ITEM

Owners Information

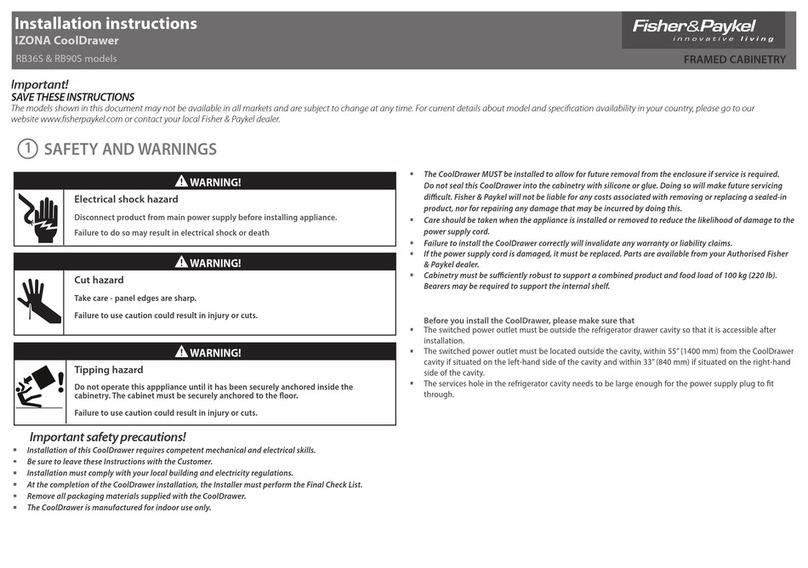

Important Safety Information

Specifications

Operation

Parts Lists

Warranty

..............................................................................................

General Information......................................................................................

General Operation Instructions.....................................................................

Warranty Information....................................................................................

.................................................................................

.........................................................................................................

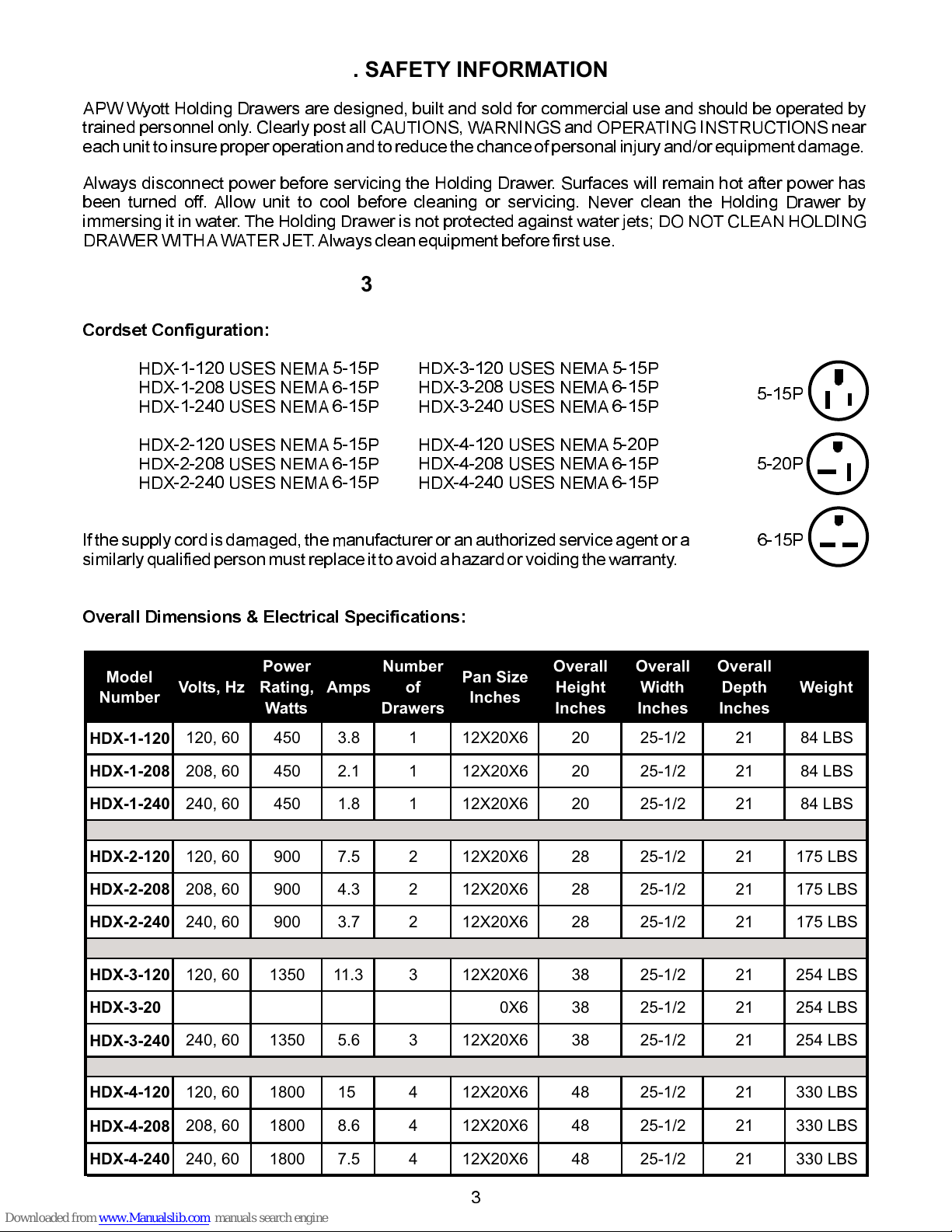

Electrical.......................................................................................................

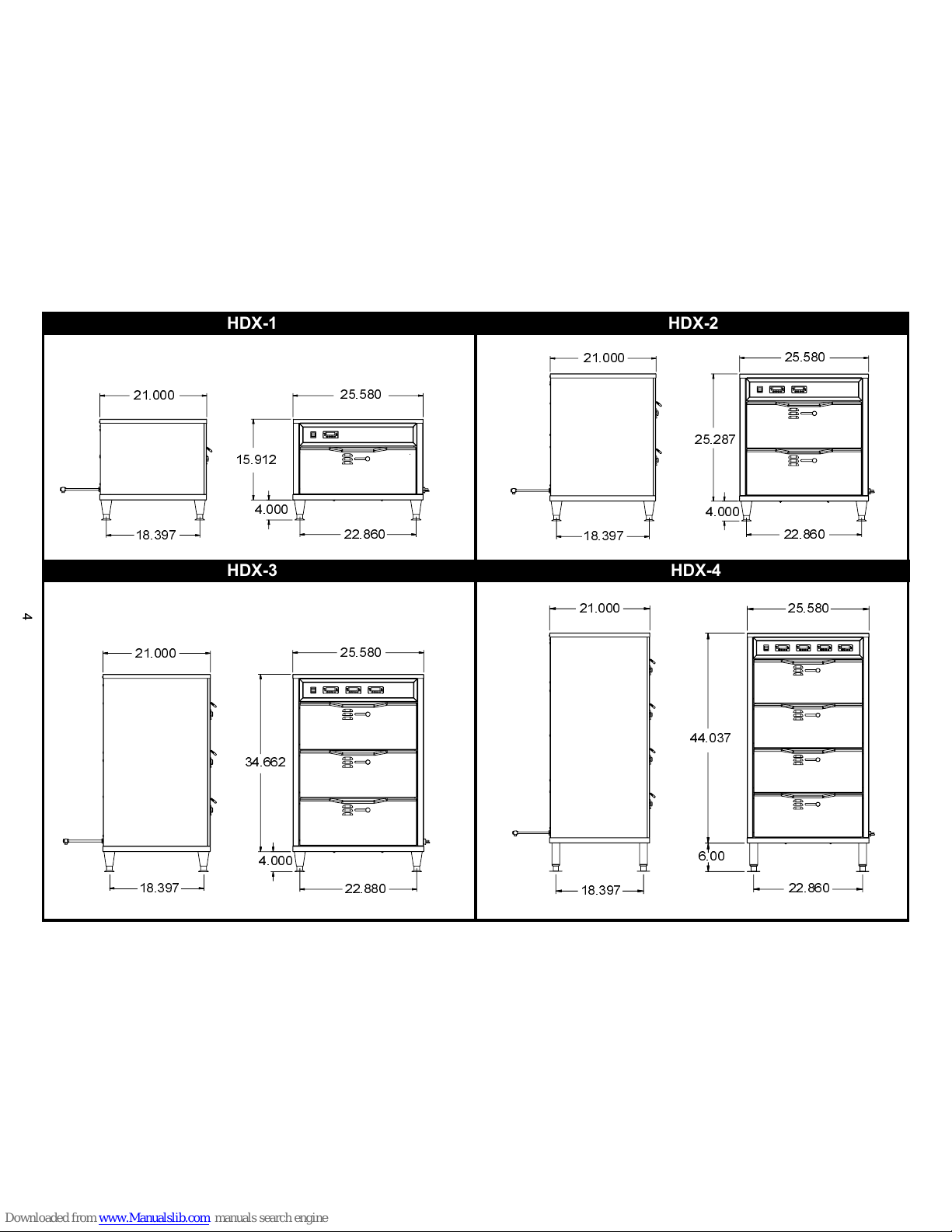

Dimensions...................................................................................................

.................................................................................................................

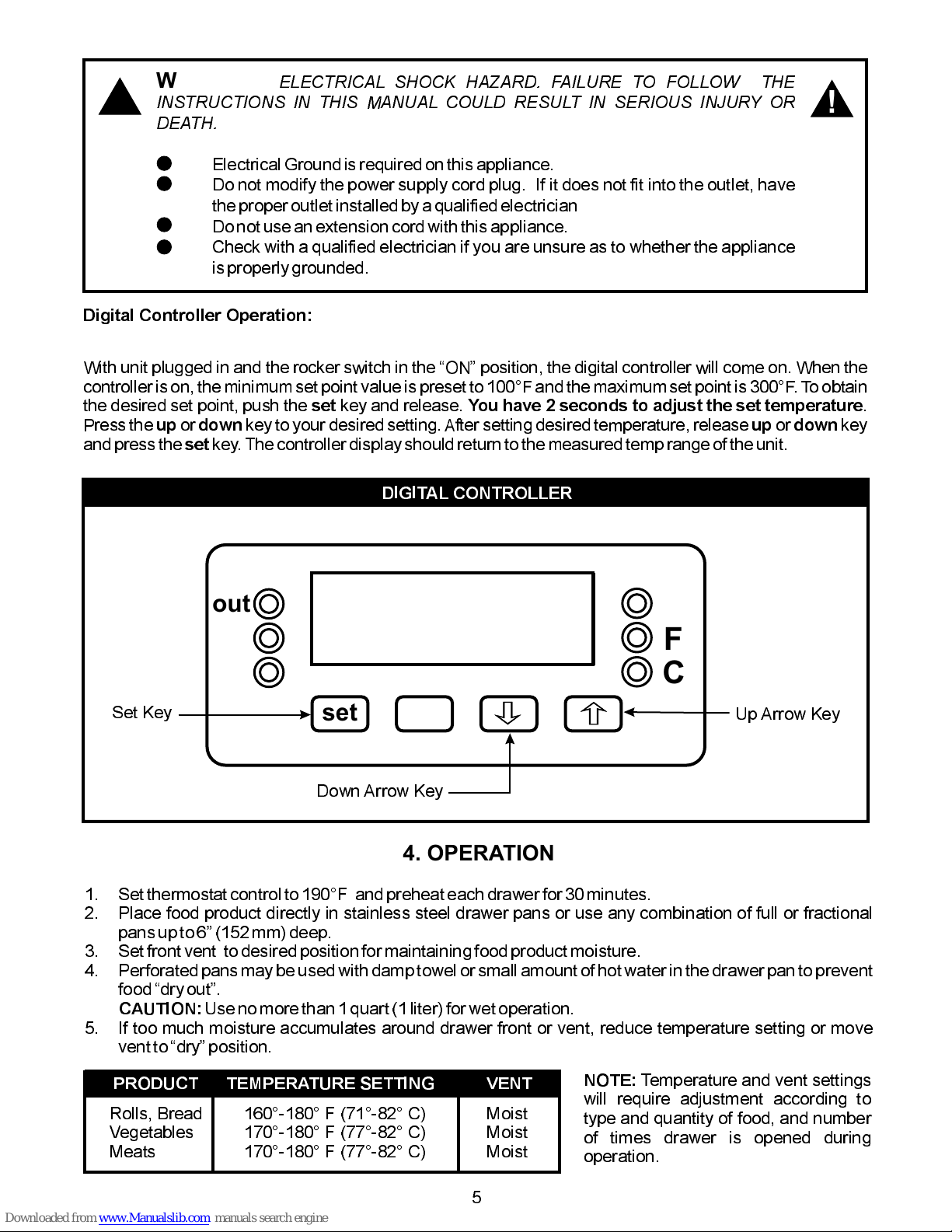

Operating Instructions...................................................................................

................................................................................................................

HDX-1 Parts List w/Exploded View...............................................................

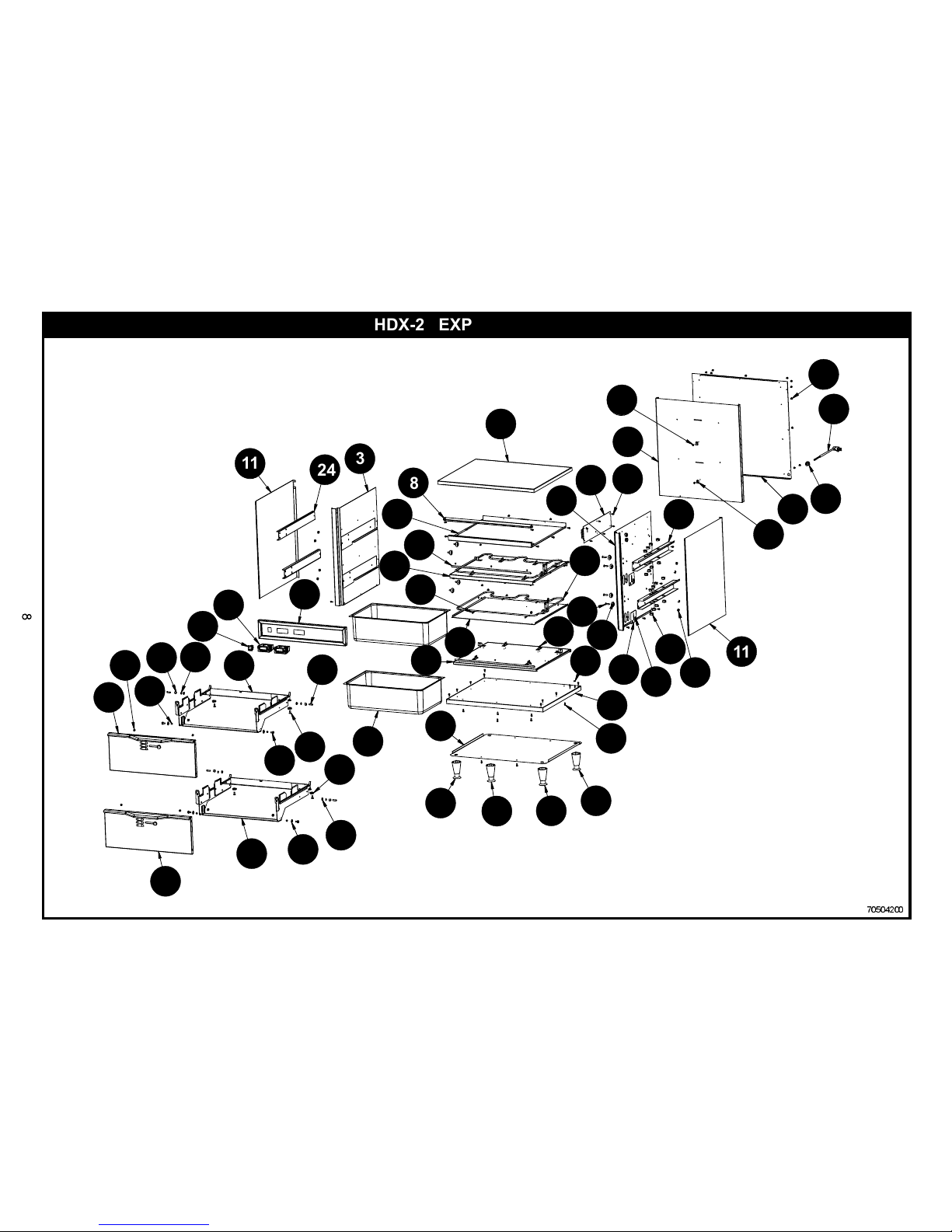

HDX-2 Parts List w/Exploded View...............................................................

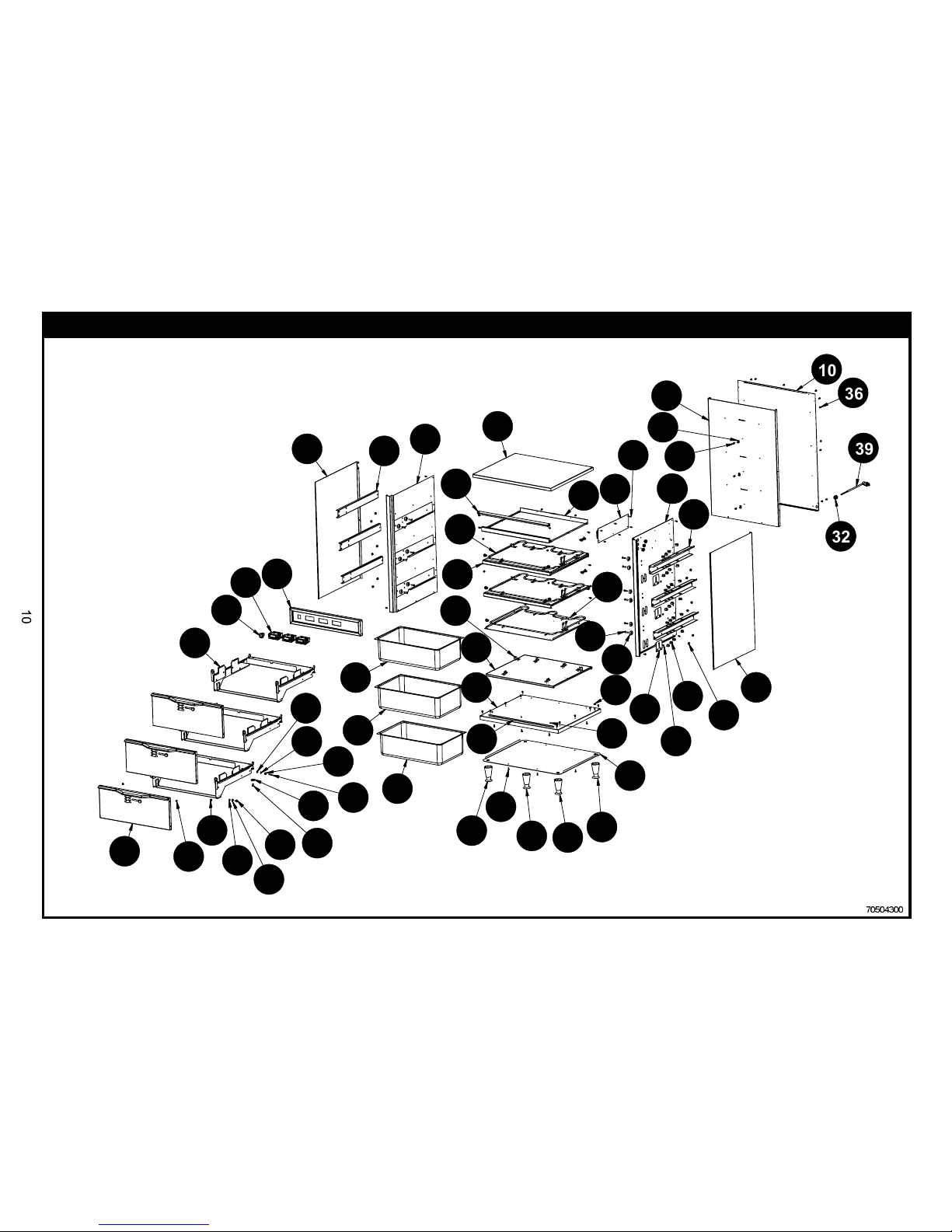

HDX-3 Parts List w/Exploded View................................................................

HDX-4 Parts List w/Exploded View...............................................................

.................................................................................................................

Wiring Diagrams

Cleaning

Troubleshooting

.....................................................................................................

..................................................................................................................

General Cleaning Instructions......................................................................

Daily Cleaning...............................................................................................

.....................................................................................................

2

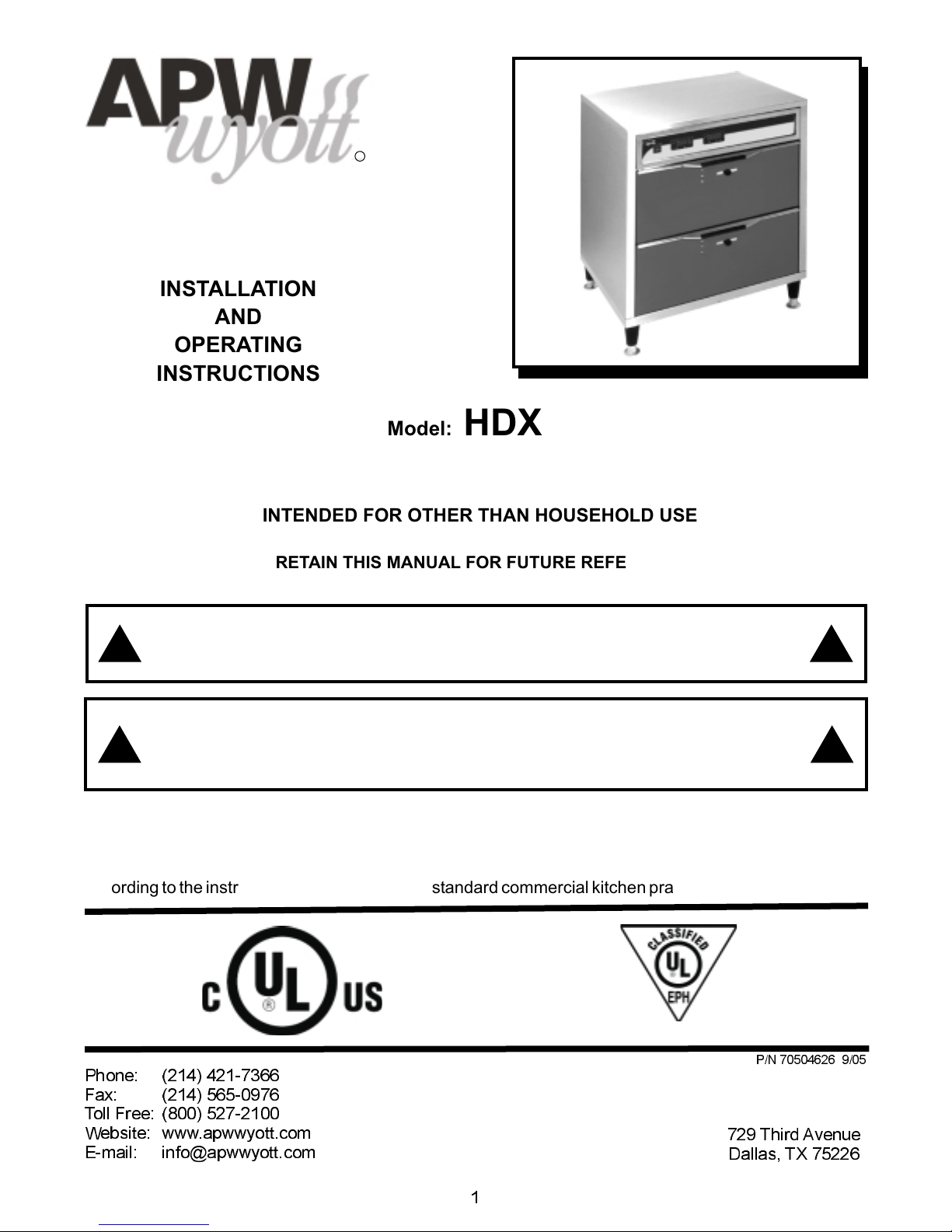

1. OWNER’S INFORMATION

GeneralInformation:

GeneralOperationInstructions:

Warranty Information:

Reliability BackedByAPW Wyotts Warranty:

ServiceInformation:

1. Alwayscleanequipmentthoroughlybeforefirst use. (See generalcleaninginstructions).

2. Checkratinglabel for your modeldesignationand electrical rating.

3. For best results, use stainlesssteelcountertops.

4. All dimensions in parenthesis in centimetersunless noted.

5. Legs are shipped unassembled. Legs must be screwedinto base of unit.

1. Allfoodserviceequipmentshouldbe operated by trained personnel.

2. Do not allow your customersto come in contact with any surface labeled CAUTIONHOT.

3. Whereapplicable:Neverpourcold water into dry heated units.

4. Neverhold food below 150°F (66°C).

All APW Wyott Holding Drawers are backed by a one year parts and labor warranty, including On-Site

Service calls within 50 milesof authorizedservicetechnicians.

ServiceHotline(800)733-2203

SECTION

1

2

3

4

5

6

7

8

9

TABLE OF CONTENTS

PAGE

2

2

2

2

3

3

3

3

5

5

6

6

8

10

12

14

18

18

18

18

20