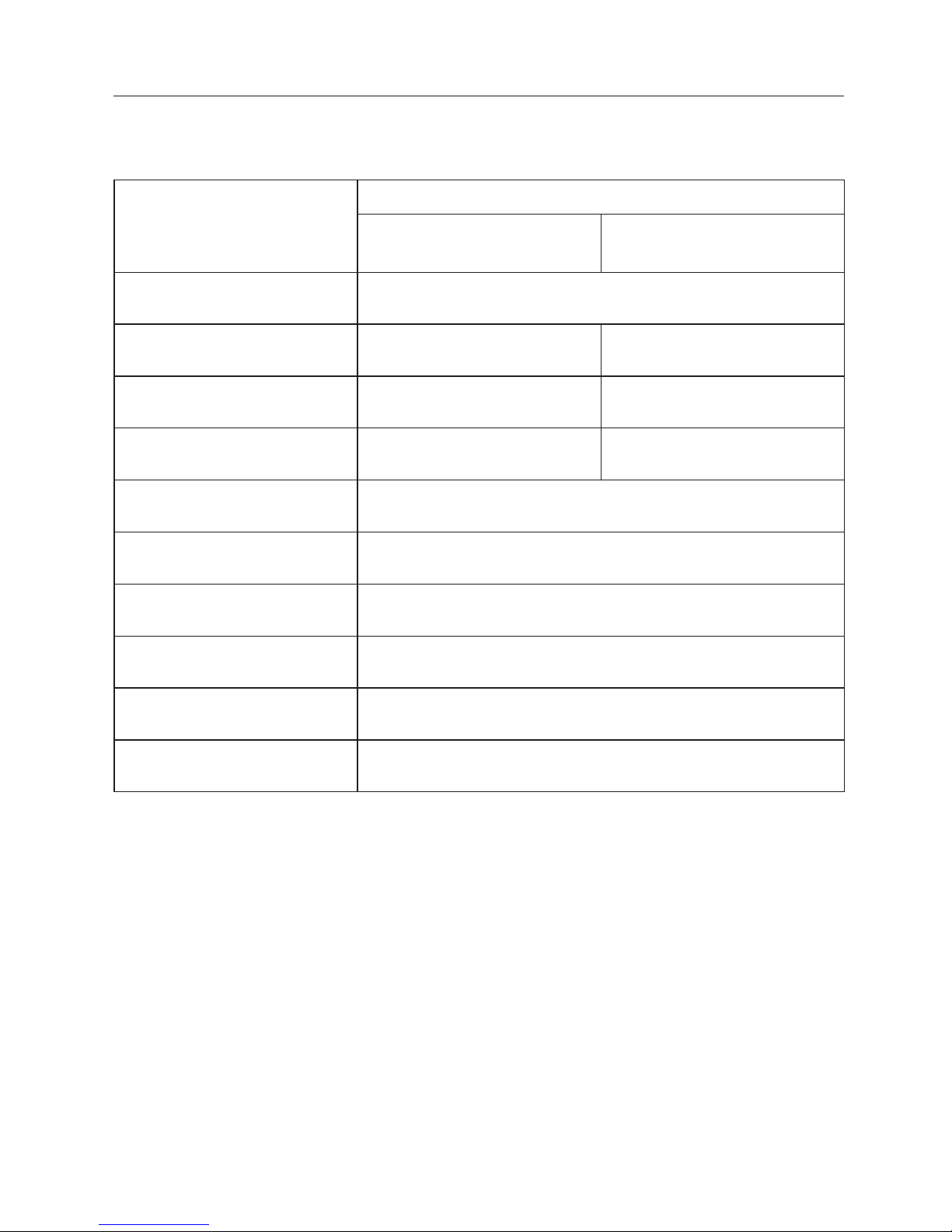

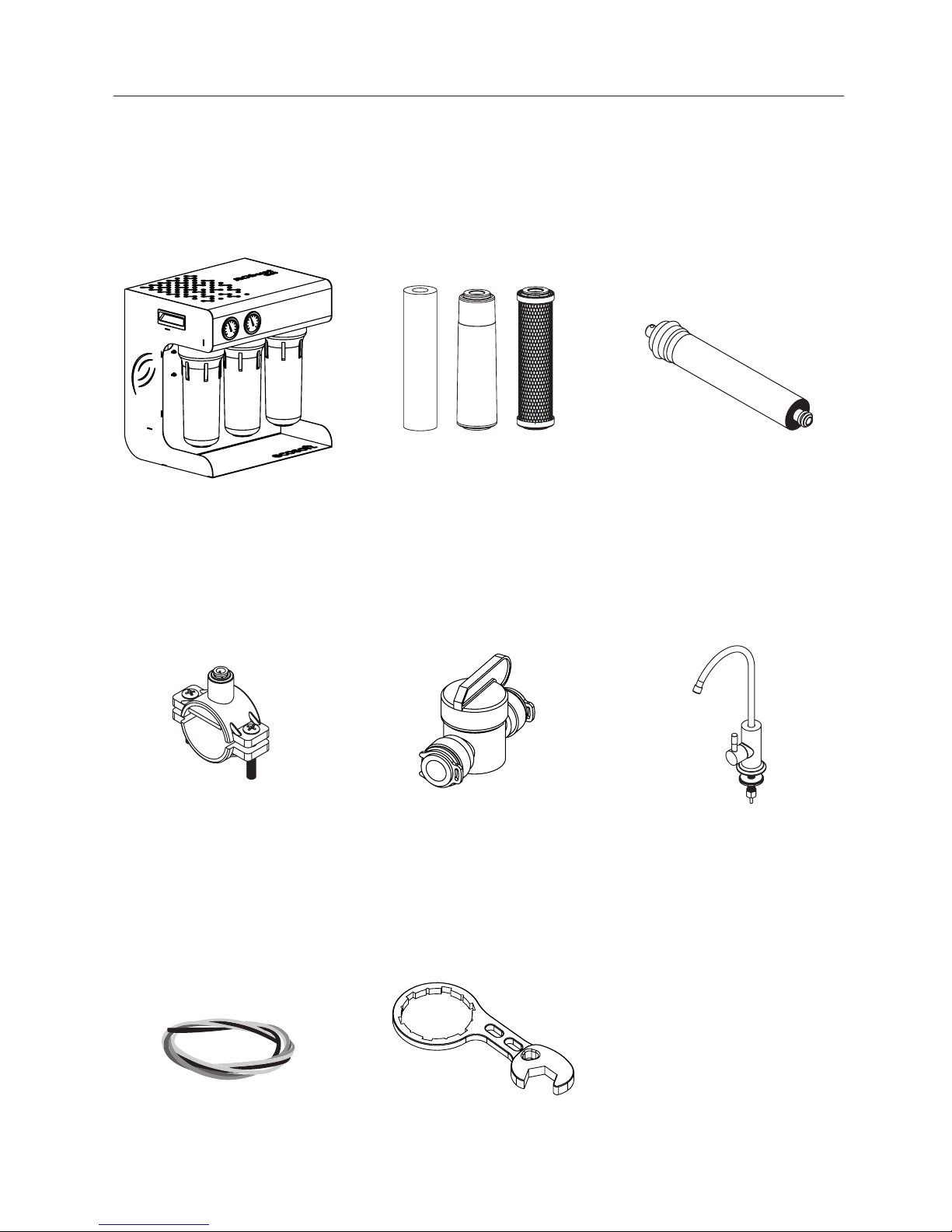

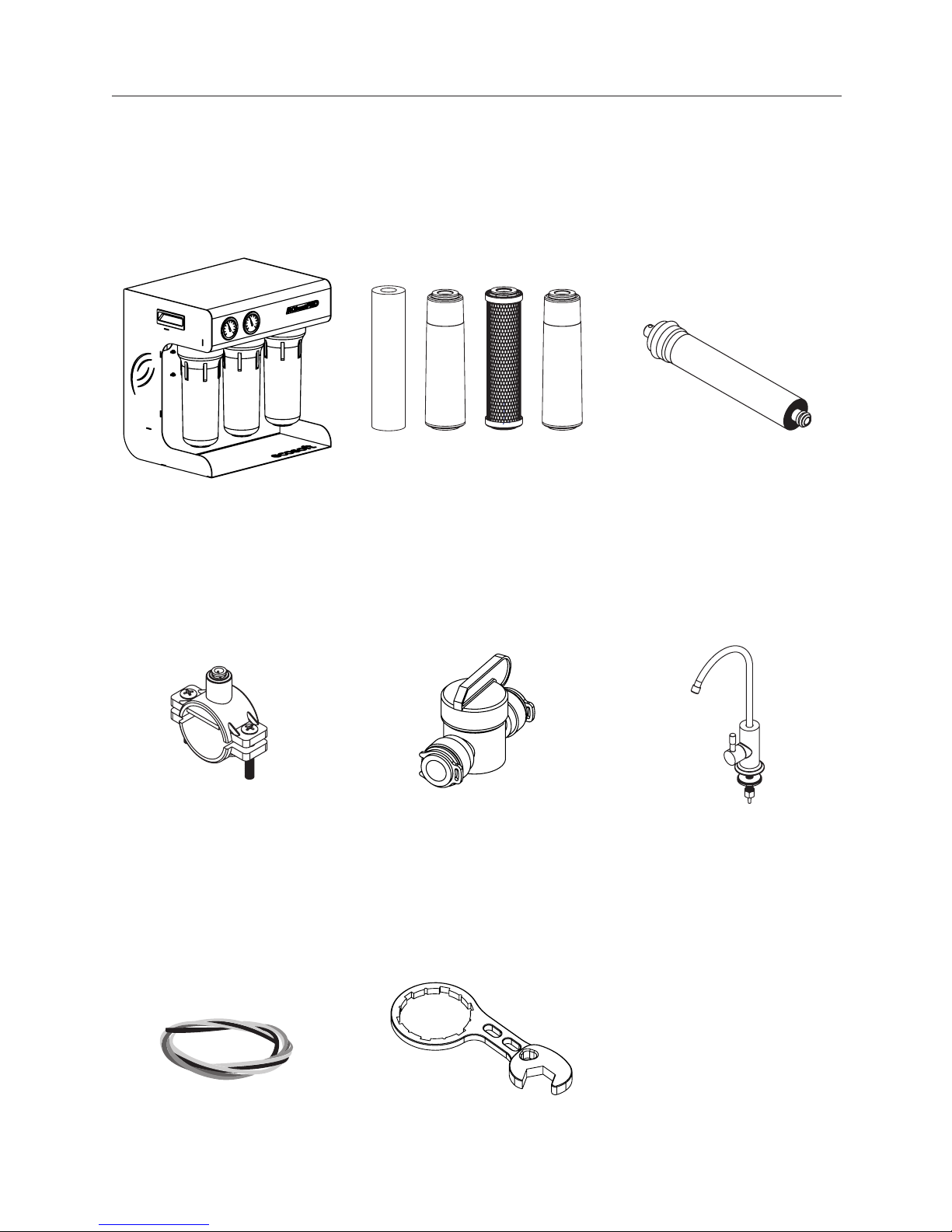

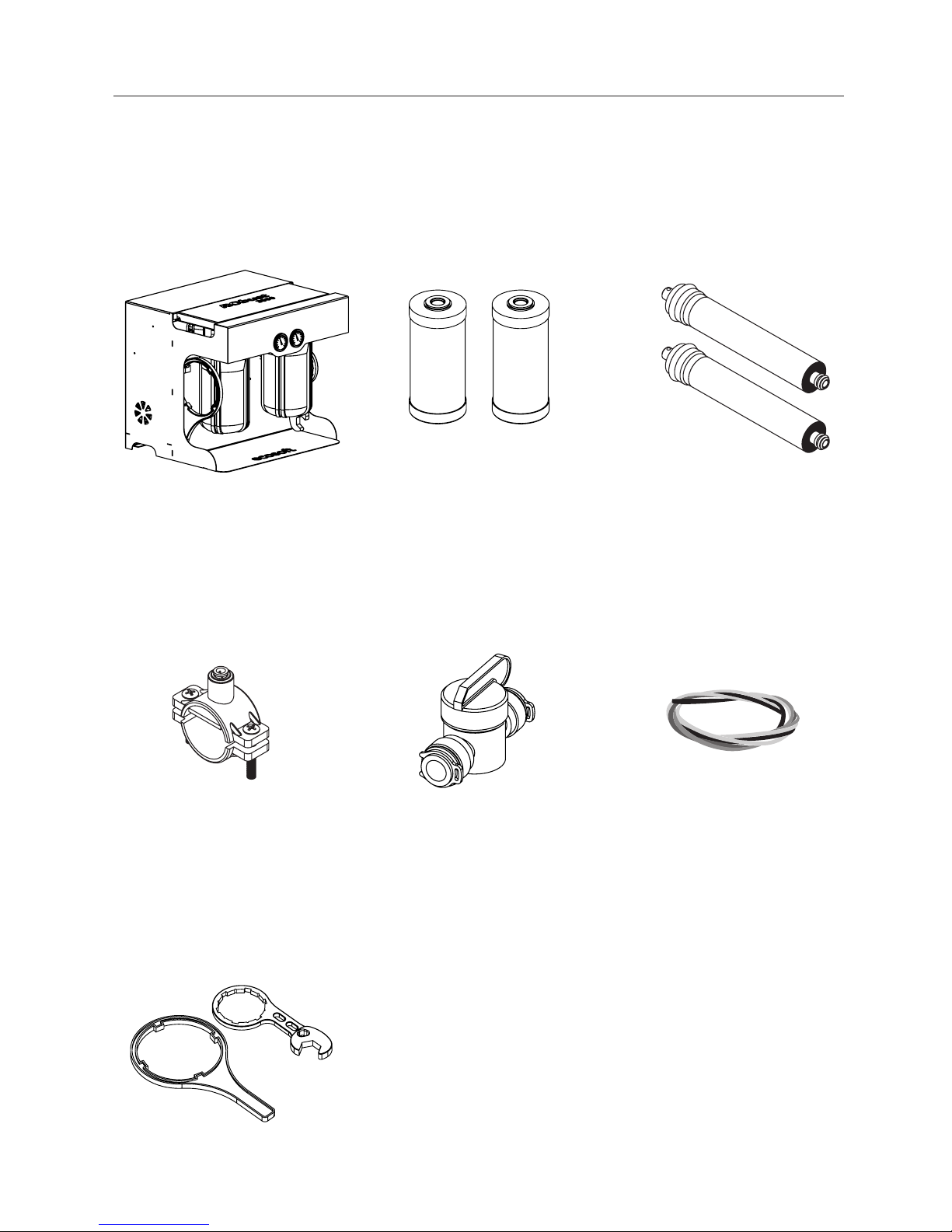

1Remove the reverse osmosis system from and the box check that all parts are inside the bag.

2Shut o water supply in place of installaon and open a water tap for 1 minute to relieve

pressure in the system. Then close the tap.

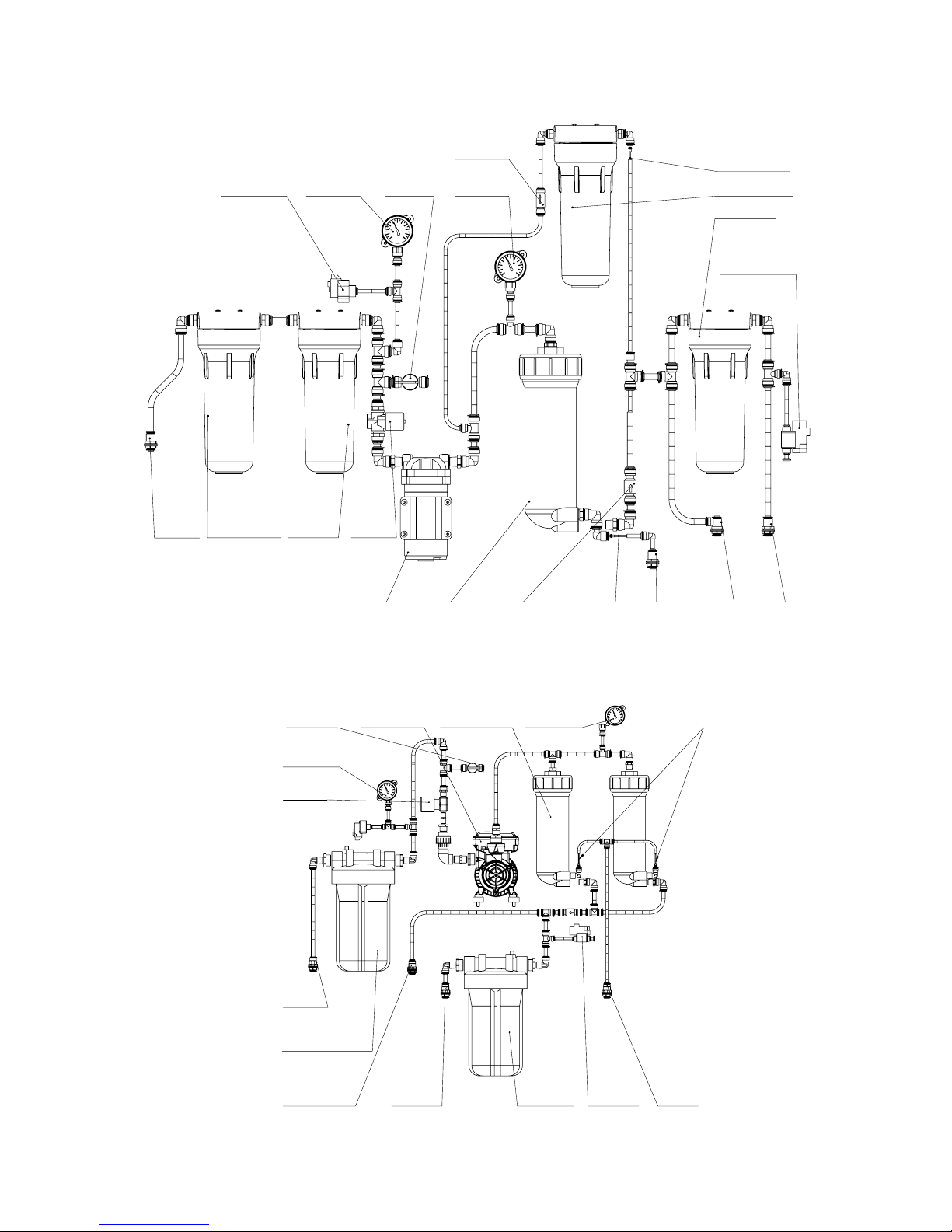

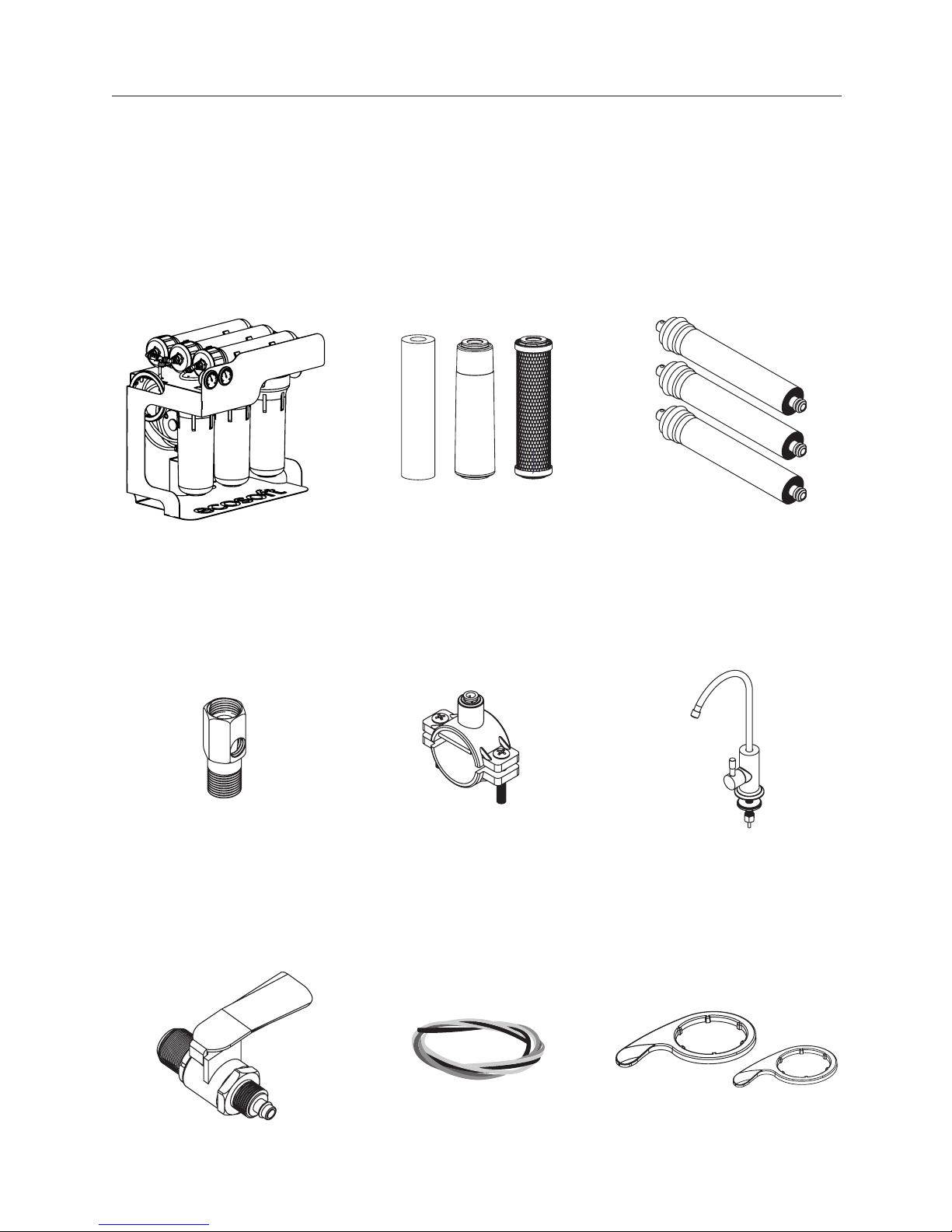

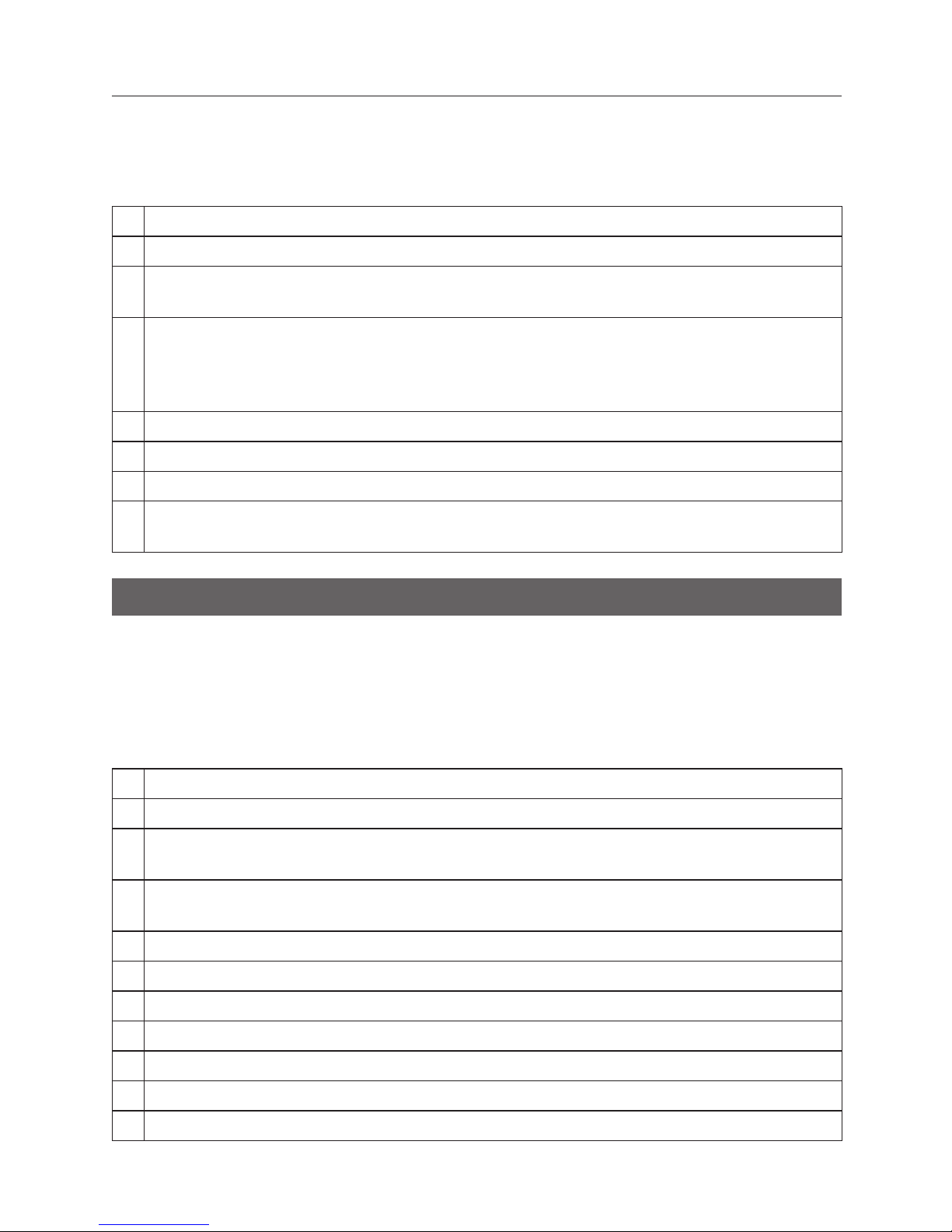

3Drain saddle ts most standard drain pipe. Install

the drain saddle on drain pipe as follows. Bore 5

mm hole in the drain pipe, apply rubber gasket with

scky base (included in the package). Install drain

saddle on top of the gasket so that push-t ng

in the saddle is located precisely above the hole in

drain pipe. Tighten nuts on drain saddle fasteners

with a wrench. Insert black tube in the push-t ng

in drain saddle. Connect the other end of black tube

with drain port of the RO system’s push-t port rack.

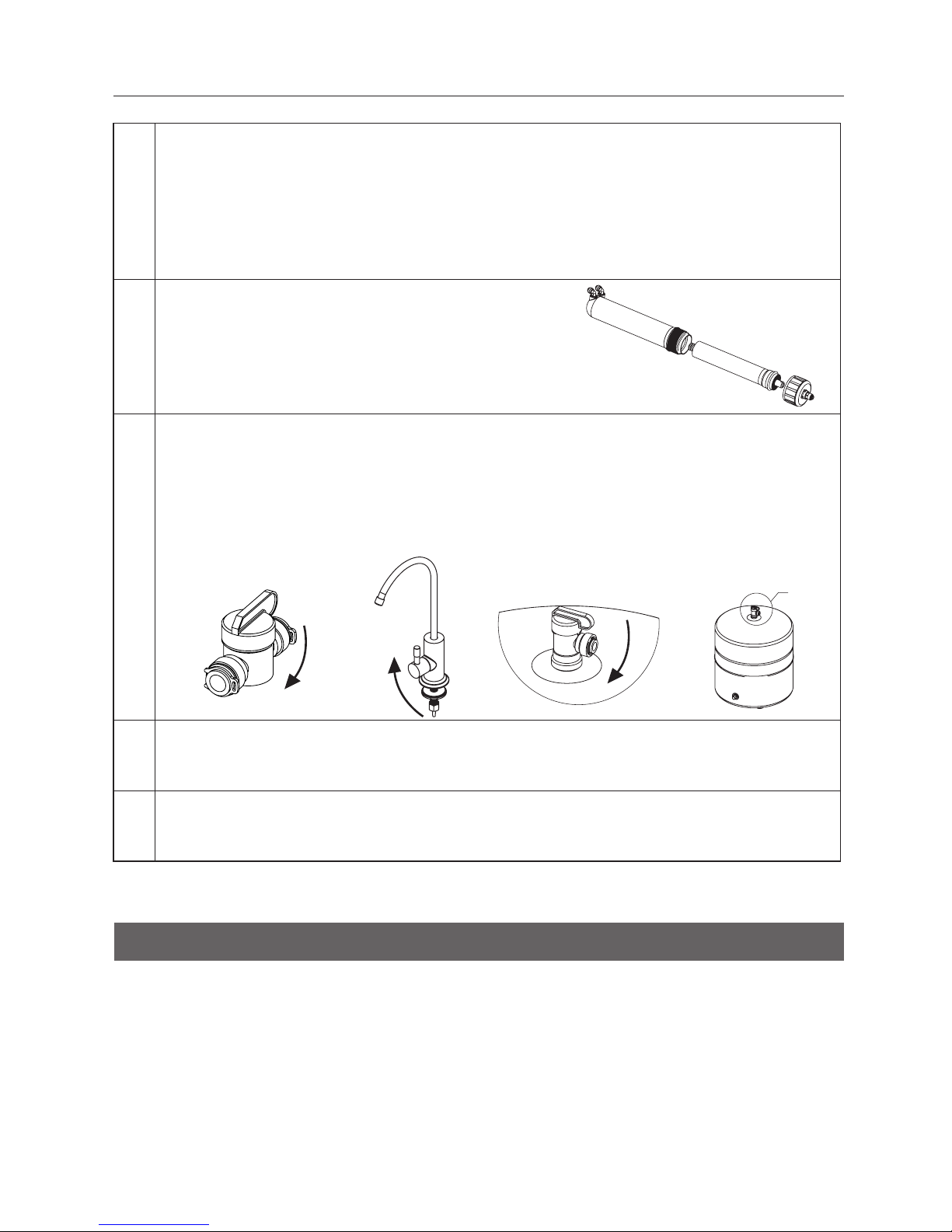

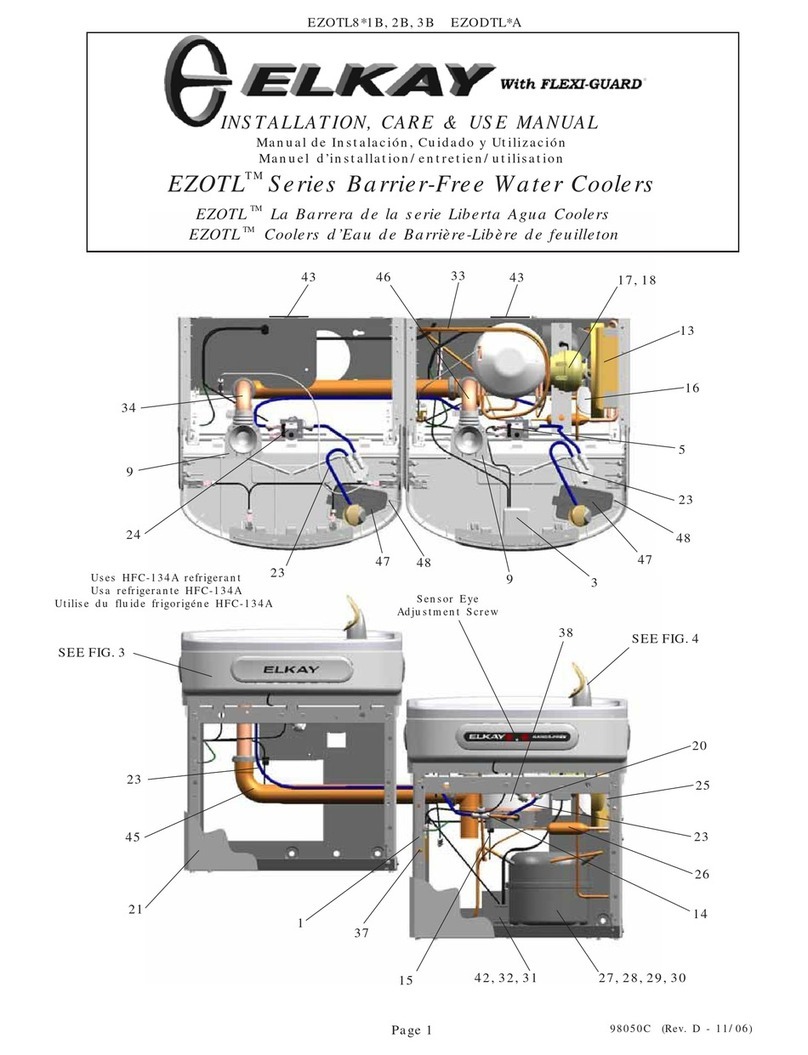

4* Put a few turns of PTFE tape on tank nipple thread.

Screw tank valve on the tank nipple. Turn the valve

fully o.

NOTE! Test air pressure in the empty tank bladder.

It should be 0.6–1.0 bar. If necessary, use air pump

with to inate the bladder. If pressure is too high

already, push on the valve stem’s core to relieve it.

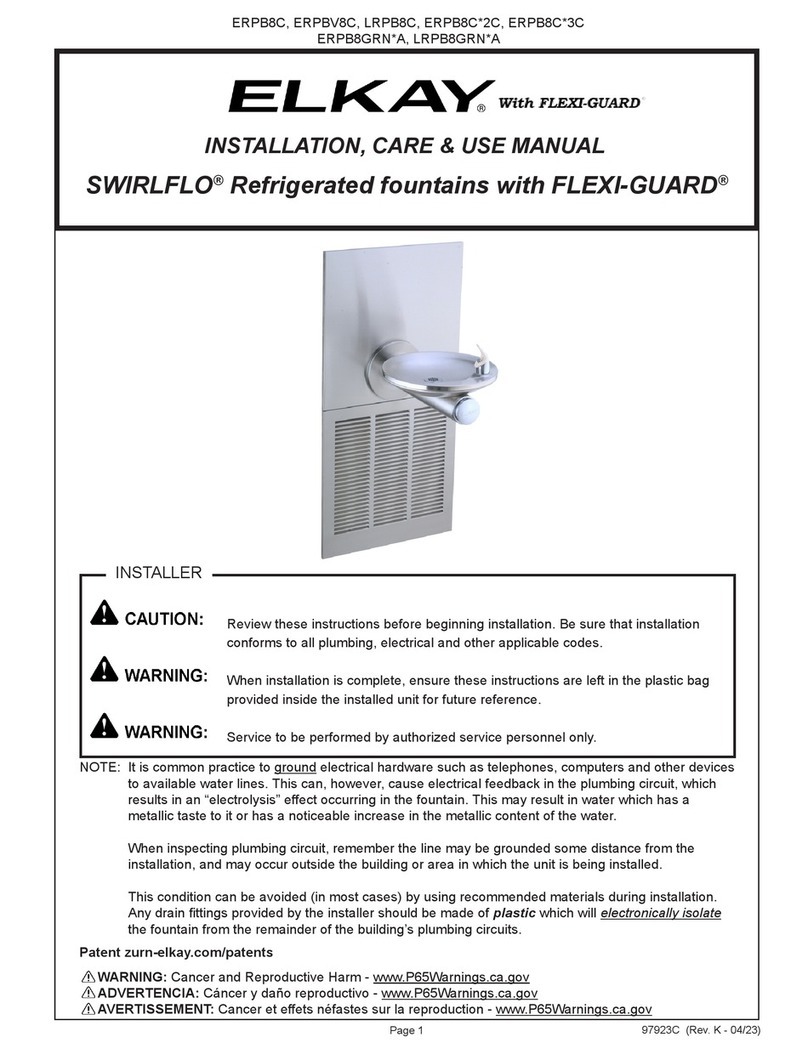

5Install the faucet.

5.1 To install puried water faucet bore a 12,5 mm

diameter hole in desired locaon on sink or

countertop.

CAUTION! Metal shavings can damage your sink,

remove them carefully once you have nished

drilling. If the mounng surface is stone or ceramic,

use a carbide drill bit.

5.2 Mount the faucet over the hole on top of small

rubber washer, chrome plated base, and large

rubber washer. Fix the faucet rmly with plasc

washer, lock washer, and nut put on the faucet

shank underneath sink surface.

5.3 Put compression nut on free end of blue tube, then

put on ferrule and put insert inside the tube.

5.4 Push the end of blue tube inside the shank boom,

seat the ferrule against shank boom and screw

compression nut snugly on shank thread. The faucet

should now be rmly xed on top of sink, and blue

tube ghtly seated in compression ng at the

boom of faucet shank.

6Install replacement lters to the 1st and 2nd housings (le to right).

7Install the housings back on the system. Hand ghten only.

PTFE seal

tank

tank valve

small rubber gasket

chrome-plated cover

large rubber gasket

large plasc gasket

lock washer

nut

counter

1/4 ferrule

1/4 compression nut

blue tube

plasc insert