1514 Your Partner in Cool.

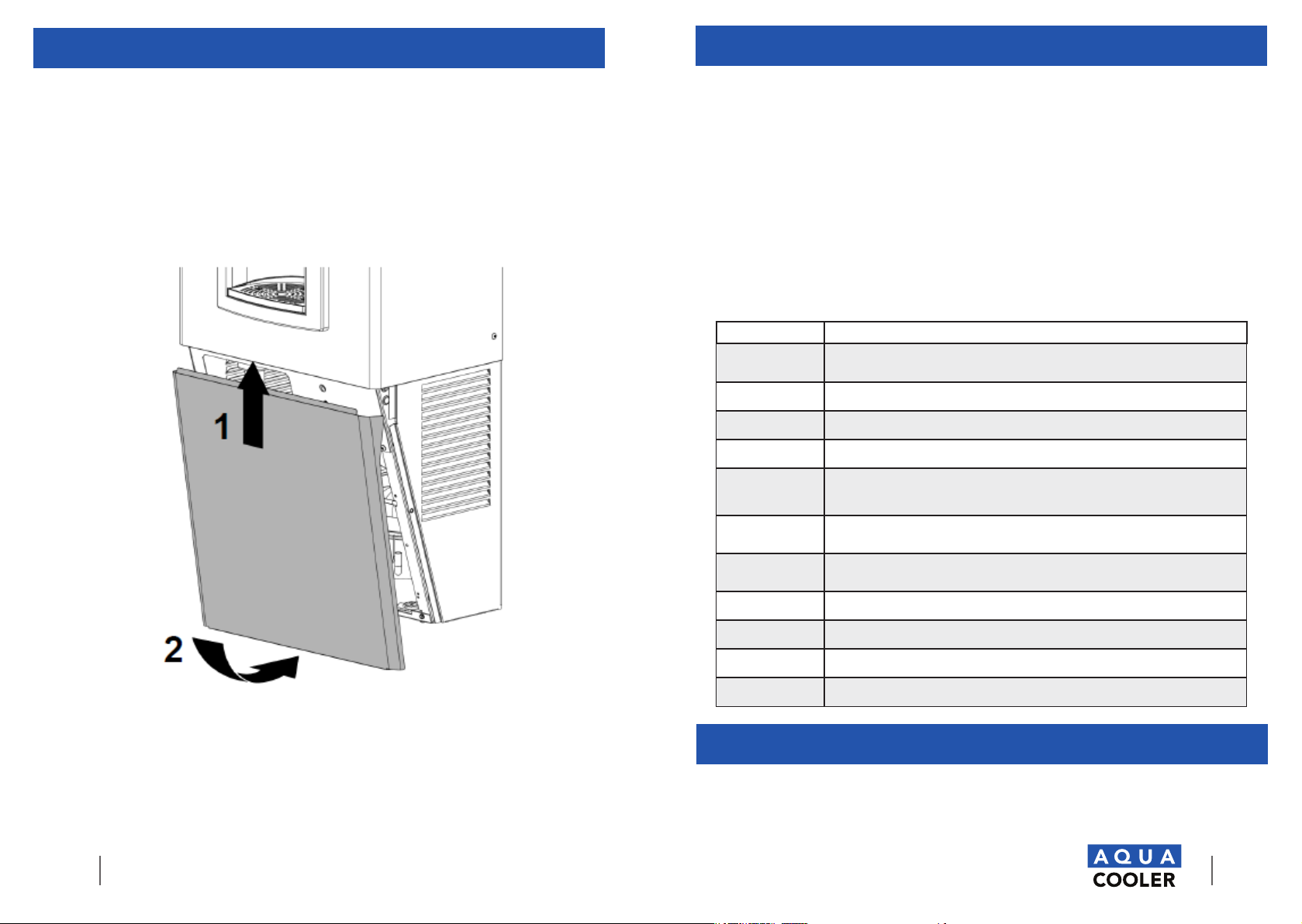

MAINTENANCE

Inspection of condenser should be made at 3 month intervals. To remove dirt and lint from

condenser, disconnect power supply cord, then use small stiff non wire or vacuum cleaner

attachment brush. Observance of this procedure will ensure adequate air circulation through

condenser so operation is efcient and economical.

Outside of unit can be wiped clean with mild soap and water mixture. Never use harsh chemicals

or abrasive cleaners, including any chlorine solutions. Rinse thoroughly with clean water, then dry

surfaces.

Overload Protection

The compressor motor, where used, is equipped with an automatic reset protector which will

disconnect the motor from the line in case of an overload.

Lubrication

This unit is equipped with a hermetically sealed compressor and requires no additional

lubrication. The fan motor, where used, on this unit seldom needs oiling, but if required, a few

drops of SAE 10 oil should be used.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

Controller is faulty Temperature sensor is faulty Check sensor connections.

Controller display is faulty Contact Aqua Cooler service team.

No water owing out of

the unit Water source has been suspended Restore water supply

The system is clogged Check the pipes

Solenoid valve is faulty Check controller and cable connections

Unit does not dispense cold

water The cooling controller is turned off Check the position of the mechanical thermostat

and set to desired temperature

Power failure Check the power cord is properly plugged in or if

there is a power outage

The ventilation around the unit is

insufcient Ensure sufcient ventilation space around the unit

System malfunction Contact Aqua Cooler service team.

The temperature of the incoming water

it too high Ensure the unit is not placed in direct sunlight or

close to other heat sources

Unit is noisy during operation Chiller unit in the machine is not level Place the chiller unit on a level at surface.

Chiller unit is touching other objects Ensure the chiller is standing free of any surrounding

objects.

The water being dispensed

has a strange taste. This is not uncommon with new

water oolers. Do not worry, this is not

dangerous to your health.

Flush as per installation instructions. Perform

cleaning procedure.

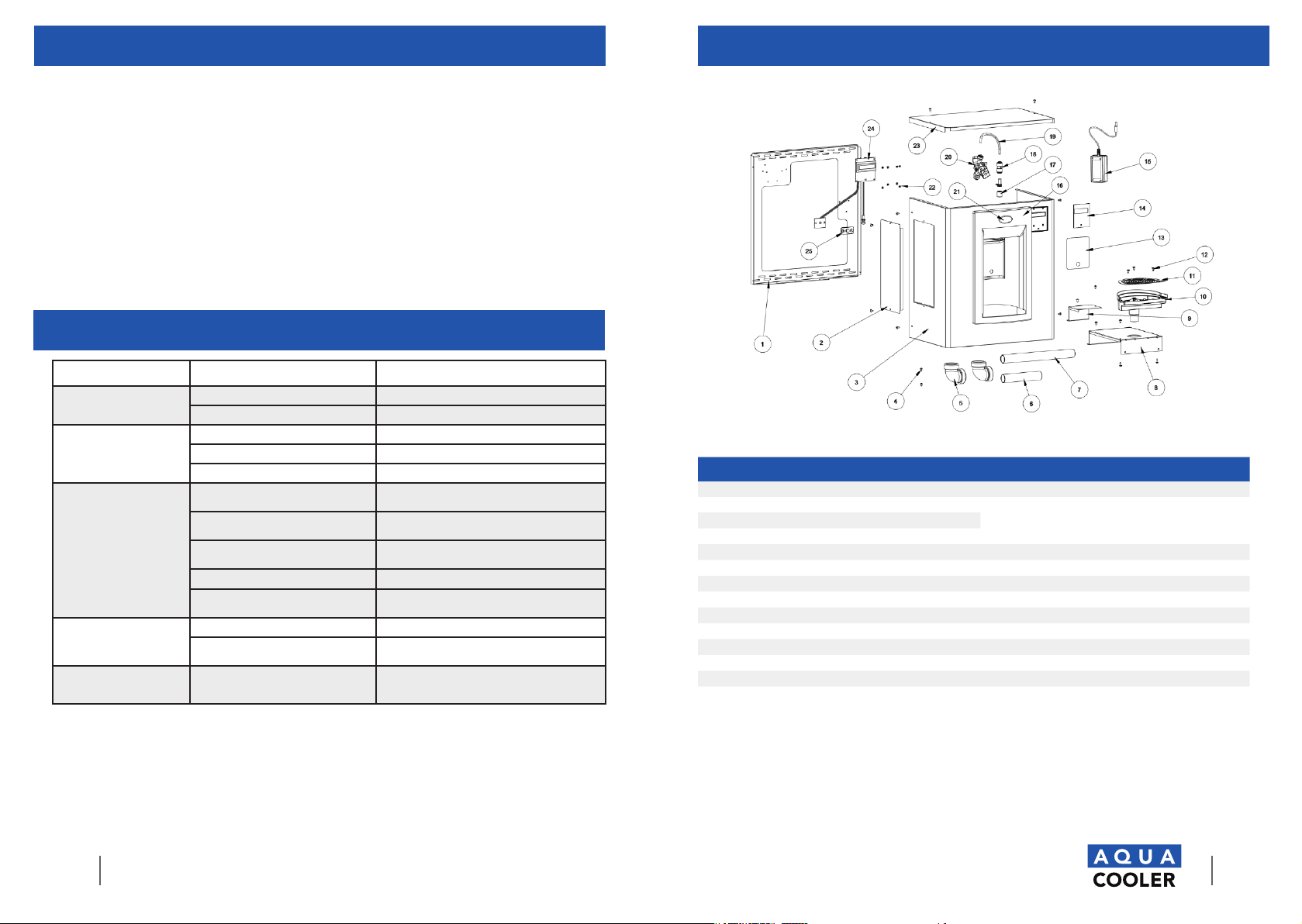

BOTTLE FILLER SPARE PARTS

ITEM QTY PART # DESCRIPTION ITEM PART # DESCRIPTION

1 1 041245-002 Frame 14 1 038031-005 Label, LCD Bezel

2 1 041241-001 Panel, NN Filter 15 1 038036-003 Power Supply,

100-240VAC/12VDC

3 1 041238-002 Wrapper

4 2 031875-003 Screw, Truss HD Tapping 16 1 036190-003 Alcove, EBF

5 2 A020967 1 1/2” Elbow, W/Nuts, 1 1/4” 17 1 038032-001 Flow Nozzle

6 1 036010-002 Waste, Tube 18 1 028668-101 FTG, PP Reducing Union

7 1 036010-013 Waste, Tube 19 1 030152-009-SP Tube, PE White 7.5”

8 1 041244-002 Bracket, Drip Tray 20 1 038030-002 Solenoid Valve 12VDC

9 1 041246-002 Bracket, Filter Support 21 1 031434-014 Nameplate, OASIS

10 1 036192-001 Drain, MSBF Support 22 1 026824-026 Nut, Hex Nylon

11 1 036192-001 Grille, Bottle Filler Drain 23 1 041243-002 Panel, Top

12 3 026675-003 Screw, Flat HD Tapping 24 1 038026-002 Electronics ASSY, IR/LCD

13 1 038031-006 Label, Alcove Sensor 25 1 038027-001 Lens, IR Bottle Filler