Contents

APRO Rugged Metal 2.5” SATA III MLC SSD – BON-II Series © 2015 APRO Co., Ltd.

CONTENTS

1. INTRODUCTION..................................................................................................................................................- 3 -

1.1. SCOPE....................................................................................................................................- 4-

1.2. SYSTEM FEATURES..................................................................................................................- 4-

1.3. FLASH MANAGEMENT TECHNOLOGY -STATIC WEAR LEVELING..................................................- 4-

1.4. DRAM BUFFER.......................................................................................................................- 5-

1.5. POWER INTERRUPT DATA PROTECTION TECHNOLOGY ...............................................................- 5-

2. PRODUCT SPECIFICATIONS..........................................................................................................................- 6 -

2.1. SYSTEM ENVIRONMENTAL SPECIFICATIONS...............................................................................- 6-

2.2. SYSTEM POWER REQUIREMENTS..............................................................................................- 6-

2.3. SYSTEM PERFORMANCE...........................................................................................................- 6-

2.4. SYSTEM RELIABILITY ...............................................................................................................- 7-

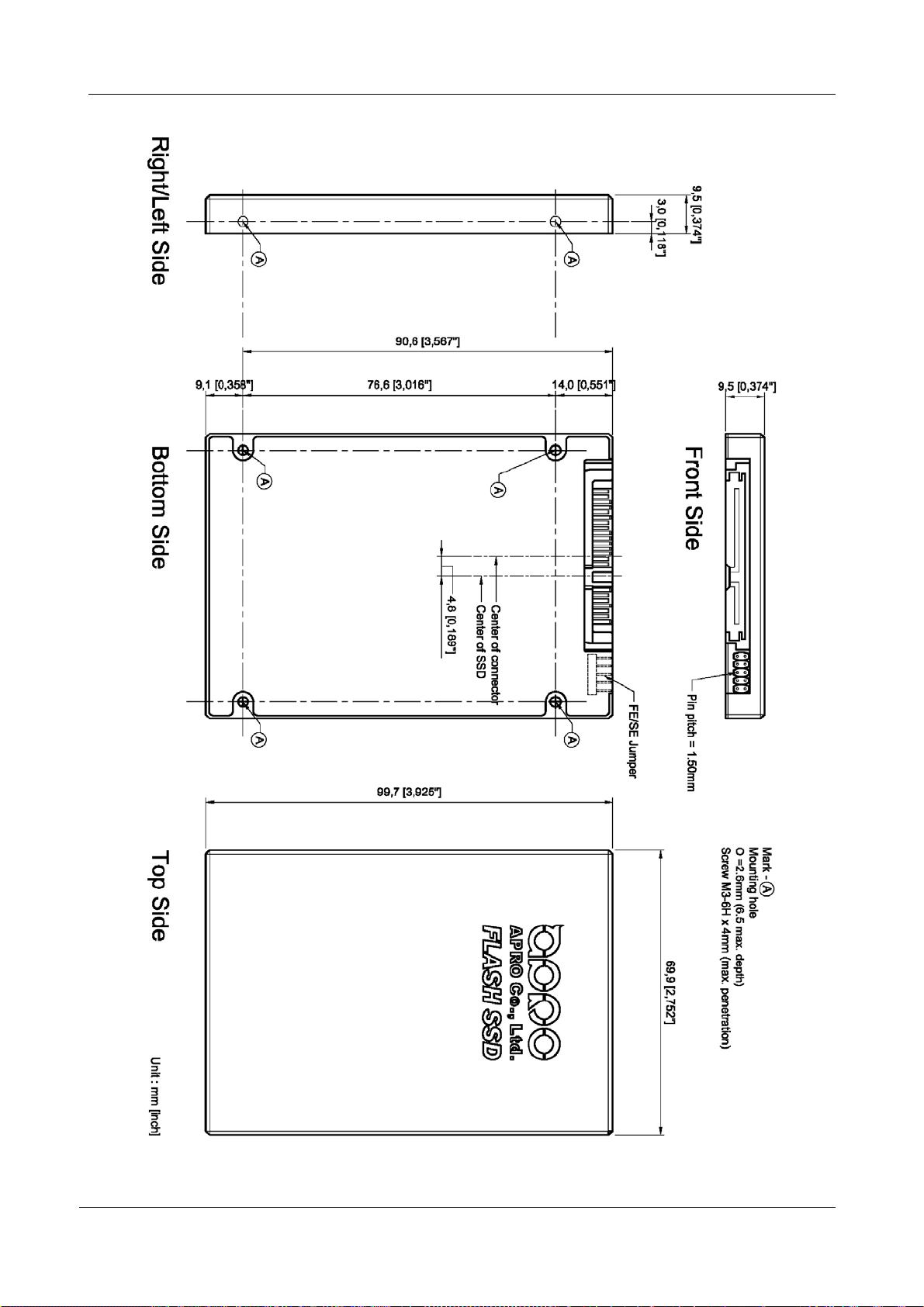

2.5. PHYSICAL SPECIFICATIONS ......................................................................................................- 7-

2.5.1. Conformal coating..............................................................................................................................- 9 -

3. INTERFACE DESCRIPTION.............................................................................................................................- 9 -

3.1. APRO RUGGED METAL 2.5” SATA III MLC SSDINTERFACE ...................................................- 9-

3.2. PIN ASSIGNMENTS.................................................................................................................- 10 -

4. CONFIGURATION OF BON-II SERIES 2.5” SATA III MLC SSD..........................................................- 11 -

4.1. FAST /SECURE ERASE JUMPER .............................................................................................- 11 -

4.1.1. Default Setting....................................................................................................................................- 11 -

4.1.2. Write Protect Function ....................................................................................................................- 11 -

4.1.3. Fast Erase............................................................................................................................................- 12 -

4.1.4. Secure Erase.......................................................................................................................................- 12 -

4.2. AUTO-RESUME FEATURES .....................................................................................................- 13 -

4.3. RANDOM DATA WRITTEN DURING THE SANITIZE PROCEDURE ..................................................- 13 -

4.4. PROTECTION MECHANISM ......................................................................................................- 13 -

4.5. USING THE SSD AFTER SANITIZING PROCEDURE ....................................................................- 13 -

5. SOFTWARE COMMANDS..............................................................................................................................- 14 -

5.1. WRITE PROTECT....................................................................................................................- 14 -

5.1.1. Inputs for Enabling Write Protect................................................................................................- 14 -

5.1.2. Inputs for Disabling Write Protect...............................................................................................- 15 -

5.2. FAST ERASE .........................................................................................................................- 16 -

5.2.1. Inputs for Enabling Fast Erase.....................................................................................................- 16 -