DOC PN:260-0922 DOC DESC: Model 851 User Manual SEPTEMBER2022. REVISION: 04

APPLIED PHYSICS SYSTEMS, INC. |APPLIEDPHYSICS.COM

6.2 –MODEL 851 SYSTEM ASCII DATA REQUEST COMMANDS ..........................................................15

6.2.1 -ASCII RATE COMMAND (KEYBOARD COMMAND 6, 0X36 HEX)..........................................15

6.2.2 -ASCII ACCELEROMETER COMMAND (KEYBOARD COMMAND 7, 0X37 HEX)..............15

6.2.3 -ASCII SEND 851 CONFIG DATA COMMAND (KEYBOARD COMMAND R, 0X72 HEX)

............................................................................................................................................................................................. 16

6.3 -MODEL 851 CONFIGURATION COMMANDS......................................................................................17

7-CORRECTIONS TO THE GAMMA COUNT RATE FOR USE IN MWD SYSTEMS ........................18

7.1 -PRESSURE BARREL CORRECTION (PB CORRECTION)...................................................................19

7.2 -DRILL COLLAR AND DRILLING FLUID CORRECTION (CM CORRECTION) .......................... 20

8-NET SYSTEMS........................................................................................................................................................22

8.1 -NET PACKET DESCRIPTION.........................................................................................................................23

8.2 -NET PROTOCOL.............................................................................................................................................. 24

8.3 -THE CRC PROGRAM..................................................................................................................................... 25

A-MODEL 851 CONFIGURATION COMMAND REFERENCE................................................................ 28

TABLES

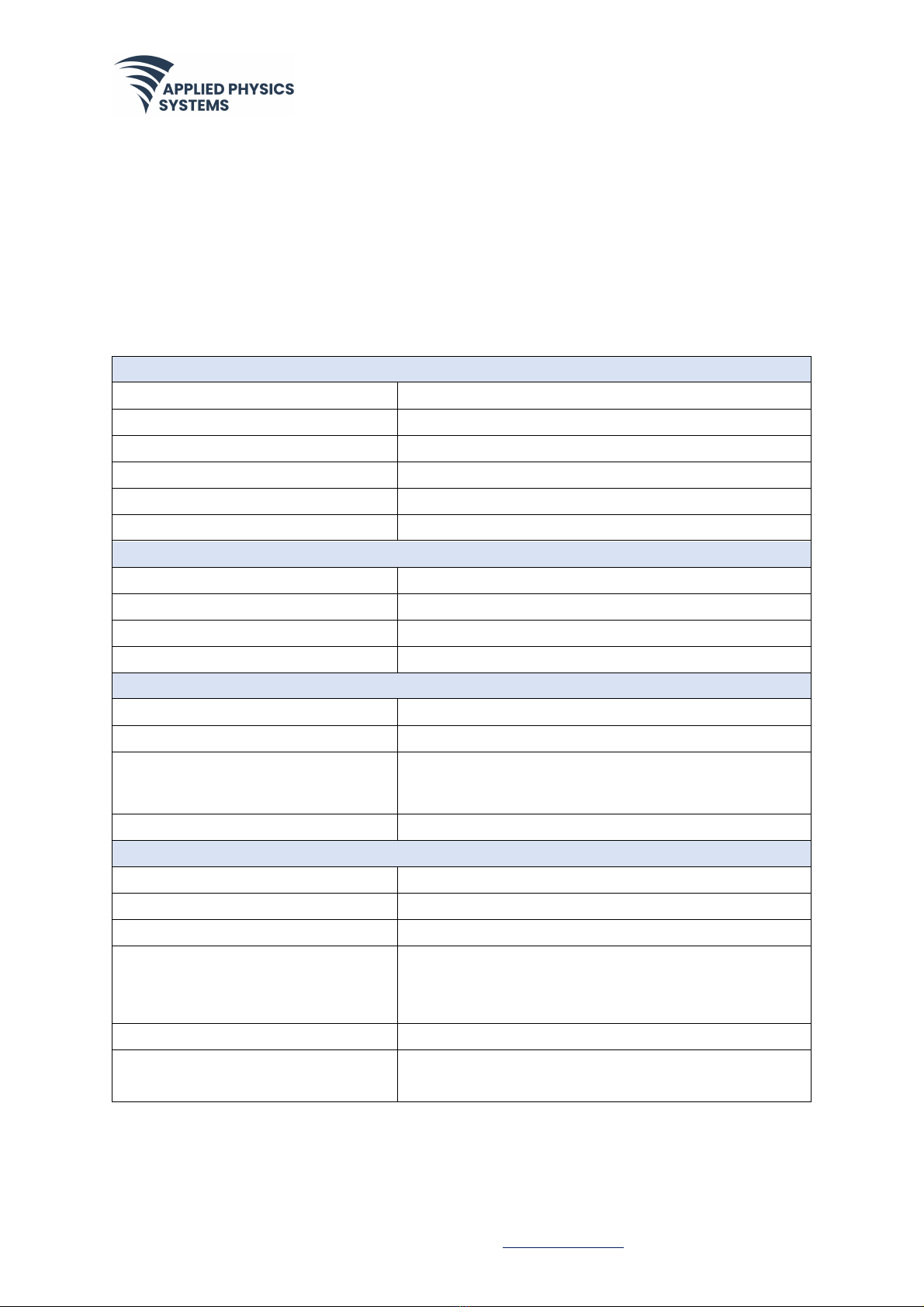

Table 1. Model 851 Gamma Sensor Specifications ............................................................................6

Table 2. Model 851 Electrical Interface.......................................................................................................8

Table 3. Model 851 Data Request Commands.....................................................................................11

Table 4. ID Command Format Example Key.........................................................................................12

Table 5. Binary Count Command Format Example Key...............................................................13

Table 6. Rate Command Format Example Key...................................................................................14

Table 7. Send Model 851 Config Command Format Example Key ....................................... 16

Table 8. Model 851 Configuration Commands ...................................................................................17

Table 9. NET Packet Key......................................................................................................................................23

Table 10. NET Directional Sensor Command Key ............................................................................. 25

Table 11. Model 851 Configuration Commands ................................................................................. 28

FIGURES

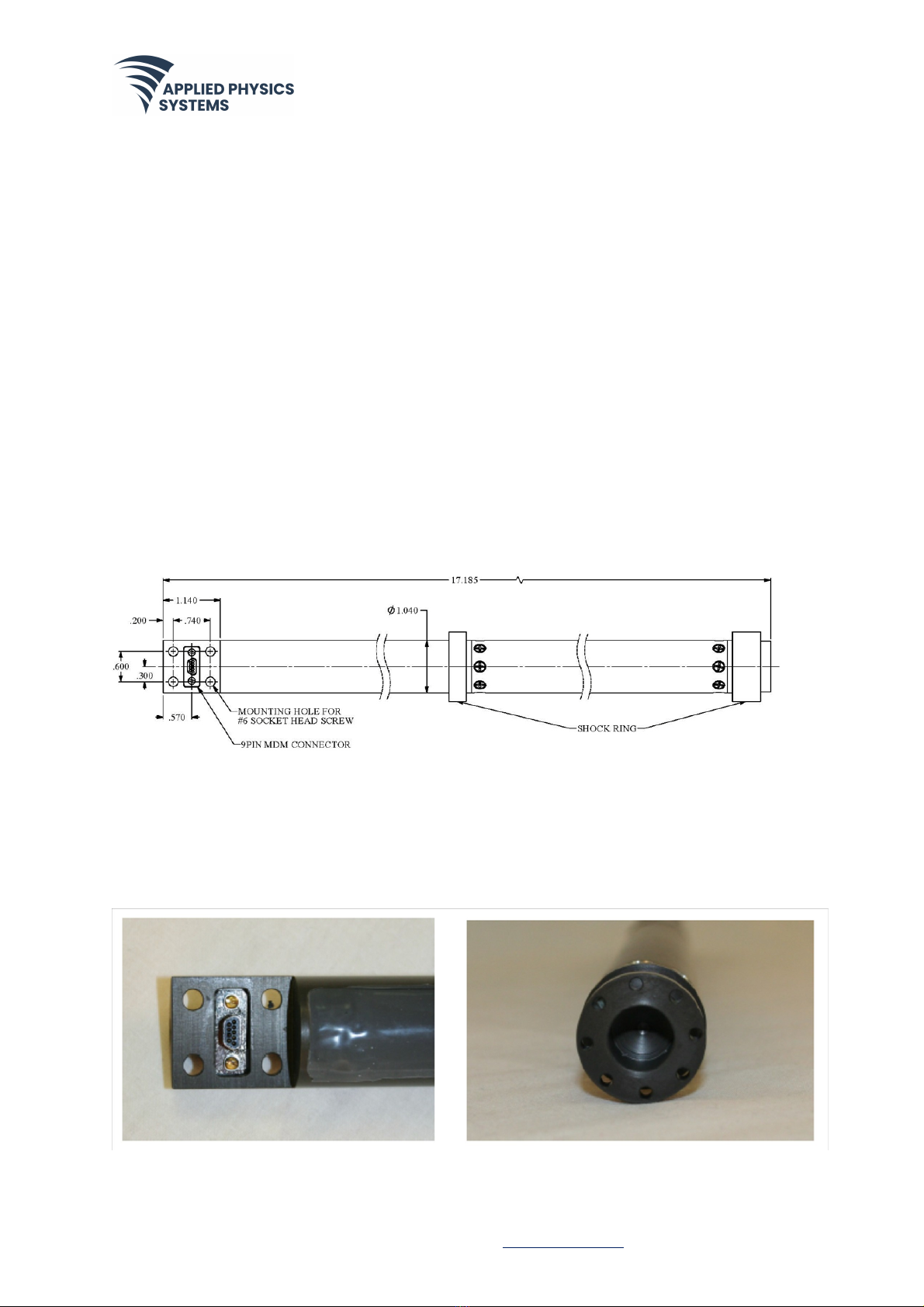

Figure 1. Model 851 Sensor with Shock Mount Rings.......................................................................... 7

Figure 2. Model 851 Connectors...................................................................................................................... 7

Figure 3. Pressure Barrel Correction Factors in Inches ..................................................................19

Figure 4. Pressure Barrel Correction Factors in Centimeters .................................................. 20