2 English

Contents

General notes

Read these operating instructions before using the system for the

first time. Also observe the original data sheets provided in the

appendix and the operating manuals for the units used. Keep

these documents for future reference or for future owners.

Target group for these instructions:

Operator

Technical specialists (persons possessing the necessary techni-

cal training allowing them to erect and commission the system)

Instructed assistant personnel

Definitions:

Fresh water is tap water.

Waste water is the dirty water coming from the washing facility.

Recycling / processed water is the treated water coming from

the treatment system that is re-used in the vehicle washing fa-

cility.

Running-in phase BioSaver®/ WRB Bio

The system requires a running-in phase of 3-6 weeks in order to

develop its full cleaning performance. The running-in phase be-

gins on the day when waste water containing treatable substanc-

es (mineral oils and company-internal waste water) is regularly

channelled into the system. During the running-in phase, the mi-

crobiological system can temporarily produce increased quanti-

ties of foam in the washing facility. Do not supply any heavily

contaminated waste water into the system during the running-in

phase.

Note

It has been observed that the drainage channels in the washing

halls and the sludge traps of the separator system are misused

for disposing of waste during the installation process. To prevent

system malfunctions during operation, such as clogging or dam-

age to the pumps, clean all foreign materials from the drainage

channels before channelling waste water into the system for the

first time.

Note

The waste water resulting from the cleaning of buildings (walls,

floors, containers etc.) may not be cleaned in the treatment sys-

tem. The system is not designed for processing or disposing of

this type of waste water.

aquadetox international GmbH accepts no liability of any kind for

damage or operational malfunctions resulting from inadequate

cleaning of the entire system.

Intended use

The BioSaver®/ WRB Bio is a biological process for waste water

treatment. The system is intended for cleaning and recycling the

waste water generated by various different types of vehicle wash-

ing facilities. The recycling water may only be used for washing

programs (e.g. pre-cleaning, high-pressure cleaning, brush

cleaning).

The waste water is cleaned through:

Settling of non-soluble particles in the sludge trap

Separation of the excess sludge in the post-treatment stage

Substance transfer of the soluble substances in the biological

stage

Environmental protection

The packing materials can be recycled. Please dispose of

packaging in accordance with the environmental regula-

tions.

Electrical and electronic devices contain valuable, recycla-

ble materials and often components such as batteries, re-

chargeable batteries or oil, which - if handled or disposed of

incorrectly - can pose a potential danger to human health and the

environment. However, these components are required for the

correct operation of the device. Devices marked by this symbol

are not allowed to be disposed of together with the household

rubbish.

On renewal of the filter material, the used filter material must be

disposed of in accordance with the applicable local regulations.

Notes on the content materials (REACH)

Current information on content materials can be found at:

www.kaercher.de/REACH

Accessories and spare parts

Only use original accessories and original spare parts. They en-

sure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at

www.kaercher.com.

Warranty

The warranty conditions issued by our relevant sales company

apply in all countries. We shall remedy possible malfunctions on

your device within the warranty period free of cost, provided that

a material or manufacturing defect is the cause. In a warranty

case, please contact your dealer (with the purchase receipt) or

the next authorised customer service site.

Safety instructions

Read the original operating manual before operating the

system for the first time. Proceed accordingly. The operat-

ing instructions must be accessible to all operators.

All persons working on the erection, commissioning, servicing,

maintenance and operation of the system must possess the fol-

lowing knowledge:

Know and adhere to the following regulations.

– National and local waste waster system regulations

– National and local accident prevention regulations

– Directive on protection from hazardous substances CHV5

(German "Gefahrstoffverordnung GefStoffVO")

Know and adhere to the operating manual for the system.

Familiarise yourself with the following regulations and guidelines

before installation and initial commissioning of the system:

EN 60204-1: Electrical equipment of machines

Local energy supply company regulations

Directive on protection from hazardous substances CHV5

(German "Gefahrstoffverordnung GefStoffVO")

The applicable national regulations

Prerequisites for operating the system:

The operator must be instructed in the correct handling of the

system.

The operator must provide verification of their capability to op-

erate the system.

The operator must be explicitly nominated to operate the sys-

tem.

Only a regularly serviced system is safe. Take care to ensure that

the maintenance intervals and instructions in the operating man-

ual are adhered to. Failure to adhere to this will invalidate all war-

ranty claims.

Servicing work may only be performed by customer service pro-

viders authorised by the manufacturer and by instructed technical

specialists.

General notes ................................................................... 2

Intended use ..................................................................... 2

Environmental protection .................................................. 2

Accessories and spare parts............................................. 2

Warranty ........................................................................... 2

Safety instructions ............................................................ 2

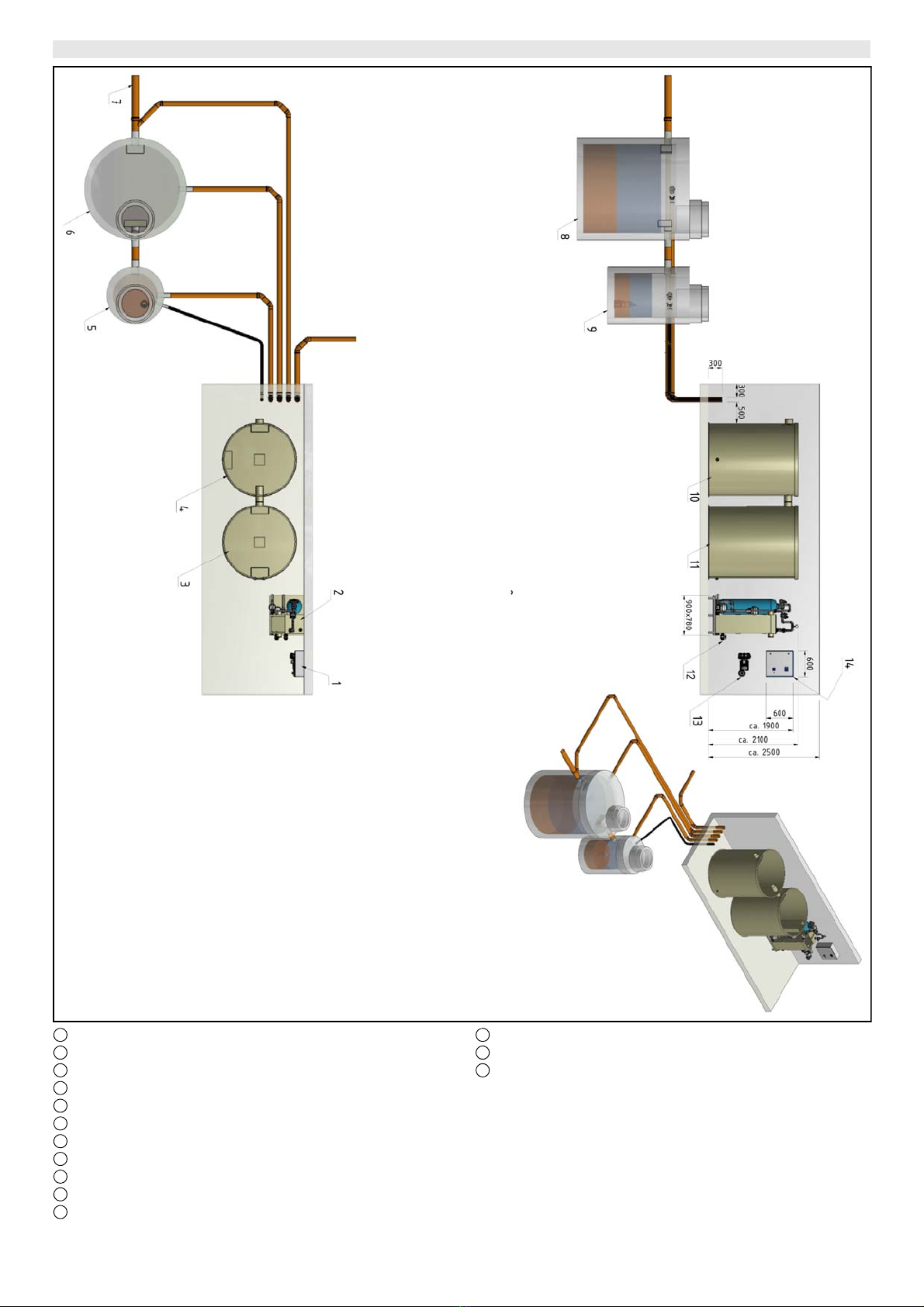

System description............................................................ 4

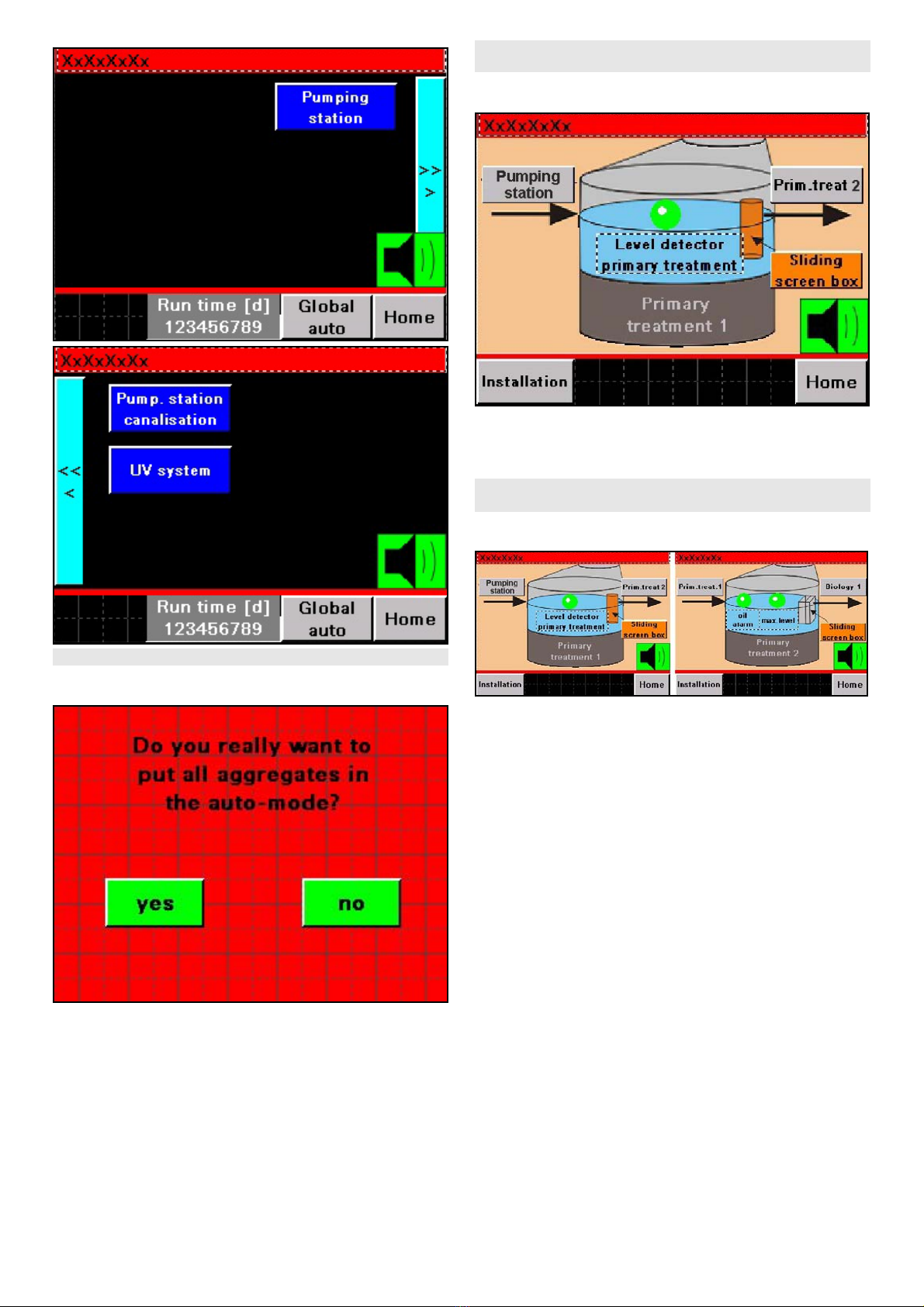

Operation .......................................................................... 7

Care and service............................................................... 15

Troubleshooting guide ...................................................... 18

Technical data................................................................... 20

EC Declaration of conformity ............................................ 20