- -

This machine can be used by children 8 and older and people with physical, sensory or mental

capabilities or lack of experience and knowledge if they have been given supervision or

instruction concerning use safely and understand the dangers supone.Los children should not

play máquina.La cleaning and maintenance of the machine must always be performed by

qualified personnel.

Attention! If the machine or the power cord is damaged, they must be repaired by the

manufacturer, its service agent or a person qualified before continuing use.

Do not dispose of this machine as if generic junk, use separate collection facilities and

licensed in your area for proper treatment. Contact local authorities for information on

the collection points available.

Before installation, you should carefully read this manual and heed the warnings and

safety instructions in this manual.

The manufacturer is not responsible or liable to take responsibility for personal injury, damage

to the pump and yield losses in the machine caused by violation of safety precautions in this

manual.

1. Applications

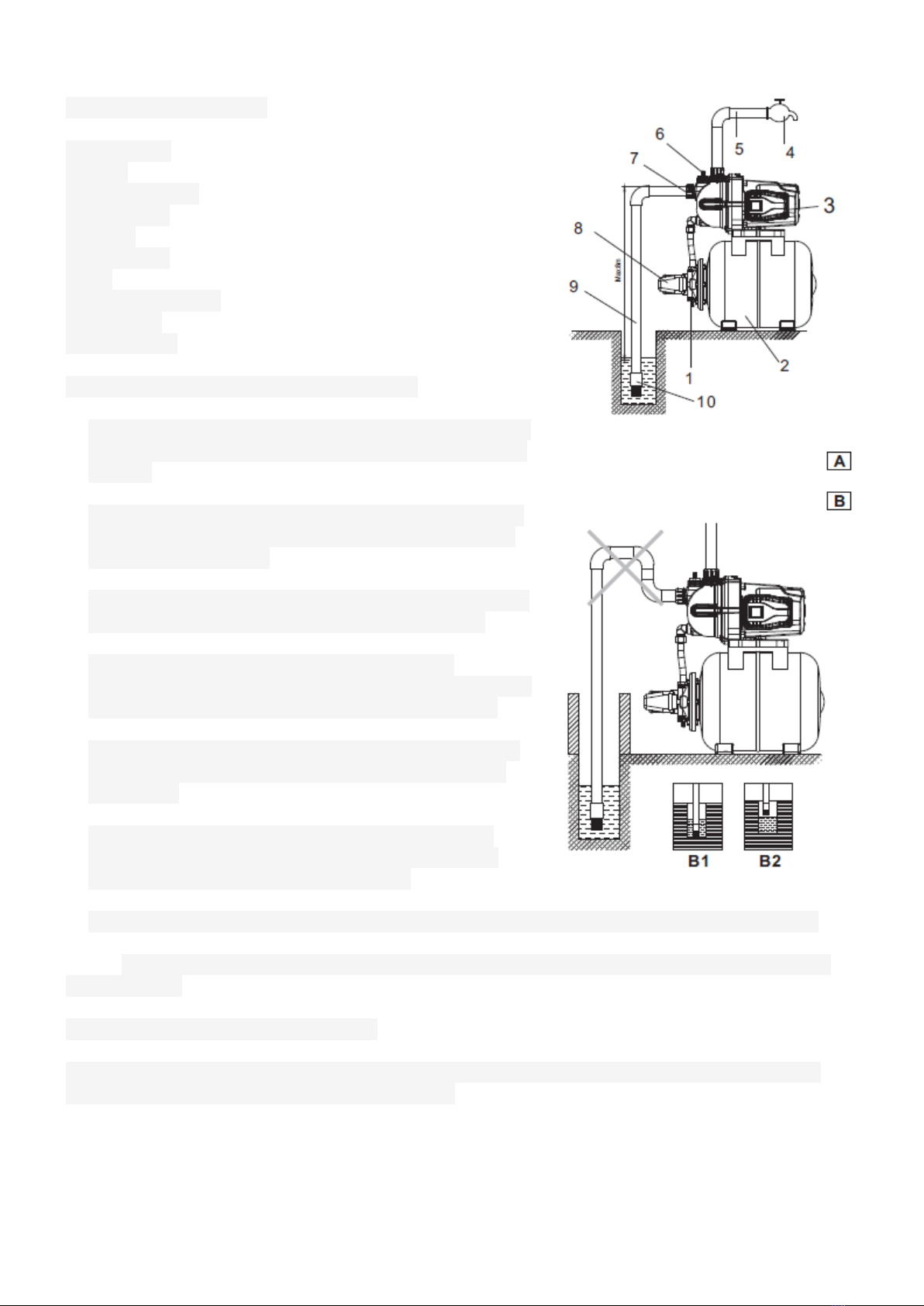

It is applicable to domestic water supply, equipment support, pressurization pipes, irrigation and

fumigation of gardens, irrigation of vegetable greenhouses, breeding, industrial and mining

supply and drainage water business buildings, high-rise, central air conditioning circulation

system and central heating. etc.Transferencia clean water and other non-corrosive liquids with

low viscosity; invalid transport of flammable liquids, explosives, and gasified liquids containing

solid particles or fibers. The pH liquid must be within 6.5-8.5.

Observation:

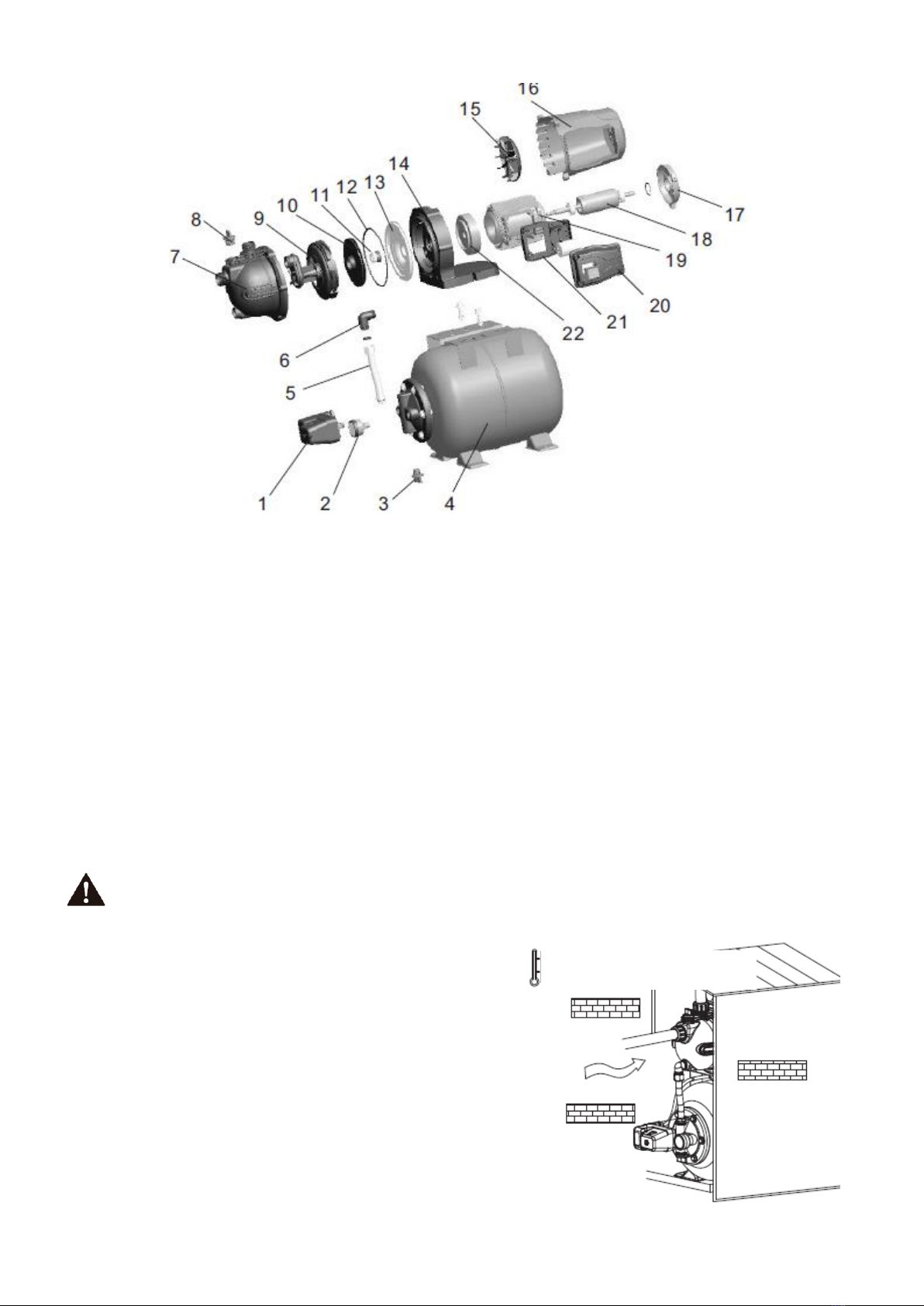

This pump could become a automatic water pump, which is configured through an external

automatic plant which comprises a pressure switch, a pressure tank, etc. The characteristics of

the function of automatic pump are as follows: when the power is on, open the tap and the

pump will start automatically; When the tap is closed, the pump stops automatically. If a water

tower along used with automatic pump, connect to the upper limit switch and the pump start or

stop working with the water level in the water tower automatically.

2. Technical data

Model: BE1300P

Motor power: 1300W

Max flow: 83L / m

Output max height: 48 m.

Start pressure: 1.8 bar

Off pressure: 3.2 bar

Max suction height 8 m

Clase Insulation IPX4

Clase protection F

Max working temperature: + 40℃