4

Introduction

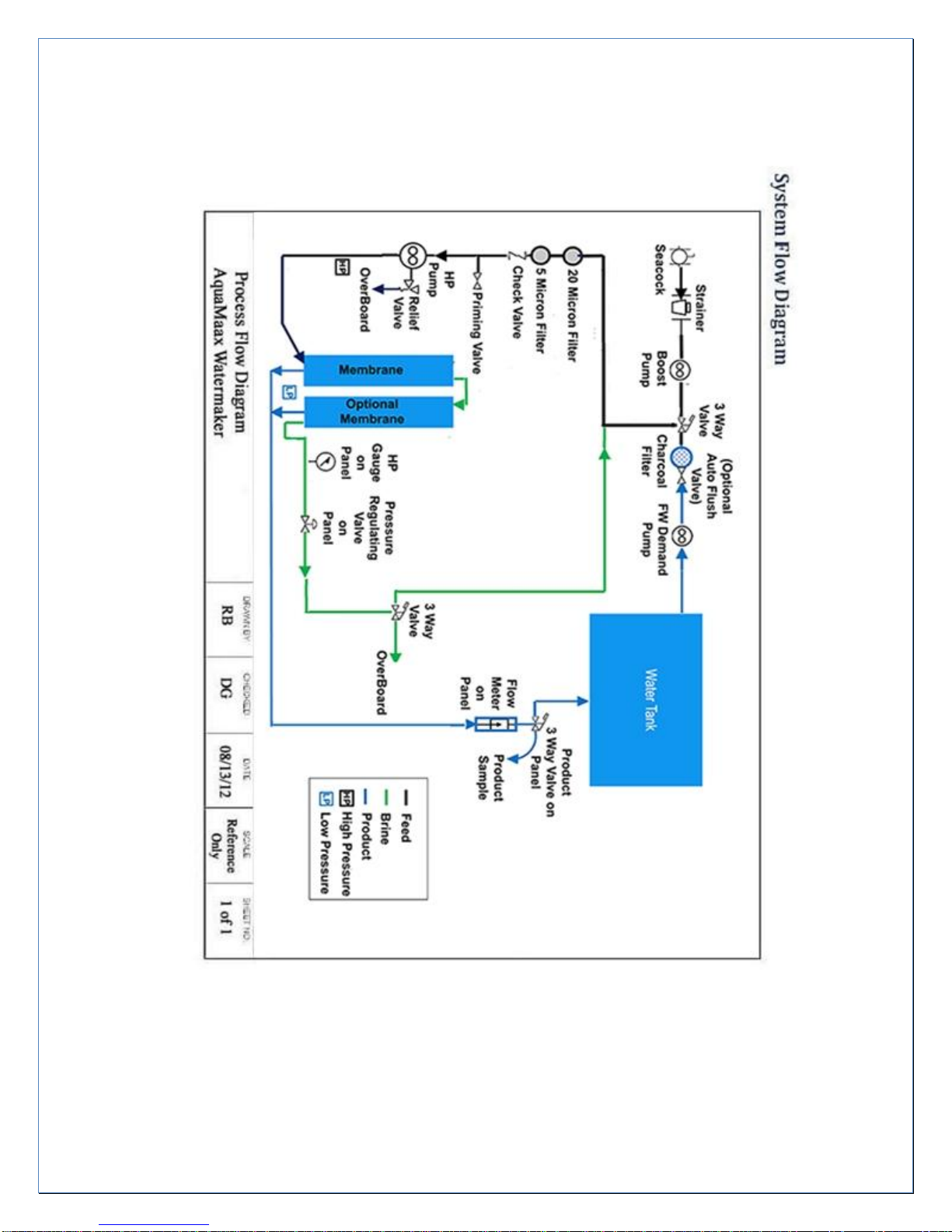

The team at ElectroMaax thanks you for your purchase of the AquaMaax reverse osmosis

watermaker. The AquaMaax design is based on real world product testing and

engineering, and we trust that you will be completely satisfied with your new unit. We are

ready to stand behind our product with an industry leading warranty and customer support.

We will assist you in your installation, start-up, and operation of your AquaMaax

watermaker.

The AquaMaax series of water makers were designed with real life cruisers in mind, so the

system is designed for easy installation, operation, and maintenance. We strongly

encourage our customers to spend time reading through our installation, operation and

maintenance manual before starting their installation process and contacting us via email,

for support if they have any questions about their particular installation or general

operation of their new watermaker. Spending some time talking to the people that actually

designed and built your watermaker can quickly help answer any question, from

installation to operation.

AquaMaax Warranty

Due to our simple design and use of commercial quality parts and assembly methods,

ElectroMaax is proud to offer the best warranty in the watermaker business.

The AquaMaax is guaranteed to be free of manufacturer defects and to perform within the

stated specification for a period of three years (36 months) from the date of shipment.

In the event of a defective component or failure during the term of the warranty,

ElectroMaax will inspect the defective part and repair or replace, with all the shipping

charges being the responsibility of the purchaser to and from their location to our offices.

As a condition of the warranty, the purchaser is responsible for conducting the

recommended maintenance according to the ElectroMaax stated schedule of maintenance

and operating their unit within the operational parameters outlined in this manual.

The warranty does not extend to parts that have failed due to misuse, improper installation,

modification, and operations outside of those defined by ElectroMaax.

The warranty does not cover parts where the serial number has been removed or defaced

and the warranty does not apply to the normally recurring consumable or wear and tear

items as defined below:

Pre-filter elements 5 and 20 micron.

Activated, carbon back-flush filter element.

High pressure pump crankcase lubrication oil.

Boost pump flexible impeller.

High Pressure Pump Valves, Packing, and Ceramic Plungers.