292930

HEATED 20” BIRD BATH

Item # 600

Miller Manufacturing, Glencoe, MN 55336 USA • www.miller-mfg.com

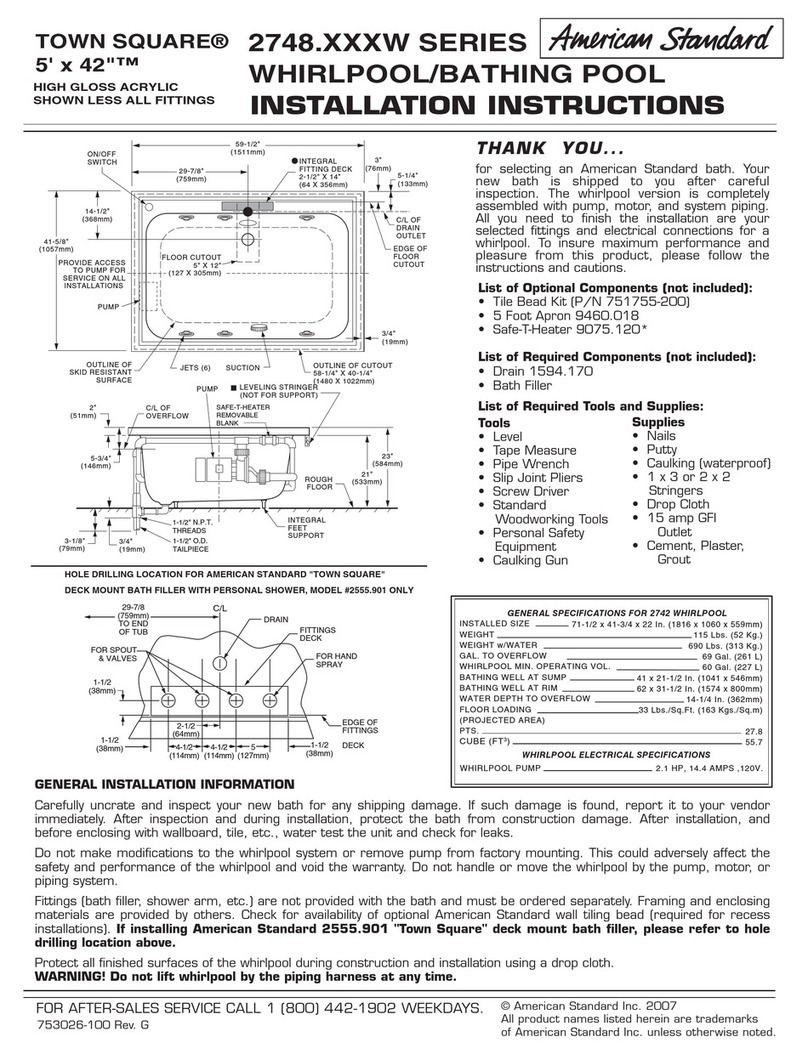

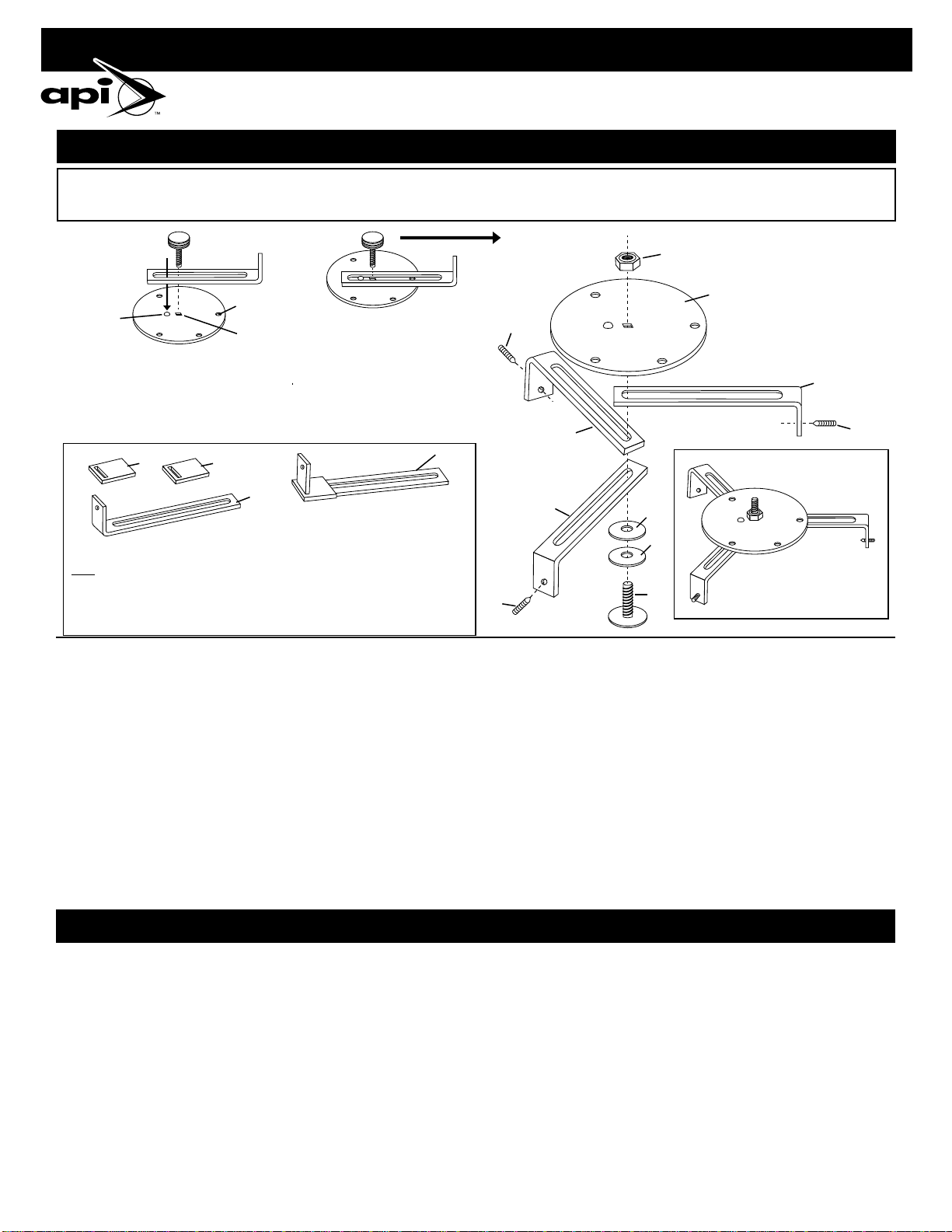

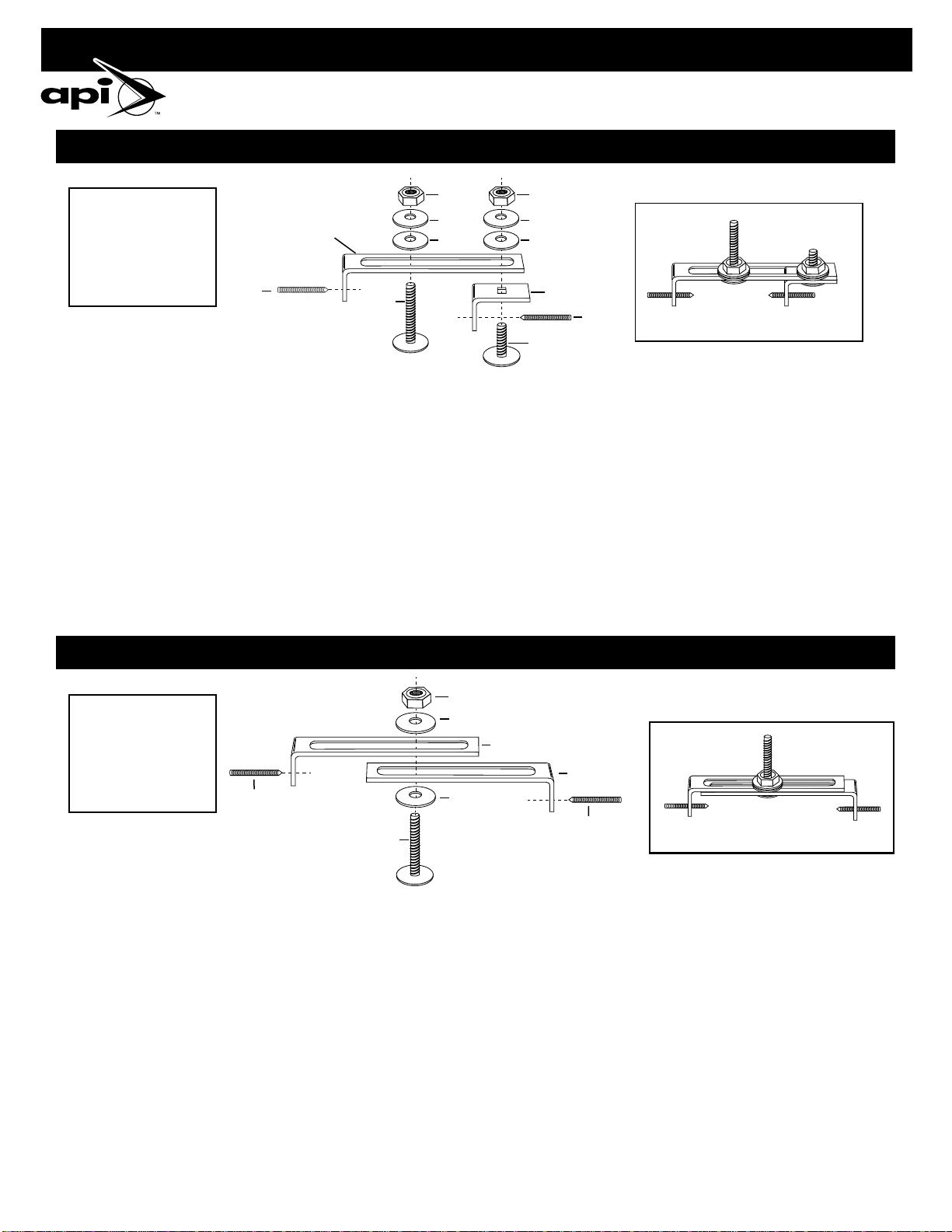

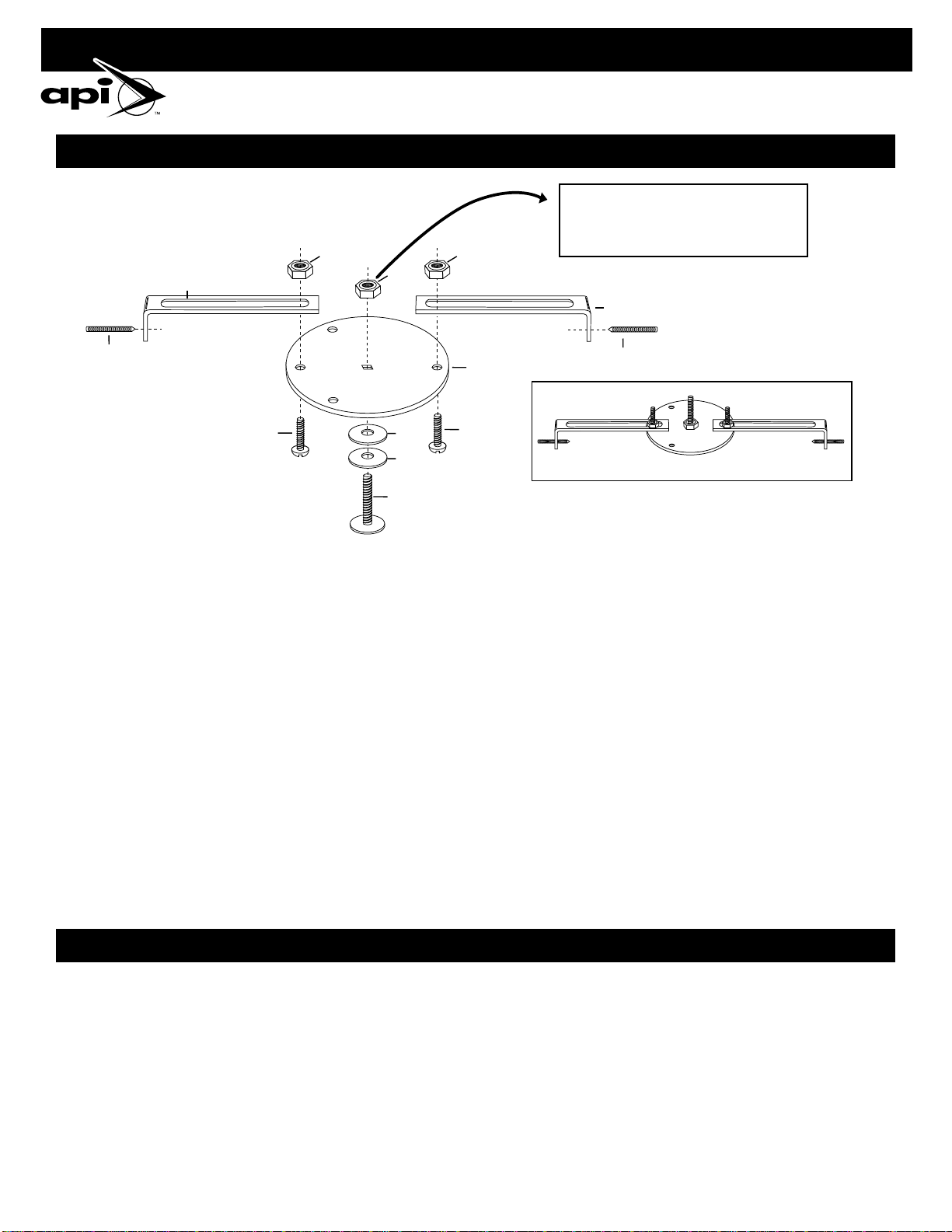

Mounting to your pedestal

1. Assemble bracket following the exploded diagrams above.

2. Back the three set screws (part #F) out as far as possible.

3. Place the mount on the center of the pedestal and center the mount so

the center bolt (part #D) is directly in the center of the pedestal.

4. Loosen the center nut (Note: you do not have to take the mount off

your pedestal to loosen or tighten this nut (part #E), located on top of

the round disc, and open or close the arms so that the mount conforms

to the sides of your pedestal.)

5. Position the arms as tight as possible against the sides of your pedestal.

6. Make sure the center bolt is still positioned in the center of your

pedestal. (If the center bolt is misaligned with the center of your

pedestal – reposition the mount and repeat step #4 again).

7. Tighten the center nut. You must use a wrench and fasten this nut as

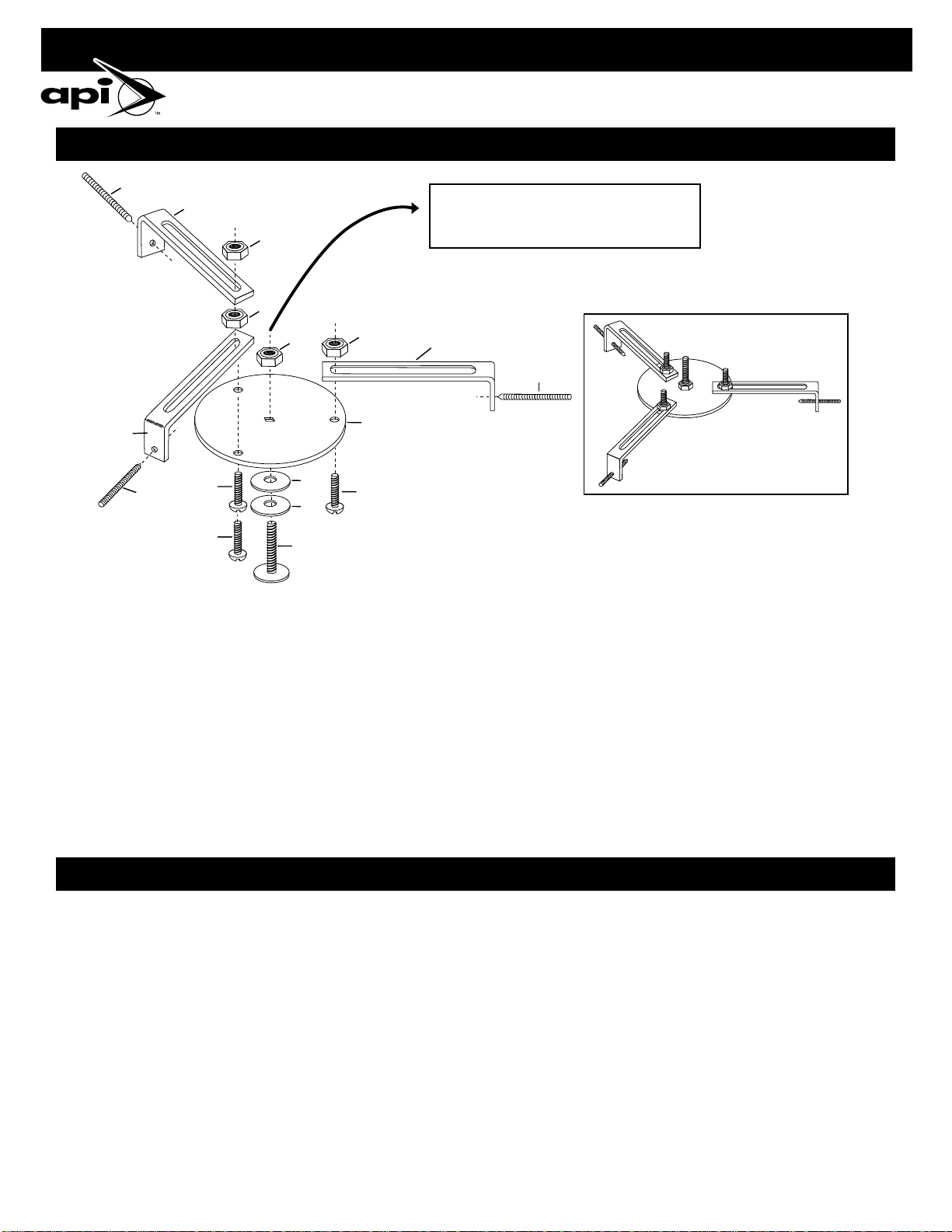

Mounting to a metal pole

1. Follow the exploded diagram for a pedestal 7.25”or less.”Substitute

long set screws (part #G) for short set screws (part #F). Screw each long

set screw (part #G) into each arm (part #A) approximately 1.25”.

2. Do not attach shims (part #B).

3. Place the mount on the center of the pole and center the mount so the

center bolt (part #D) is directly in the center of the pole.

4. Each of the three arms (part #A) should be extended an equal distance

from side of the pole (i.e. the 1.25”distance allowed for each set screw).

If not, loosen the center nut (Note: you do not have to take the mount

off your pole to loosen or tighten this nut (part #E), and open or close

the arms so that the cone points of the long set screws (part #G) rest

against the sides of the pole.

tight as possible. (Note: you do not have to remove the mount from

your pedestal to loosen or tighten this nut).

8. Check to be sure the mount is aligned straight. If the mount is slightly

crooked, move the corresponding arm upward in order to compensate.

9. Use a screwdriver to tighten the three set screws (part #F). Do not over

tighten these screws because this will bend the arms of the mount.

Just tighten each one enough to dig slightly into the surface (if your

pedestal is plastic, the set screws will probably not dig into the surface

which will be sufficient).

10. Place the bath on the center screw and rotate the bath clockwise until tight.

11. If your bath sits crooked, you may remove the bath by rotating counter-

clockwise. Then loosen the proper set screw and adjust the mount by

moving the corresponding arm upward, re-tighten the set screw before

placing your bath back on the mount.

5. Tighten the center nut. You must use a wrench and fasten this nut as

tight as possible. (Note: you do not have to remove the mount from

your pedestal to loosen or tighten this nut).

6. Press on the top of your mount as you tighten the set screws (part #G).

Do not let the mount rise off the pole as you tighten the set screws. The

lowest arm (part #A) should always remain level and flush against

the top of the pole surface. Do not over-tighten the set screws!

7. Place the bath on the center screw and rotate the bath clockwise

until tight.

8. If your bath sits crooked, then you have probably over-tightened the

three set screws. Remove the bath, loosen the three set screws (part #G)

and repeat step 6.

MOUNTING TO A FEEDER POLE OR OTHER METAL POLE

IF MOUNTING TO A PLASTIC PEDESTAL OR IF THE DIAMETER OF YOUR BIRD BATH IS 7.25” OR LESS

1. Place the first arm (part #A) so the dimple in the round disc (part #C) is inside the slot in

the arm (part #A). 2. The slot in the arm (part #A) should be in a straight line with the dimple,

the square hole and the round hole on the edge of the disc. 3. Make sure the dimple is at

the opposite end from the right angle bend in the arm (part #A). 4. Proceed with placing the

other two arms (part #A) in place followed by the washers (part #K) and elevator bolt (part #D)

as shown in the diagram labeled Assembly #2.

Attachment of Shims

Only if your bird bath pedestal is hollow or has a hole in the center, attach the three

shims (part #B) as shown. These enable the mount to rest level. Two shims should be

placed on the first arm (part #A) which rests against the round disc (part #C). One shim

should be placed on the middle or second arm which is “sandwiched” between the first

and third arm. No shims should be attached to the third arm.

The bracket has been preassembled in this position and is attached to the bottom of the bird bath. To remove, simply spin the bracket counterclockwise. You will still have to assemble

the shims – if necessary (see diagram on shim attachment). Loosen the nut (part #E) to allows adjustment of the arms (part #A) to the diameter of your pedestal. Then follow directions

#3 through #10 under “Mounting to your Pedestal”.

(Assemble 1)

Dimple

Round

Hole

Square

Hole

(Assemble 2)

(Exploded Diagram)

(Exploded Diagram)

(Exploded Diagram)

(Finished Diagram)

(Finished Diagram)

(Finished Diagram)

A

A

BB

E

F

F

F

C

D

K

K

A

A

A