aquilar AquiTron AT-G-ALERT User manual

AquiTron AT-G-ALERT

Refrigerant Sensor

QUICKSTART

GUIDE

AT-G-ALERT

Refrigerant Gas Sensor For Occupied Spaces

OVERVIEW

The AquiTron AT-G-ALERT detects refrigerant leaks in occupied spaces.

The detector is for indoor applications. It is housed in an ABS enclosure that ts into most 47mm depth 2-gang UK electrical back boxes

(not included). Thinner metal mounting tabs are provided for ush mounting in UK back boxes with higher mounting tabs.

LEAK DETECTION SOLUTIONS

1

Figure 1. AT-G-ALERT with examples of available fascia plates.

INSTALLATION SPECIFICATION

AT-G-ALERT

100 to 240 VAC, 50/60 Hz

POWER CONSUMPTION

4 watt

WIRING POWER

3-core cable, 14 to 20 AWG (0.5 to 2.0

mm2)

RELAYS

Number: Two

Type: SPDT

Rating: 1 A at 125 and 250Vac, resistive

load.

WIRING RELAYS

3-core cable, 18 to 20 AWG (0.5 to 1.0

mm2)

MODBUS

Connection: RS-485 terminal block

Baud rate: 9600 or 19200 (selectable)

Default baud: 9600

Start Bits: 1; Data Bits: 8

Parity: None (default), odd, even

(selectable)

Stop Bits: 1 (default) or 2 (selectable)

Retry Time; 500 ms (min) between retries

End of Msg; Silent 3.5 characters

WIRING MODBUS

2-core twisted, shielded pair 18 to 24 AWG

7 (0.2 to 1 mm2) with 120 Ω characteristic

impedance; Use Belden 8761 or similar;

Maximum diameter of cable + heat shrink

8 must be ≤5 mm (0.2 in)

The AT-G-Alert is designed for use

in 2- gang UK back boxes with a

minimum depth of 47 mm (1.9”).

Gas alarms and status messages are indicated visually by a 3-coloured LED and audibly by a buzzer. In case of an alarm and/or fault, relays

switch (for example, shut-o valves or alarm devices).

The refrigerant detector can be calibrated and maintained non-intrusively using a magnetic wand.

2

3

4

5

6

1

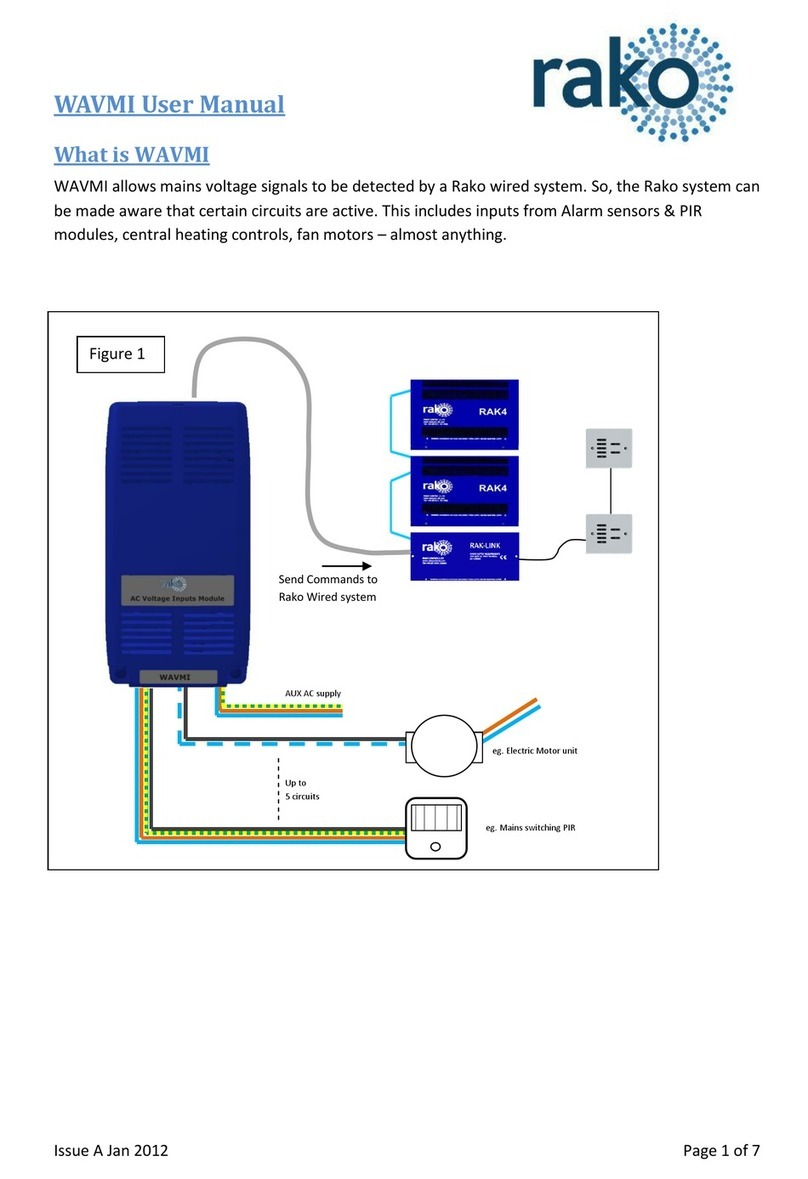

Figure 2. AT-G-ALERT components overview.

1. Magnetic wand

2. 3-colour status LED

3. Magnetic Switch 1 ( on top)

4. Magnetic Switch 2 ( on bottom)

5. Sensor Module

6. Plastic Mounting Tabs

MOUNTING CONSIDERATIONS

ENVIRONMENTAL CONSIDERATIONS: Carefully consider the

full range of environmental conditions to which the instruments

will be exposed.

TARGET GAS CONSIDERATIONS: The physical data of the gas or

vapour to be detected must be observed.

APPLICATION CONSIDERATIONS: The specics of the

application (for example, possible leaks, air movement/draft,

etc.) must be observed.

ACCESSIBILITY CONSIDERATIONS: The degree of

accessibility required for maintenance purposes must be

granted.

ELECTRONIC CONSIDERATIONS: The system contains

sensitive electronic components that can be easily

damaged. Do not touch or disturb any of these components.

2

Mount the AT-G-ALERT according to the above considerations, product dimensions, and maximum wiring lengths.

Figure 3. AT-G-ALERT Proper vs. Improper Placement.

10

SAFETY INSTRUCTIONS

CODE COMPLIANCE: Comply with all local and national laws, rules,

wiring codes, and regulations associated with this equipment.

TECHNICIAN USE ONLY: This unit must be installed by a suitably

qualied technician who will install this unit in accordance with

these instructions and the standards in his particular industry/

country. Operators of the unit should be aware of the regulations

and standards in their industry/country for the operation of

this unit. These notes are only intended as a guide and the

manufacturer bears no responsibility for the installation or

operation of this unit.

Failure to install and operate the unit in accordance with these

instructions and with industry guidelines may cause serious injury

including death and the manufacturer will not be held responsible

in this regard.

SAFE MOUNTING: This detector must be connected by a marked,

suitably located and easily reached switch or circuit-breaker as

means of disconnection.

Figure 4. Typical AT-G-ALERT Installation in an Occupied Space Application

CAUTION: DO NOT MOUNT the AT-

G-ALERT in an area that may contain

ammable liquids or vapours. Operation of

electrical equipment in such an area constitutes

a safety hazard.

CAUTION: Mounting in ceiling voids in a

hotel room would not strictly comply with

EN378.

CAUTION: RS-485 signal cable must be

insulated to the highest voltage level in

the system. Protect the RS-485 signal cable by

using the supplied installation kit.

IMPORTANT Mount at a height between

100 and 150 mm (4 and 6 inches) o

the oor. Avoid drafts and heat sources (like

radiators), and avoid sources of steam.

3

CONFIGURATION

PIN 1 - RESTART

O: Normal Operation (Default)

On: Restart AT-G-ALERT

PIN 2,3 - ALARM ON DELAY

O,O: No Delay (Default)

O,On: 5 miniute Delay

On,O: 10 miniute Delay

On,On: 15 miniute Delay

PIN 4 - FAILSAFE

O: Normal relay Operation (Default)

On: Failsafe relay operation

PIN 5 - RELAY 2 FAULT INDICATION

O: High alarm or fault (Default)

On: High alarm only

PIN 6 - ALARM LATCHING

O: Alarms automatically reset (Default)

On: Alarms latch and require manual

reset

PIN 7 - BUZZER DISABLE

O: Buzzer enabled (Default)

On: Buzzer Disabled

PIN 8 - ENABLE RESET TO

FACTORY DEFAULTS

O: Normal Operation (Default)

On: Reset enabled (see manual for

details)

Figure 5. Switches for Conguring the AT-G-Alert

INSTALLATION

Note: Before installing the AT-G-ALERT, refer to the

calibration gas concentration label and record the

value for use in step 16 of the calibration procedure.

When inserting the wire into the terminal, release the spring

clamp by pushing back the release latch.

Caution: Ensure all wiring connections are made

before applying power.

Push to release

Modbus

(See steps 1-6)

Figure 6. Wiring Power & Modbus

1. Prepare signal cable and put boot over the signal

cable (1).

2. Add ferules if required (2).

3. Apply 10 cm piece of shrink wrap as close to the

wire ends/ferules as possible while leaving some

free wire to allow connection to the detector (3).

4. Heat the shrink wrap (4).

5. Connect signal wires/ferules to the detector (5).

6. Slide rubber boot along the wire and shrink wrap

assembly and connect it to the detector (6).

Figure 7. Details for Connecting Modbus Communications Wiring

SHIELD WIRE WARNING: Connect the shield

of Modbus wires to the earth ground of the

central control system (e.g., chassis, ground bus bar,

etc.).

Figure 8. Wiring Relay 1 (Low Gas Alarm) and Relay 2 (High Gas Alarm or Fault)

GROUND: If a metal plate is used please

make sure that this plate is grounded to

earth.

3

4

6

7

3

5

4

6

8

8

8

4

Brushed Aluminium Eect

1

2

Figure 9. AT-G-ALERT Components

1. Example of a custom faceplate

2. Example of a UK back box

3. Mounting tabs

4. Direction arrows (x2) for proper

mounting.

5. Sensor type / calibration and ID/

serial number labels

6. Test point access holes (x2)

7. Replaceable sensor module

8. Sensor alignment ribs (x3)

Note: For UK back boxes with

“higher” mounting tabs, remove

the thick plastic mounting tabs from the

detector (using wire snips or nippers) and

screw on the thinner metal mounting tabs

(included) to ensure ush wall mounting

of the faceplate. Be sure to dry t the

plastic tabs before cutting them from

the detector to verify that they are too

thick for proper ush mounting of the

faceplate to the wall. Figure 10. AT-G-ALERT Retrot of Thinner Metal Mounting Tabs

OPERATION OVERVIEW

5

GENERAL CALIBRATION PROCEDURE

1. Verify that the detector is NOT in alarm and does not have a fault condition (i.e., it

must not have a continuous orange LED).

2. Verify that the calibration gas is in a balance of air, not Nitrogen (N2).

3. Fit testing hood to the fascia plate (7) or base plate (6) (see below).

4. Ensure switch 8 is OFF . The buzzer will be OFF and the LED will be OFF.

5. Connect the tubing to the barbed ttings of the pressure regulator and testing

hood.

6. Verify that gas ow is approximately 0.3 to 1.0 L/min.

7. If operation is intended to be at higher altitudes, the factory calibration will result

in a reading lower than the reading at sea level (reduced partial pressure). A

new span adjustment is recommended if the altitude or the ambient pressure is

changed. The factory calibration is set to sea level.

8. Always perform a zero adjustment before a span adjustment.

4

12

3

5

1. Flow meter

2. Pressure regulator

3. Calibration gas

4. Tubing

5. Testing hood (UK

version)

Warning: Ambient air can be used to zero the sensor instead of synthetic

air only if the area is known to be free of the target gas or any gas to which

the sensor may be cross- sensitive. In this case, no cylinder or testing hood is

needed for the zero adjustment.

Figure 11. Details for Connecting Modbus

Communications Wiring

Zero Adjustment ( ... continued for General Procedure)

9. Tap and hold ( • ) for more than 5 seconds. The LED will blink green-green-red to indicate the detector is ready. Verify that the

calibration gas is in a balance of air, not Nitrogen (N2).

10. Apply synthetic air (or use ambient air per the warning above).Set switch 8 to OFF. The buzzer will be OFF and the LED will be OFF.

11. Tap ( • ) within 30 seconds to conrm start of calibration. Otherwise the detector will time-out and return to normal operation.

12. As the process progresses, the LED will blink green-red, green-red-red, green-red-red-red, etc.

• To abort calibration, tap and hold ( • ) for >5 seconds, turn o gas ow and remove the testing hood. The detector will return to

normal operation.

• If calibration is successful (green LED), skip to step 15.

• If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap ( •) to discard the

13. Turn o gas ow from synthetic air

14. Replace synthetic air tank with calibration gas tank in preparation for span adjustment.

Span Adjustment

15. Tap and hold ( • • ) for >5 seconds. The LED will blink green-green-orange when the detector is ready.

16. Apply span gas in the concentration listed on the cal gas concentration label (beneath the detector’s cover plate). This may require the

temporary removal of the bezel and cover plate to see the label.

17. Tap ( • • ) within 30 seconds to conrm initiation of the calibration. Otherwise the detector will time-out and return to normal

operation.Turn o gas ow from synthetic air

18. As the calibration process progresses, the LED will blink green-orange, green-orange-orange, green-orange-orange-orange, etc.

• To abort calibration, tap and hold ( • • ) for >5 seconds, turn o gas ow and remove the testing hood. The detector will return to

normal operation.

• If calibration is successful, the LED will blink green-orange-red indicating ‘oine’. Turn o gas ow and remove the testing hood.

After 6 minutes the detector will return to normal operation.

• If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap ( • • ) to discard the calibration attempt, and see Section 5.3 on

page 21 on the user manual for troubleshooting. Turn o gas ow and remove the testing hood. After 6 minutes the detector will

return to normal operation.

Bump Test

1. Inform building personnel of test so that certain alarms may be inhibited (e.g. shutdown valves, notication of authorities, etc.).

2. Connect adapter and target gas according to instructions in General calibration procedure

3. Apply a suciently high concentration of target gas to trigger alarms, but not pure refrigerant or hydrocarbons (e.g., do not use a

butane lighter), as this might damage the sensor.

4. Once the alarm thresholds are exceeded, all designated gas alarm relays will be activated and the digital outputs will transmit the

corresponding gas concentrations.

5. Turn o gas ow and remove testing hood.

6

Important: All information, including illustrations, is believed to be reliable. Users, however, should independently evaluate the suitability

of each product for their application. Aquilar Limited makes no warranty as to the accuracy or completeness of the information, and

disclaims any liability regarding its use. The only obligations of Aquilar Limited are those in the Aquilar Standard Terms and Conditions of

Sale for this product, and in no case will Aquilar Limited be liable for any incidental, indirect, or consequential damages arising from the

sale, resale, use or misuse of the product. Specications are subject to change without notice. In addition, Aquilar Limited reserves the

right to make changes – without notication to Buyer

– to processing or materials that do not aect compliance with any applicable specication.

AquiTron is a trademark of AquiTron Limited

Aquilar is a trademark of Aquilar Limited

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

V1 07.2020

Other manuals for AquiTron AT-G-ALERT

1

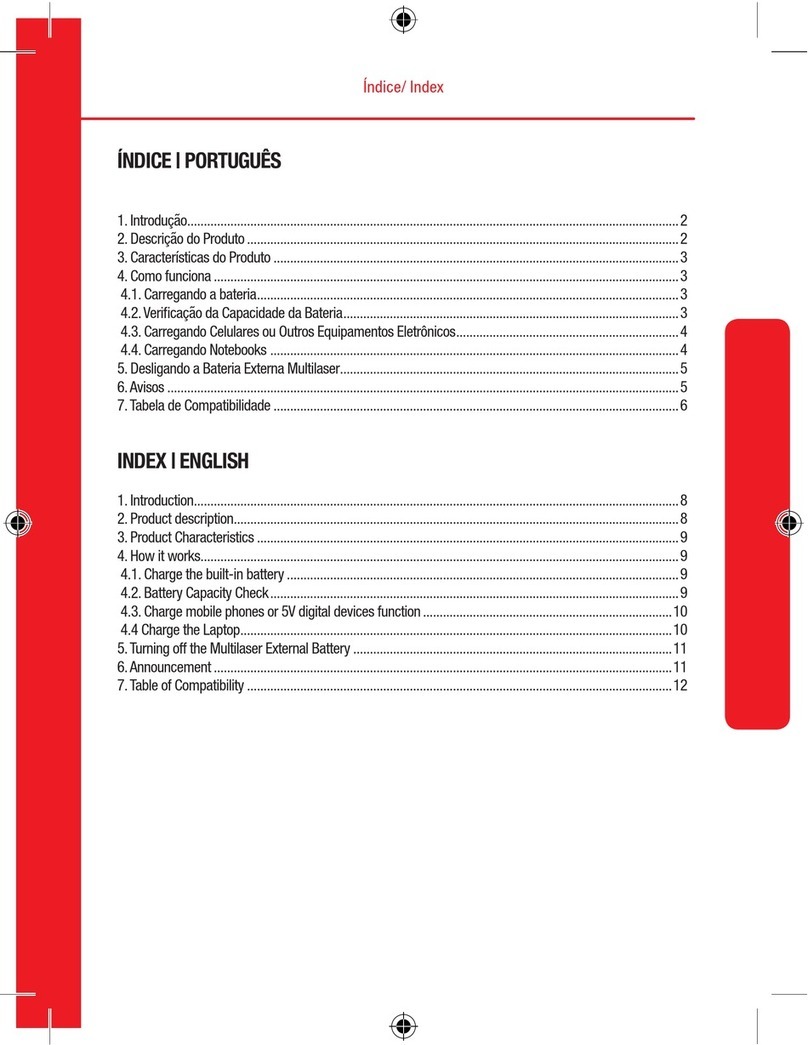

Table of contents

Other aquilar Accessories manuals

Popular Accessories manuals by other brands

Honeywell

Honeywell RPW300 Mounting instruction

Multilaser

Multilaser CB066 user manual

Nokia

Nokia TFF-3 Series Service manual

Campbell

Campbell SDMS40 instruction manual

M-Audio

M-Audio PCI Audio & MIDI Interface Audiophile 2496 Bedienungsanleitung

Rechner Sensors

Rechner Sensors SMART Paddle instruction manual