Copyright© 2016 Aqua Logic, Inc. Effective date of 1/2016

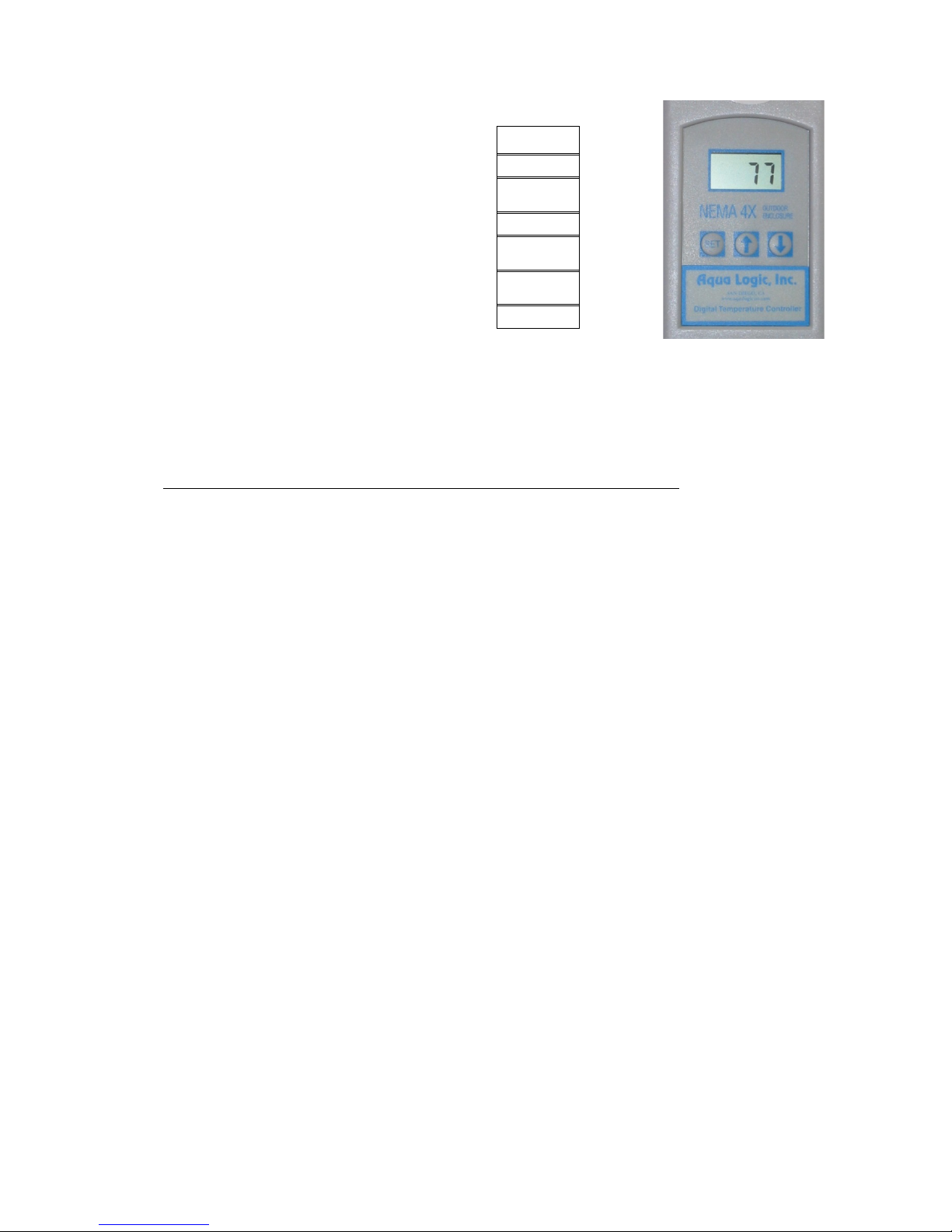

HEAT PUMP 2 STAGE CONTROLLER PROGRAMMING

or C

Fahrenheit or Celsius Scale

Stage 1 Set point Temperature

S1

Stage 1 Differential

Temperature

Stage 2 Set point Temperature

Stage 2 Differential

Temperature

Liquid Crystal Display (LCD)

The LCD display provides a constant readout of the sensor temperature and indicates if the output relay is energized. When the S1 or S2

annunciator is constantly illuminated during operation, the relay is energized. The display is also used in conjunction with the keypad to allow

the user to adjust the set point temperature, differential and heating /cooling modes.

Programming Steps and Display

The control can be programmed in four simple steps using the LCD display and the three keys on the face of the control. (See photo for

display and keys.)

NOTE: Stage 1 must be set for heat mode and Stage 2 for cool mode for correct operation.

1. To start programming, press the SET key once to access the Fahrenheit/Celsius mode. The display will show the current status, either F

for degrees Fahrenheit or C for degrees Celsius. Then press either the up arrow or down arrow key to toggle between the For C

designation.

2. Press the SET key again to access the heat mode set point temperature. The LCD will display the current set point temperature and the

S1 annunciator will be blinking to indicate that the control is in the set point mode. Press either the up key to increase or down key to

decrease the set point to the desired temperature.

3. Press the SET key again to access the heat mode differential temperature. The LCD will display the current differential and the DIF 1

annunciator will be blinking to indicate that the control is in the differential mode. Then press either up key to increase or the down

key to decrease the differential to the desired setting (minimum 1˚F, maximum 30˚F).

4. Press the SET key again to select heat mode. The LCD will display the current mode: C1 or H1. Then press either up key to increase

or the down key to select the correct Stage 1 mode. Stage 1 MUST be in the H1 mode for correct operation.

5. Press the SET key again to access the chill mode set point temperature. The LCD will display the current chill set point temperature and

the S2 annunciator will be blinking to indicate that the control is in the set point mode. Then press either the up key to increase or down

key to decrease the set point to the desired temperature. S1 and S2 should both be set for the same temperature.

6. Press the SET key again to access the chill mode differential temperature. The LCD will display the current differential and the DIF 2

annunciator will be blinking to indicate that the control is in the differential mode. Then press either up key to increase or the down

key to decrease the differential to the desired setting (minimum 1°F, maximum 30˚F). DIF1 and DIF2 should both be set to the same

value for best results.

7. Press the SET key again to access the heating mode. The LCD will display the current mode: C2 or H2 Stage 2 MUST be in the C2

mode for correct operation.

8. Press the SET key again to exit programming mode. Controller will display current water temperature.

Controller will automatically drop out of “program mode” and return to “operating mode” 30 seconds after last key press.

Troubleshooting Controller Error Messages:

Display Messages

•E1 - Appears when the up or down key is pressed when not in the programming mode.

To correct: If the E1 message appears even when no keys are being pressed, replace the control.

•E2 - Appears if the control settings are not properly stored in memory.

To correct: Check all settings and correct if necessary.

•EP - Appears when the probe and or flow switch is open shorted or sensing a temperature that is out of range.

To correct: Check to see if the sensed temperature is out of range. If not , check for probe damage by comparing it to a known ambient

temperature between -30˚F and 220˚F. Replace the probe is necessary. Also, check for proper water flow through heater. If water flow is

correct, flow switch.

•EE - Appears if the EEPROM data has been corrupted.

To correct: This condition cannot be field repaired. Replace the control.

•CL - Appears if calibration mode has been entered.

To correct: Remove power to the control for least five seconds. Reapply power. If the CL message still appears, replace the control