you get to the „Operating times“display.

Starting continuous measurement

Continuous leakage measurement will start immediately. Make sure

– that during the following days, at least for once during a time frame of

12 hours, no operational compressed air production takes place.

– that the compressor be set into the "ready" mode by means of the control

unit and that the green LED of the control be lit.

In order to start continuous measurement:

1. Keep ENTER key pressed for three seconds.

The value next to LE starts blinking.

2. Press the key .

The value next to Lc starts blinking.

3. Press ENTER key for three seconds.

The number 9999 appears next to Lc. Continuous measurement will start

immediately and keep being carried out. After the twelve-hour time frame,

during which no operational production has taken place, has been exceed-

ed a sound measurement value is obtained.

FOCUS 1.3 Display information

Page 10 BOGE FOCUS compressor control for piston compressors

The control system will always save the lowest value. A search for the lowest

value – as a background process – will be restarted once a week. This allows,

after expiry of another week, a higher value compared to the one of the previ-

ous week to be displayed if the measured minimum value has increased dur-

ing that period. Any potential increase of leakages in the compressed air net-

work will therefore also be possible to be determined.

Any power failures during measurement will not be indicated by a sequence of

digits because new values will be calculated every six hours and because any

such power failure during measurement will not prevent the values of the sub-

sequent measurement to be displayed.

If the value next to Lc is blinking and no measurement is intended to be carried

out:

– Press INFO key

The value will stop blinking, and the measurement process is not started.

By pressing the key, you get to the „Operating times“display.

Info # 1 Pressing the key in the operating hours display causes the control display

to show „Info # 1“. This display serves to show information on the compressor

set-up.

Status RS485 1:19200;8N1 The RS485 interface is parameterized as a slave:

address: baud rate, data bits parity stop bits – no com-

munication has taken place as yet.

O.K. The last communication has taken place less than

1 minute ago.

Time: This serves to indicate when the last – valid communi-

cation has taken place (up to 7 days).

C2 (C3 C4) When parameterized as a master and master control

this serves to display which of the compressors are in

communication. Blinking of the combination indicates

defective communication.

On / Off Local: via keyboard.

Remote: via contact and / or Bus.

On: Compressor is switched on.

Off: Compressor is switched off.

Output release Internal: via internal pressure sensor.

External: Output release via contact and / or Bus.

Yes: Output release enabled.

No: Output lock is active.

Auto-Restart n / a: No Auto-Restart after (control) power failure.

Time: Auto-Restart active, Auto-Restart time.

Note!

Changes to the displayed settings have to be accomplished by means of the

parameter settings, if applicable, (see also chapter „1.4 Settings“, page 13)

or by changing the automatically registered configuration (see also ’Remove

modules and input contacts‘).

BOGE FOCUS compressor control for piston compressors Page 11

FOCUS 1.3 Display information

Info # 2 The information to the control settings as master control resp. the current sta-

tus of the integrated timer are displayed here.

The priority sequence is only displayed if the number of compressors in the

base load switch control is above 1. In case the number of compressors is set

to 1, n / a is displayed here.

The display of the priority sequence shows the currently effective sequence for

selecting the compressors. Depending on the setting the priority sequence

is changed cyclically (base load switch control) or selected by means of the

switch clock.

For each parameterized compressor the current output signal status, the cur-

rent priority level and the time until the next priority change, with switched-on

base load switch control, is displayed. If only the switch clock is active (cyclic

changing time set to 0) no time is displayed.

Meaning:

C1 C2 C3 means, that the compressors 1–3 are connected and the sequence

1, 2, 3 is chosen – in this case none of the compressors receives an output

signal.

C1 C3 C2 means as in the first example, that the compressors 1–3 are param-

eterized although they are selected in the sequence 1, 3 and 2. Furthermore,

compressor 1 receives an output signal in this case.

The output signal status is shown by means of a black background in the graph-

ical presentation of the compressors in the display.

Date / Time This menu page shows the current setting of the real-time-clock.

The time is displayed in hours, minutes and seconds and the date with day of

the week, day, month and year.

In case of a switched-off power supply the real-time-clock is operated by its

battery – provided the plug-in jumper contacts arranged next to it are connect-

ed and their voltage is sufficient (see also chapter Maintenance).

Pressure range Activated pressure range

System pres-

sure / net pres-

sure

Shows the current system pressure / net pressure.

Switch clock – A-Z active timer channel

– n / a no channel active

Priority se-

quence (time

until change

of priority)

Set priority sequence, active compressors and time in h and min until

next change of priority.

Note!

Changes to the displayed data have to be accomplished by means of the

base load switch control (see also chapter „1.4 Settings“, page 13) or switch

clock settings.

FOCUS 1.3 Display information

Page 12 BOGE FOCUS compressor control for piston compressors

Set date / time In order to set both time and date, keep the ENTER key on the menu page

"date / time" for three seconds.

The cursor jumps to the time display and the digits of the hour display start

blinking.

Use keys / to set digits.

With the ENTER key the input is acknowledged and the cursor moves to

the next field. Proceed the same way with all other place values until all values

are correctly adjusted. In case a value has to remain unchanged just actuate

the ENTER key , to jump to the next value.

To leave the time adjustment, actuate ENTER key until none of the place

values is blinking any longer. Actuate key to reach the previous page or ac-

tuate the key to go to the next page.

If the INFO key is actuated while adjustments are made to the real-time-

clock, this setting is left without accepting the parameterized changes.

Display of version The version display can be reached in the menu by pressing the /keys.

Here the name of the control, the software number and the manufacturer are

displayed.

If the key is pressed now you get to the Module Info display.

Here the addresses and the installed software versions of the connected mod-

ules are shown.The first display refers to the basic module (Address: 0), all

other connected modules can be displayed by actuating the / keys.

If the display of a module is flashing the communication with this module is

faulty.

You can leave Module Info by actuating the INFO key .

Module Address Position of rotary

switch

Basic module 0 --

TAN 1 --

FC (frequency converter) module 10 0

FC module for connection of soft starters 11 1

System pressure module 12 2

Dryer module 20 --

RS485 module 30 0

Analog output module 50 0

Note!

Relay modules are not displayed.

BOGE FOCUS compressor control for piston compressors Page 13

FOCUS 1.4 Settings

1.4 Settings

Entering of codes

in general

1. Actuating the key leads from the main display 1 to the Version display.

2. If now the ENTER key is actuated, a display is shown asking you to

enter a 5-digit code (see code list).

3. The first place value of the code is blinking. By means of the keys /

a digit can now be changed.

4. By actuating the ENTER key or key the cursor jumps to the next

value and the value can be changed accordingly.

5. Once the last digit has been set the code is acknowledged by actuating the

ENTER key . According to the entered code either windows for various

settings or a parameter list opens. When entering the second ... fifth digit

actuating the INFO key causes an erasing of the previous digit, so that

it can be entered again.

Actuating the INFO key when entering the first digit the code setting is

left and you return to the version display.

Parameter list If the code for the parameter list is entered, parameters can be edited.

To leave the parameter list actuate INFO key and you get back to the main

display.

If you are in the adjustment range of a parameter, it can be left again by actu-

ating the INFO key . You have to actuate the INFO key once more to

close the list.

CODE Meaning

17391 User- Code / parameter list

00000 Parameter display / access previous code

00111 Setting / Resetting servicing intervals

00988 Parameter restoring

00798 Switch clock settings

00356 View input status

Note!

If the parameter editing code is entered, you may return to the parameter list

left previously within 15 min after leading it via code 00000 without having to

enter the code again.

An arrow at the beginning of the line shows where the cursor currently is and

whether a value can be changed or not.

If the arrow is only displayed as an outline , it is an informational value; if

the arrow is solid , the value can be changed.

In the parameter setting actuating the / keys makes the cursor move one

parameter forwards or backwards.Use / keys to scroll to the previous /

next page.

FOCUS 1.4 Settings

Page 14 BOGE FOCUS compressor control for piston compressors

Set parameters 1. Opening of the parameter list by means of the desired code (user code,

service code, BOGE code).

2. If the cursor points at the parameter which is to be changed, e.g. maximum

pressure in the pressure range 1 (P012), this selection is acknowledged

by actuating the ENTER key .

3. If a digit (e.g. 130 psi) is blinking on the right side of the parameter, the de-

sired value can be set (e.g. 145 psi) by actuating the / keys.

4. By actuating the ENTER key this input is acknowledged and stored.

Actuating the INFO key at this place causes a leaving of the setting

without accepting the changes.

You can proceed with every parameter in the same way.

Parameters The setting of the parameters can be accomplished as described above (see

also parameter list).

P001 Language

The following display languages are available:

German (DE), English (GB), Italian (IT), Russian (RU), Finnish (FI),

Danish (DK), Lithuanian (LT), Swedish (SE), Polish (PL), Spanish (ES),

Portuguese (PT), French (FR), Dutch (NL), Latvian (LV), Turkish (TR),

Czech (CZ), Hungarian (HU).

P012 pmax Pressure range 1

Pressure range 1 is the default pressure setting for the compressor.

Here the upper pressure target value for pressure range 1 is set. As soon as

the net pressure has reached pmax the compressor changes from load run to

idling.

P013 pmin Pressure range 1

Pressure range 1 is the default pressure setting for the compressor.

Here the bottom pressure target value for pressure range 1 is set. If the com-

pressor is in the Ready state and the net pressure drops below pmin, the com-

pressor starts with the output.

P014 pmax Pressure range 2

Pressure range 2 offers the possibility for pressure decreases and the value

must not be set above that of pressure range 1.

Note!

If pmax is set so that pmin is larger or the minimum hysteresis (P011) is not

complied with, confirming it with the -key will force you to edit P013.

Note!

If the pressure range selection is effectuated by a master control or the exter-

nal contact you have to observe when setting the pressure ranges, that in

case of a power failure or fault of the master control, the compressor control

eventually falls back on this pressure range.

Other manuals for FOCUS

1

Table of contents

Other Boge Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens SINAMICS S120 Equipment manual

Omron

Omron SYSMAC C200H-TC Operation manual

Pentair Pool Products

Pentair Pool Products Fleck 2750 Service manual

Z3 Technology

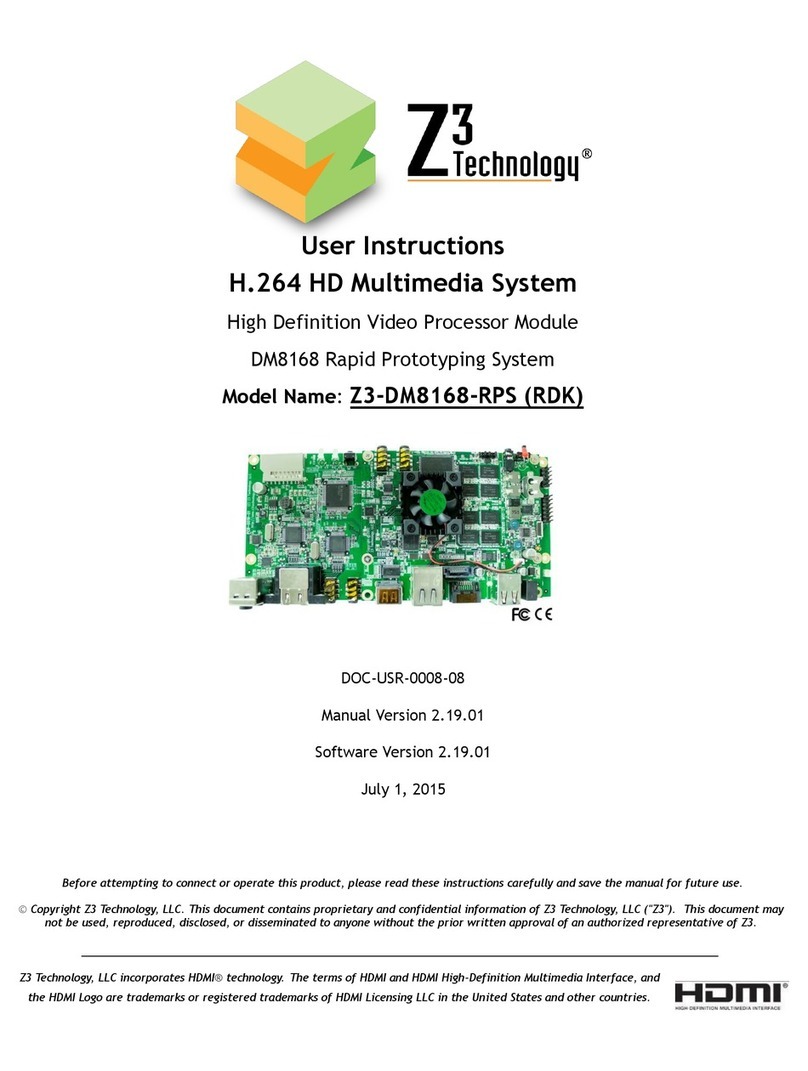

Z3 Technology Z3-DM8168-RPS User instructions

SMC Networks

SMC Networks SV Series Operation manual

Festo

Festo SPC200-SMX-1 Brief description