SAFETY CAUTIONS

-ONLY qualified mechanics/technicians should use this equipment.

-Do NOT overload or serious injury may result.

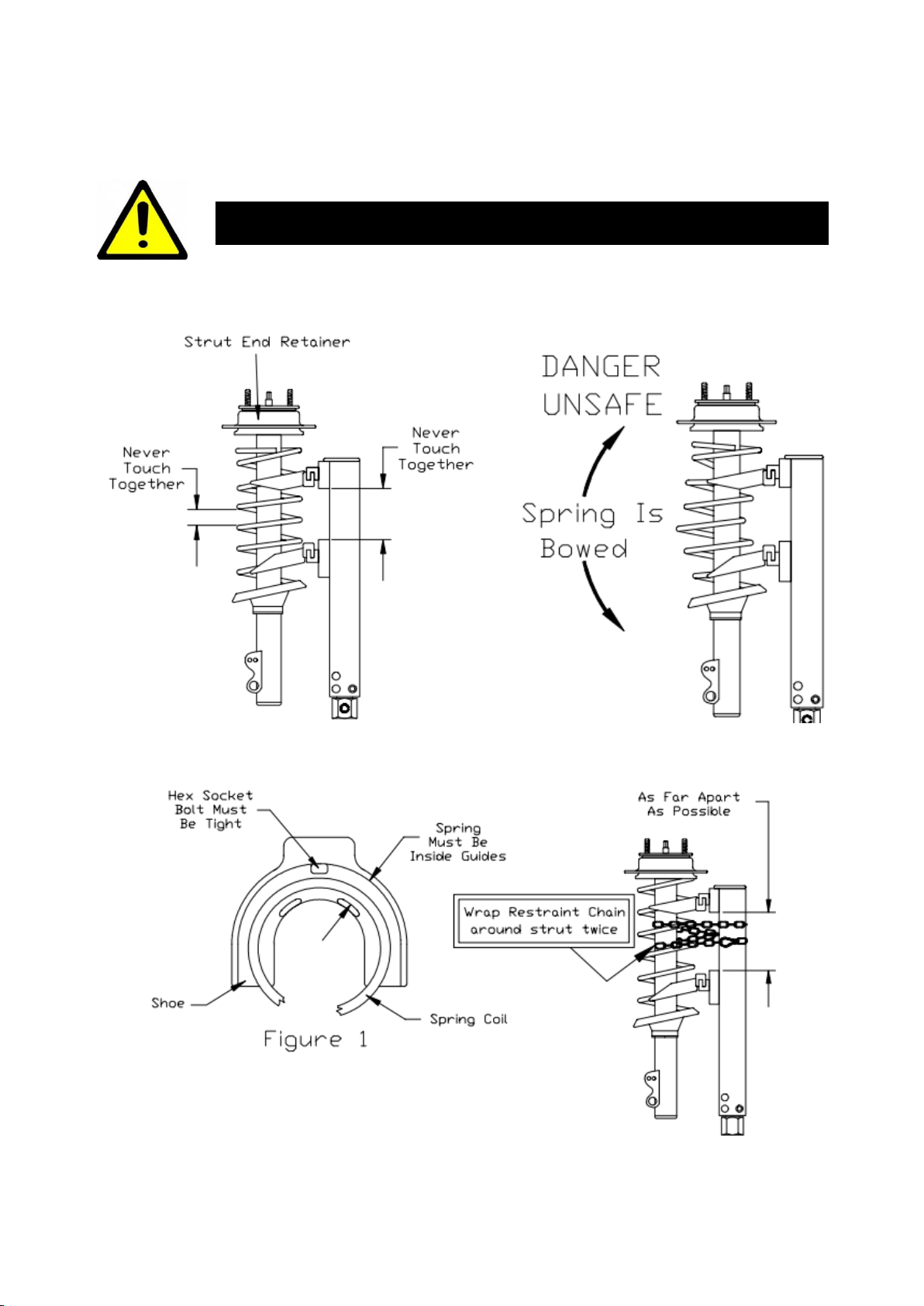

-Do NOT Compress spring until coils touch or bind.

-A compressed spring is VERY DANGEROUS.

-ALWAYS unload spring before removing from strut.

-Do NOT compress spring if it tends to bow.

-Do NOT drop spring compressor assembly.

-Compress spring only to remove or install strut.

-If the strut assembly is difficult to compress or the spring bows or tilts, release

tension immediately and REPOSITION the strut assembly.

-Keep fingers and hands clear of any moving parts.

-Do NOT make any modifications to this equipment.

-ALWAYS inspect before use. Do NOT use if components are damaged in any way,

or if the hydraulic ram is leaking.

-Make sure that your workpiece is centered-loaded and secure. DISTRIBUTE THE

LOAD EVENLY ACROSS THE ENTIRE SADDLE SURFACE.

-Be sure to REMOVE strut support plate from the bottom of the strut before compressing

springs. Strut support plate is only designed to hold heavy weight of strut TEMPORARILY.

- When not in use, store the hydraulic shop press in a dry location with the ram and

piston of the cylinder fully RETRACTED.

Before you begin, understand units’operation limit.