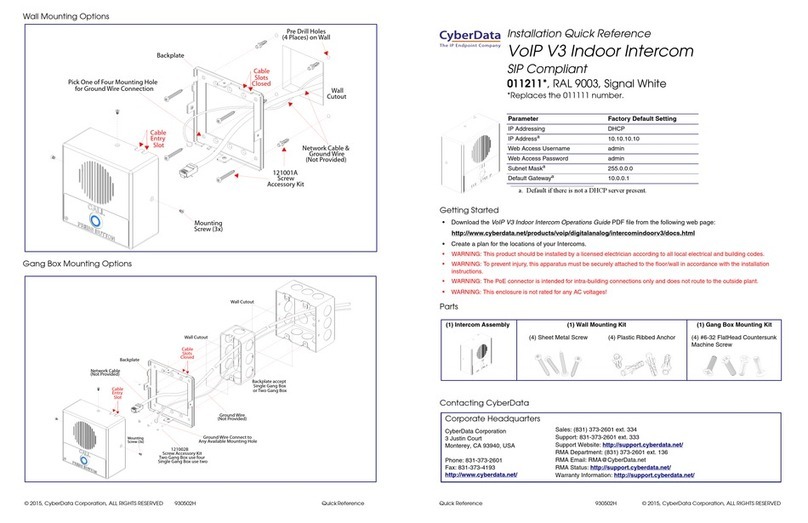

2.3.1.3 Shielded Cable: Another available cable contains at least one twisted,

shielded balanced cable and a second twisted, shielded or unshielded pair. The

unshielded pair is used for the earphones, while the balanced, twisted pair is used

for the microphone. Unlike spiral four cable, little can go wrong with this system,

provided the microphone is connected to the shielded, twisted, balanced cable.

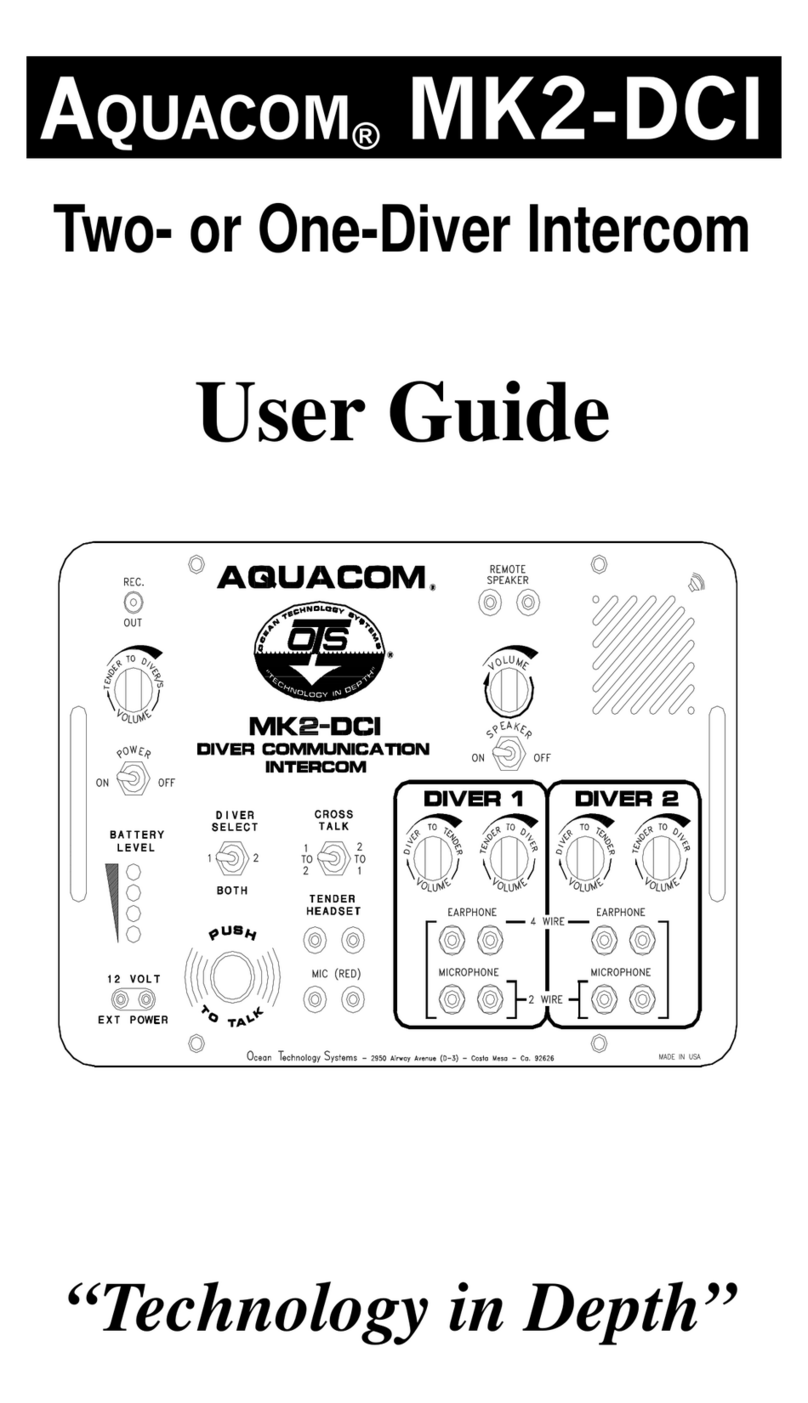

2.3.2 DIVER MICROPHONES

See Figure 1 for examples of non-powered and powered (preamplied) micro-

phones.

2.3.2.1 ME-16R Hot-Mic

®

(912086-000): The ME-16R Hot-Mic

®

(Fig. 1A) is

a 150-ohm, water-resistant microphone element. It is a state-of-the art dynamic

microphone element designed to give you long, trouble-free use and the highest

intelligibility possible.

Although the Hot-Mic is trouble free, it should be maintained. Rinse it with

freshwater after use to get all dirt, debris, or salt water from the grill. Dry it with a

clean, soft towel. If the element ever needs to be replaced, it is easily removed by

unscrewing the two small screws located on its base.

Getting the microphone wet does not harm it. However, the microphone element

can only withstand an 8- to 10-foot depth/pressure differential. If you removed your

diving FFM at the back of the boat and the microphone became wet, there would

be no problem; but if the FFM with element dropped more than 8 to 10 feet into the

water, the change in pressure probably would damage the microphone element. In

tests we have taken off the FFM at 30 feet and replaced it, still at 30 feet, without

any problem; but if one were to take off the FFM at 30 feet and drop down to 40

feet, the pressure difference may damage the microphone.

2.3.2.2 Super Mic

®

Depth Master: The Super Mic

®

offers patented technol-

ogy* that overcomes a limitation of other microphones. It can be used at any depth

and—unlike the Hot-Mic or many other microphones—can withstand changes in

depth while submerged, so it will not be damaged if the diver needs to descend

with the mask ooded (such as when a full-face mask is removed and stowed

when the diver changes to another air system). It is a ceramic microphone with a

compact, lightweight design and noise-cancelling properties, reducing background

noises for clearer communications. When only the highest quality of intelligibility

is required, the Hot-Mic is the preferred choice; but the Super Mic’s intelligibility

is sufcient for most diving situations.

To assure clear communications when using the Super Mic, it should be no more

than 1/4 inch from the corner of the diver’s mouth.

After each dive, clean the Super Mic by rinsing it with freshwater and drying it

with a clean, soft towel. No other maintenance is required.

5

*U.S. Patent no. 7,170,822; EU patent nos. 000458351-0001, -0002, -0003, -0004, -0005, -0006.