5

Introduction

The principle of reverse osmosis (RO)

In natural sciences and technology, osmosis is perceived as the directed migration of

molecules through a semi permeable membrane. The chemical and physical structure of the

membrane determines which molecules are able to pass and which are not. For this reason,

it is called semi-permeable, which means as much as halfway or partial permeability.

RO Membrane

If one mixes different liquids, like in this case water with different salinities, they aim to

equalize their concentration. That way, the seawater would be thinned out and the drinking

water would be enriched with salts. The effect would be a less concentrated, homogeneous

dissolution. Pouring sea- and fresh water in equal amounts into a container where both

liquids are separated by an adequate semi-permeable membrane, there would be one side

with seawater that is highly loaded with salts, on the other side more or less “clean” water

without or with little dissolved components. The natural tendency of both liquids to equalize

their salinity leads to the migration of water molecules from the fresh water side towards the

seawater side. As a result, the volume of water on the fresh water side decreases while it

increases on the seawater side. This process of osmosis takes place until the pressure on

the seawater side is in accordance with the osmotic pressure. Then it stops. In this case, the

osmotic pressure is around 30 bar. The described process however is reversible by exposing

the liquid on the seawater side to mechanical pressure. At a pressure of 30 bar, the osmotic

process cannot take place or would rather be reversed. When pressure is increased beyond

30 bar, for instance 60 bar, water molecules from the seawater side migrate to the fresh

water side. All other components of the seawater dissolution are not able to pass the

membrane. As a result, the dissolution on the seawater side remains highly-concentrated

while there is a gain of fresh water on the other side of the membrane. This process is

referred to as reverse osmosis (R.O.)

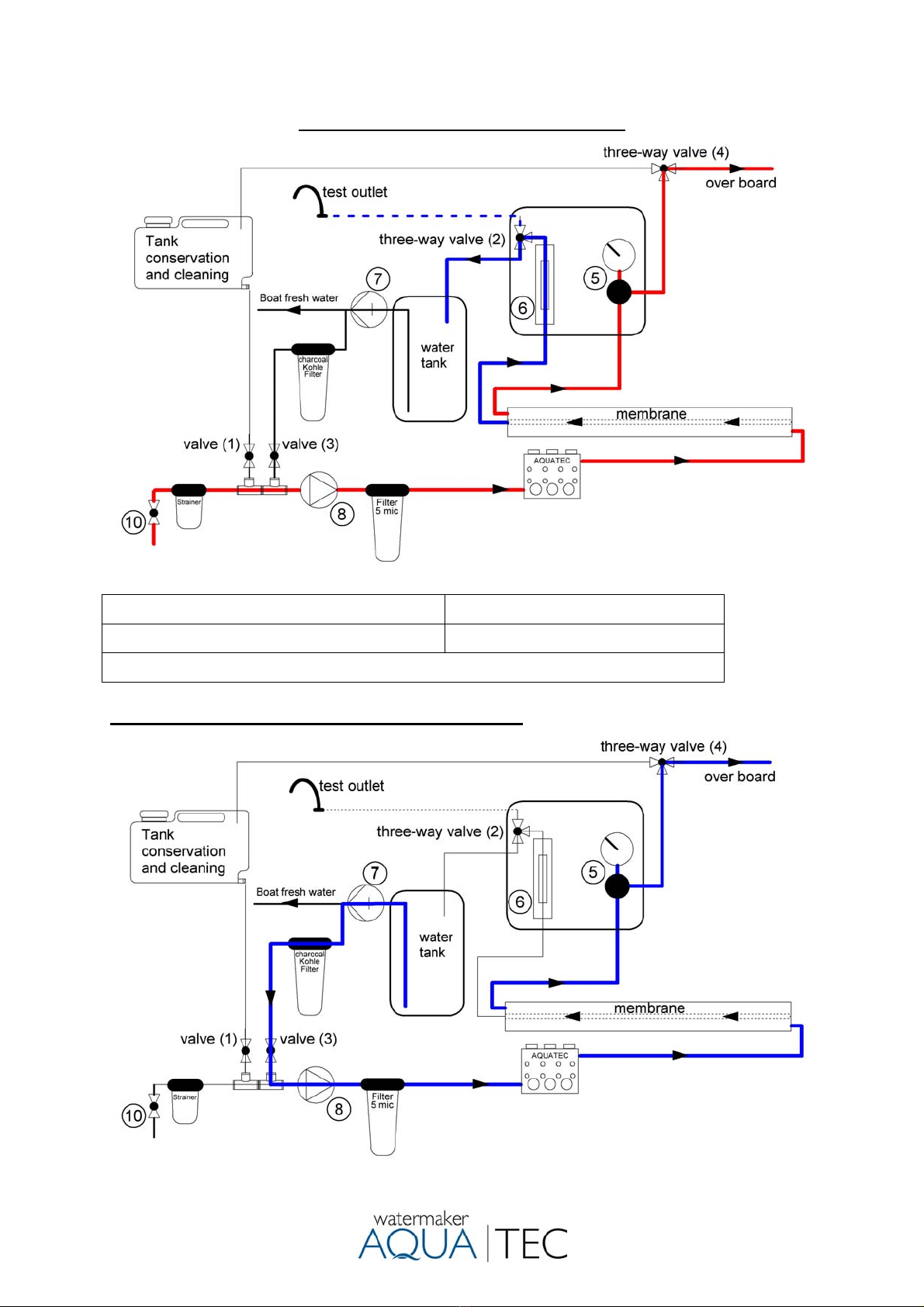

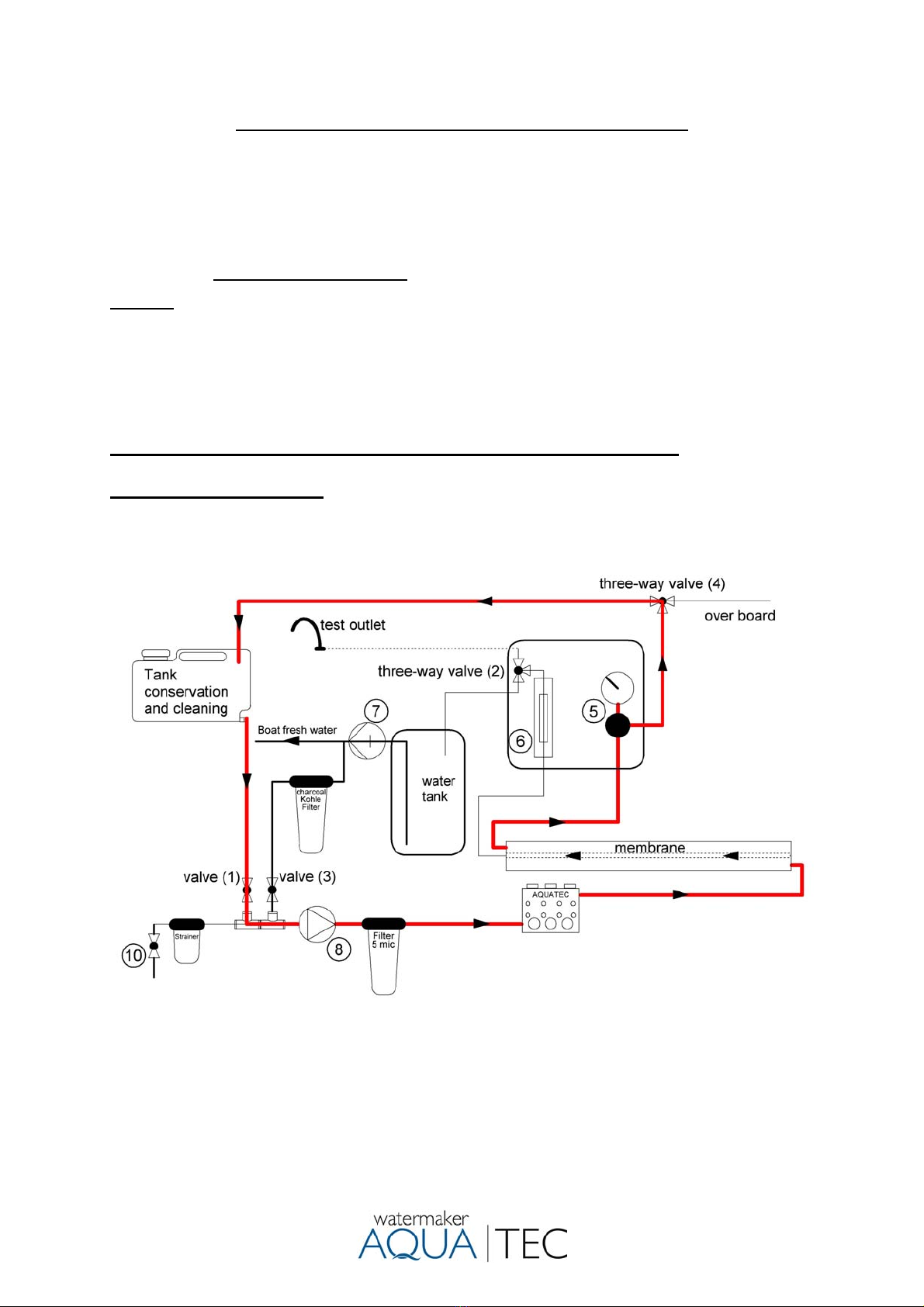

The seawater is delivered to the pressure pipe’s entry side of a RO-system by a high-

pressure pump. The osmotic membrane is located in the pressure pipe and is merely

permeable for the vehicle “water“ (solvent) and detaining the soluted substances.

When the pressure difference is more than leveling out the osmotic head, the water

molecules are able to pass the membrane that works like a filter, while the

“unpurified” molecules are detained. In opposite to a classic membrane-filter,

osmosis membranes do not have continuous pores. In fact, the ions and molecules

are migrating through the membrane by diffusing through the membrane material.

Inside of the membrane, the permeate-tube is located which transports the fresh

water through one of the two end caps of the pressure pipe towards the fresh water

tank. The excess seawater, now referred to as concentrate (brine), is drained off

overboard through the outlet of the pressure pipe by a pressure control valve.