Unit Setups:

Heat Pumps Require the Following: (Please See Owner’s Manual for All Details)

-Water Flow, Water Flow & Water Flow!!! (Require: 25 to 80GPM & Recommend: 40 to 80GPM)(Vary per Model)

-Proper Voltage (Switch Wire Location on Transformer if 208 Volts) See details on other side of this Document.

-Proper Ground and Bond per NEC Requirements.

-Level Pad & Allowance for Condensation Drainage

-Installed Outside with Clearance around the Heat Pump for Maintenance and Air Flow.

-No Roof Drainage on Heat Pump

-Any Additional Heater(s) (Solar, LP, Natural, etc…) much be Downstream of Heat Pump(s).

-Any Chemicals added (Chlorinators, Salt Generators, etc…) must be added Downstream of any

Heater(s) with a Check Valve Separating them.

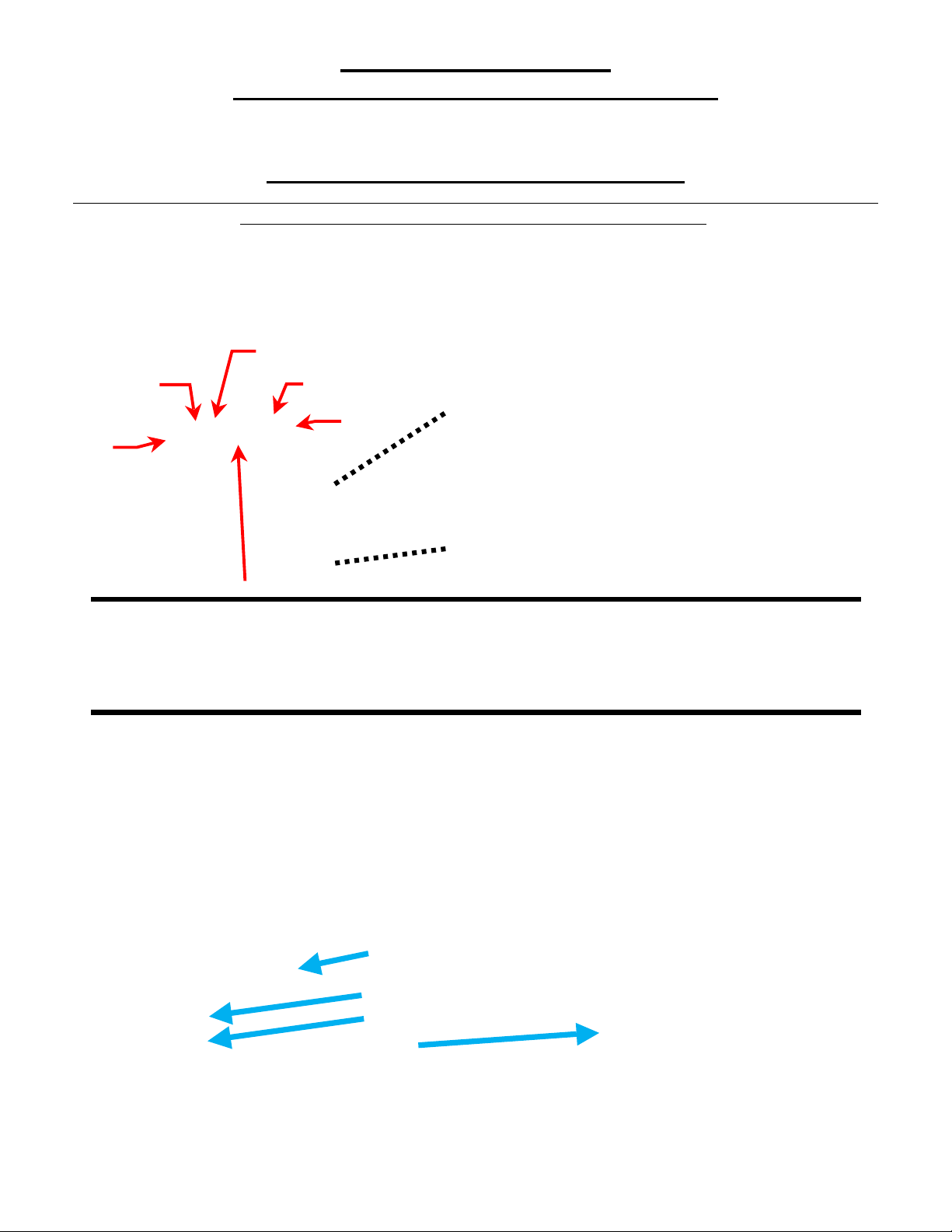

Commercial & Multiple Heater Setups:

-Water Flow, Water Flow & Water Flow!!! (Require: 25 to 80GPM & Recommend: 40 to 80GPM)(Vary per Model)

*Please Note: Due to Health Code Requirements Requiring a Mandatory GPM, Some Circumstances

Request Restrict the Water Flowing throughout the Heat Pump(s) to Increase the Total Required GPM

for the System… aka: HP Code. This can Results in Improper Water Flow Flowing throughout the Heat

Pump(s) which can Result in High Electric Bills, Voiding Warranty, Loss of Performance, Over Heating

the Heat Pump(s), Damage to the Unit, Fire, Injury, or Possibly Even Death. It is Required to have a

Water Flow Meter on All Heat Pumps. A Water Flow Meter will Help Guarantee a Longer, Better Life

& Performance of your Heat Pump(s).

-Proper Voltage (Switch Wire Location on Transformer if 208 Volts) See details on other side of this Document.

*** Failure to do so will result in voiding warranty, damage to the unit overtime due to Overheating Components, fire, injury,

or possibly even death.***

-Proper Ground and Bond per NEC Requirements.

*** Failure to do so will result in voiding warranty, damage to the unit, fire, injury, or possibly even death.***

-Level Pad & Allowance for Condensation Drainage.

-Installed Outside with Clearance around the Heat Pump for Maintenance and Air Flow. ***Please

Note: When Installing 2 Heat Pumps side-by-side, the Coil Clearance increases to 24” between Heat

Pumps.

-No Direct Roof Drainage on Heat Pump.

-Any Additional Heater(s) (Solar, LP, Natural, etc…) must be Downstream of Heat Pump(s).

-Any Chemicals added (Chlorinators, Salt Generators, etc…) must be added Downstream of any

Heater(s) with a Check Valve Separating them.

-For any questions regarding Plumbing Recommendations, Please Call Manufacture.

Winterizing:

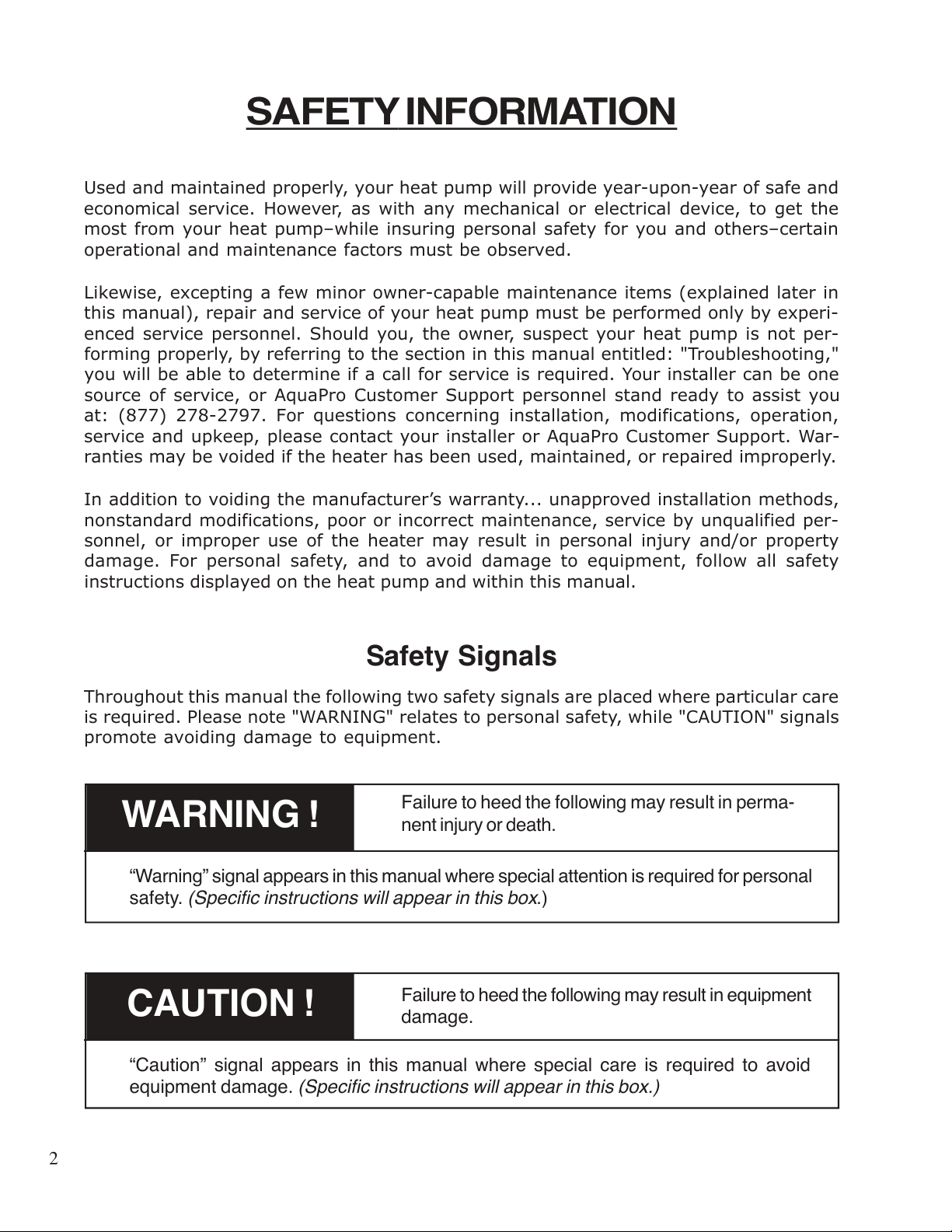

After shutting Down the Pool and (or) Spa with All Water Removed from the Plumbing/ PVC,

Disconnect the Supplied Unions on the Front of the Heat Pump. Use an Air Blower to Blow the Water

Out of the Heat Pump. The Air Blower has to be High Volume, but Low Pressure (like a Shop Vacuum

in Reverse). Blow into the Inlet until the Water stops coming out of the Outlet, then Blow into the Outlet

until water stops coming out of the Inlet. Cycle back and forth until No Water coming out in Any

Direction. Start the Unions back on the Heat Pump to Prevent Dirt, Debris, Foreign Objects and (or)

Bugs, Snakes, Mice, Lizards, Frogs, etc… from Entering the Heat Pump Plumbing.

***For More Details: Please Refer to Owner’s Manual or Contact the Manufacture with the Supplied

Number on your Heat Pump Serial # Decal with the Serial # Available. Thank you***