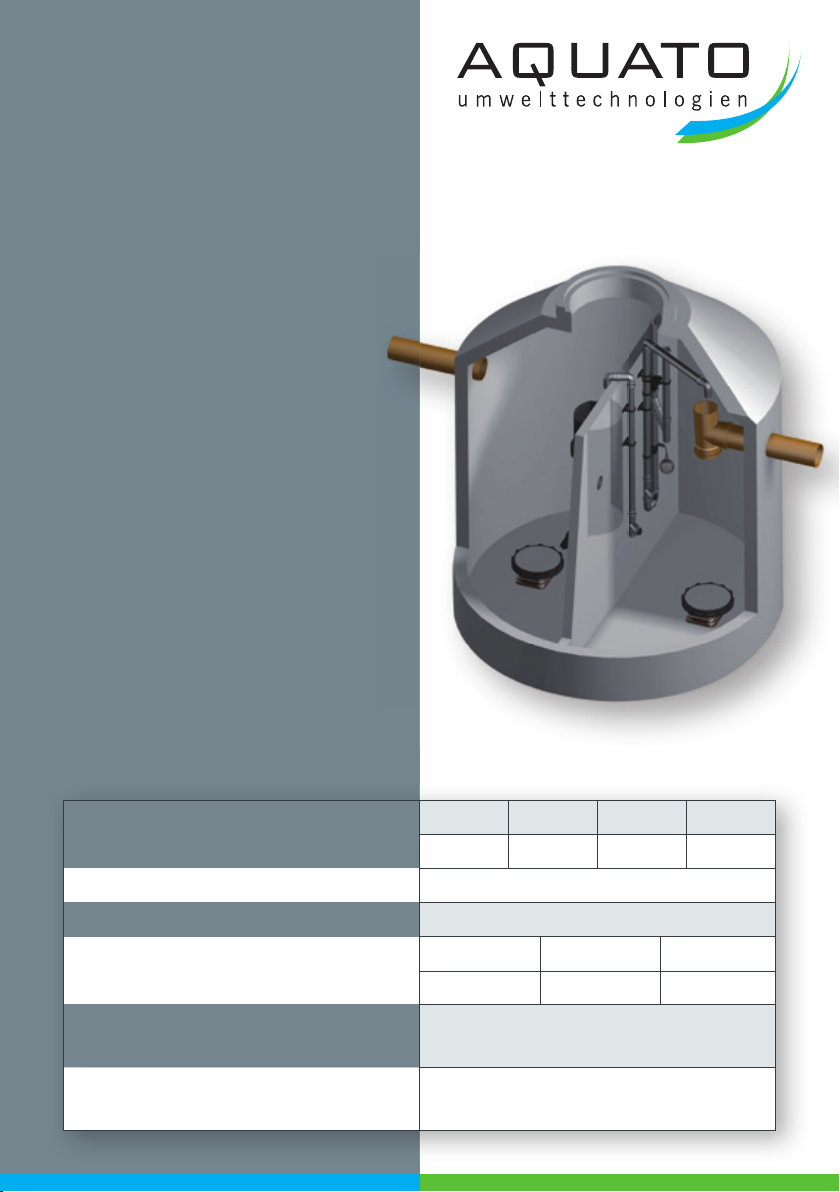

STABI-KOM

AQUATO

®

STABI-KOM -Package Plant & Retrofitting

Installation Instructions As of:March 2014

Page 4

7.1.3 Frost protection ............................................................................................................................... 20

7.1.4 Additional criteria ............................................................................................................................ 20

7.1.5 Depth of the excavation pit ............................................................................................................. 20

7.1.6 Surface of the excavation pit .......................................................................................................... 20

7.1.7 Connection of in-and outlet, sampling (optional) ........................................................................... 21

7.1.8 Empty pipe between outdoor cabinet and tank .............................................................................. 21

7.1.9 Hoses and float switch cable .......................................................................................................... 21

7.1.10 Adjustment of air hoses................................................................................................................ 21

7.1.11 Connection of hoses..................................................................................................................... 22

7.2 I

NSTALLATION MANUAL

AQUATO

®

STABI-KOM

RETROFIT UNIT

.................................................................22

7.2.1 Surroundings................................................................................................................................... 22

7.2.2 Preparatory work............................................................................................................................. 22

7.2.3 Installation of coarse material blanket and separation wall ............................................................ 23

7.2.4 “ATTENTION Desludging here“ plate ............................................................................................. 24

7.2.5 Installation procedure ..................................................................................................................... 24

7.2.6 Aeration device ............................................................................................................................... 26

7.2.7Hoses and float switch cable (optional) .......................................................................................... 27

7.2.8Tank without separation wall .......................................................................................................... 27

7.2.9Laying of the installed hoses........................................................................................................ 28

7.2.10Installation of the float switch (optional) ....................................................................................... 29

7.2.11Max waterlevels with backpressure ............................................................................................. 30

7.2.12Clearwater discharge with submersible pump ............................................................................. 30

7.3 I

NSTALLATION MANUAL FOR CONTROL PANELS AND WALL BRACKETS

............................................................ 31

7.3.1 Safety instructions........................................................................................................................... 31

7.3.2 Mains Connection ........................................................................................................................... 32

7.3.3 Float switch ..................................................................................................................................... 32

7.3.4 Clearwater Pump ............................................................................................................................ 32

7.3.5 Floating contact............................................................................................................................... 32

7.3.6 Connections .................................................................................................................................... 33

8

OPERATION............................................................................................................................... 34

8.1 O

PERATION AND

D

ISPLAY

.......................................................................................................................... 34

8.2 C

OMISSIONING

......................................................................................................................................... 34

8.3 M

AIN

D

ISPLAY

.......................................................................................................................................... 35

8.4 M

ENU

....................................................................................................................................................... 36

8.4.1 Menu structure ................................................................................................................................ 36

8.4.2 Display of operating hours .............................................................................................................. 37

8.4.3 Service menu .................................................................................................................................. 37

8.4.4 System test / Trial run ..................................................................................................................... 37

8.4.5 Manual mode .................................................................................................................................. 38

8.4.6 Selection of plant type .................................................................................................................... 38