Maintenance and Repairs

We recommend an inspection at least once-per-year. Additional checks must take place after extreme

loading. As a rule, the products should be briey checked after each assembly. In the inspection, please pay

attention to any sharp edges which may have occurred or to any possibly loose parts.

Please contact us in the event of missing parts or serious damage to the products.

We will happily clarify with you the further use or the delivery of spare parts of the units. Repairs must be only

be carried out by qualied personnel or following consultation with our employees. On decommissioning

the products, disposal can also be carried out through us.

The inspections must be carried out by qualied personnel. We will be happy to offer you the inspections

carried out by our employees.

Minor visual inspections, for example, of the connectors or the feet can also be done by non-qualied

personnel.

Please contact our competent team for questions about repairs, maintenance or spare part procurement.

Instructions for Use

Our StandardStage 750 platforms have been tested by TÜV with a 750 kN/m2load-bearing capacity.

Therefore, travelling over them in a wheelchair presents no problems. But should you want to

travel on them with larger vehicles, please discuss this with us in advance in order to clarify the

dynamic loads.

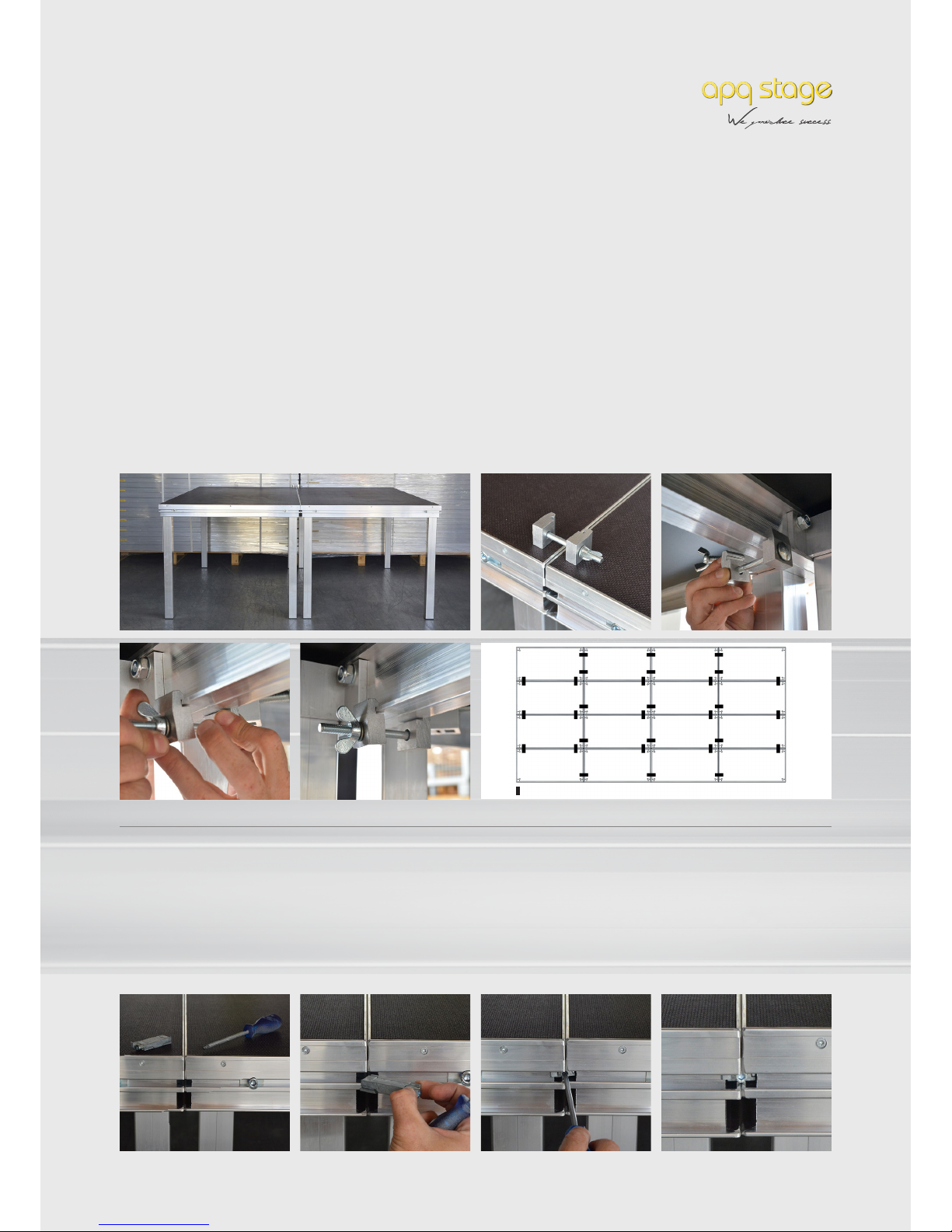

Instructions for Assembly / Dismantling

Before assembling the stage platform, ensure that the load-bearing capacity of the installation site is at

least the same as the nominal load of the platform. Ideally, the platforms should be assembled by two

people. Where appropriate, please wear safety gloves and safety shoes in order to prevent injuries during

assembly / dismantling. In addition, pay attention to the correct and proper use (for example, beech

veneer panels for indoor use only and screen printed panels for indoor and outdoor use) and where

applicable, to additional wind and snow loads.

4