Safety Volt Transformer Warranty

This Limited Warranty applies to the models listed in this guide (all versions and voltages) purchased through an

authorized dealer and installed inside the contiguous United States after May 01, 2011. This warranty shall begin

upon the date of purchase as verified by the owner/operator’s proof of purchase documents. In lieu of owner

documents, the warranty initiation date shall be sixty-days (60) from the date of manufacture (as verified by

factory production records). AquaCal AutoPilot, Inc. (hereafter referred to as: “Manufacturer”) warrants the

following models (hereafter referred to as: "product"), to the original owner and installation site, to be free of

material or workmanship defects for a limited term.

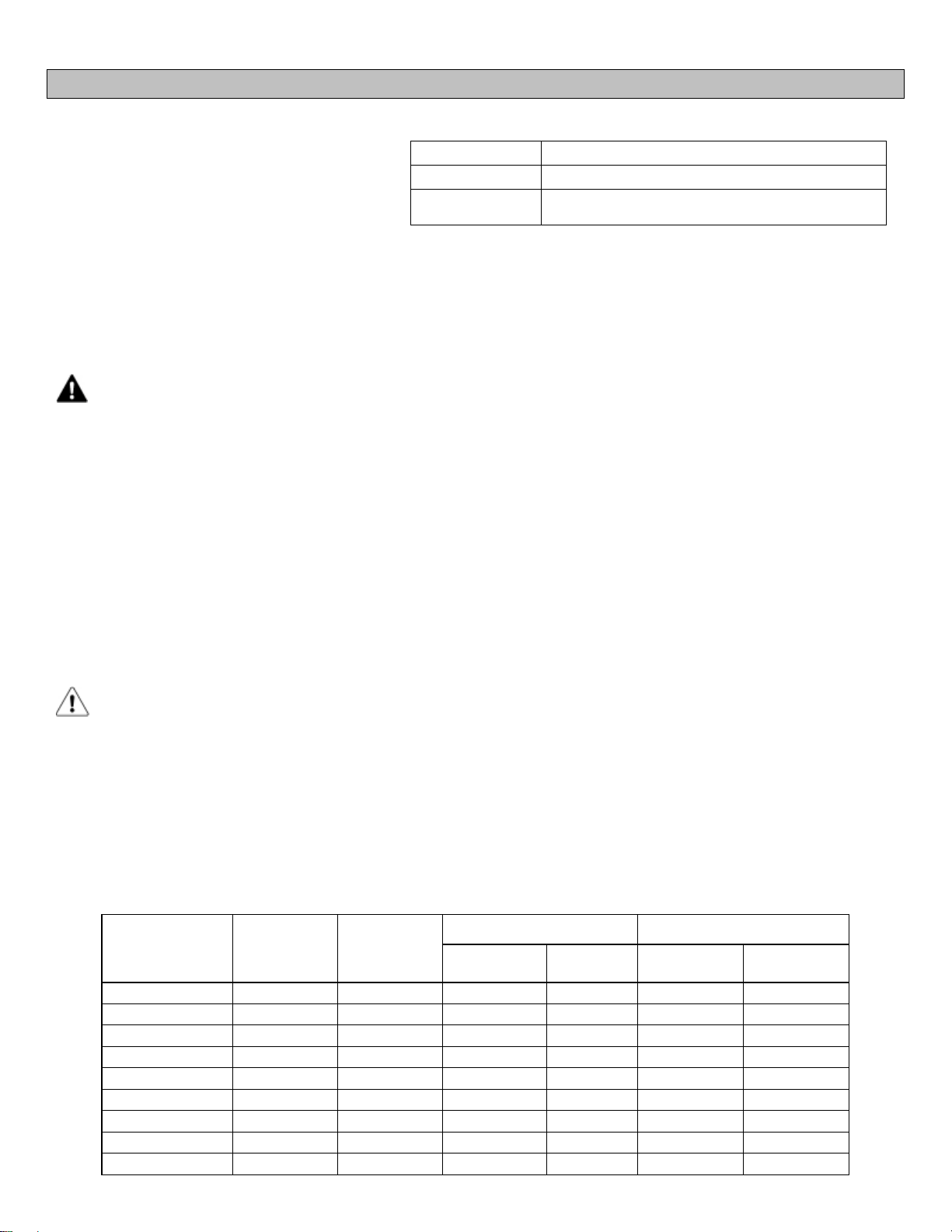

Residential

and

Commercial 5 Years Parts

Replacement parts are additionally warranted for a period of one year or the end of the original warranty term, whichever is

greater.

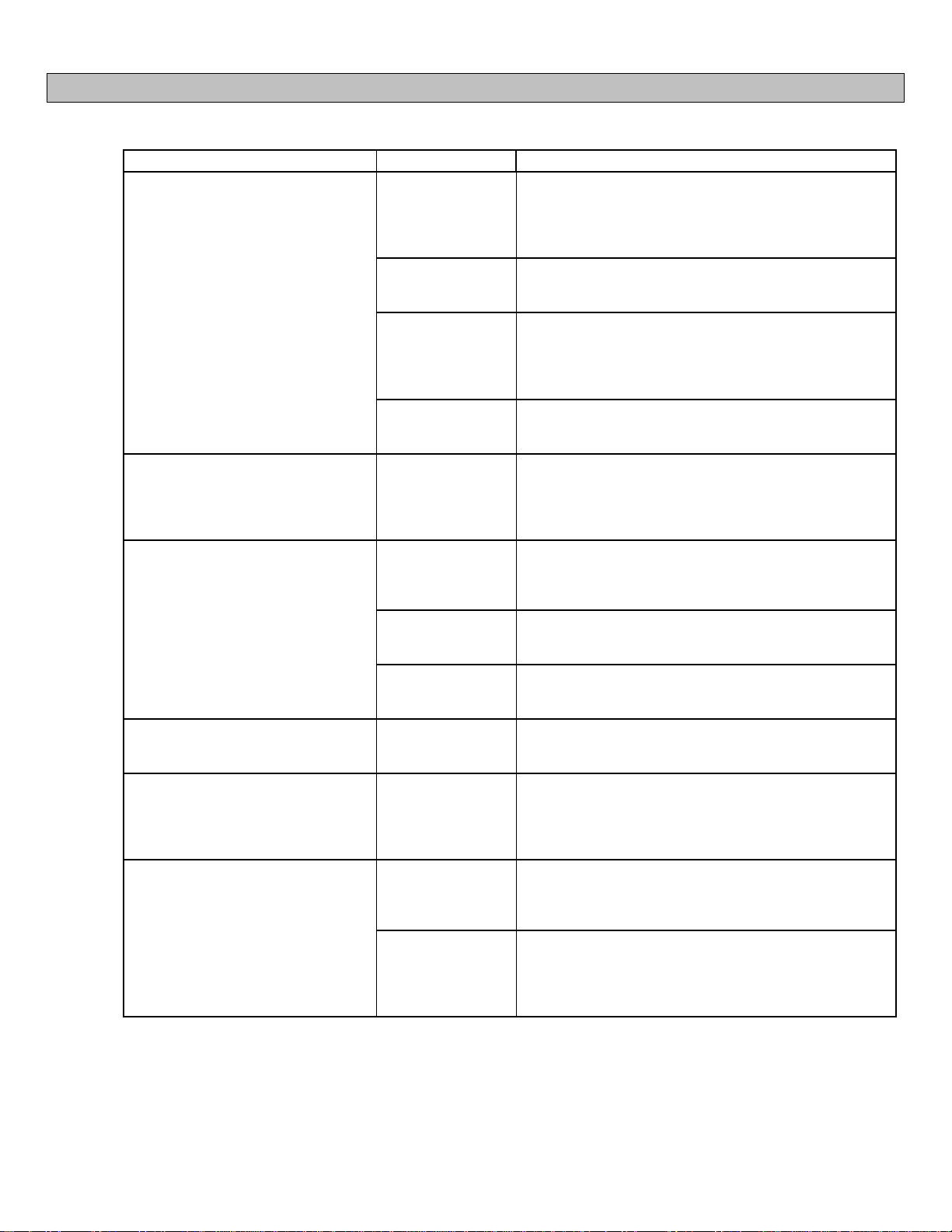

1) This warranty does not include transportation charges for equipment or component parts to, or from, the Manufacturer.

The owner/operator shall be responsible for any travel charges imposed by the warranty center or servicing agent.

2) At its sole discretion, the Manufacturer reserves the right to replace defective parts with new or refurbished replacement

parts.

3) At the option of the Manufacturer, the Owner may be required to return the product to the factory, freight prepaid, to

provide warranty service. This may become necessary if the product was installed in an area not supported by a Factory

Authorized Service Center.

4) Claims for warranty reimbursement must have prior authorization by the Manufacturer and be performed by a Factory

Authorized Service Center.

5) The use of parts other than genuine Manufacturer parts will void this limited warranty.

6) Purchasing original and / or replacement equipment through an un-authorized dealer will void this limited warranty.

7) This warranty is applicable only if the product has been installed, operated, and maintained expressly and completely in

accordance with this product’s installation guide.

8) This warranty is void if the product is repaired, replaced, or altered in any way by any persons or agencies other than a

Factory Authorized Service Center, and is in lieu of all other warranties, expressed or implied, written or oral.

9) The liability of the Manufacturer shall not exceed the repair or replacement of defective parts under the referenced

limited warranty term and shall not include applicable consumables.

10) This warranty does not include damage due to freezing conditions, negligence or abuse, installations in corrosive

environments or atmospheres, nor acts of God.

11) There are no implied warranties of merchantability or fitness for a particular purpose that apply to this product. Under no

circumstances shall the Manufacturer be liable for any loss, damage, or injury, whether direct, consequential or

incidental, arising out of the use or inability to use this product.

12) Each application has its own individual requirements. This limited warranty does not warrant that this product will supply

100% of those requirements.

13) No dealer, distributor, or other similar person has any authority to make or extend any warranties or representations

concerning Manufacturer’s products beyond the express terms contained herein. Manufacturer assumes no

responsibility for any warranties beyond the expressed terms contained in this limited warranty. Customer releases and

holds Manufacturer harmless from any claims stemming from any unauthorized representations.

14) The foregoing limited warranty gives the Customer specific legal rights that may vary from state to state, and

accordingly, some of the listed conditions and exclusions may not apply to Customers living in certain states. Any

dispute between Customer and Manufacturer will be settled by binding arbitration, conducted in Pinellas County, Florida,

under the rules of the American Arbitration Association, and an award of attorney’s fees and costs will go to the

prevailing party.