the left.

Back Cover Mounting

Locate the control on the mounting surface being sure to allow clearance

for the necessary wiring connections. Mark the mounting hole locations and

remove the back cover from the work space. Make the stripped/labelled

wiring connections now. CAUTION: Be sure that no exposed portions of

wires are touching.

If installing onto wood, mount the back cover with the provided screws. If

installing onto drywall, drill pilot holes using a 7/32” drill bit (not provided)

and tap the provided drywall anchors into place. Mount with provided

screws. NOTE: Velcro can be used to mount the control instead of screws

if necessary.

Verify that wiring connections are correct and secure.

Align the front cover with the

back cover starting on the left

side. Push the front cover

towards the back cover in a

“hinging” motion from the left to

the right. CAUTION: Make sure

the front cover is aligned properly

with the back cover to avoid

damaging the control. Press

down until the front cover snaps

securely into place.

Sensor Mounting

The ES24V comes with a temperature sensor (26AWG, 2 wire) and

humidity sensor (6P6C, telephone wire), both 10” long. Install the sensors

at a location so that they will be exposed to the fresh air intake (ex: the

fresh air ductwork). Drill 2, 3/4" diameter holes, spaced appropriately and

install the sensors with the provided hardware. NOTE: the sensor wires can

be extended up to 300 feet without deviation. Use appropriate duct tape to

seal joints/openings as necessary.

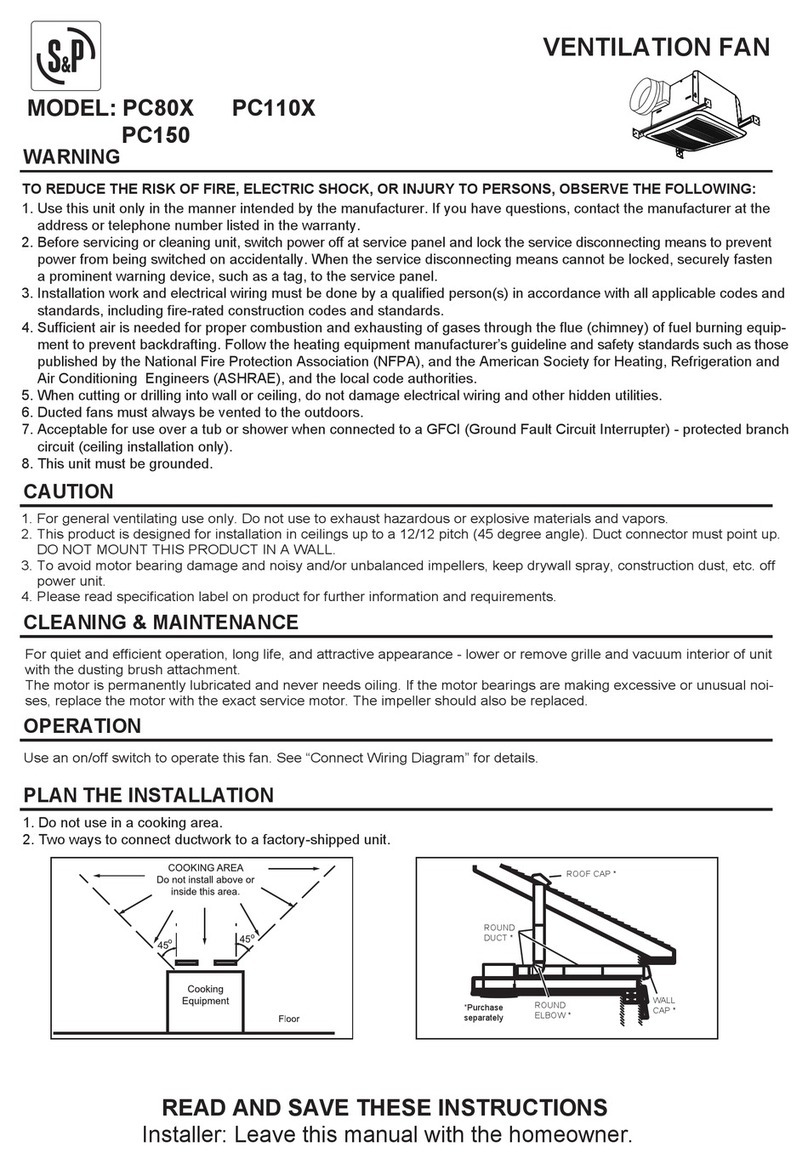

DIMENSIONS (in)

SCREEN DIAGRAM

OPERATING MODES

OFF Mode: All outputs are off.

ON Mode: The Fresh Air Fan, Motorized Damper (if enabled), and

Furnace Blower (if enabled) are on continuously. The Duct Heater

will follow the user settings (see FUNCTION SETTINGS below).

Eco Mode: Eco Mode limits the Fresh Air Fan operation during

periods of extreme temperature and/or humidity. The Fresh Air

Fan, Motorized Damper (when enabled), Furnace Blower (when

enabled), and Duct Heater (when enabled) will follow the user

settings when the outside air temperature/humidity is within the

user set limits (see FUNCTION SETTINGS below).

The Fresh Air Fan will run for the user set amount of time/hour

while the temperature/humidity limits are within range. The

temperature/humidity sensors evaluate the fresh air conditions

every 10 seconds. While the fresh air temperature/humidity is

within the user set limits, the Fresh Air Fan/accessories will run

per the user settings. When the fresh air temperature/humidity

exceeds the user set limits, the Fresh Air Fan/accessories will turn

off and engage a timer. The timer will run the fan for 5 minutes

every 15 minutes in order to meet code requirements. NOTE: the

Furnace Blower (if enabled) will not run during this check

procedure to prevent cycling. The fan will continue this check

procedure until the temperature/humidity limits are within the user

set limits.

If Enabled (in SETUP):

The Furnace Blower will be on: any time there is a call from “G”

Input or any time the Fresh Air Fan is on (excluding the check

procedure above).

The Motorized Damper will be on anytime the Fresh Air Fan is on.

The Duct Heater will be on any time the Fresh Air Fan is on and

the set point > room temperature +2°F.

(Motorized Damper, Furnace Blower, and Duct Heater are

required to be enabled in SETUP)

BUTTONS

Keys Description

Mode Select the operating mode

Set Confirm settings

▲ Increase settings

▼ Decrease settings

ES24V