Contents

................................................................................................1. Important Information!3

...........................................................................................................................................1.1. Scope of Manual!3

............................................................................................................................................1.2. Local Standards!3

.....................................................................................................................................1.3. Authorized Person(s)!3

...................................................................................................................1.4. Collector Dimensions & Weights!3

.........................................................................................2. Unpacking and Inspection!4

.............................................................................................................................................2.1. Component List!4

......................................................................................................................................................2.2. Inspection!4

............................................................................................................................................................2.3. Frame!4

............................................................................................................3. System Design!4

..............................................................................................................................................3.1. System Design!4

..................................................................................................................................................3.2. Avoid Shade!4

...........................................................................................................................................3.3. Installation Angle!4

.............................................................................................................................3.4. Collector Horizontal Slope!4

..........................................................................................................................3.5. Collector and Tank Location!5

.........................................................................................................................................3.6. Collector Direction!5

......................................................................................................................................3.7. Heat Transfer Fluids!5

...................................................................................................................................3.8. Correct System Sizing!6

.........................................................................................................................3.9. Stagnation and Overheating!6

............................................................................................3.10. Pressure and Temperature Control and Relief!6

.........................................................................................................................................3.11. Freeze protection!6

..............................................................................................................................................3.12. Wind Loading!7

..................................................................................................................................................3.13. Snow Load!7

...........................................................................................................................................3.14. Hail Resistance!7

......................................................................................................................................................3.15. Lightning!7

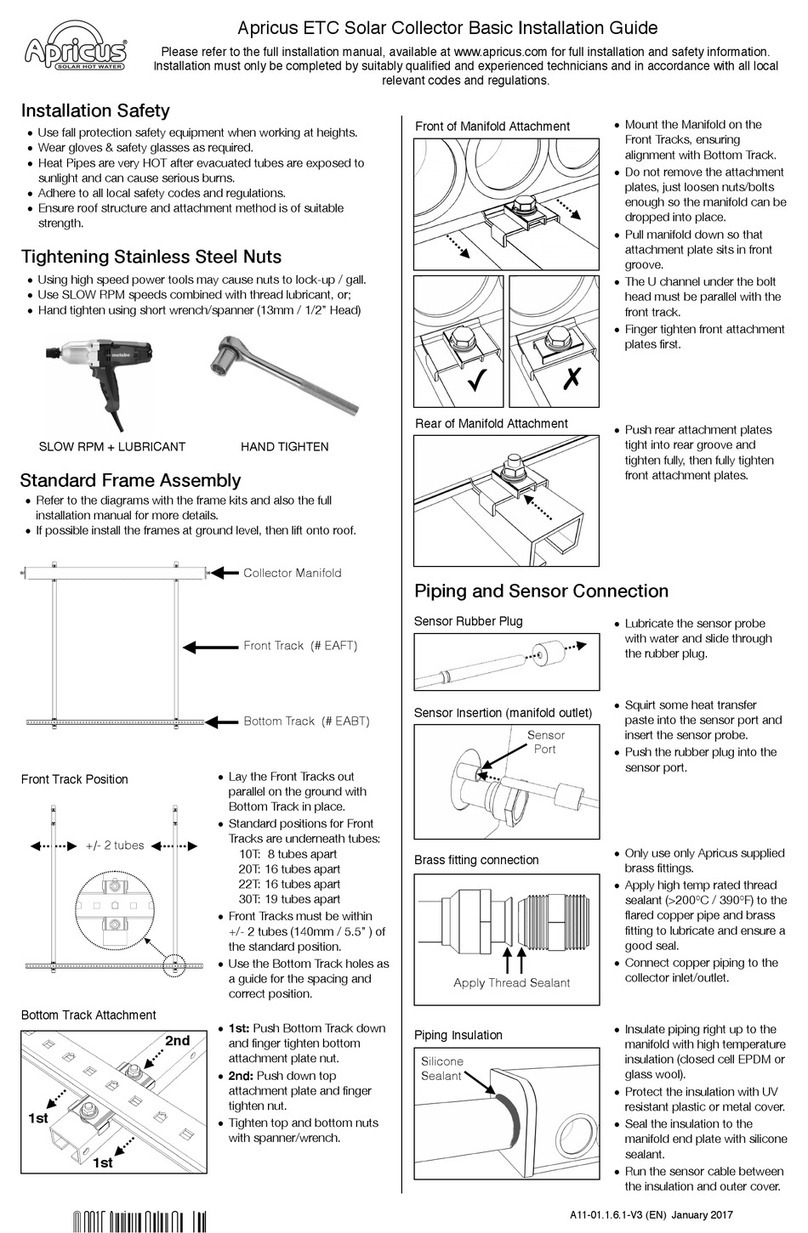

.....................................................................................................4. Collector Mounting!8

..............................................................................................................................................4.1. Frame Material!8

.............................................................................................................................................4.2. Roof Clearance!8

.........................................................................................................................................4.3. Galvanic Reaction!8

......................................................................................................................................4.4. Installation Planning!8

.............................................................................................................................4.5. Frame Assembly Process!8

.............................................................................................................................4.6. Roof Attachment Strength!8

.........................................................................................................................................4.7. Roof Penetrations!9

........................................................................................................................................4.8. Collector Mounting!9

...................................................................................................................4.9. Frame Components Diagrams!10

.......................................................................................................................4.10. Frame Component Details!12

.................................................................................................................................4.11. Angled Frame Guide!14

............................................................................................................................................4.12. Wall Mounting!15

.......................................................................................5. Piping & Collector Layout!16

....................................................................................................................................................5.1. Flow Rate!16

.....................................................................................................................................................5.1. Pipe Size!16

........................................................................................................................5.2. Single Collector Connection!16

...............................................................................................................5.3. Connection of Multiple Collectors!17

.............................................................................................................................................5.4. Pipe Insulation!17

.....................................................................................................................................................5.5. Air Purge!17

...........................................................................................................................................5.6. Pump Selection!18

..............................................................................................................5.7. Pressure Drop Graphs (FPC-A32)!18

.........................................................................................................6. System Control!19

.....................................................................................................................................................6.1. Controller!19

.........................................................................................................................6.2. Temperature Measurement!19

.............................................................................................................................6.3. Solar Controller Settings!19

..............................................................................................................7. Maintenance!19

......................................................................................................................................................7.1. Cleaning!20

......................................................................................................................................7.2. Other Components!20

.....................................................................................................................................................7.3. Insulation!20

.....................................................................................................................................7.4. Broken Glass Cover!20

..................................................................................................................................7.5. Draining the Collector!20

......................................................................................................................................7.6. Other Components!20

........................................................................................................8. Troubleshooting!21

..................................................................................................................9. Disclaimer!22

..........................................................................10. Manufacturer’s Limited Warranty!23

.......................................................................................11. Installation Record Form!24

Apricus FPC-A Flat Plate Solar Collector Installation and Operation Manual

Copyright © 2013 – Apricus Solar Co., Ltd A11.02.1.1-PB-V4 Page 2 of 24