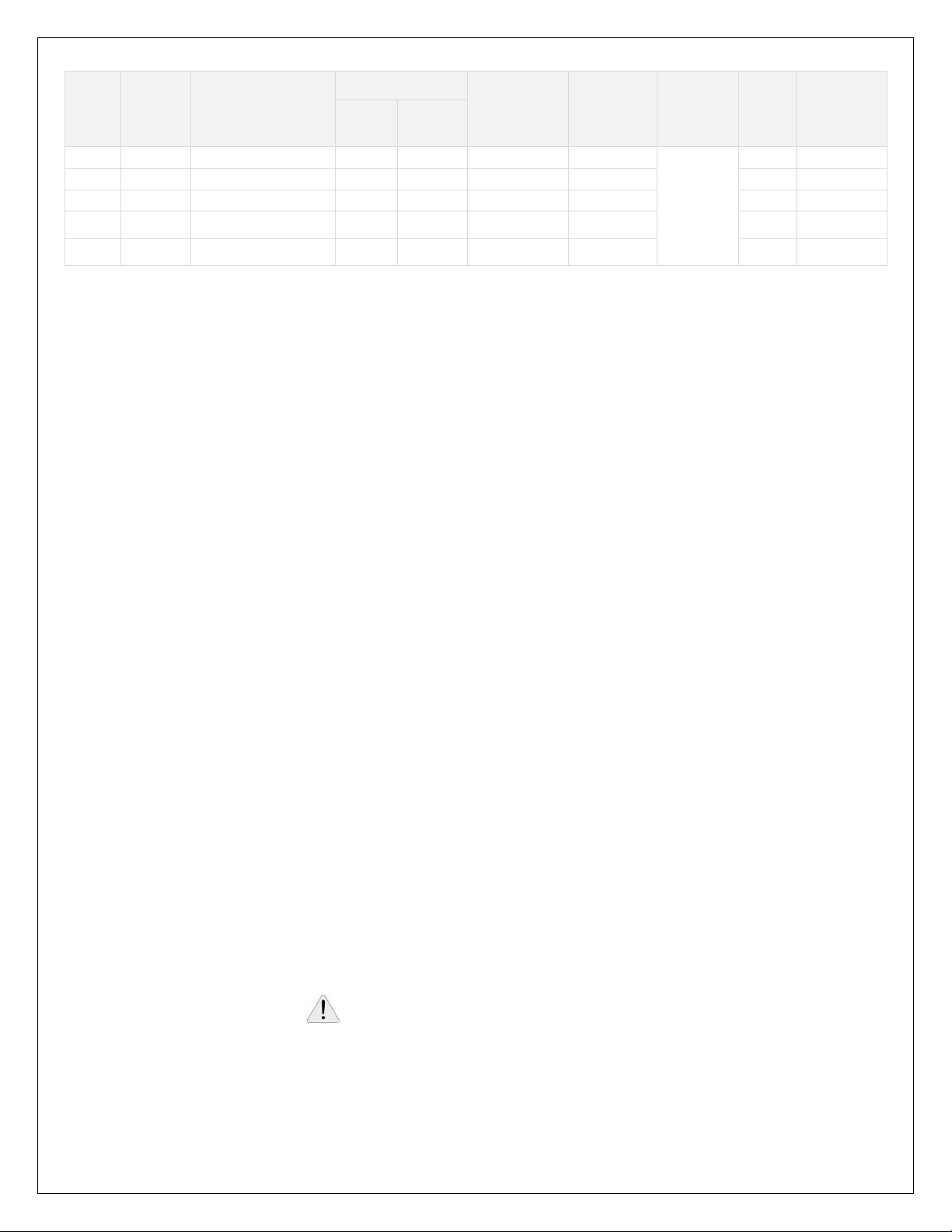

A. SYSTEM SPECIFICATIONS & DIMENSIONS

System

Capacity

(Grains)○

Rated Softening

Capacity (Grains)

Pressure Drop

at Rated Service

Flow (psi)

Max Flow

to Drain

(US GPM)

The manufacturer reserves the right to make product improvements which may deviate from the specifications and descriptions stated herein, without

obligation to change previously manufactured products or to note the change.

These softeners conform to NSF/ANSI 44 for the specific performance claims as verified and substantiated by test data. These models are efficiency

rated. The efficiency rating is valid only at the stated salt dose and maximum service flow rate. They have a demand initiated regeneration (D.I.R.)

feature that complies with specific performance specifications in-tended to minimize the amount of regenerant brine and water used in their

operation. These softeners have a rated softener efficiency of not less than 3350 grains of total hardness exchange per pound of salt (based on sodium

chloride) and shall not deliver more salt than their listed ratings. The rated salt efficiency is measured by laboratory tests described in NSF/ANSI

Standard 44. These tests represent the maximum possible efficiency that the systems can achieve. Operational efficiency is the actual efficiency after

the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and

other contaminants that reduce the softener’s capacity.

Feed Water Quality:

Iron < 0.5 PPM; Manganese < 0.05 PPM ; Turbidity < 1 NTU ; Free Chlorine < 0.5 PPM ; Hydrogen Sulphide –Nil ; Organics –Nil.

If feed water quality exceeds above limits, please call Rainfresh for advice on additional treatment that may be necessary.

B. HOW YOUR WATER CONDITIONER WORKS

Your Rainfresh Softener removes hardness using a process called Ion Exchange. In this process, when hard water flows

through the unit, hardness-causing minerals such as Calcium & Magnesium, are trapped by the media (called Resin) and an

equivalent amount of sodium ions are released into the water. When the capacity of the resin to trap hardness minerals is

exhausted, the unit is re-charged by softener salt in an automatic process called Regeneration. During regeneration, the

unit first backwashes to remove any sediment, rust or other particulates, that may have accumulated in the unit. This is

followed by introduction of a saturated salt solution (brine) that bumps off the trapped hardness to drain and recharges the

resin with sodium. It then goes through a final rinse & refills the salt tank with water for the next regeneration.

Once you program the unit at the time of installation, the regeneration process happens automatically. All you need to do is

to ensure that there is always enough salt in the salt tank. The unit automatically calculates when to regenerate based on

your water hardness and use.

C. SAFETY PRECAUTIONS

-Follow all applicable province/state and local regulations.

-Handle your water softener carefully. Do not lie on side, turn upside down, drop or drag.

-This softener uses salt (sodium chloride) to regenerate. Persons on sodium restricted diets should consider the

added sodium as part of their overall intake. Potassium chloride can be used as an alternate in such situations.

Please consult Rainfresh technical support.

○ –@ 15 lbs salt/ft³. Values not supported by test data. Only tested at one salt

setting (Rated Capacity)

•Rated Efficiency : 4,543 grains/lb of salt

•Feed Water Temperature = 4°C - 38°C (39 - 100°F)

•Operating Pressure = 25 (172 kPa) - 100 PSIG (689 kPa)*

•Voltage = 110 V AC

* Note: Install pressure regulator and water hammer arrestor if pressure

exceeds rated pressure at any time.

•At the stated service flow rates, the pressure drop through these

devices will not exceed 15 psig.

•The manufacturer reserves the right to make product

improvements which may deviate from the specifications and

descriptions stated herein, without obligation to change

previously manufactured products or to note the change.