SUBSTRATE SELECTION:

ONCE ALL OF THESE STEPS HAVE BEEN COMPLETED

YOU ARE NOW READY TO FILL YOUR STATION LINER

WITH YOUR SUBSTRATE OF CHOICE.

THE PRECISION CULTIVATION SYSTEM IS COMPATIBLE

WITH EVERY KIND OF SUBSTRATE AND SOIL TYPE.

YOU SIMPLY ADJUST THE TOTAL NUMBER AND

DURATION OF WATERING CYCLES PER 24 HOUR

PERIOD DEPENDING ON THE WATER RETENTIVENESS

OF YOUR CHOSEN SUBSTRATE OR SOIL.

TO BE USED AS A GUIDE ONLY. IF USING A COMMON

INERT MIXTURE OF 70 PERCENT COCO COIR AND

30 PERCENT PERLITE; YOU WOULD START WITH

1 X 10 TO 15 SECOND WATERING CYCLE EVERY 12

TO 24 HOURS. THIS WOULD GRADUALLY INCREASE

TO 4 X 10 TO 15 SECOND WATERING CYCLES PER 24

HOUR PERIOD AS THE PLANTS INCREASE IN SIZE

AND DEVELOPMENT. EACH WATERING CYCLE SHOULD

DELIVER APPROXIMATELY 1 GALLON (3.7 LITRES)

PER STATION WITH AN OVERALL RUNOFF OF 10 TO 20

PERCENT. WHEN OVERALL RUN OFF BECOMES LESS

THAN 10 TO 20 PERCENT; IT IS TIME TO INCREASE

THE WATERING CYCLE DURATION.

WHEN USING A LESS WATER RETENTIVE AND

HIGHER OXYGEN CAPACITY SUBSTRATE SUCH

AS PURE PERLITE; YOU WILL REQUIRE MORE

FREQUENT AND LONGER WATERING CYCLES.

WHEN RUNNING PURE PERLITE; YOU SHOULD USE

A COARSE GRADE #4 AND START WITH 1 X 15 TO 30

SECOND WATERING CYCLE EVERY 4 HOURS UNTIL

HARVEST AND INCREASE YOUR WATERING CYCLE

DURATION AS NECESSARY.

WHEN FIRST LEARNING THE FUNCTION OF THE

PRECISION CULTIVATION SYSTEM WE RECOMMEND

TO CHOOSE A SUBSTRATE WHICH YOU HAVE PRIOR

EXPERIENCE WITH.

FIRST PLANTING:

FILL EACH STATION TO 1/2” (13MM) BELOW

THE TOP OF EDGE OF YOUR STATION LINER.

ONCE THE STATION/S HAVE BEEN FILLED YOU

CAN NOW PLACE YOUR PLANT/S OR CUTTING/S

INTO THE CENTER OF THE SYSTEM.

ONCE PLANT/S OR CUTTING/S HAVE BEEN PLANTED

WE STRONGLY RECOMMEND TO HAND WATER THEM

IN FOR THE FIRST 7 DAYS IN ADDITION TO RUNNING

THE SPRAY SYSTEM. THIS ALLOWS FOR THE PLANTS

ROOT ZONE TO BECOME ESTABLISHED BEFORE

COMPLETELY RELYING ON THE SPRAY SYSTEM

FOR WATERING DUTIES.

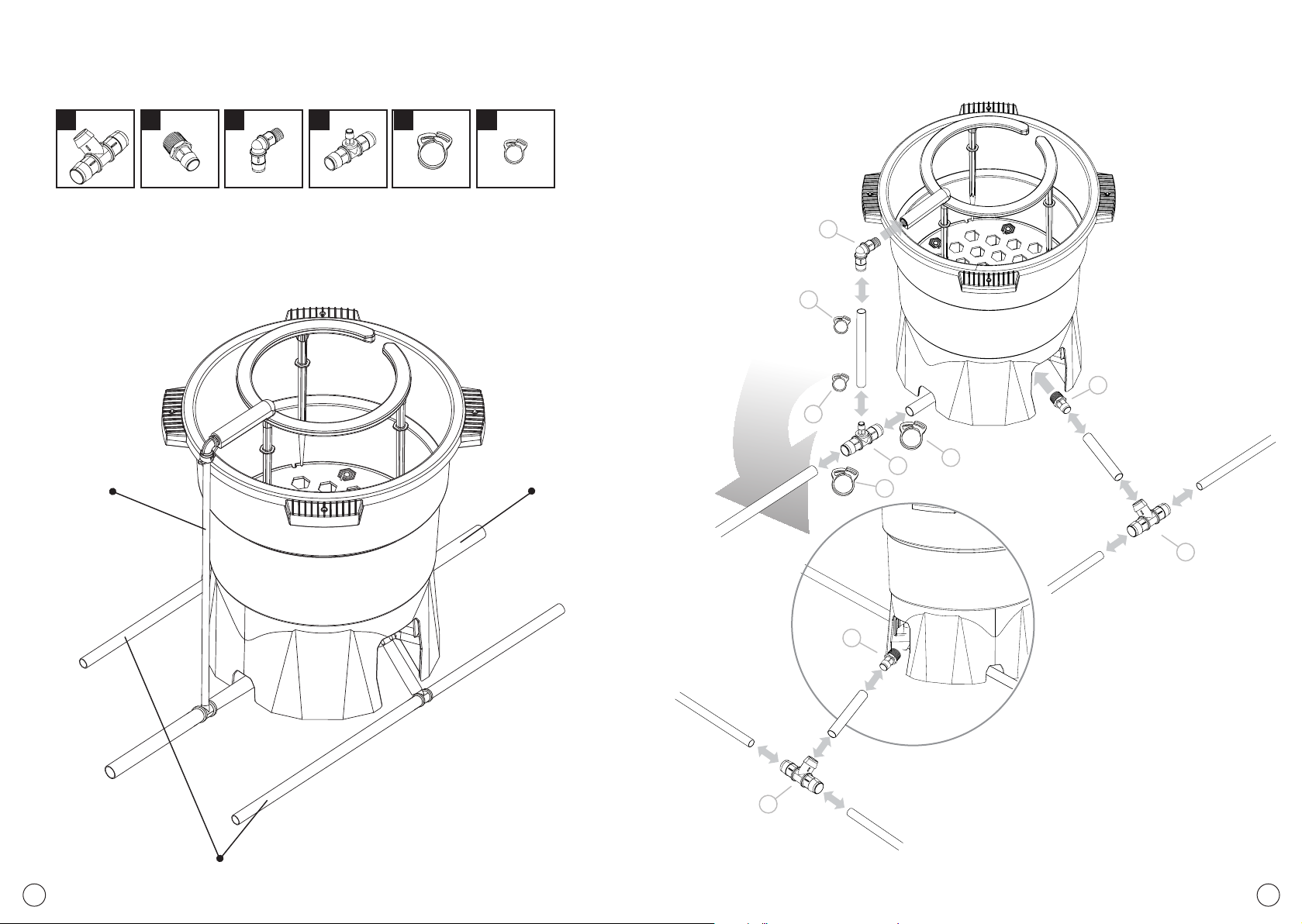

INSTALLING THE PCS SPRAY SYSTEM:

THE SPRAY SYSTEM SHOULD BE PLACED CENTERED

OVER THE CORE. WHILE HOLDING BOTH SIDES OF

THE SPRAY SYSTEM; PUSH EVENLY DOWNWARDS

INTO THE SUBSTRATE UNTIL THE HEXAGONAL

SHAPED DEPTH GUIDES LOCATATED ON THE SPRAY

SYSTEM LEGS TOUCH THE TOP OF THE SUBSTRATE.

THIS PREDETERMINED DEPTH SETS THE CORRECT

OPERATIONAL HEIGHT OF THE SPRAY SYSTEM TO

PROVIDE EVEN SATURATION ACROSS THE ENTIRE

CORE WHILE LEAVING A 4” (100MM) DRY ZONE

AROUND THE BASE OF THE PLANT STEM/S.

YOU CAN NOW CONNECT YOUR 1/2” (13MM) IRRIGA-

TION RISER TO YOUR 1/2” (13MM) NPT THREAD TO

BARB ELBOW FITTING (AS SHOWN ON PAGE 10 & 11).

DUE TO THE HIGH PRESSURE IN WHICH THE SPRAY

SYSTEM OPERATES; WE STRONGLY RECOMMEND

TO SECURE ALL IRRIGATION MAIN LINE AND RISER

CONNECTIONS WITH SUITABLE LINE CLAMPS TO

PREVENT WATER LEAKS AND LINE RUPTURES.

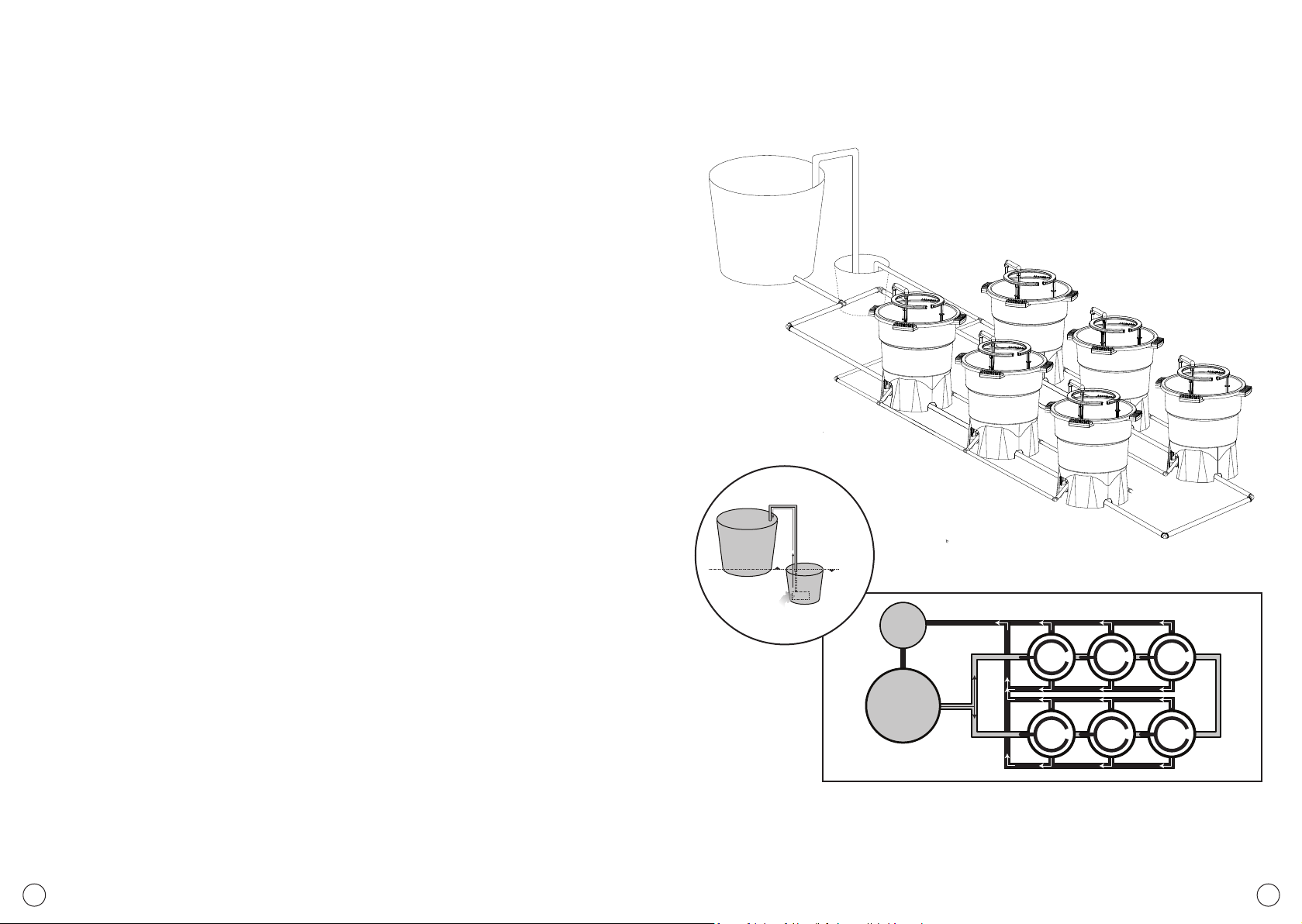

IRRIGATION PUMP SELECTION:

IT IS CRITICAL TO SELECT THE CORRECT SIZE

IRRIGATION PUMP TO ACHIEVE THE PROPER

FUNCTION OF THE SPRAY SYSTEM. EACH INDIVIDUAL

STATION CONNECTED TO THE MAIN IRRIGATION

LINE WILL REQUIRE A MINUMUM OF 500 GALLONS

(2,000 LITRES) PER HOUR OF FLOW WITH A TOTAL

HEAD HEIGHT OF 3’ (1 METRE).

WHEN CONNECTING MORE THAN A SINGLE STATION

TO THE MAIN IRRIGATION LINE THEN MULTIPLY

500 GALLONS (2,000 LITRES) PER HOUR OF

FLOW FOR TOTAL NUMBER OF STATIONS YOU

HAVE INSTALLED AND BASE YOUR PUMP

SELECTION ON TOTAL FLOW RATE REQUIRED.

FOR LARGER INSTALLATIONS THAT HAVE MULTIPLE

ROWS OF OVER 10 STATIONS PER LINE; YOU USE

THE SAME FLOW RATE CALCULATIONS ABOVE AND

USE INDIVIDUAL SOLENOID VALVES TO CONTROL

EACH MAIN IRRIGATION LINE PER ROW OF STATIONS.

PRECISION CULTIVATION SYSTEMS INSTALLATION AND USER GUIDE

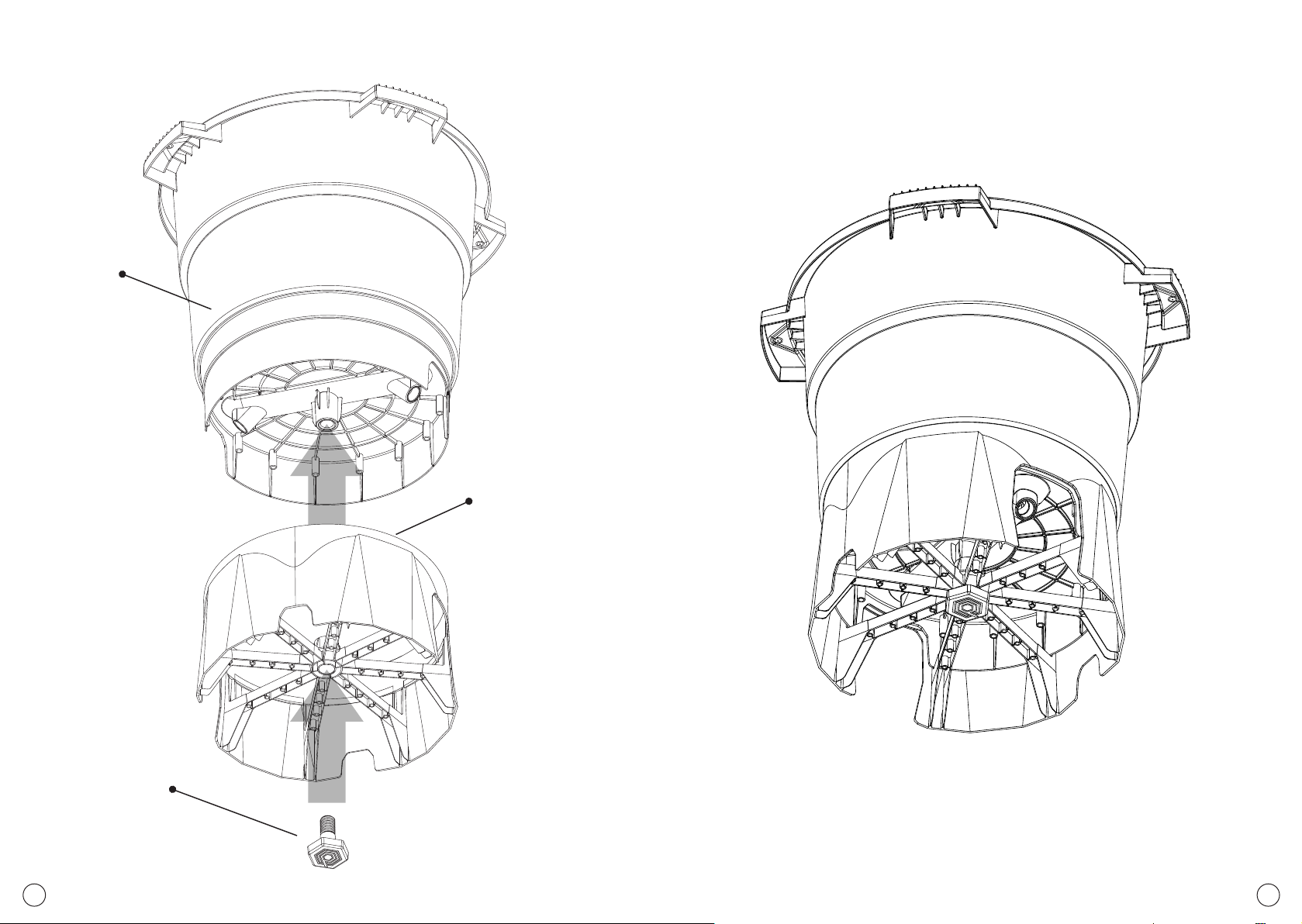

ASSEMBLING THE PCS STATION:

PLACE THE CORE FACE DOWN SO THE THREE

STAINLESS STEEL THREADED INSERTS ARE NOW

SHOWING ON THE BOTTOM OF THE CORE. SCREW

IN YOUR TWO 3/4” (19MM) NPT THREAD TO BARB

CONNECTORS INTO THE TWO OUTSIDE DRAIN HOLES

(REQUIRED PART “B” AS SHOWN ON PAGE 10)

ALIGN THE CUT OUTS ON THE BASE WITH THE CUT

OUTS ON THE CORE AND PLACE THE BASE ONTO

THE CORE (AS SHOWN ON PAGE 2 & 3). LOCATORS

ON THE BASE AND THE CORE WILL ASSIST WITH

ASSEMBLY AND PREVENT THE BASE FROM TURNING.

LOCATE THE HOLE IN THE CENTER OF THE BASE.

NOTICE THE STAINLESS STEEL THREADED INSERT

BELOW AT THE CENTER OF THE CORE. USING THE

BASE BOLT FIX THE BASE TO THE CORE BY TURNING

THE BASE BOLT IN A CLOCKWISE DIRECTION UNTIL

HAND TIGHT. THE STATION IN NOW READY TO BE

TURNED UPRIGHT.

PLACE THE GRID INTO THE CORE (AS SHOWN

ON PAGE 4) WITH THE CONCAVE SIDE FACING

UPWARDS AND THE HONEYCOMB SIDE FACING

DOWNWARDS. THE GRID WHEN INSTALLED

CORRECTLY WILL REST FLAT AGAINST THE

BOTTOM OF THE CORE. THE STATION IS

NOW READY TO BE PLACED INTO POSITON.

WE RECOMMEND THAT THE STATION LINER

AND THE SPRAY SYSTEM ARE NOT INSTALLED

UNTIL ALL OF YOUR STATIONS ARE PLACED WITH

THE IRRIGATION AND DRAINAGE TUBING CONNECTED

(SEE PAGES 10-13)

ASSEMBLING THE PCS SPRAY SYSTEM:

TAKE CARE WHEN REMOVING THE SPRAY SYSTEM

FROM THE SECONDARY BOX TO PREVENT OVER

FLEXING. THE SPRAY SYSTEM IS ULTRASONICALLY

WELDED TOGETHER AND OVER FLEXING MAY

CAUSE THE WELD TO BREAK RESULTING IN

CATASTROPHIC FAILURE.

START BY INSTALLING YOUR 1/2” (13MM) NPT THREAD

TO BARB ELBOW FITTING (REQUIRED PART “C” AS

SHOWN ON PAGE 10) INTO THE STAINLES STEEL

THREADED END OF THE SPRAY SYSTEM.

FIRST APPLY TEFLON TAPE TO THREAD OF YOUR

1/2” (13MM) NPT THREAD TO BARB ELBOW FITTING.

HOLD THE ARM OF THE SPRAY SYSTEM FIRMLY IN

ONE HAND FOR SUPPORT AND THEN SCREW IN YOUR

1/2” (13MM) NPT THREAD TO BARB ELBOW FITTING

UNTIL TIGHT.

WHEN INSTALLED CORRECTLY THE INLET OF YOUR

1/2” (13MM) NPT THREAD TO BARB ELBOW FITTING

SHOULD BE FACING DOWNWARDS.

ATTACH THE SPRAY SYSTEM LEGS BY PUSHING

THE HEXAGONAL END INTO THE LOCATORS ON

THE UNDER¬SIDE OF THE SPRAY SYSTEM

ASSEMBLY (AS SHOWN ON PAGE 6).

ALWAYS SUPPORT THE TOP SIDE OF THE SPRAY

SYSTEM WHEN INSTALLING THE SPRAY SYSTEM

LEGS TO AVOID ANY OVER FLEXING.

THE SPRAY SYSTEM LEGS HAVE BUILT IN HEXAGONAL

SHAPED DEPTH GUIDES LOCATATED 3” (75MM) FROM

THE TOP WHICH ARE USED TO SET THE CORRECT

INSTALLATION HEIGHT FOR YOUR SPRAY SYSTEM

TO PROVIDE EVEN AND ACCURATE WATERING.

INSTALLING THE PCS STATION LINER:

THE STATION LINER IS TO BE FITTED ONLY ONCE

THE GRID HAD BEEN INSTALLED INSIDE OF THE

CORE (AS SHOWN ON PAGE 5 & 6).

PLACE THE STATION LINER INSIDE THE CORE WITH

THE MESH MATERIAL FACING DOWNWARDS UNTIL

IT IS RESTING FIRMLY AGAINST THE GRID.

ALIGN THE FOUR CUT OUTS NEAR THE TOP OF THE

STATION LINER WITH THE CORE HANDLES AND FOLD

THE EDGES OF THE STATION LINER OVER THE EDGE

OF THE CORE (AS SHOWN ON PAGE 6 & 7).

EACH PCS COMPLETE STATION KIT COMES WITH THE FOLLOWING COMPONENTS 1 X CORE (MAIN POT)

AND 1 X ACCESSORIES KIT (PARTS). INSIDE THE ACCESSORIES KIT YOU WILL FIND THE FOLLOWING COMPONENTS

1 X BASE, 1 X GRID, 1 X BASE BOLT, 1 X STATION LINER, 1 X SPRAY SYSTEM AND 3 X SPRAY SYSTEM LEGS.