Page 1

Colorado Springs, Colorado USA

web site: www.ApogeeRockets.com

The Minii-Condor rocket is another ne product from:

Kit #05008

Mini-Condor

(Competition Boost Glider for 1/2A & A

motors)

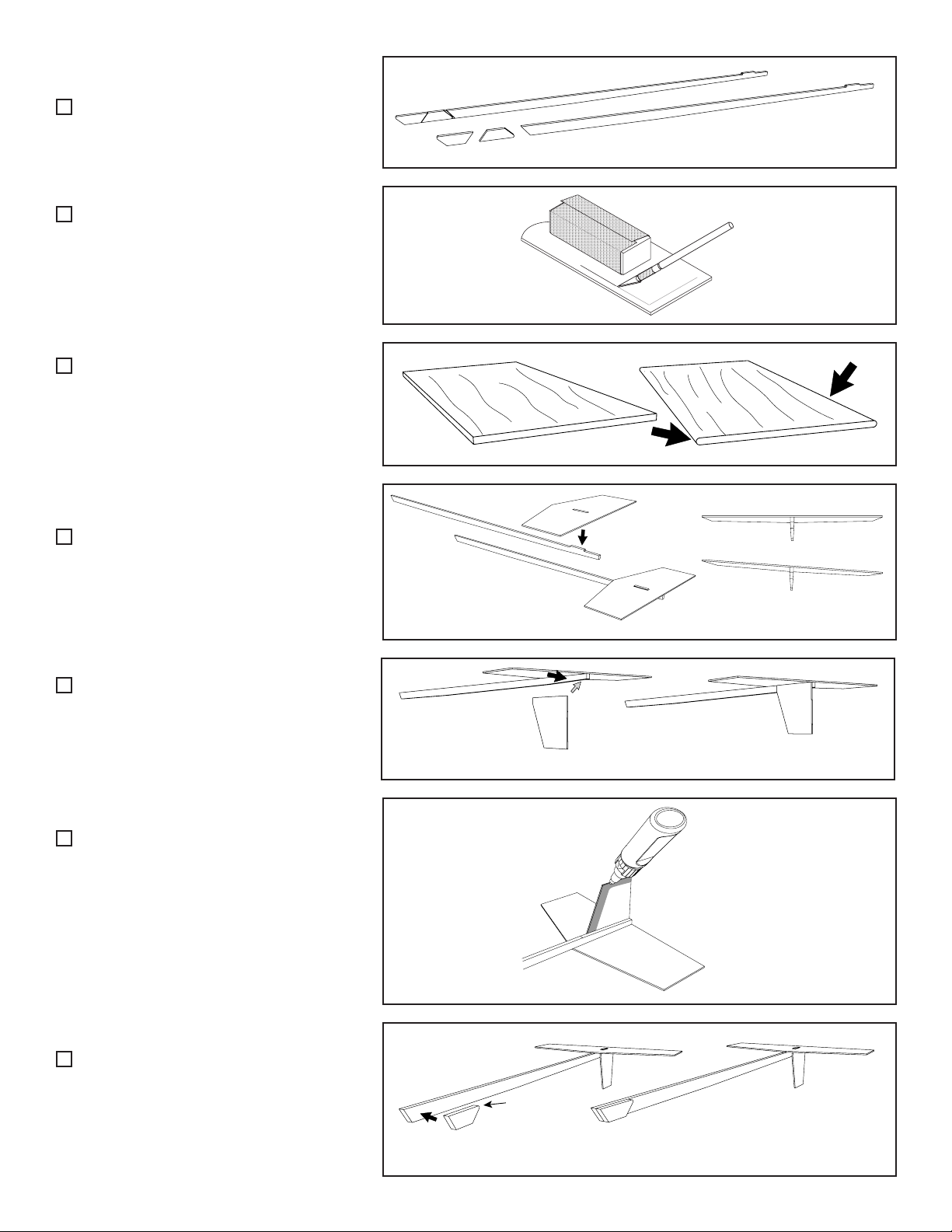

P/N Description Qty

10058 AT-13/9.0” Body Tube 1

13020 CR 10-13 Green Engine Block 1

13051 1/8” Launch Lug 1” Long 1

15578 Tail Fins 1/32” X 3” X 6” Balsa 1

15579 Wing Panel 3/32” X 3” X 6” Balsa 2

15581 Fuselage Boom 3/32” Basswood 1

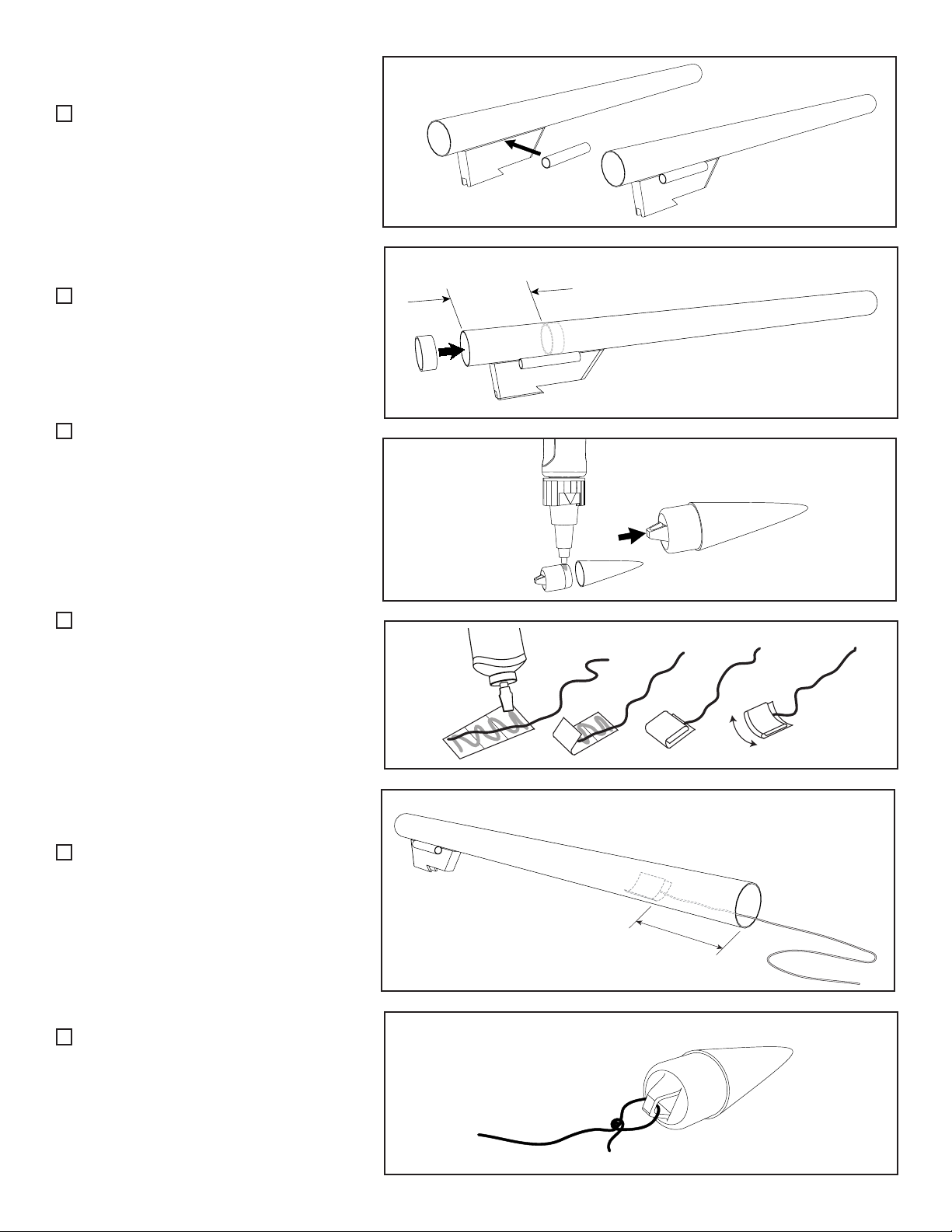

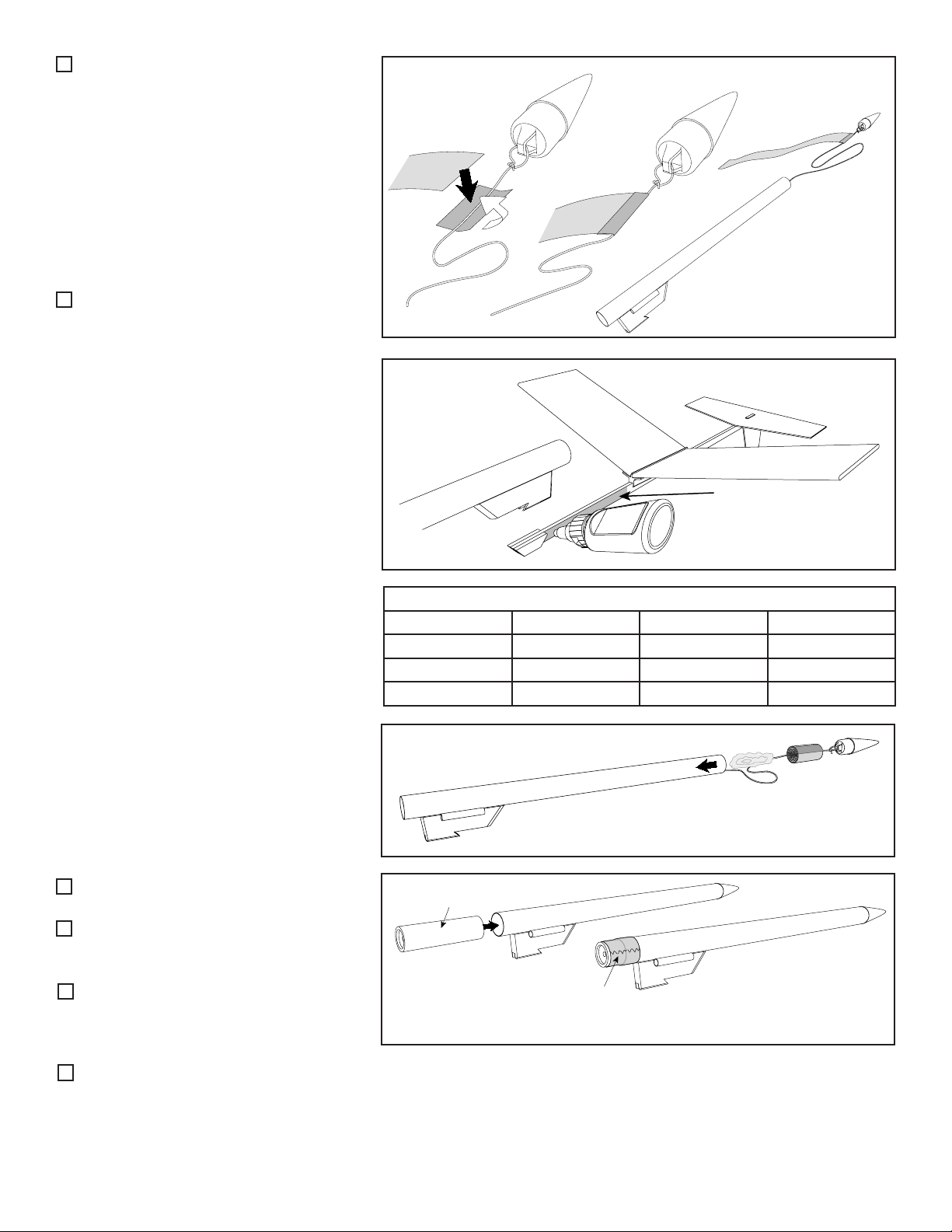

17061 Wing Dihedral Attachment (resin) 1

17062 Pop-Pod Attachment Hook (resin) 1

19100 PNC-13A Nose 1

19101 PNC-13A Shoulder 1

29514 100# Kevlar X 3 ft 1

29004 2” Mylar Streamer x 18” 1

29600 Clay Nose Wt (5g) 1

31130 Mini-Condor Instruction Sheet A 1

31131 Mini-Condor Instruction Sheet B 1

47122 Clear Plastic Bag 6x14x2mil 1

Other Tools and Materials Needed

Pencil

Hobby knife

Wood glue

Super glue (thick viscosity)

Plastic packaging tape

Paint supplies (spray paint, brushes, etc.)

Wood sealer

Sandpaper (220 and 400 grit)

Wood dowel for spreading glue inside tubes

Mini-Condor

p/n 31130

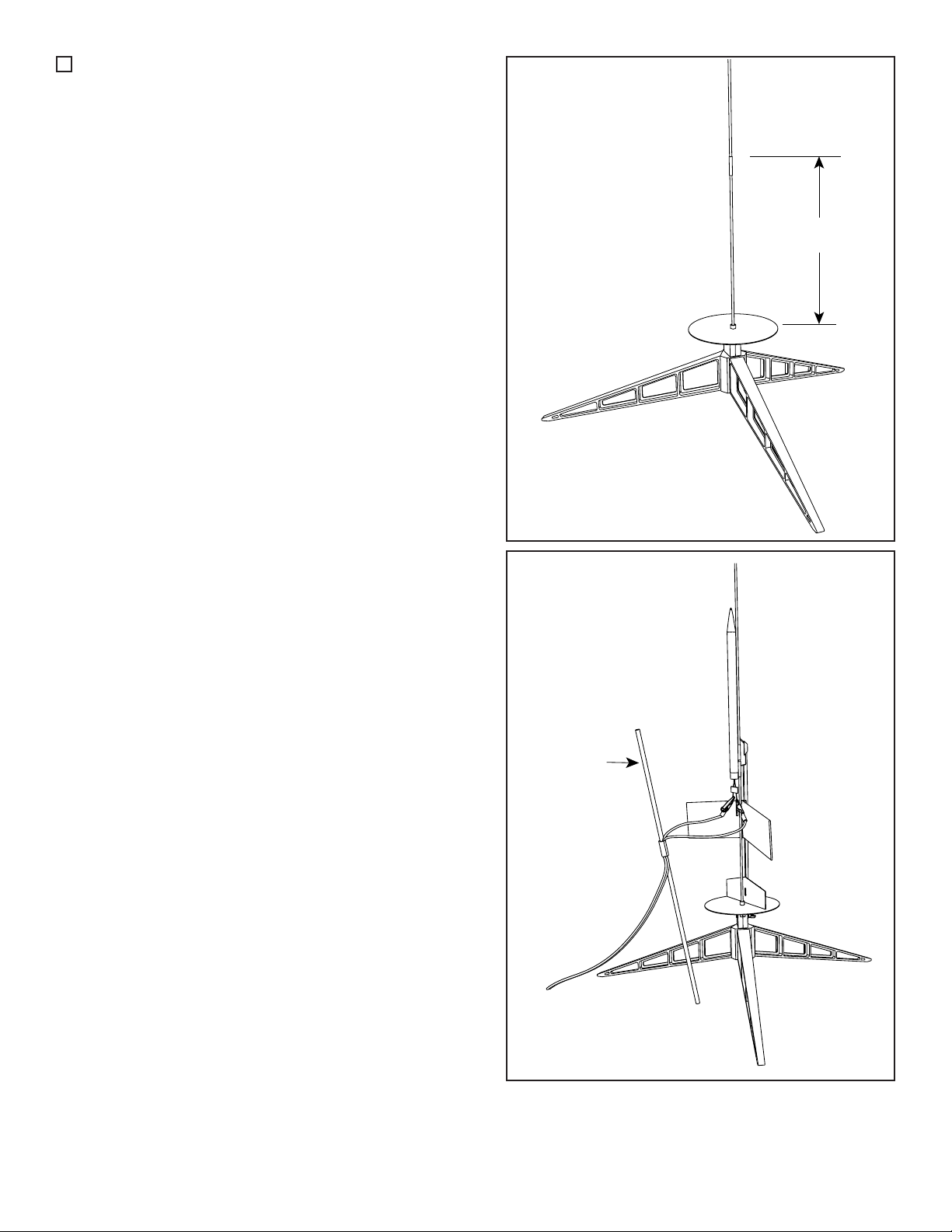

Shock Cord Anchor Pattern

The Mini-Condor is an easy-to-build glider that rst

timers can use to get a successful glide. Seasoned

competitors will love it because it performs like a

champ. It boosts straight and transitions easily into a

nice, thermal-hunting glide.

The design has similar features to the larger Condor

that makes it such a great boost-glider. The primary

component is a pre-molded plastic wing dihedral at-

tachment piece that assures that the wings are at the

proper dihedral angle with respect to the fuselage,

and that the wings are pitched up slightly. This forces

the glider to right itself so that the top is towards the

sky, and the glider pull out of a dive. This piece is what

makes it easy to trim to get a nice, steady glide.

The other unique feature is a molded pop-pod hook.

This piece allows the pop-pod to be easily attached to

the glider and to detach when the streamer deploys. All

the complexity has been removed from the model, so it

is a joy to build and it trims easily.

The glider was designed for use as a competition

model for using either mini-engines with 1/2A or A-size

total power.

Skill Level 3: Average Skills Needed