CONTENTS

TABLE DES MATIÈRES

1 SAFETY............................................................ 3

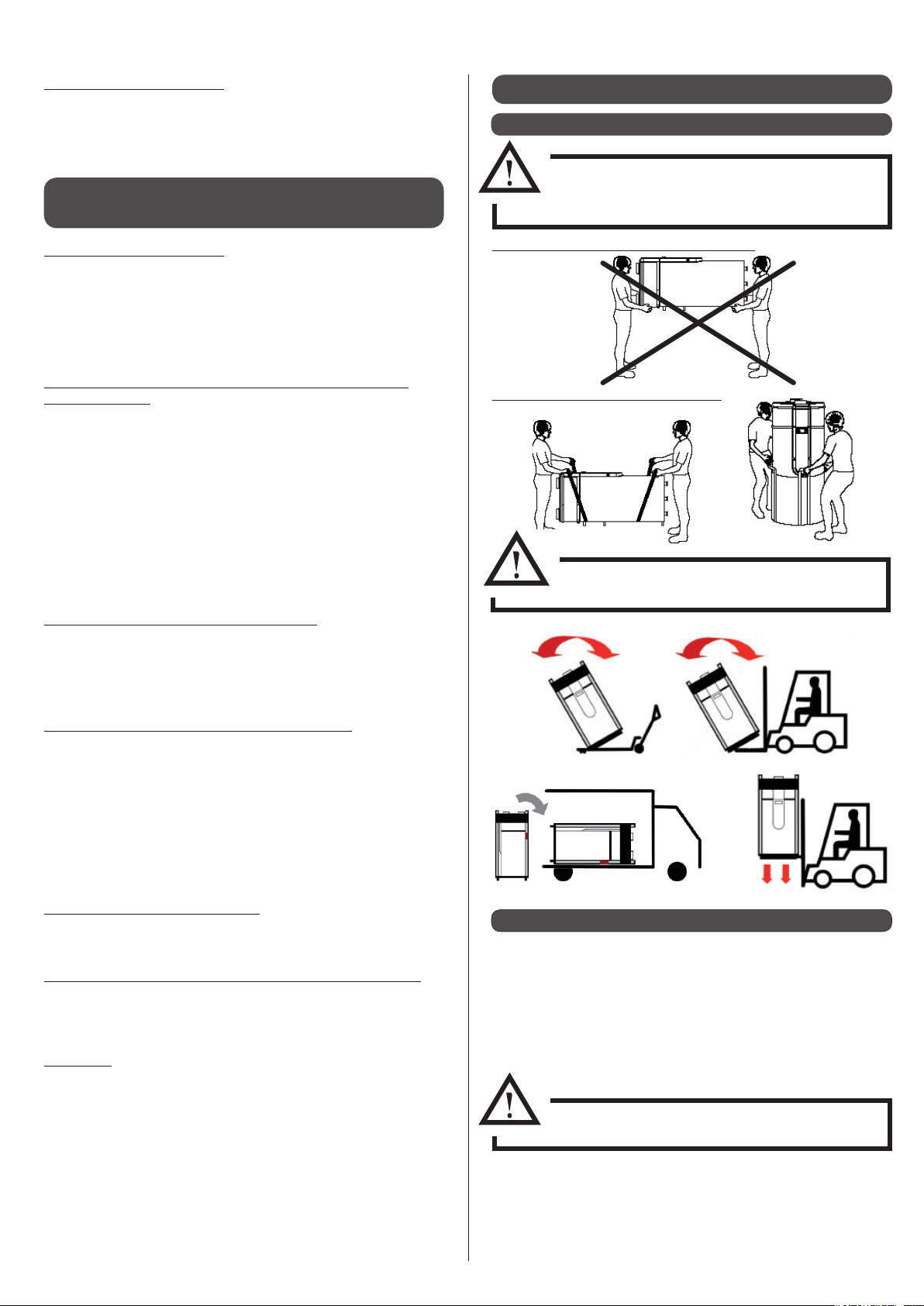

1.1 - Storage and transport........................................................................3

1.1.1 - On-site installation................................................................................................... 3

1.1.2 - Unpacking...................................................................................................................3

1.1.3 - Contents of package ............................................................................................... 4

1.1.4 - Symbols used............................................................................................................. 4

1.1.5 - Storage......................................................................................................................... 4

2 INSTALLATION................................................ 4

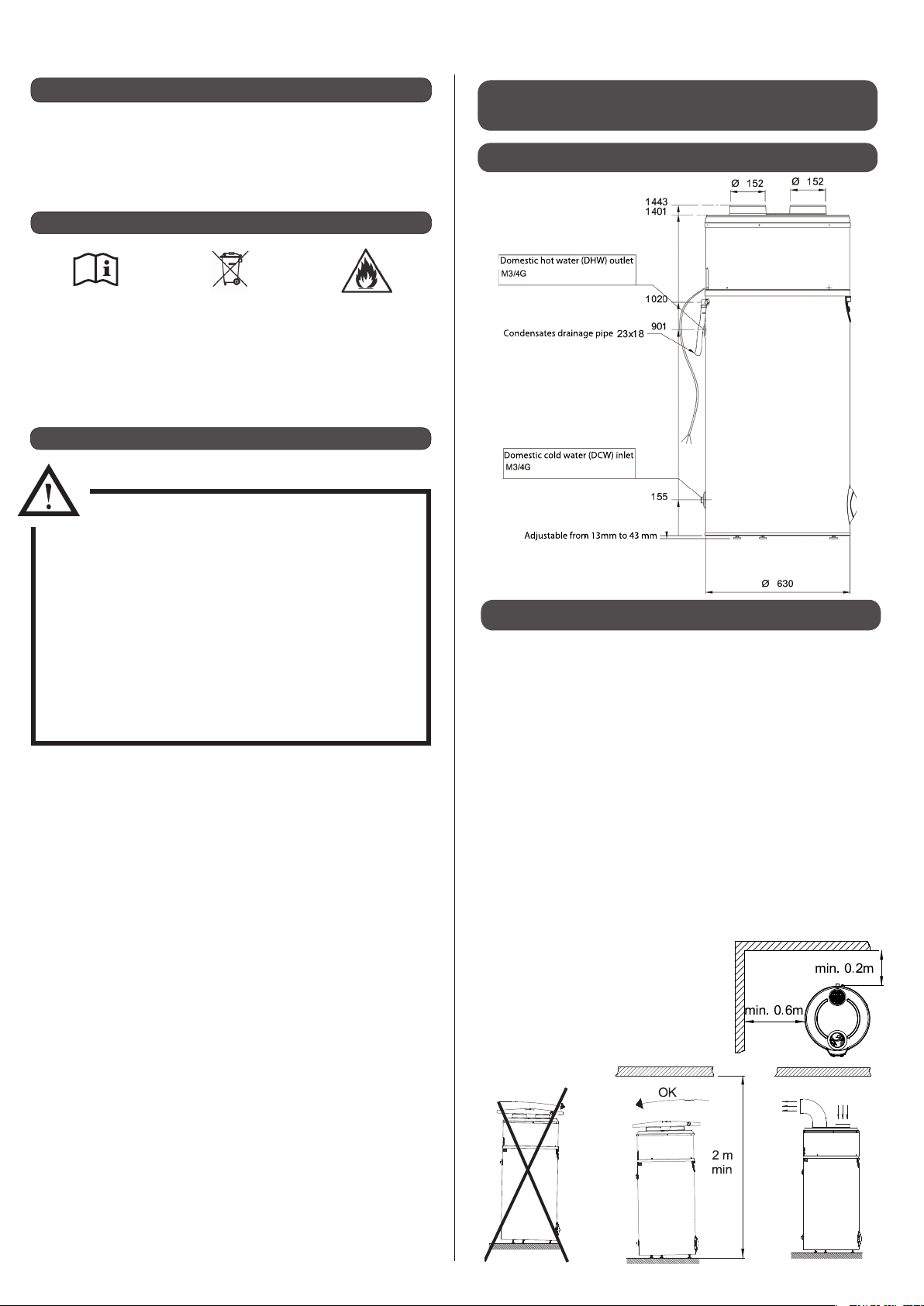

2.1 - Dimensions ............................................................................................4

2.2 - Choosing the right place...................................................................4

2.3 - Air connection ......................................................................................5

2.3.1 - Without piping...........................................................................................................5

2.3.2 - With piping ................................................................................................................. 5

2.4 - Pipe dimensions...................................................................................5

2.4.1 - Ventilation accessories............................................................................................ 5

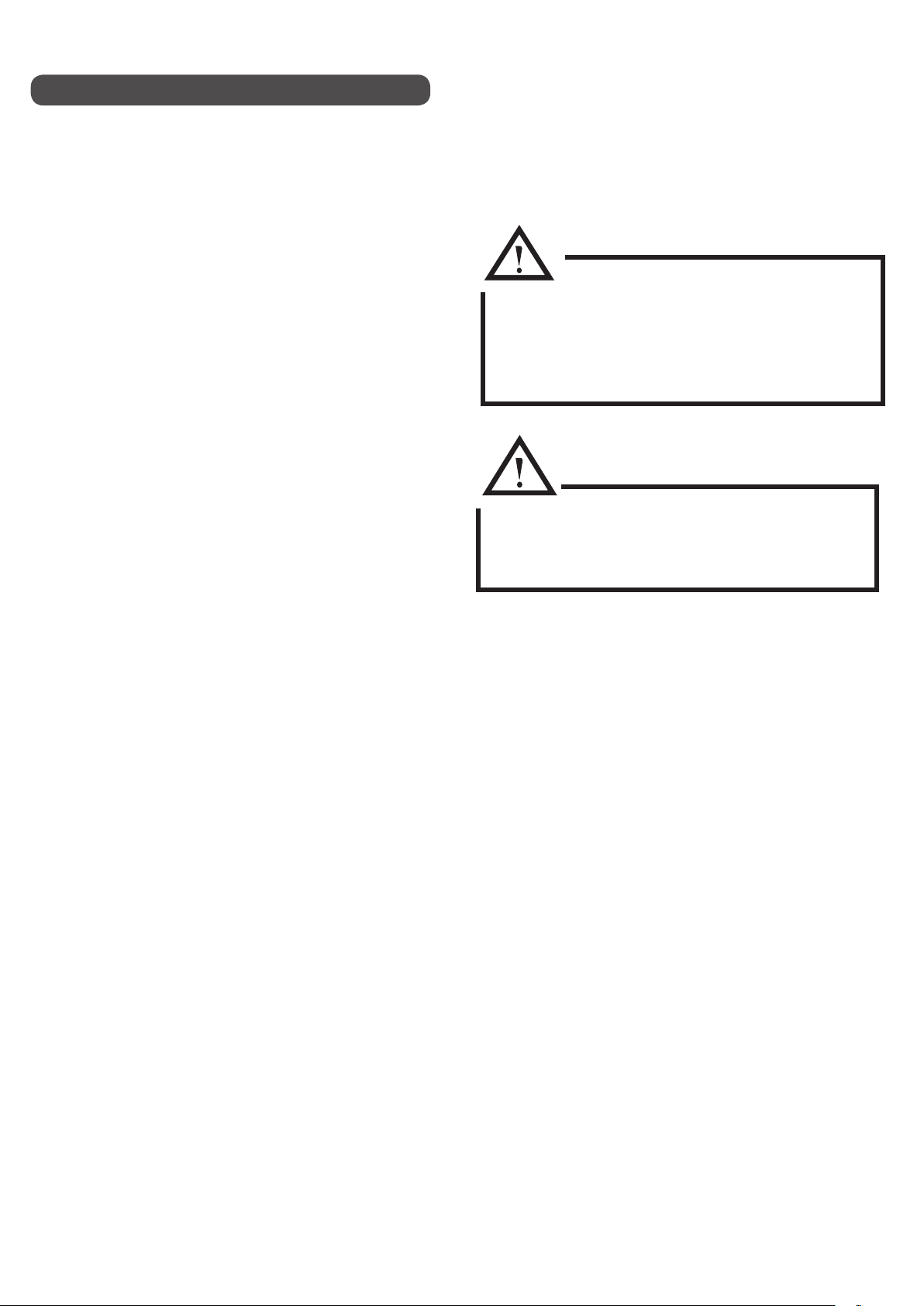

2.5 - Plumbing connections.......................................................................6

2.6 - Condensates drainage.......................................................................7

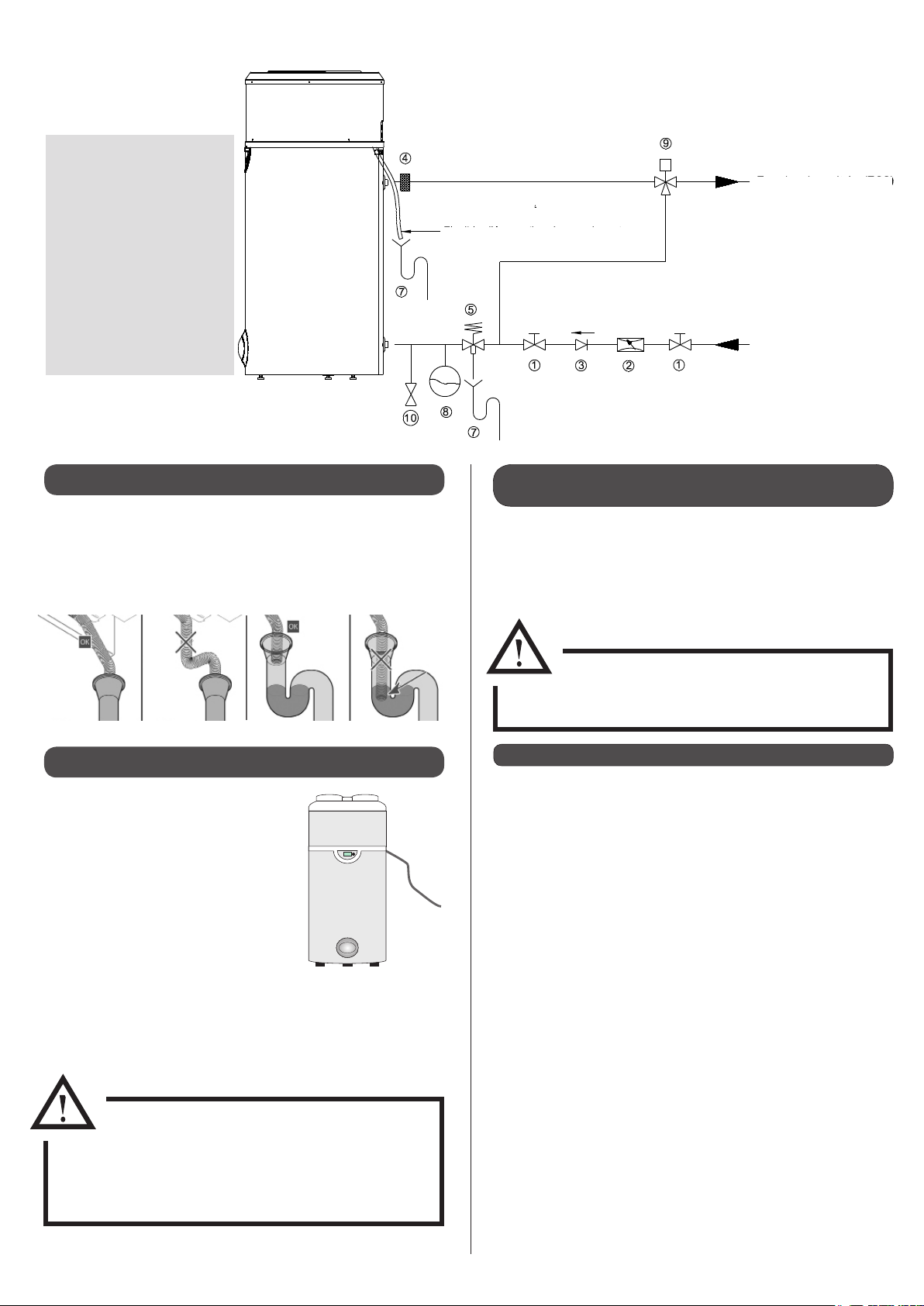

2.7 - Electrical connections ........................................................................7

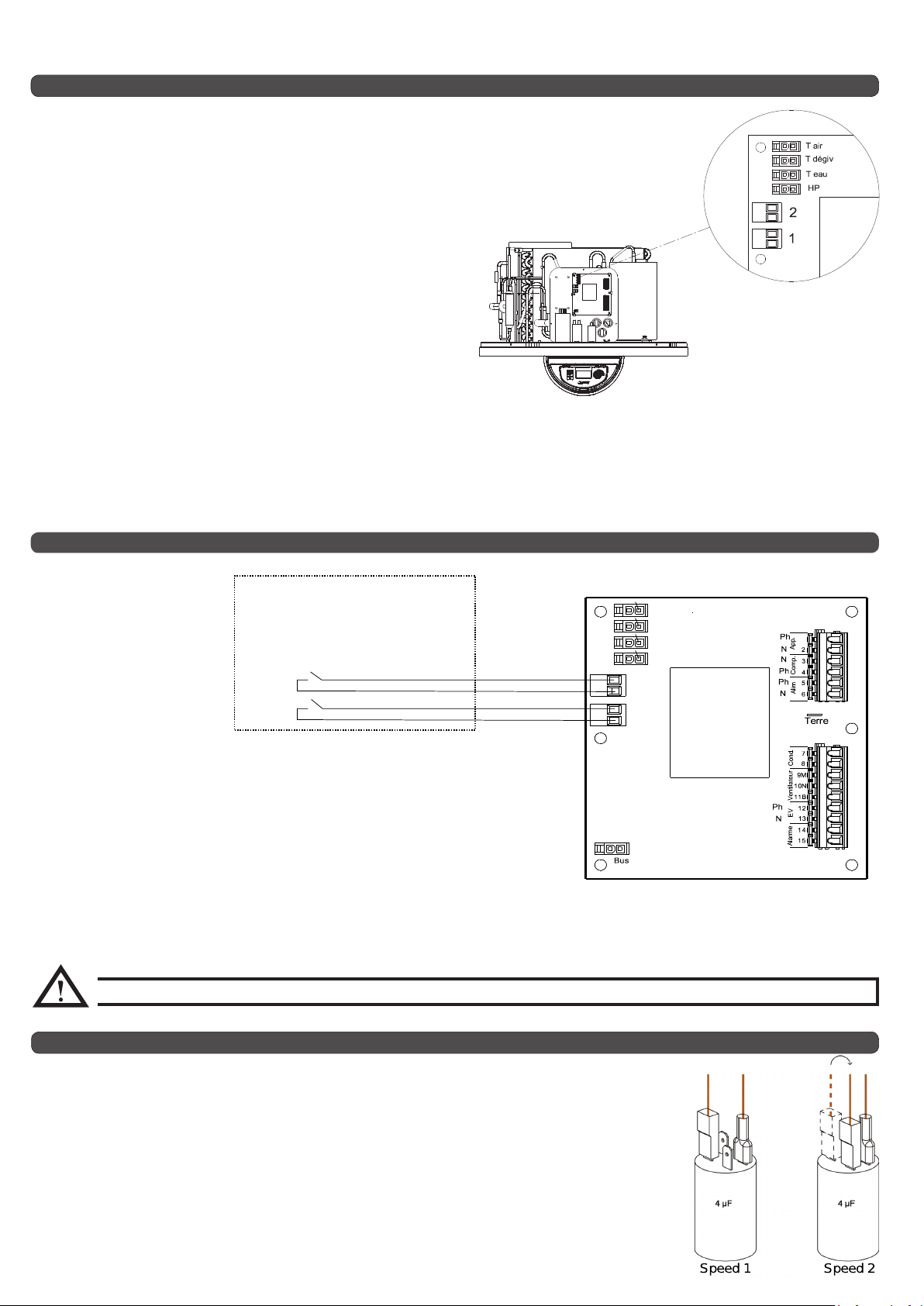

2.7.1 - External control (o-peak operation, controlled ventilation) ..................7

2.7.1.1 -Controlled ventilation............................................................................. 7

2.7.1.2 - Electricity provider contact ..................................................................8

2.7.1.3 - Connecting the PV function................................................................. 8

2.7.2 - Changing the fan speed......................................................................................... 8

3 SETUP AND USE............................................ 9

Filling the hydraulic circuit.........................................................................9

3.1 - Control box ............................................................................................9

3.2 - Setting the language..........................................................................9

3.3 - Setting the time...................................................................................9

3.4 - Setting the water temperature.....................................................10

3.4.1 Settings in PV mode.................................................................................................10

3.5 - Standby mode ....................................................................................10

3.6 - BOOST function

(for occasional use and guaranteed comfort) ..................11

3.8 - Programming .....................................................................................11

3.7 - Electric mode

(to operate with electrical backup) ....................................11

3.9 - Installer menu .....................................................................................12

3.9.1 - PV mode.....................................................................................................................12

3.9.2 - Adjusting the operating settings......................................................................12

3.9.2.1 - ANTI-BACT Cycle anti-légionellose .......................................13

3.9.2.2 - mode vent Mode de ventilation..........................................13

3.9.2.3 - T°C. MINITempérature mini .............................................13

3.9.2.4 - delestage Degré

d’autorisation en heures pleines.......................................................... 13

3.9.2.5 - Max time Max heating time......................................13

3.9.3 - Locking the keyboard...........................................................................................14

3.9.4 - Resetting parametres............................................................................................14

3.9.5 - Reading data ............................................................................................................14

3.9.6 - Counters (meters)...................................................................................................14

4 MAINTENANCE AND REPAIRS ....................15

4.1 - Water circuit / condensate draining............................................15

4.2 - Air intake circuit..................................................................................15

4.4 - Troubleshooting.................................................................................16

4.5 - Sensor data ..........................................................................................16

4.5 - Parts........................................................................................................16

4.7 - Error message codes: errors, solutions and operating in case

of error...................................................................................................18

5 WARRANTY ...................................................20

5.1 - Warranty limits....................................................................................20

5.1.1 - General information ..............................................................................................20

5.1.2 - Exclusion from warranty ......................................................................................20

5.1.2.1 - Use...............................................................................................................20

5.1.2.2 - Handling....................................................................................................20

5.1.2.3 - Installation site........................................................................................20

5.1.2.4 - Electrical connections ..........................................................................20

5.1.2.5 - Hydraulic connections .........................................................................20

5.1.2.6 - Accessories...............................................................................................21

5.1.2.7 - Maintenance............................................................................................21

6 APPENDICES.................................................21

6.1 - Performance statistics......................................................................21

6.1.1 - Development of the COP.....................................................................................21

6.1.2 - Heating time.............................................................................................................21

6.2 - Technical data .....................................................................................21

6.3 - Electrical wiring diagram ................................................................22

- INSTALLER - AIR SOURCE HEAT PUMP WATER HEATER -200L- INSTRUCTIONS --

INSTALLER

- AIR SOURCE HEAT PUMP WATER HEATER -200L-

INSTRUCTIONS -

2