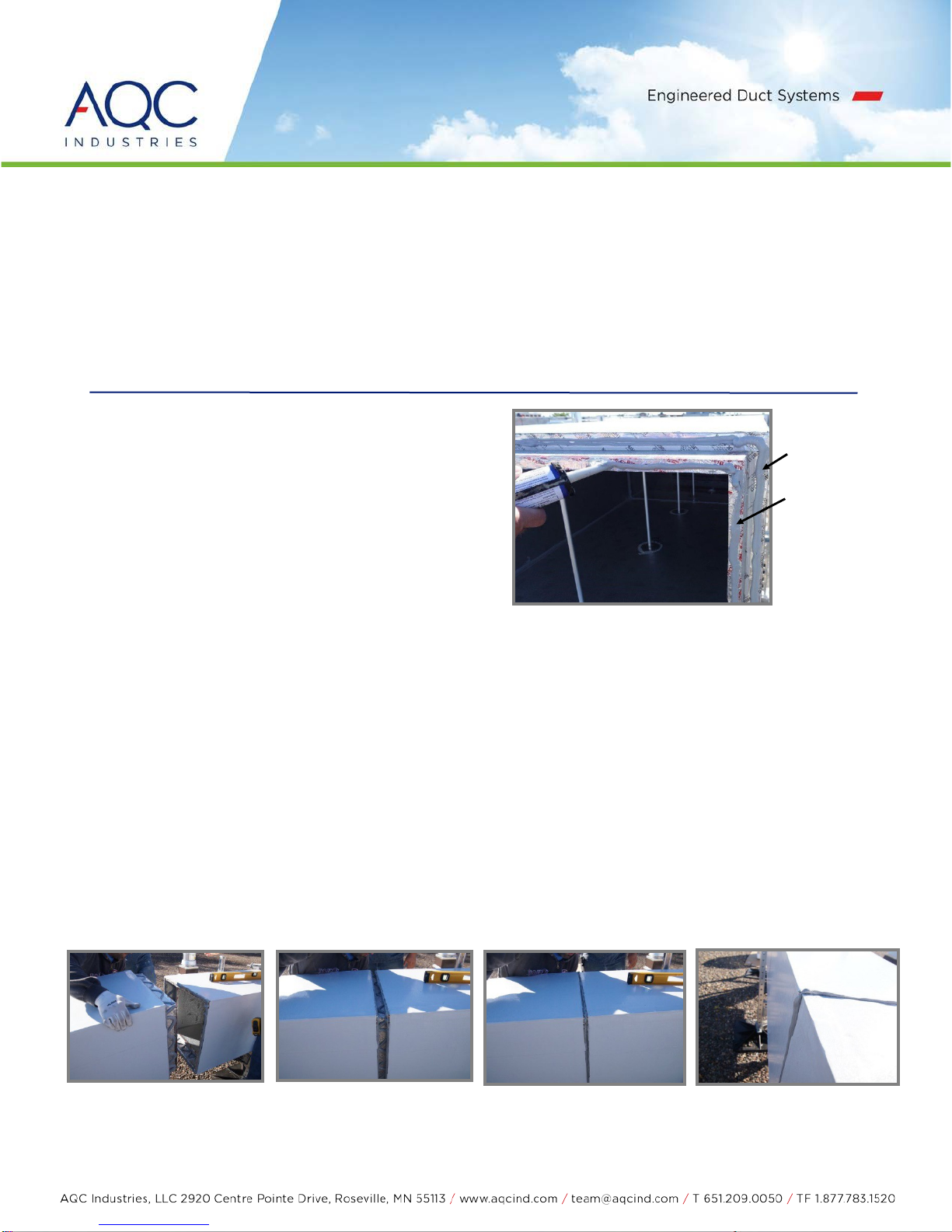

SITE CONDITION AND PREPERATION

The QDuct is intended for outdoor ducting. Lay cardboard or plywood on

roof surface before staging or placing any QDuct product on roof surface

to prevent possible damage to product. QDuct is not intended to be

installed underground. For underground applications, please visit

www.aqcind.com to learn more about The BlueDuct® preinsulated

underground system.

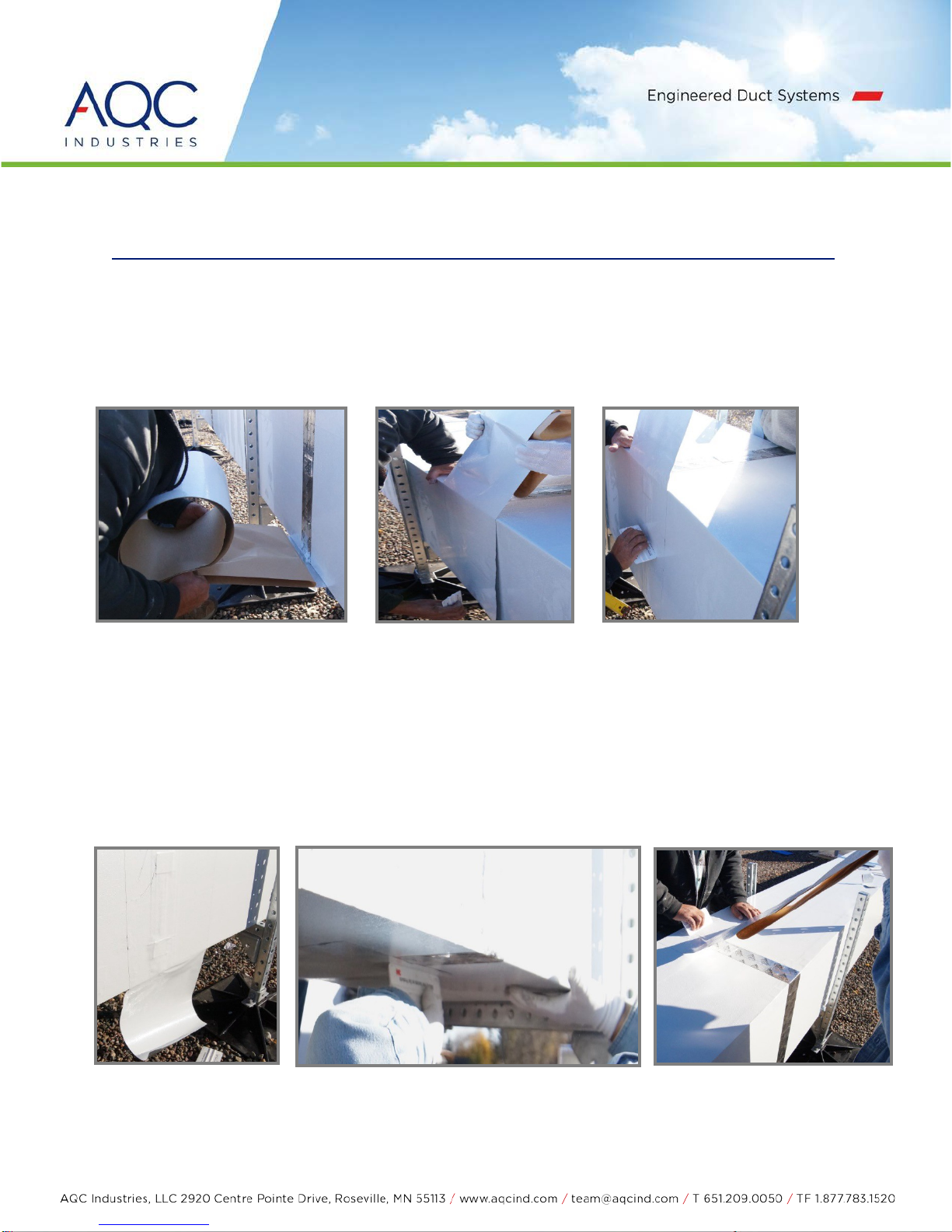

IDENTIFYING QDUCT® SECTIONS

To ease the installation, each QDuct system is shipped with a project specific drawing and list of

material. The drawing is numbered for each part. Each QDuct part is numbered to match the drawing

and the list of material. AQC recommends installing QDuct from the unit outward.

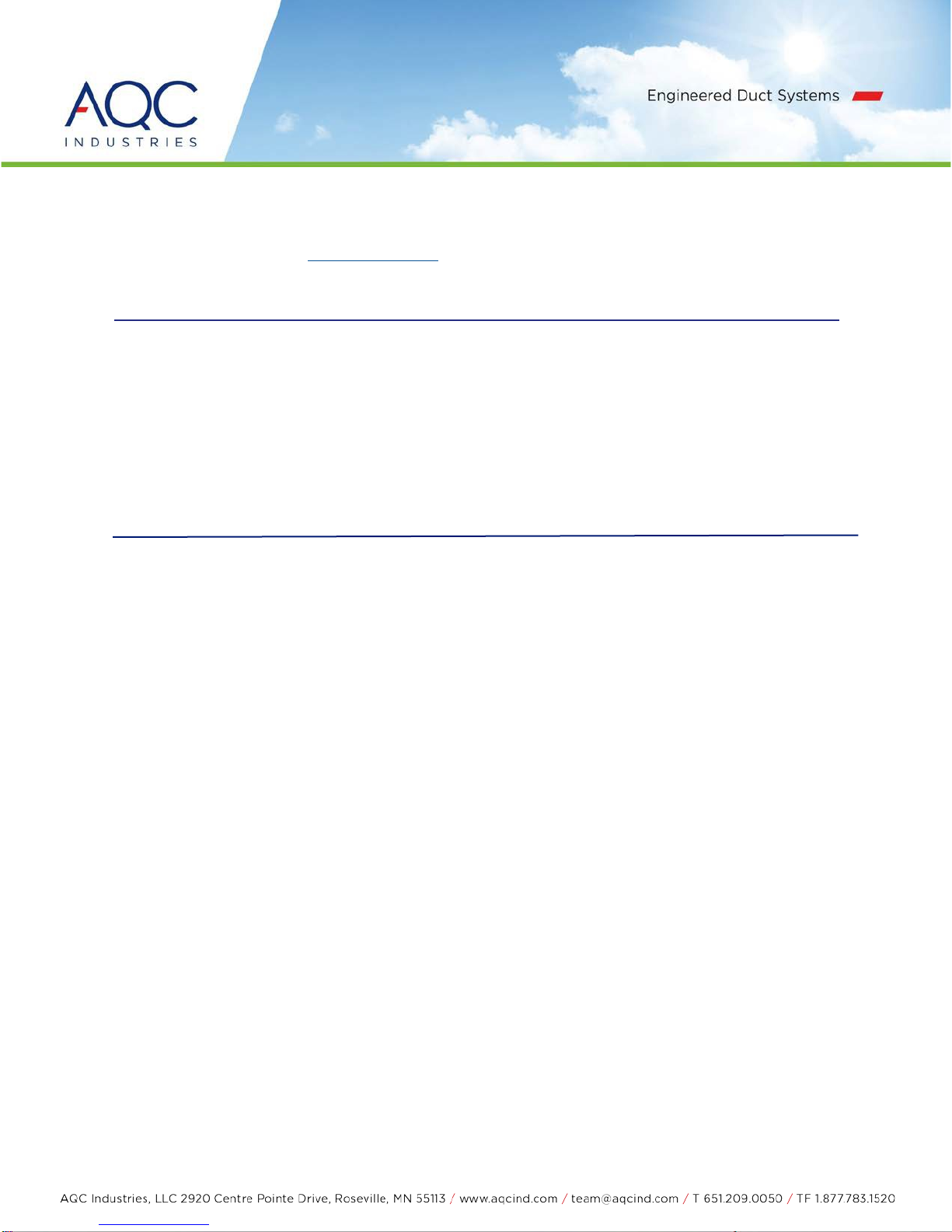

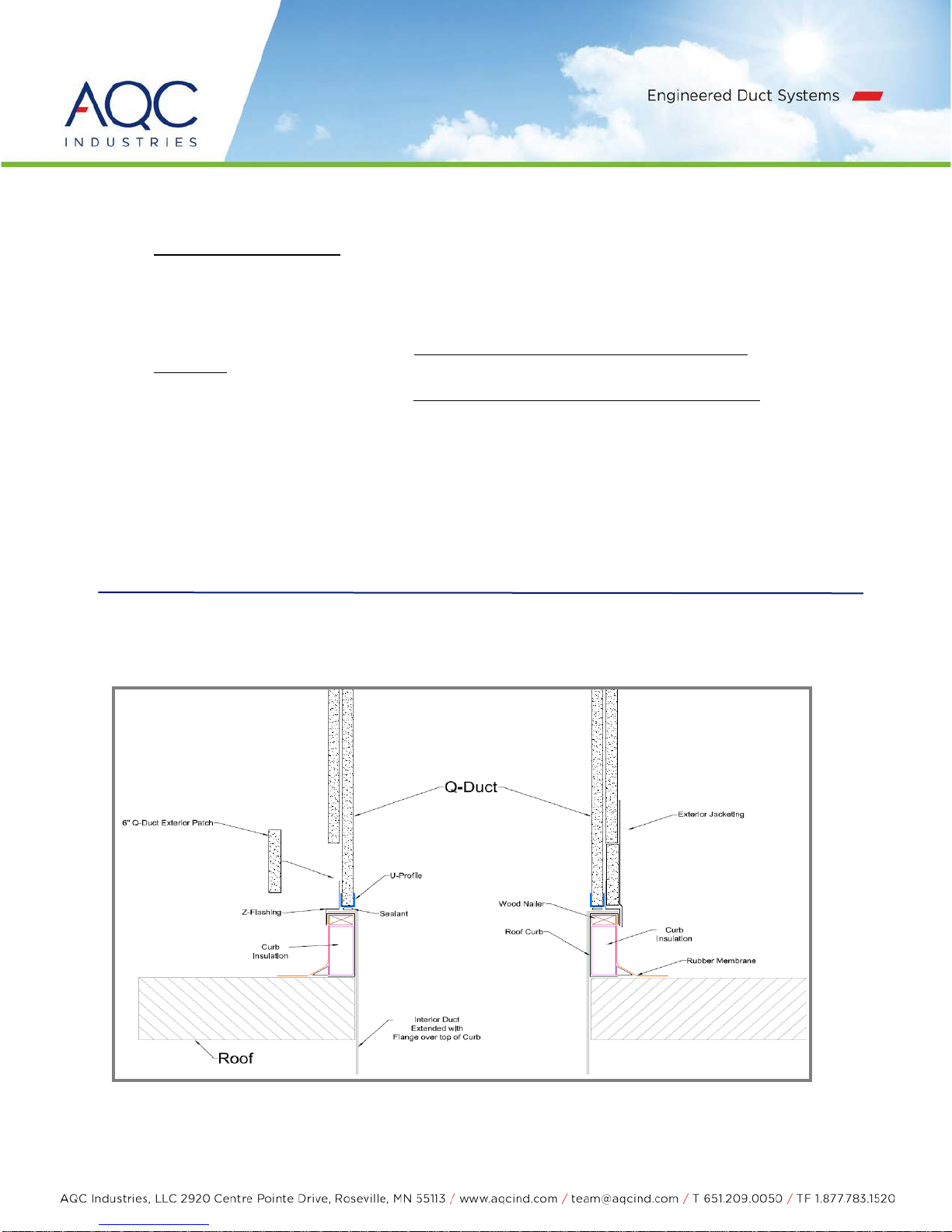

DUCT SUPPORTS

•

AQC recommends that duct supports be used in

compliance with SMACNA guidelines for “Phenolic Duct

Construction Standards”, ANSI/SMACNA 022- 2015 as

applicable for exterior ducting.

•

Duct supports should be designed per engineer standards

to conform to local codes and consider potential for snow

load.

•

Duct supports should be fully enclosed (bottom, left side,

right side and top) around the external walls of the QDuct

ensuring resistance to lift caused by windforce.

•

Supports should never be secured to the QDuct system

using screws,pins or other methods that would penetrate

the external jacket of the Q Ductsystem.

•

Duct support spacing shall be every 72 inches or one

support per duct section.