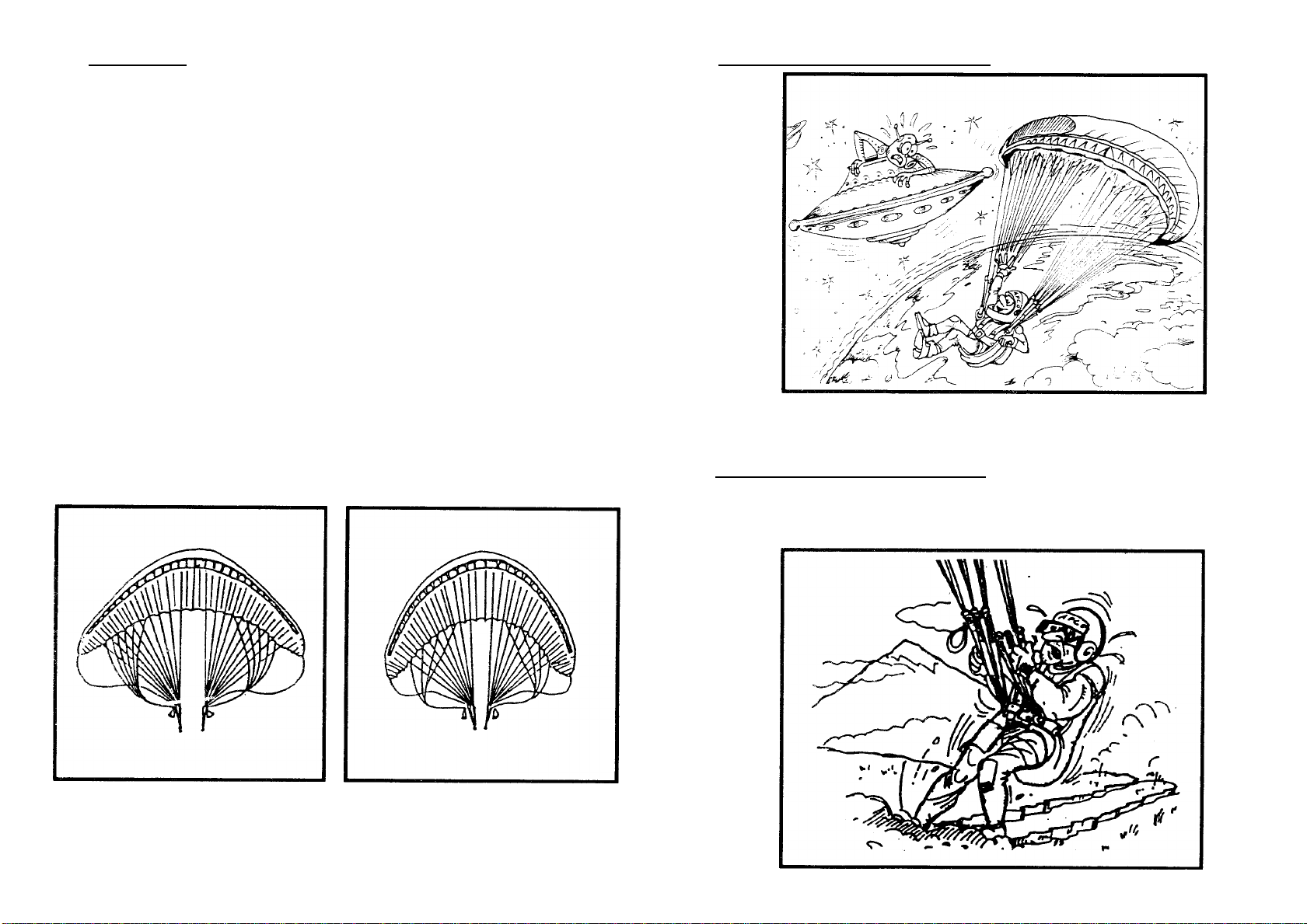

"B" Stail:

To lose height quickly so as to avoid had weather or land in a

restricted area the Futura can be "B" stalled by gripping the "B" riser at the

attachment shackle of the "B" unes. Pull down slowly for the first 10 cm. There

will be strong resistance at first.

The canopy chape will distort and fall a little

behind the pilot's head. Pulling a further 8 cm will stabilize the glider above the

pilot's head . Pull down equally or a turn may develop. Vertical descent rates of

10 meters per second can be safely achieved

To recover release both v-unes slowly at first and fast for the last 10 cm to

accelerate the glider to flying speed.

Big Ears:

Height can also be lost in a controlled way by collapsing both tips. To

do this take no more than the last one "A" line from the tips and pull 10 cm

down sharply. This will collapse 20% of the wing at each tip. This can give sink

rates of up to 5 meters per second. In certain circumstances the tips will remain in

without holding the "A" unes. Steering control can be maintained by weight

shifting with the harness.

To recover, let go of the "A" unes and pull the brakes

down 50 % on both the collapsed sides until the wing is fully inflated.

Do not

do any extreme maneuvers with the tips collapsed as this puts an

excessive load on the tenter unes which may lead to failure of old or damaged

unes.

Spiral Dives:

By progressively applying the brake on one side, the glider can be

put into a spiral dive. Safe, high sink rates can be achieved if done with tare.

High speeds and excessive loads result from strong spiral dives caused by using

too much brake. Recovery must be done by slowly releasing the brake, otherwise

strong forward to rear surges will result in the canopy losing air pressure and large

collapses occurring. Take tare that you have enough height to safely exit the

spiral.The Futura will need 1 to 2 turns to exit neatly from very deep spirals.

11. LANDING

Before landing, the pilot should check the wind direction, which can be seen by

smoke, flags etc., or the speed of the glider in comparison to the ground.

At a

height of forty to seventy meters the final part of the flight must begin. The pilot

should head straight into wind towards the landing field by gently braking or by

making s-turns the exact point can be chosen.

At a final height of twenty meters, descent should, preferably be made at trim

speed.

At a height of one to two meters the landing should be achieved by using

full brake.

Steering not functioning.

If the pilot cannot reach the steering unes for any

reason or if they are not functioning properly, (for example: if they are broken

after damage ), use the alternative method of steering by pulling the rear v-line.

Steering in this way is much slower than normal. Care should be taken when

landing this way to avoid stalling too high.

Strong turbulence.

Continue flying by pulling the brakes down 20% in order to

increase the air pressure inside the canopy.

Tree landings:

If it is not possible to land in an open clearing, steer towards the

highest tree and sink down towards it, protecting your face with your hands,

elbows pressed to the body. Secure yourself to the tree with the unes if descent

from the tree involves danger, wait for assistance.

After a tree landing, all the

unes must be remeasured and the canopy checked.

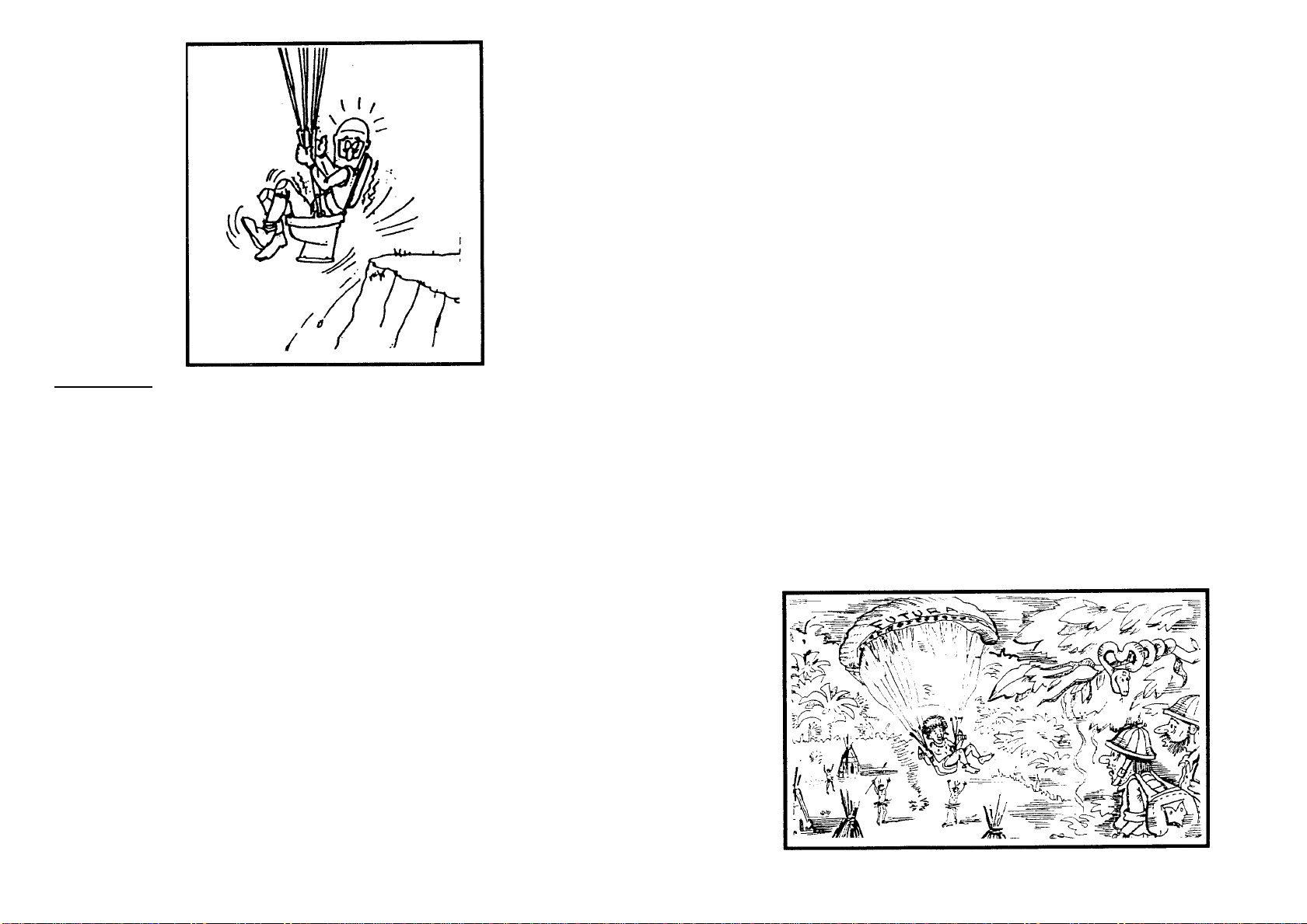

Water landings:

As you approach landing, release all the buckles of the harness

except one leg.

Just before hitting the water, release the remaining leg buckle

and continue braking.

Swim away from the harness and glider to avoid

entanglement.

On impact, if the glider is allowed to rotate completely forwards

until it hits the water with the front openings, the air inside will then be trapped,

making the canopy into a big floating balloon which will give the pilot more time

to escape and make for a better recovery of the canopy which will not be so full

of water.

-

12 -