3901726 JobSmart 4 Gallon Air Compressor Assembly & Operating Instructions 7

Handle: Rubber gripped handle for easy transport.

Air Regulator: Controls the air flow pressure. Turn regulator

clockwise to increase air pressure, counter-clockwise to

decrease.

Air Chuck: Allows for fast, easy connection to an air hose.

Tank Drain Valve: Open to allow moisture and compressed

air to be released from the Air Tank.

WARNING The Tank Drain Valve should always be

opened slowlv to avoid damage to equipment and

possible injury.

Oil Breather Cap: As the compressor motor operates

pressurized air must be released from the crank case. The oil

breather cap allows built up air to escape, while shielding your

air compressor from airborne impurities.

Air Tank: Powder coated steel tank, with a 4 gallon capacity,

stores the compressed air until it is needed.

Power Switch: Red tipped power switch turns the air

compressor on and off. When switch is pulled up, compressor

is turned ON. When switch is pushed down, compressor is

turned OFF.

Note: Always make sure that compressor Power Switch is in

the OFF position before performing any maintenance or

plugging the compressor Into a power supply.

Pressure Gauges: Dual gauges indicate the amount of air

pressure built up in the air tank, as well as the air pressure

being delivered to the air chuck.

Safety Valve: Relieves pressure from the Air Tank in the

event of excessive pressure build up. Preset at factory. Do not

attempt to make any adjustments to the Safety Valve.

Periodically pull ring on the Safety Valve end to check that it is

working properly.

Air Filter: Heavy duty metal air filter keeps your compressor

running clean by filtering out impurities.

ASSEMBLY

Before performing any assembly or maintenance, make sure compressor is turned off and unplugged

from the power supply.

Your air compressor is shipped without oil in the crankcase. YOU MUST ADD OIL TO THE CRANKCASE

BEFORE STARTING THE AIR COMPRESSOR.

1. Place compressor on level ground.

2. Remove the Oil Shipping Plug from the Oil Fill hole, located on the top of the crankcase cover at the rear.

3. Pour the oil into the Oil Fill hole, until the oil level rises to the center of the red dot on the Oil Sight Glass.

Note: This compressor uses only SAE 5W-30 motor oil.

4. Install the Oil Breather Cap into the Oil Fill hole.

5. Firmly hand-tighten the Oil Breather Cap by turning clockwise.

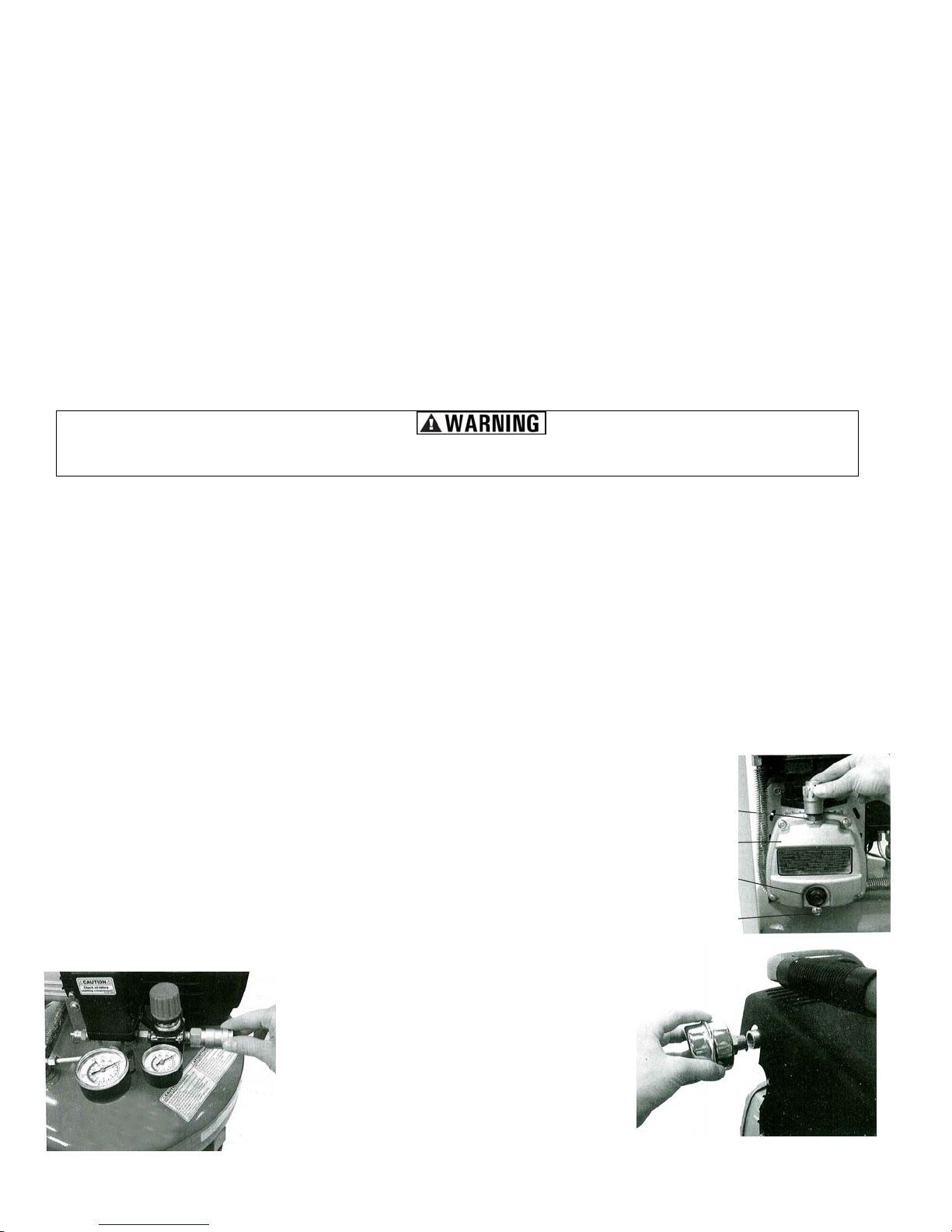

lnstalling the Air Chuck

Note: Use a sealant tape on the threads of the Air Chuck to prevent air leakage.

1. Thread the Air Chuck into the Air Regulator by turning the Air Chuck clockwise.

2. Securely tighten the Air Chuck in place with a wrench.

Note: DO NOT over tighten Air Chuck.

lnstalling the Air Filter

The metal Air Filter is installed into the threaded port of the cylinder head.

1. Thread the Air Filter into the Cylinder Head by turning Air Filter clockwise.

2. Securely tighten the Air Filter in place with a wrench. (See Figure 4)

Note: DO NOT over tighten Air Filter.

Figure 4

lnstalling the

Air Filter

Figure 3

lnstalling the

Air Chuck

Figure 2

lnstalling the

Oil & Oil

Breather Cap

Oil Fill

Crankcase

Sight Glass

Drain Plug