1. Important Information!3"................................................................................................................

1.1. Scope of Manual!3............................................................................................................................................

1.2. Local Standards!3.............................................................................................................................................

1.3. Authorised Person(s)!3......................................................................................................................................

1.4. Component Materials!3.....................................................................................................................................

1.5. Collector Specifications!4..................................................................................................................................

2. Transport, Unpacking and Inspection!5".......................................................................................

2.1. Safe Transportation!5........................................................................................................................................

2.2. Component Lists!5............................................................................................................................................

2.3. Tube & Heat Pipe Unpacking & Inspection!5.....................................................................................................

2.4. Frame Unpacking & Inspection!5.......................................................................................................................

3. System Design!6"..........................................................................................................................

3.1. System Design!6...............................................................................................................................................

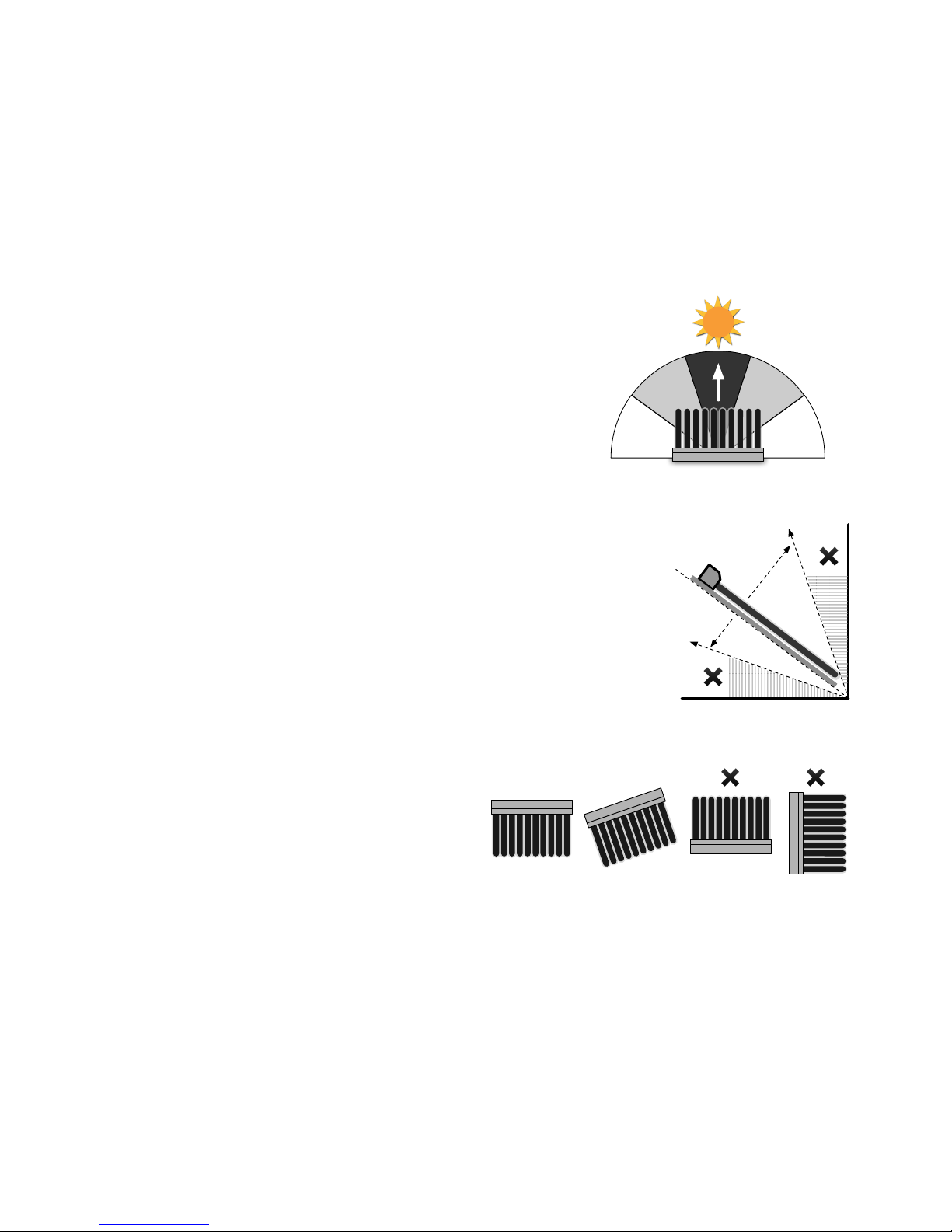

3.2. Collector Direction!6..........................................................................................................................................

3.3. Installation Angle!6............................................................................................................................................

3.4. Collector Plane!6...............................................................................................................................................

3.5. Avoid Shade!6...................................................................................................................................................

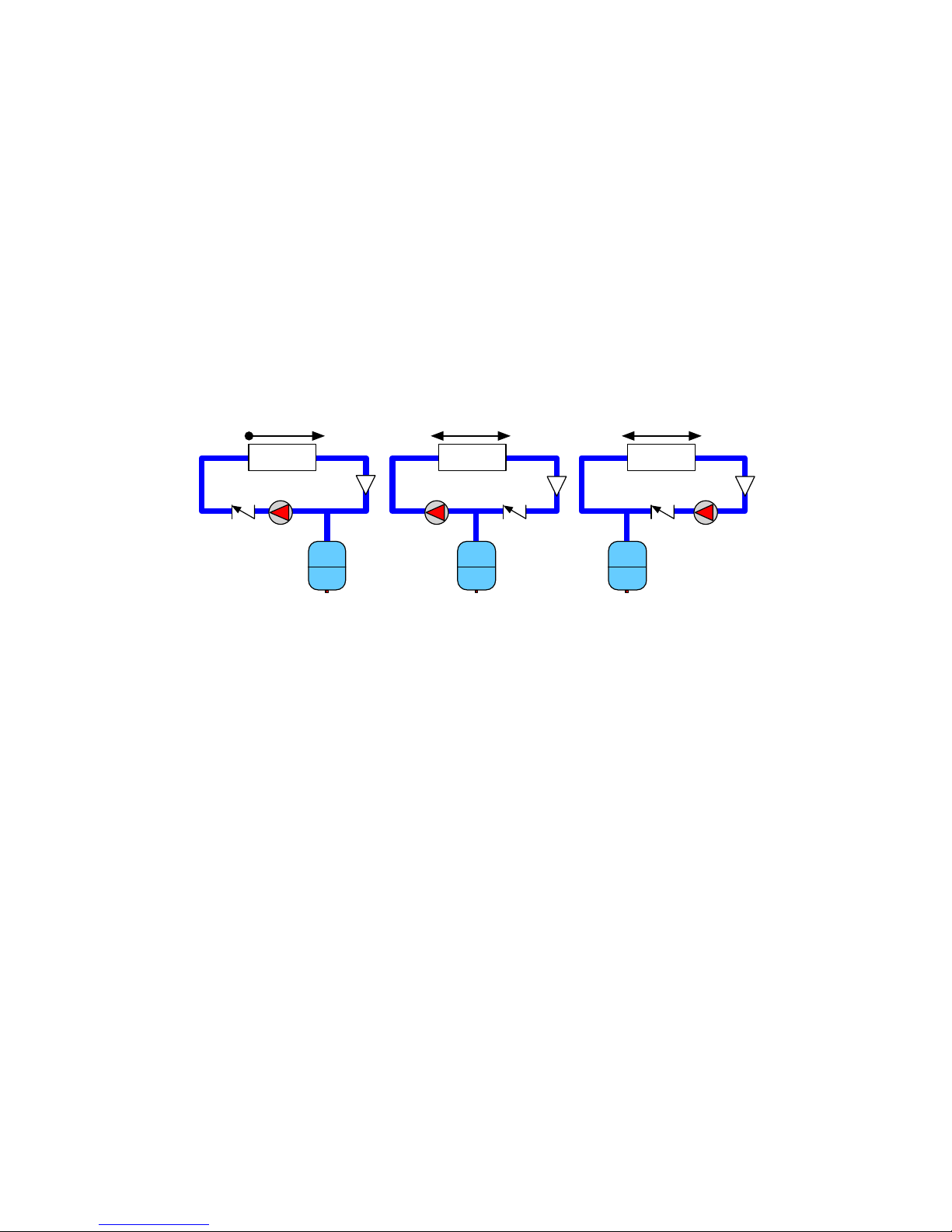

3.6. Collector and Tank Location!6...........................................................................................................................

3.8. Heat Transfer Fluids!7........................................................................................................................................

3.9. Solar Controller Settings!7.................................................................................................................................

3.10. Correct System Sizing!7..................................................................................................................................

3.11. Stagnation and Overheating!7.........................................................................................................................

3.12. Pressure and Temperature Control and Relief!8...............................................................................................

3.13. Freeze protection!8.........................................................................................................................................

3.14. Wind Loading!9...............................................................................................................................................

3.15. Snow Load!9..................................................................................................................................................

3.16. Hail Resistance!9............................................................................................................................................

3.17. Lightning!9......................................................................................................................................................

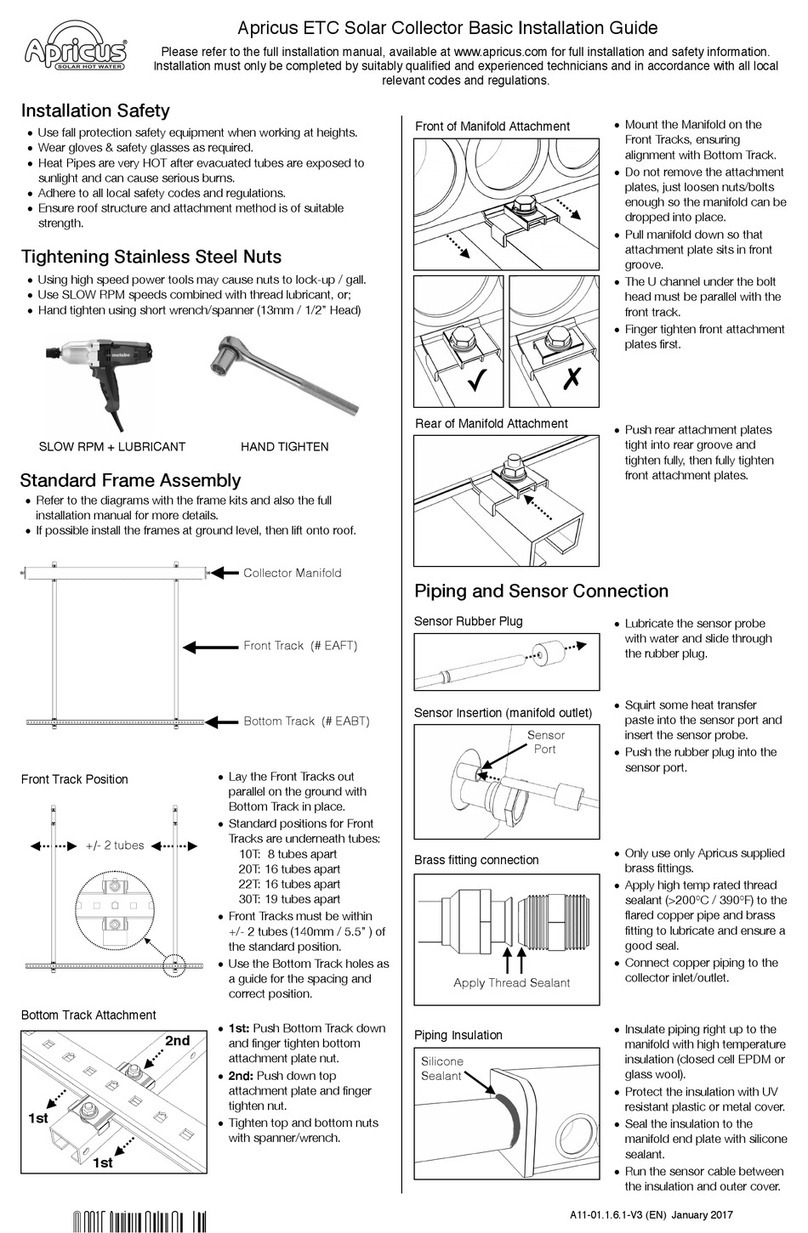

4. Collector Mounting!10"..................................................................................................................

4.1. Frame Material!10.............................................................................................................................................

4.2. Roof Attachment Strength!10............................................................................................................................

4.3. Galvanic Reaction!10........................................................................................................................................

4.4. Installation Planning!10......................................................................................................................................

4.5. Frame Assembly Process!10.............................................................................................................................

4.6. Frame Attachment Points!10.............................................................................................................................

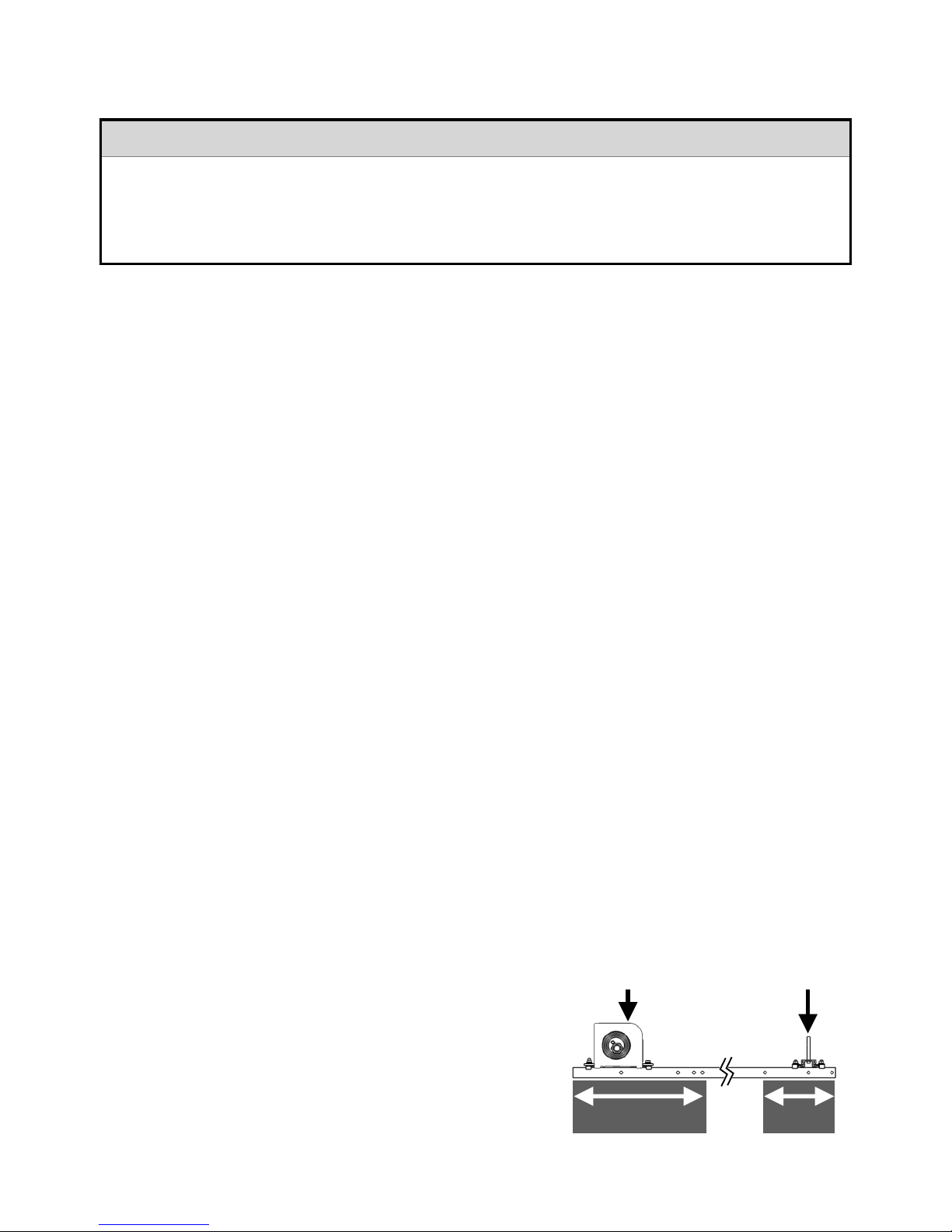

4.7. Frame Front Track & Leg Spacing!11................................................................................................................

4.8. Standard Frame Overview!12............................................................................................................................

4.9. Angled Frame!13...............................................................................................................................................

4.10. Frame Attachment Option (Roof Rails)!14........................................................................................................

4.11. Frame Attachment Option (U Feet)!15.............................................................................................................

4.12. Frame Option (Leg Extensions)!16...................................................................................................................

4.13. Mounting Frame Leg Length & Feet Spacing!17..............................................................................................

4.14. Mounting Frame (Depth & Height Dimensions)!18...........................................................................................

4.15. Wall Mounting!19............................................................................................................................................

4.16. Manifold Attachment!20..................................................................................................................................

4.17. Bottom Track Attachment!20..........................................................................................................................

5. Piping Connection!21"...................................................................................................................

5.1. Collector Connection to Plumbing!21................................................................................................................

5.2. Pipe Size and Flow Rates!21.............................................................................................................................

5.3. Flow Rate & Temperature Rise!22.....................................................................................................................

5.4. Pressure Drop Curve!22....................................................................................................................................

5.5. Pump Selection!22............................................................................................................................................

5.6. Pipe Insulation!23..............................................................................................................................................

5.7. System Filling & Air Purge!23.............................................................................................................................

6. Evacuated Tube Installation!24"....................................................................................................

6.1. Tube & Heat Pipe Preparation!24......................................................................................................................

6.2. Tube & Heat Pipe Insertion!24...........................................................................................................................

6.3. Post Installation Cleaning!25.............................................................................................................................

7. Temperature Sensor Installation!25"..............................................................................................

7.1. Temperature Sensors!25...................................................................................................................................

8. Post Installation Check!26"...........................................................................................................

9. Maintenance!27"............................................................................................................................

9.1. Cleaning!27.......................................................................................................................................................

9.2. Other Components!27......................................................................................................................................

9.3. Broken Tube Replacement!27...........................................................................................................................

9.4. Insulation!27......................................................................................................................................................

9.5. Draining the Collector!28...................................................................................................................................

9.6. Other Components!28......................................................................................................................................

10. Troubleshooting!29".....................................................................................................................

11. Disclaimer!30"..............................................................................................................................

12. Manufacturer’s Limited Warranty!31"..........................................................................................

13. Installation Record Form!32.......................................................................................................